Patents

Literature

94results about How to "Considering both high and low speed conditions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

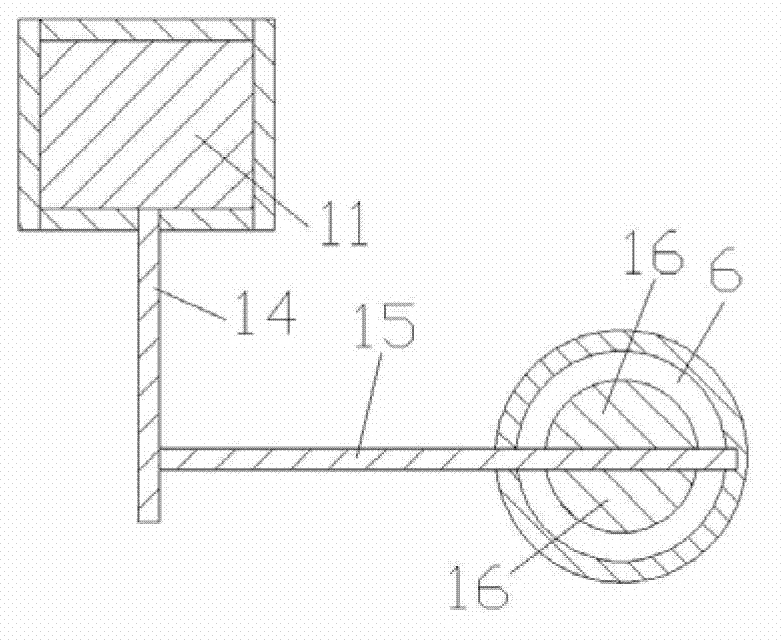

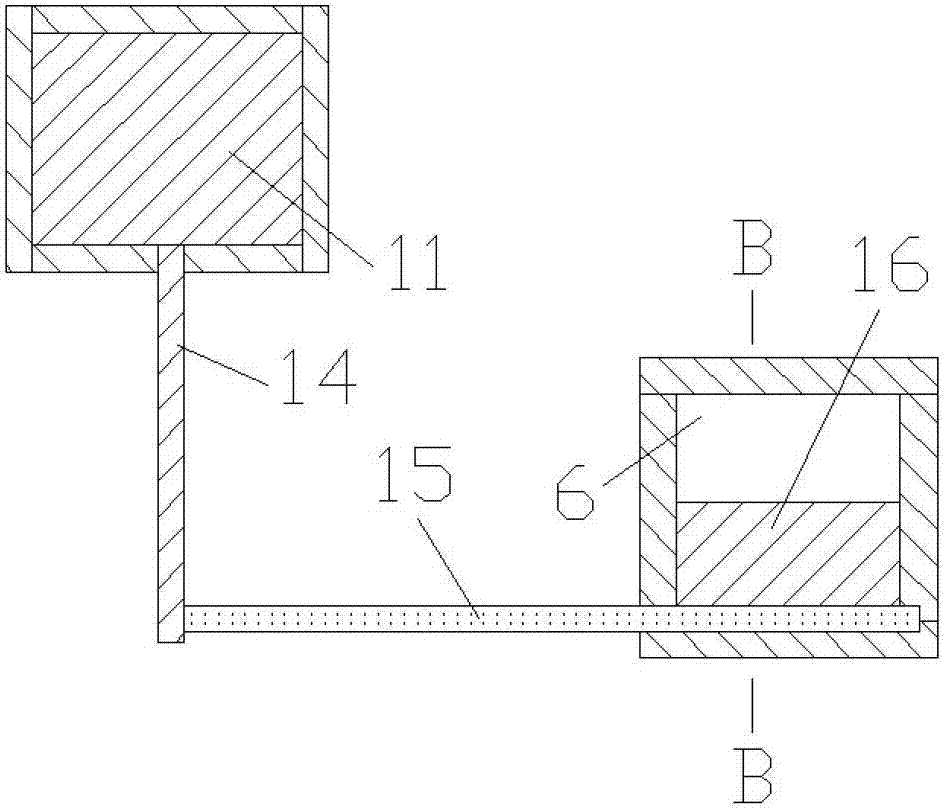

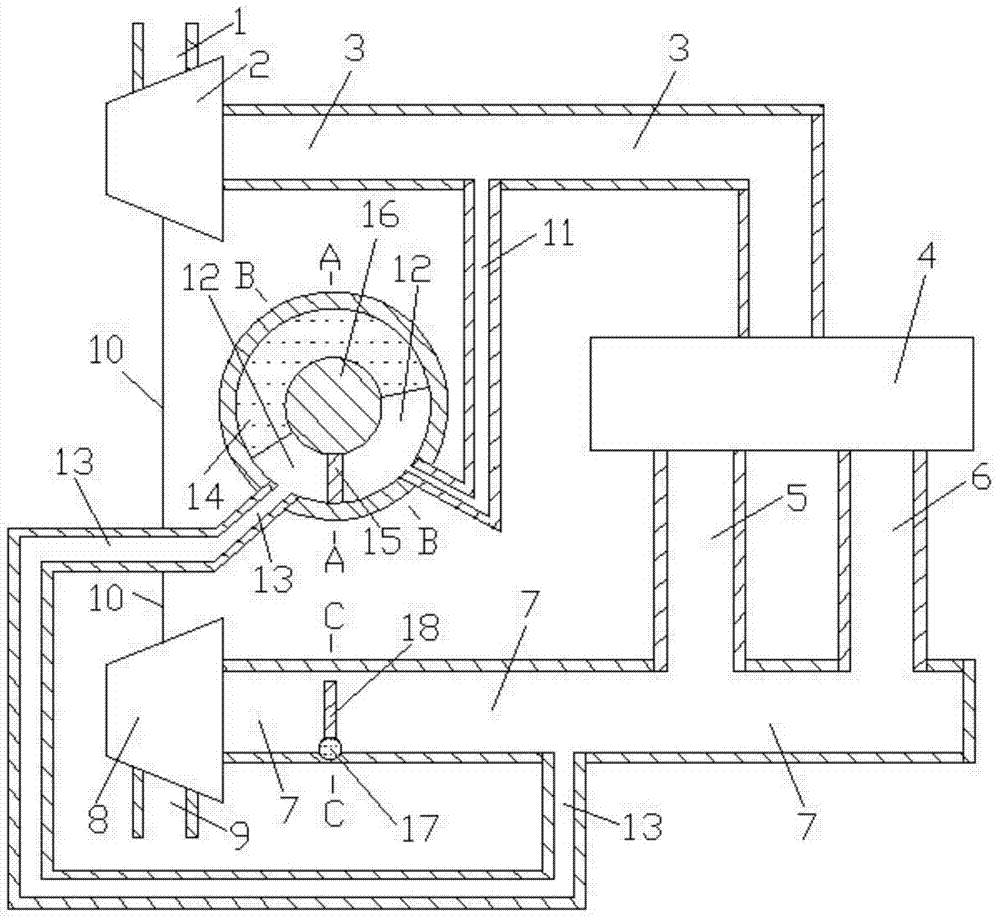

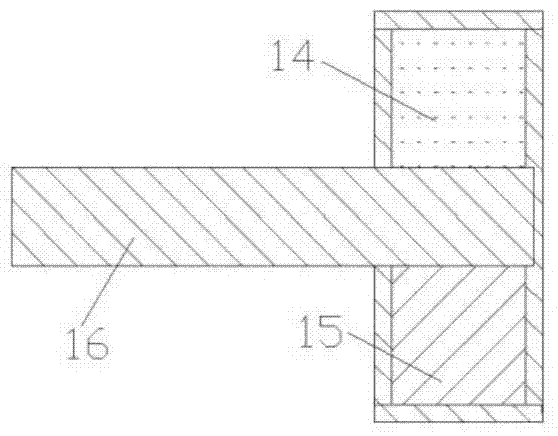

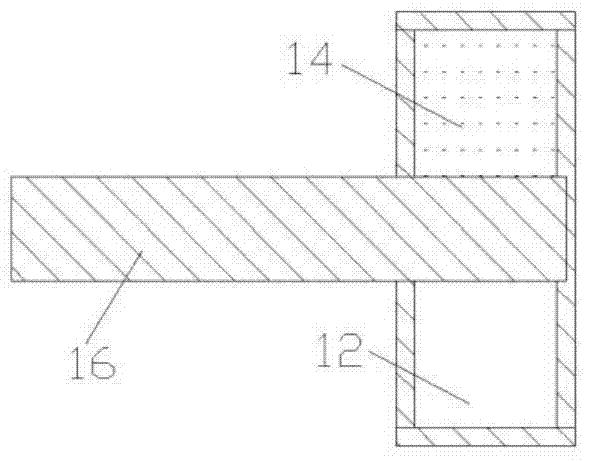

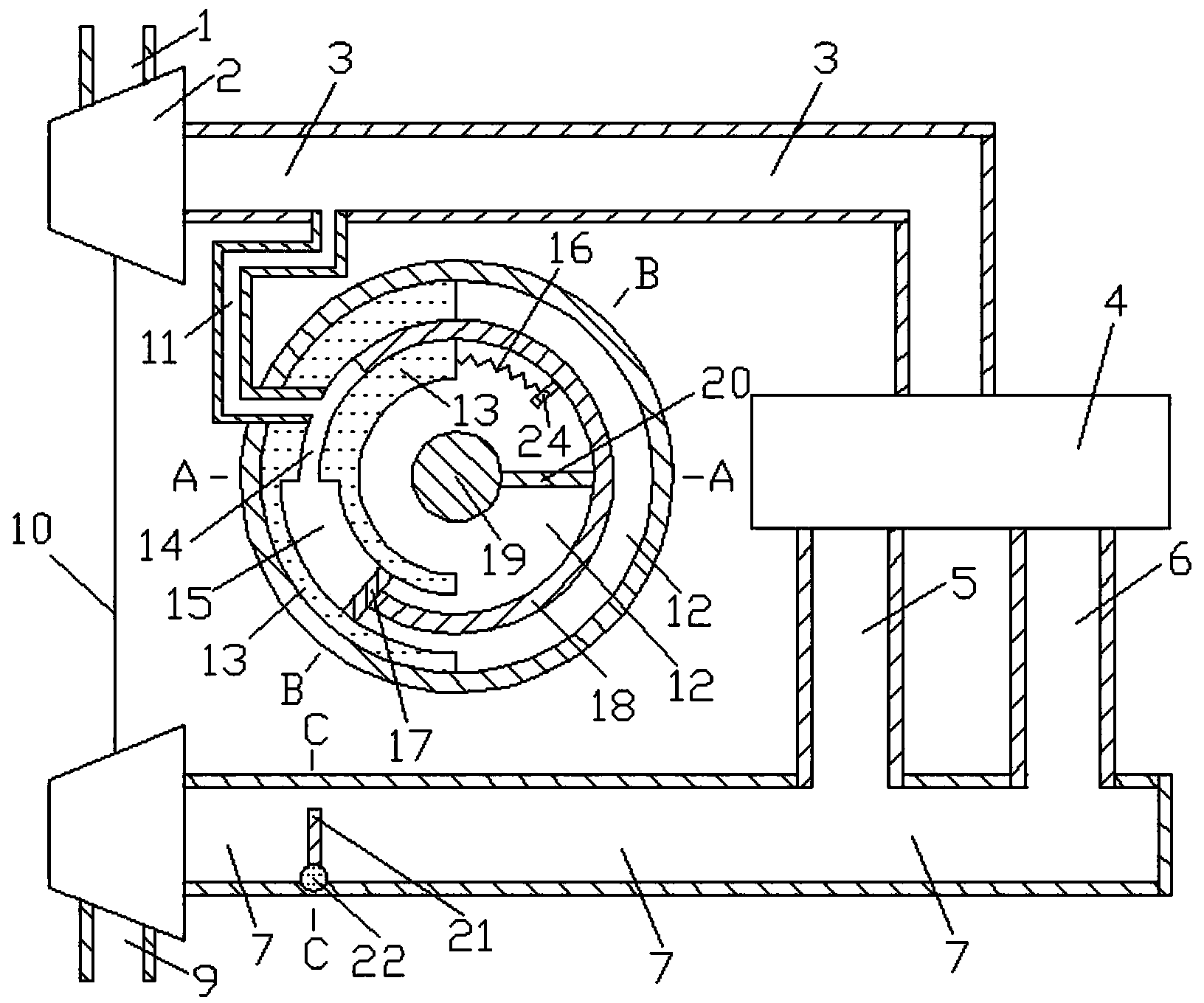

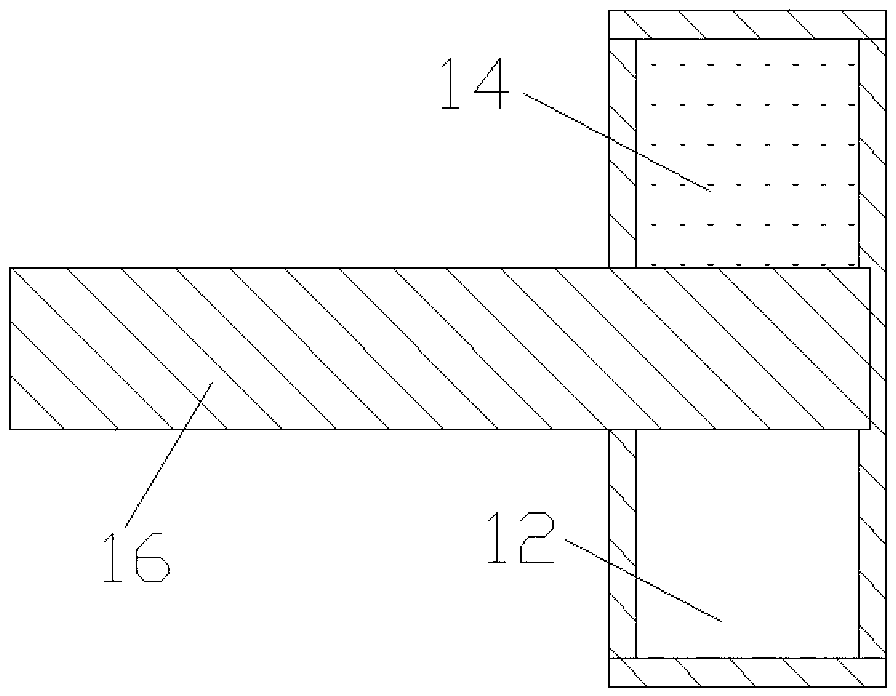

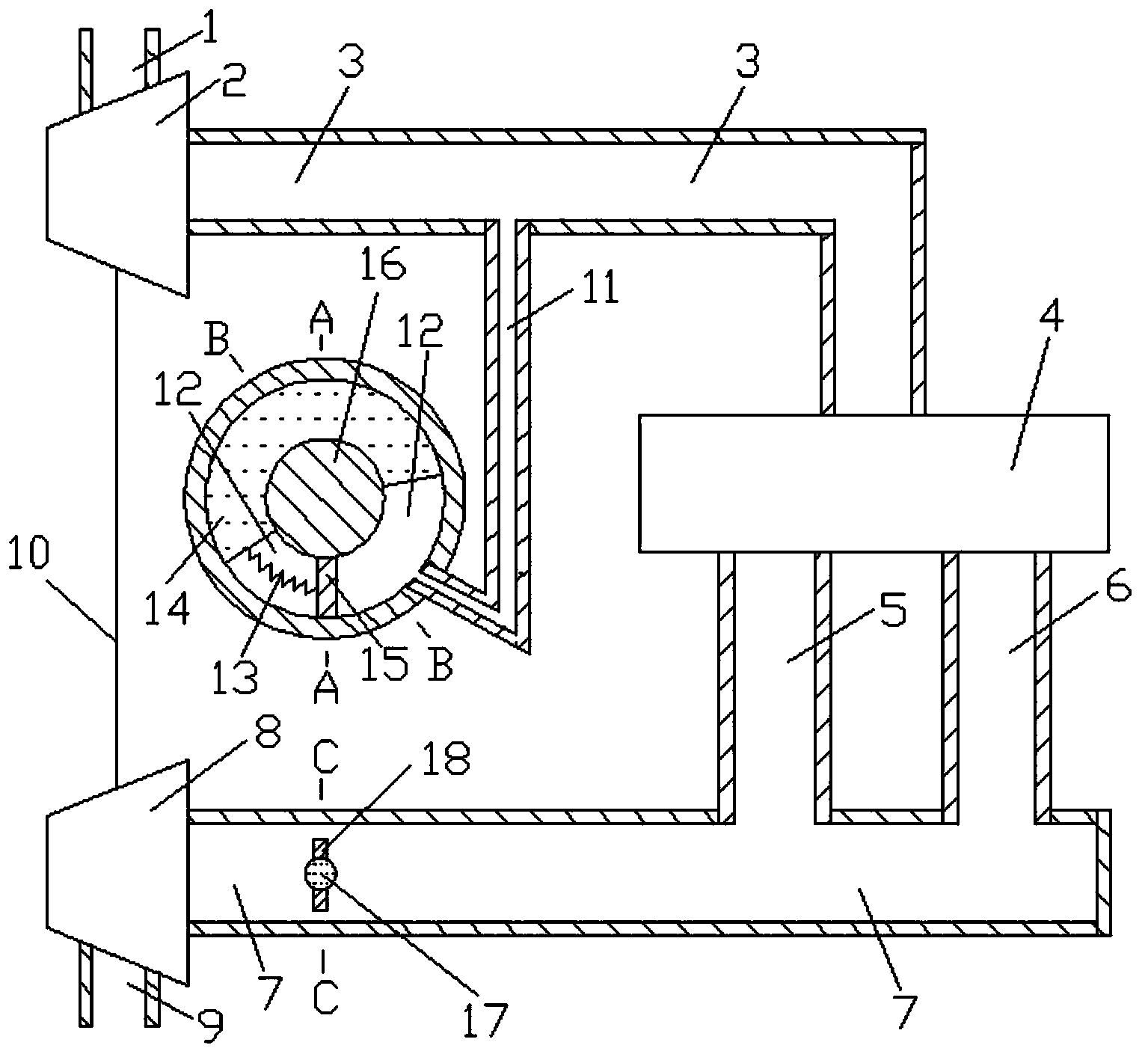

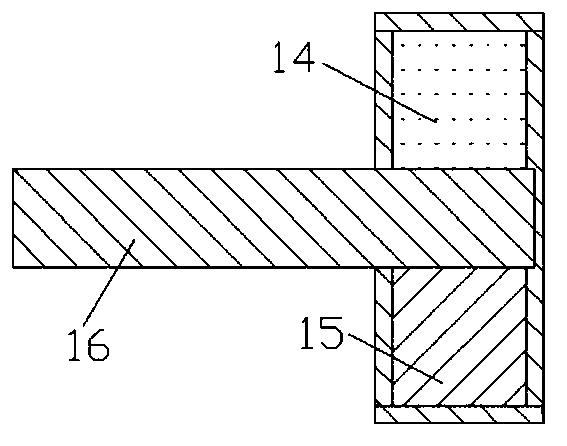

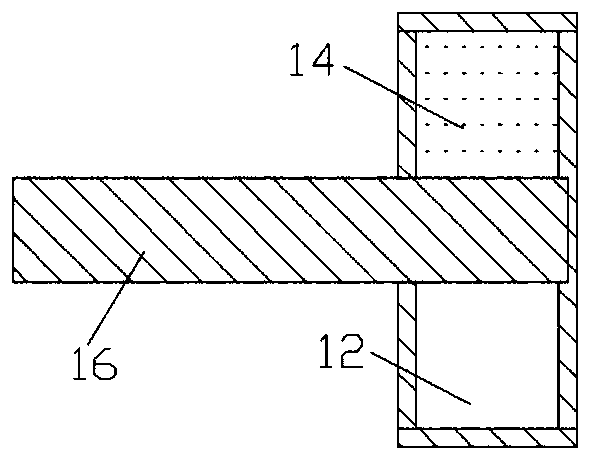

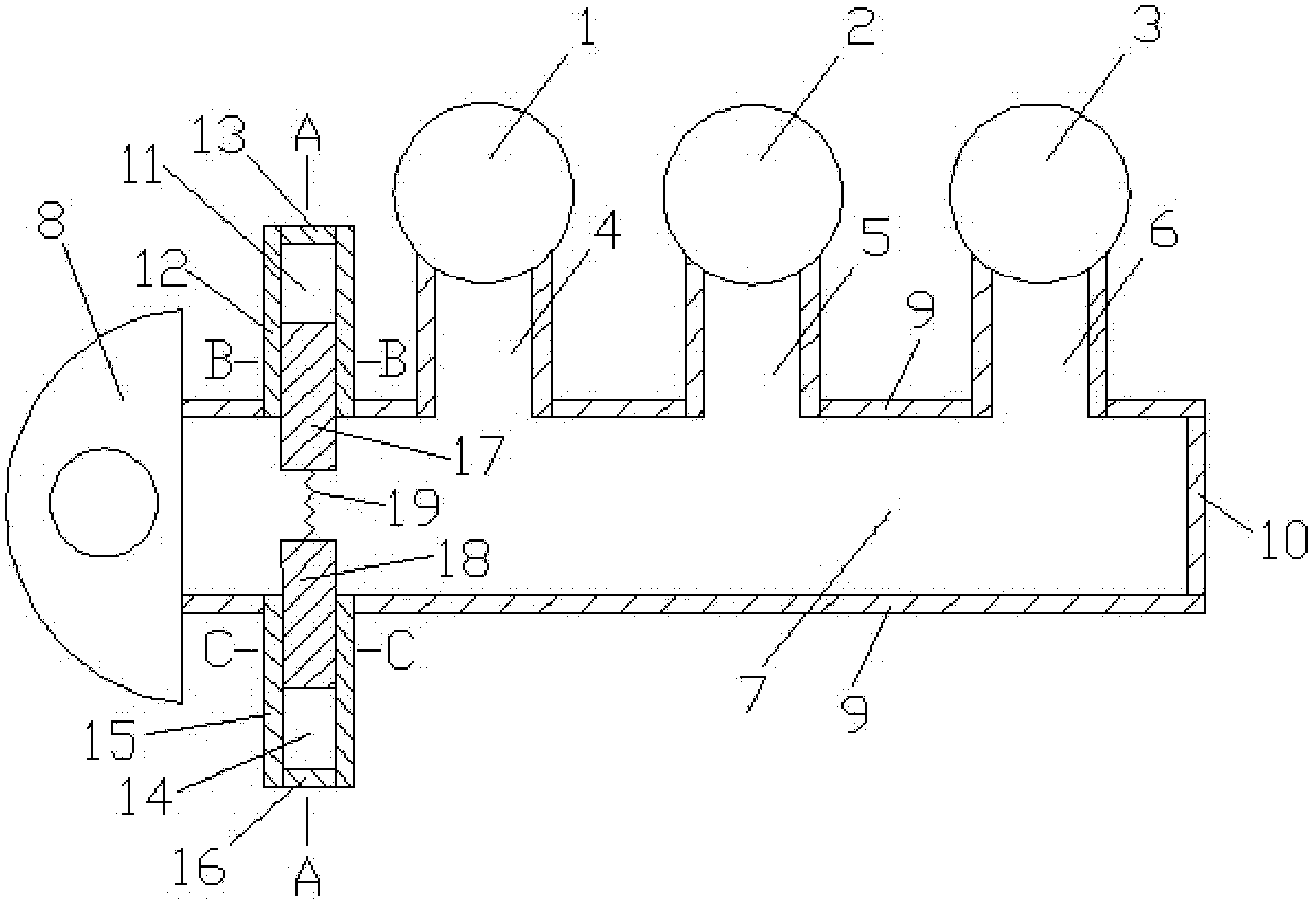

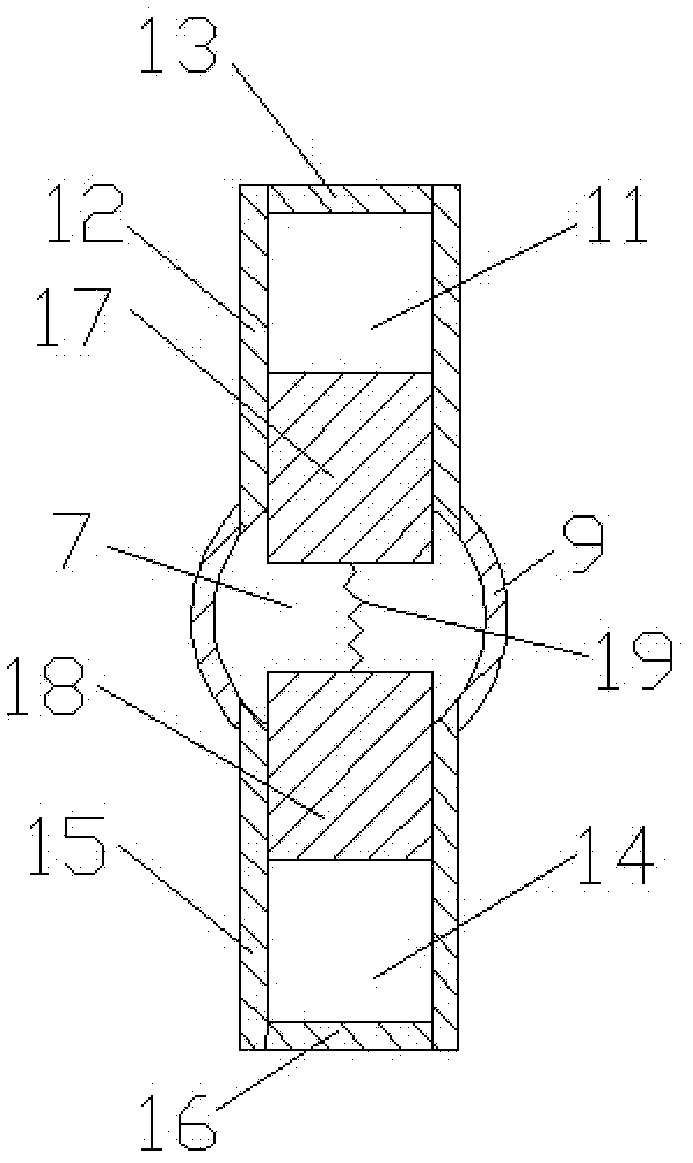

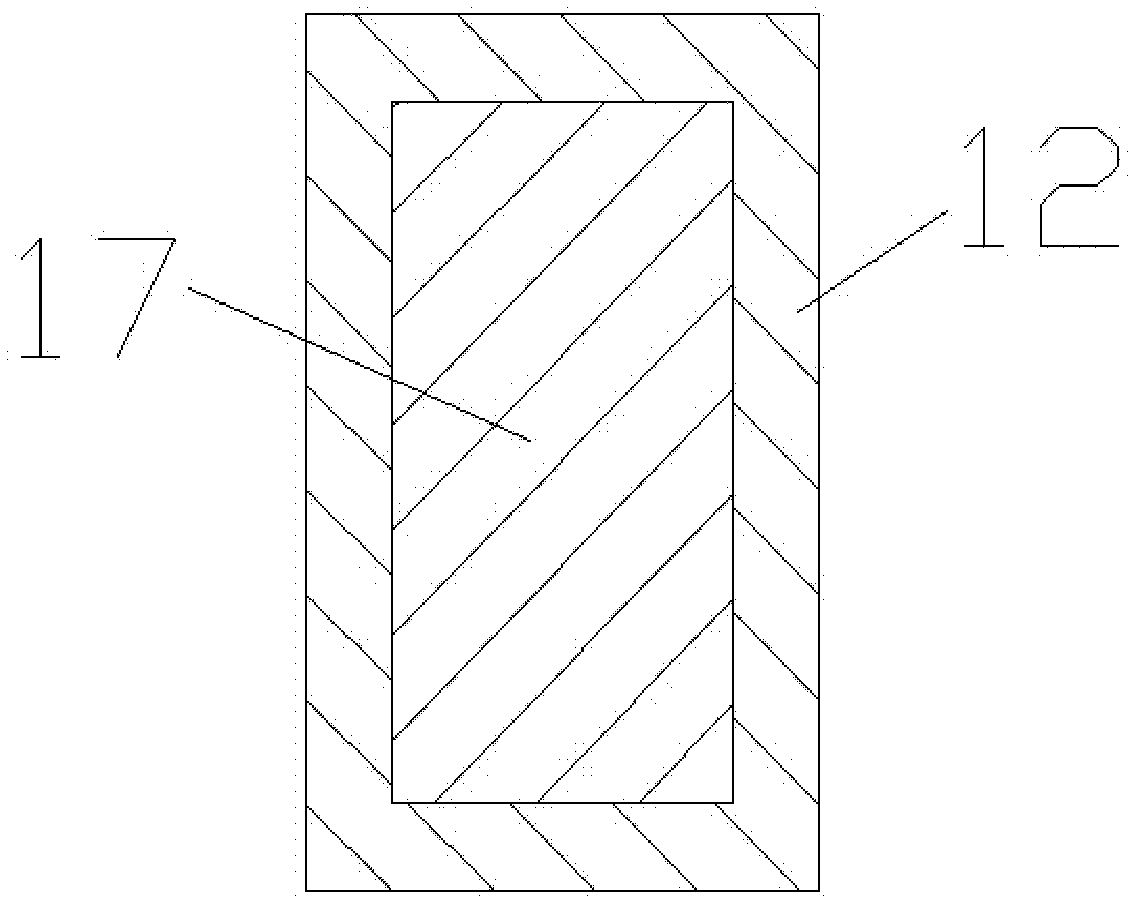

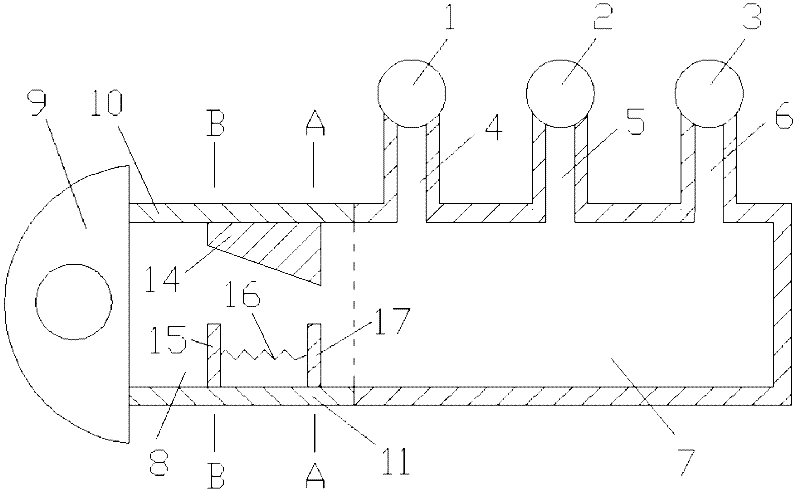

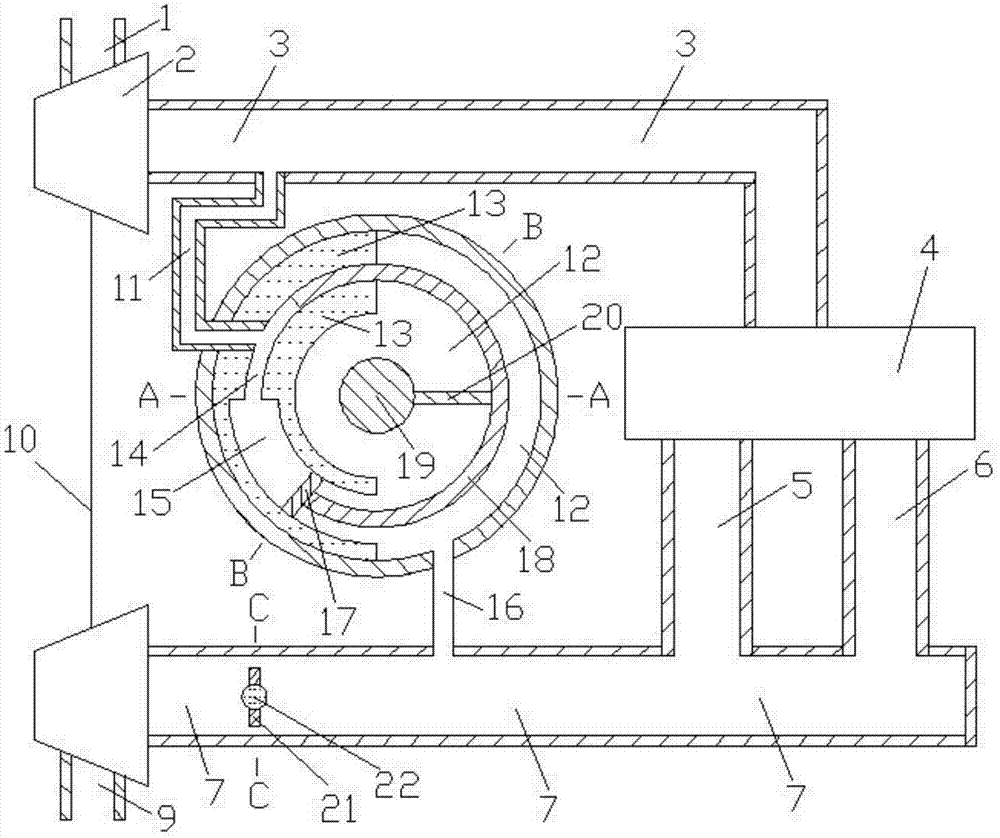

Rotation control type pipeline reducing rate variable device

ActiveCN103089410AConsidering both high and low speed conditionsReasonable designInternal combustion piston enginesGas compressorInlet pressure

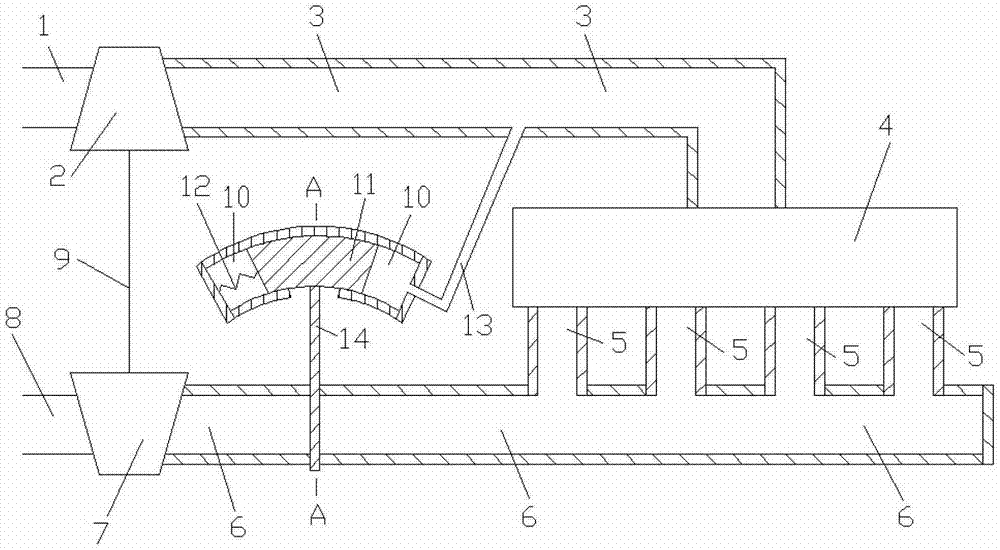

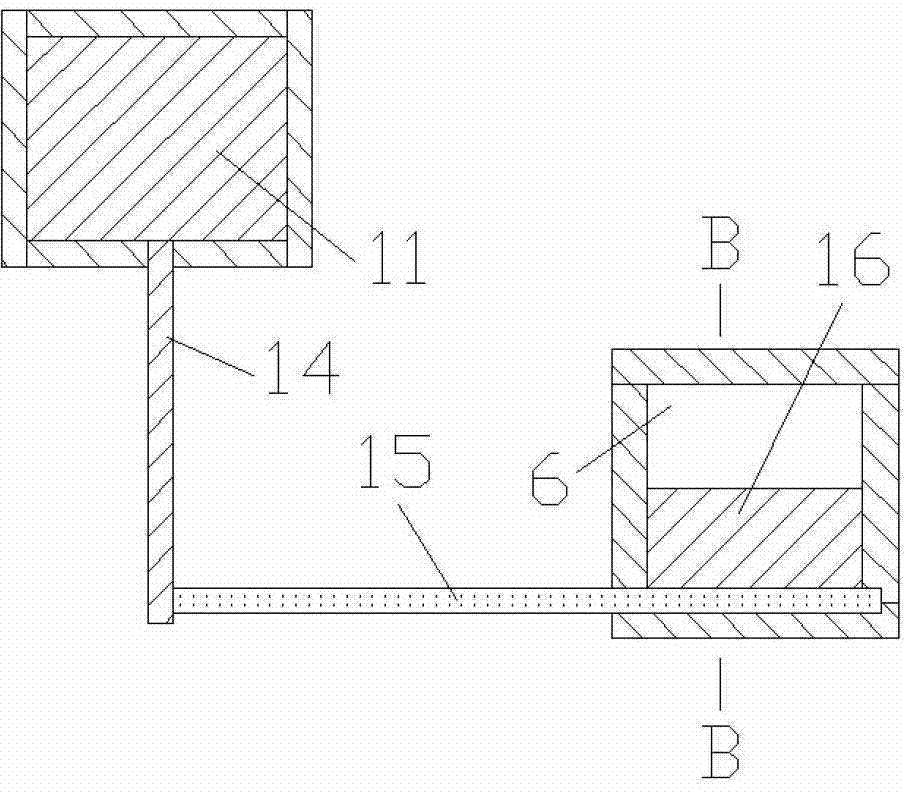

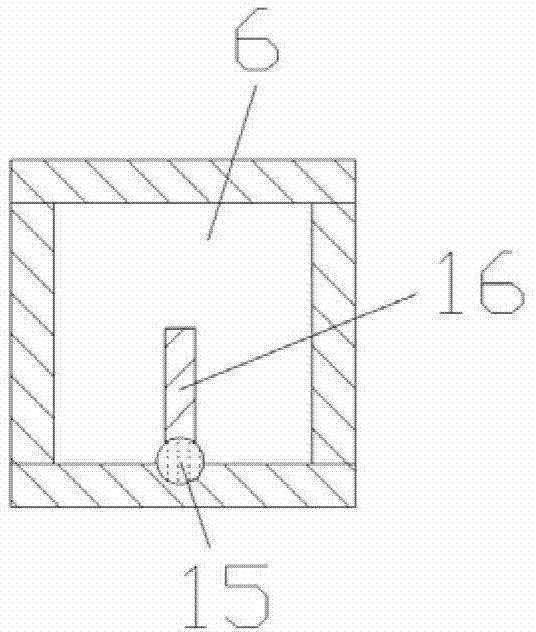

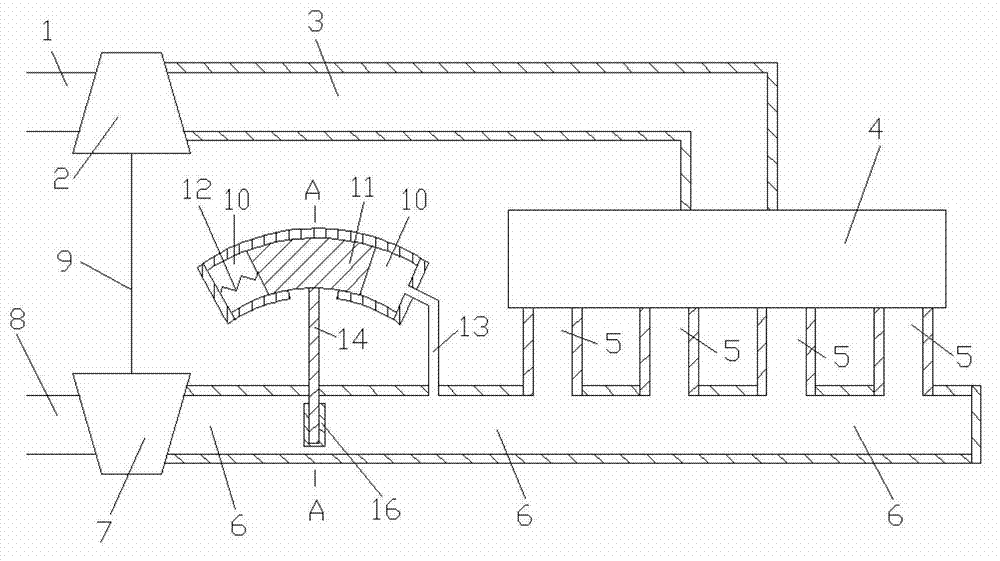

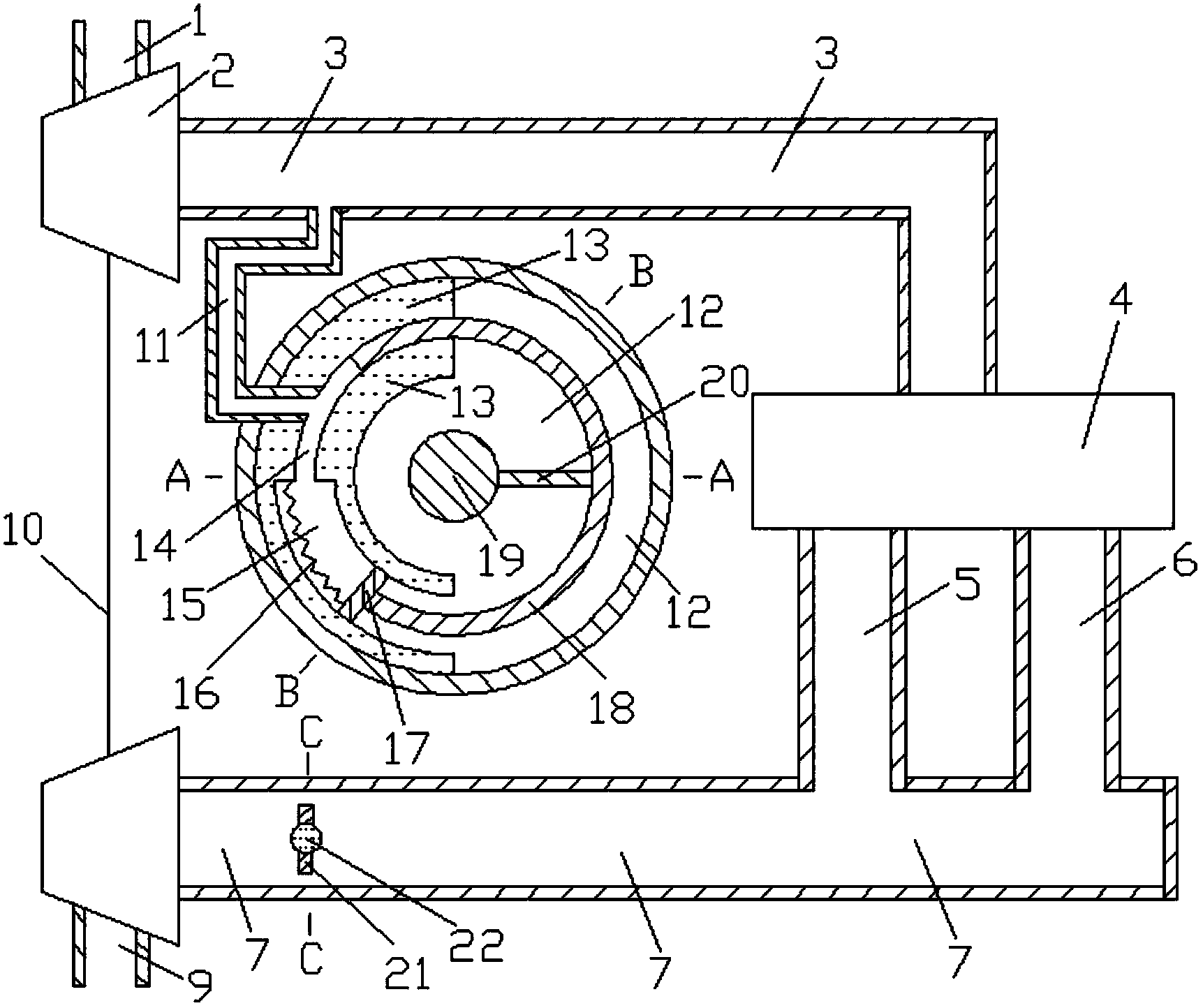

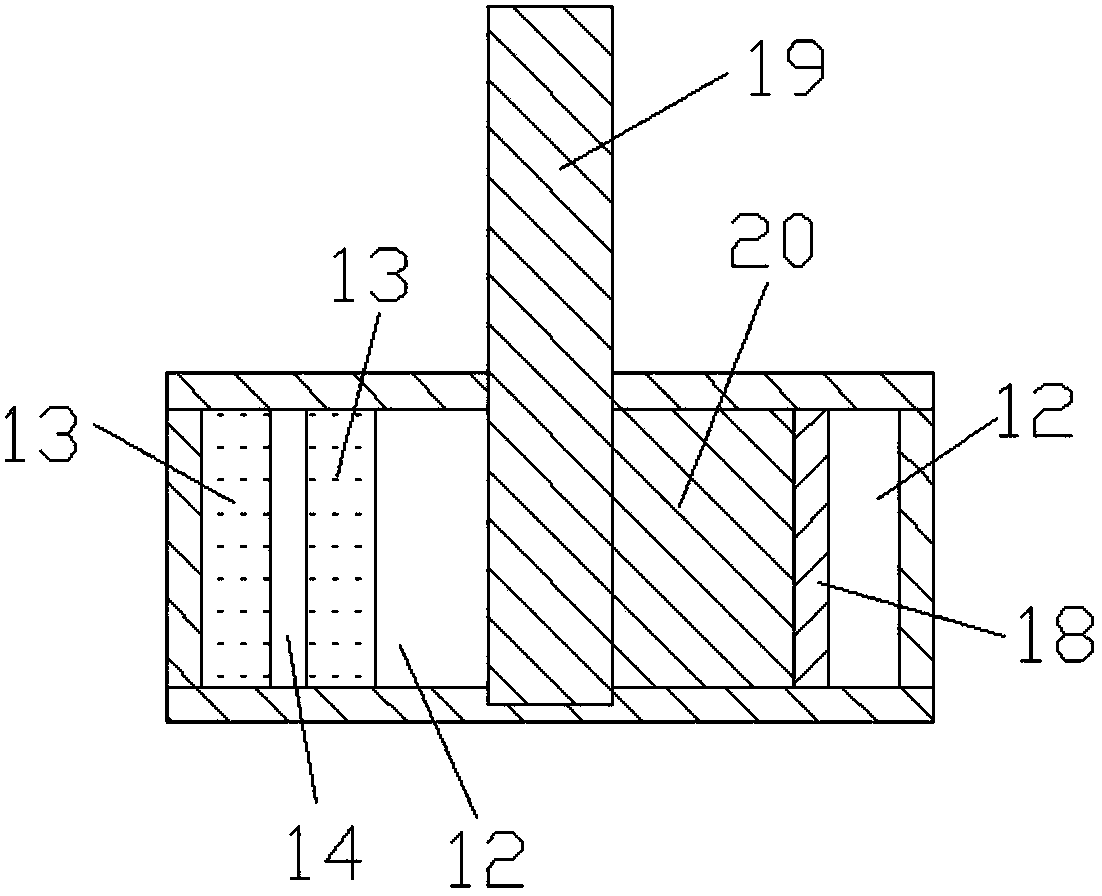

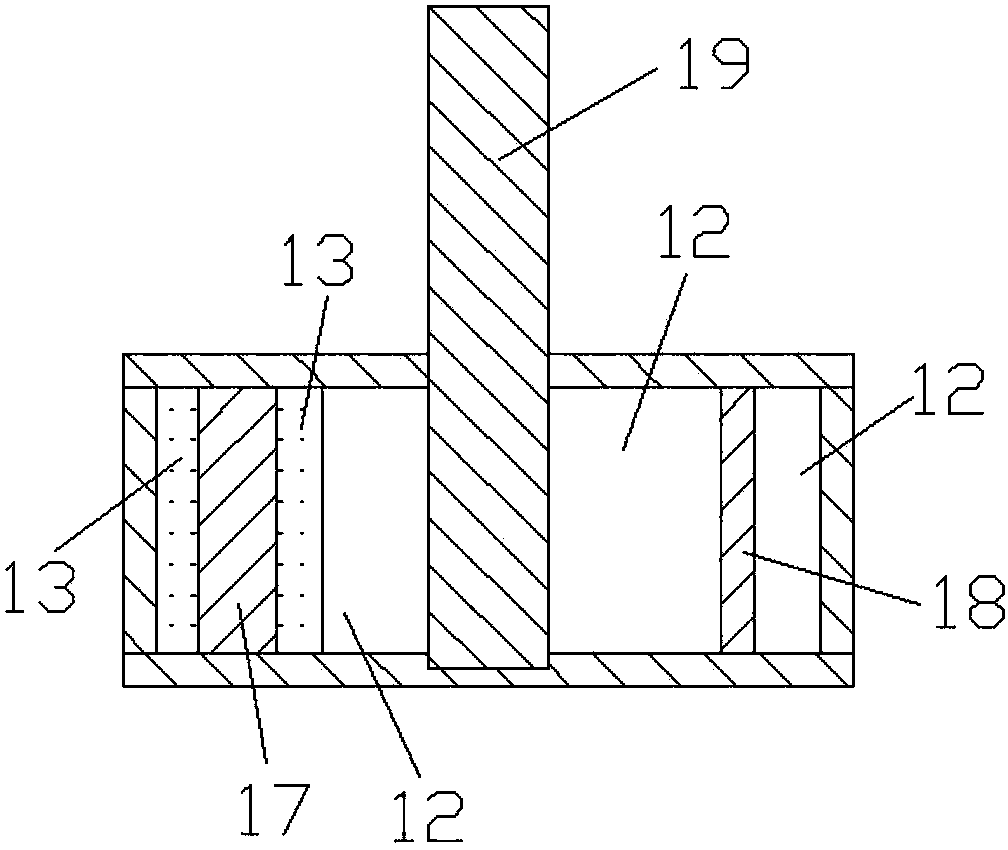

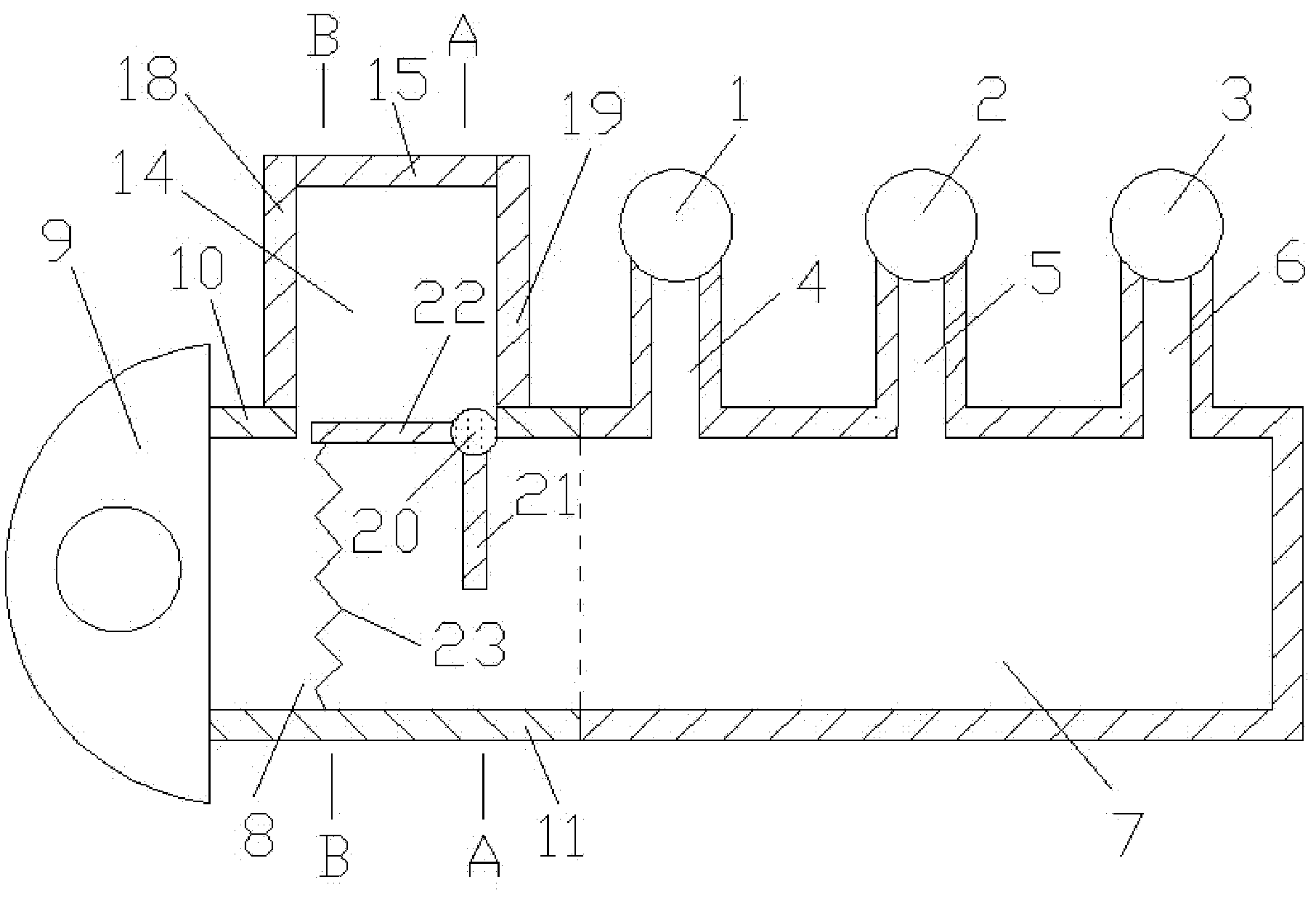

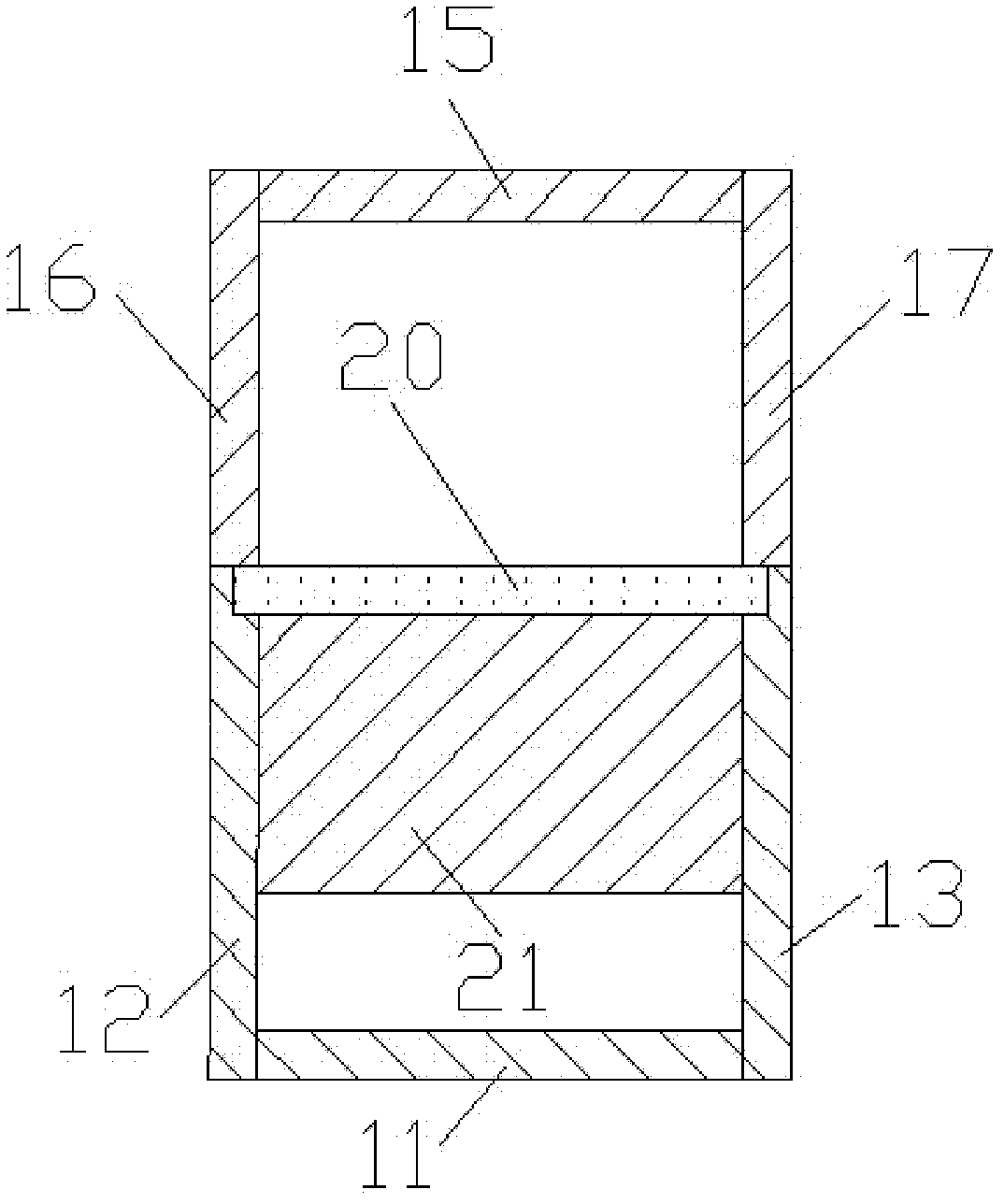

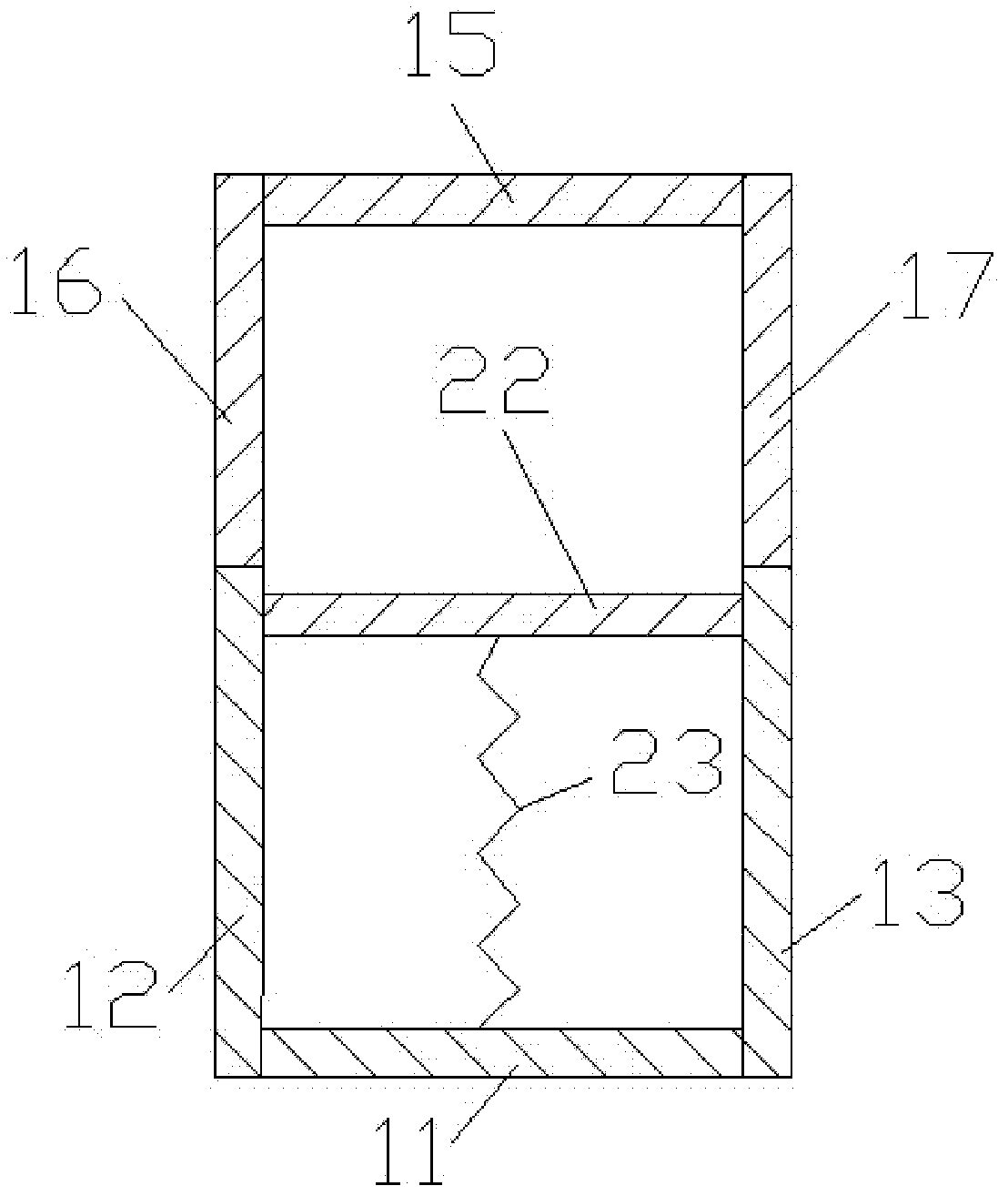

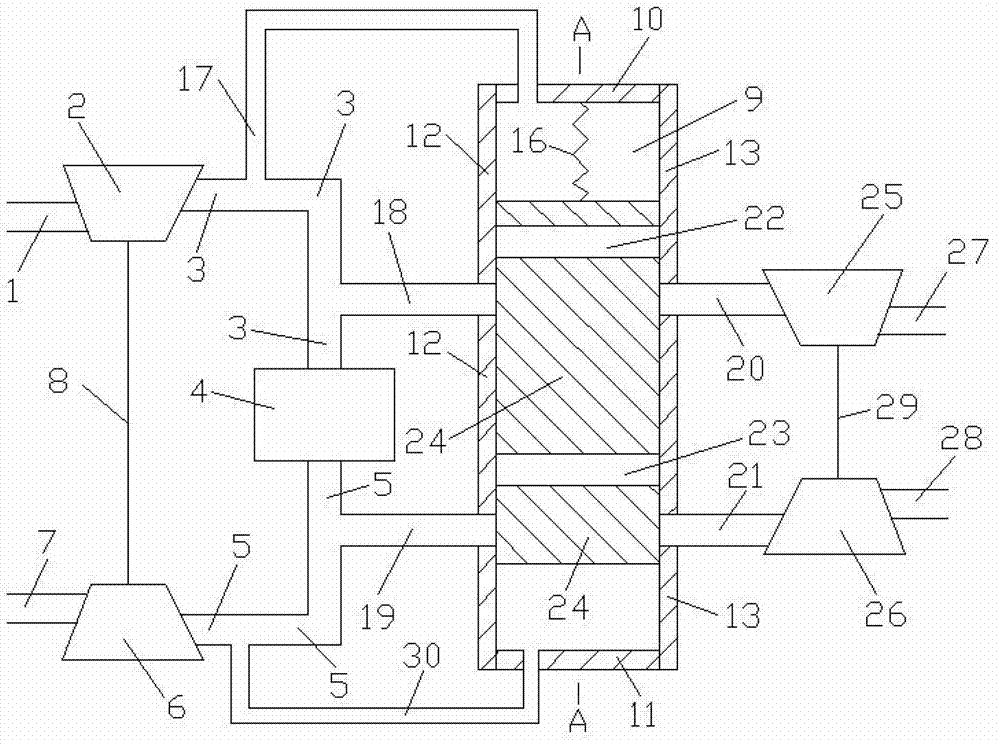

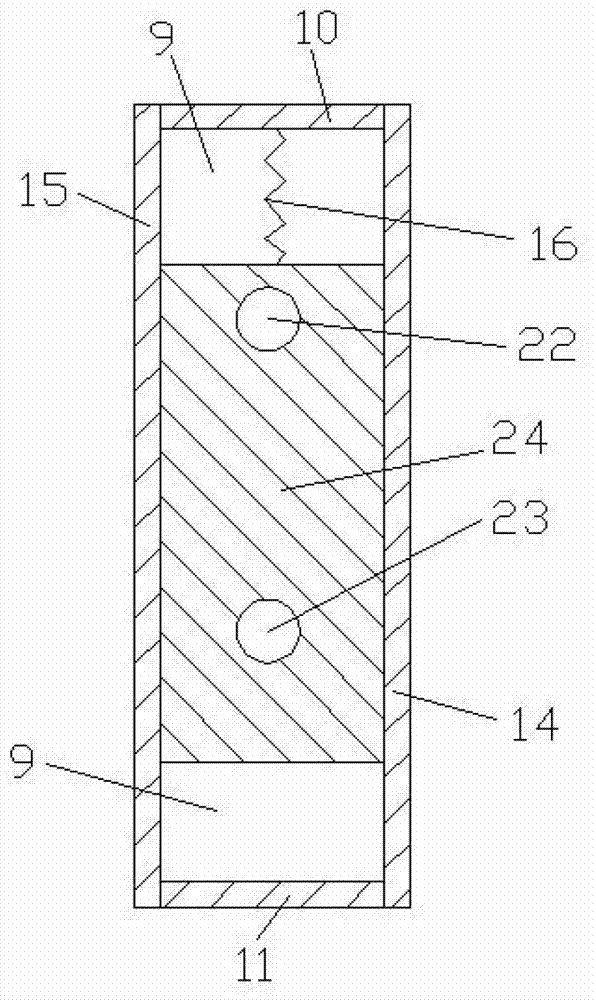

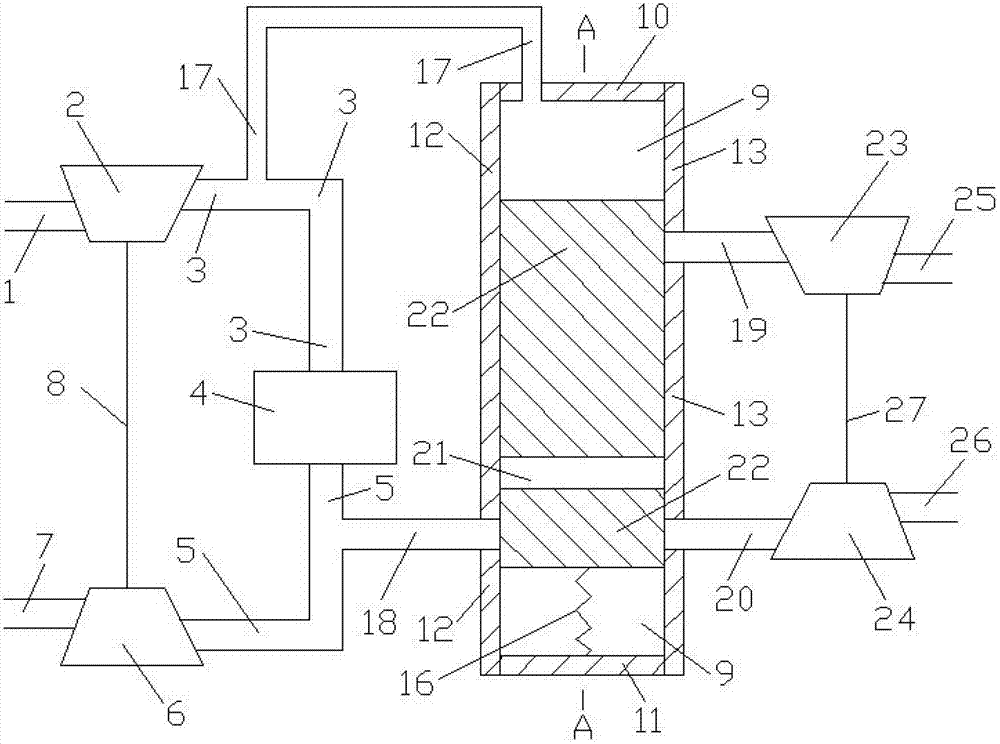

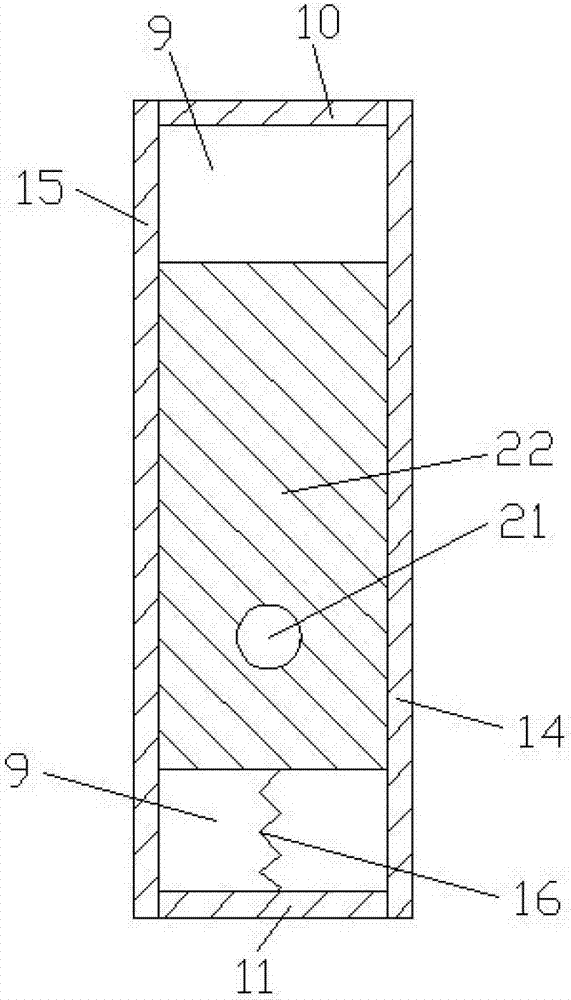

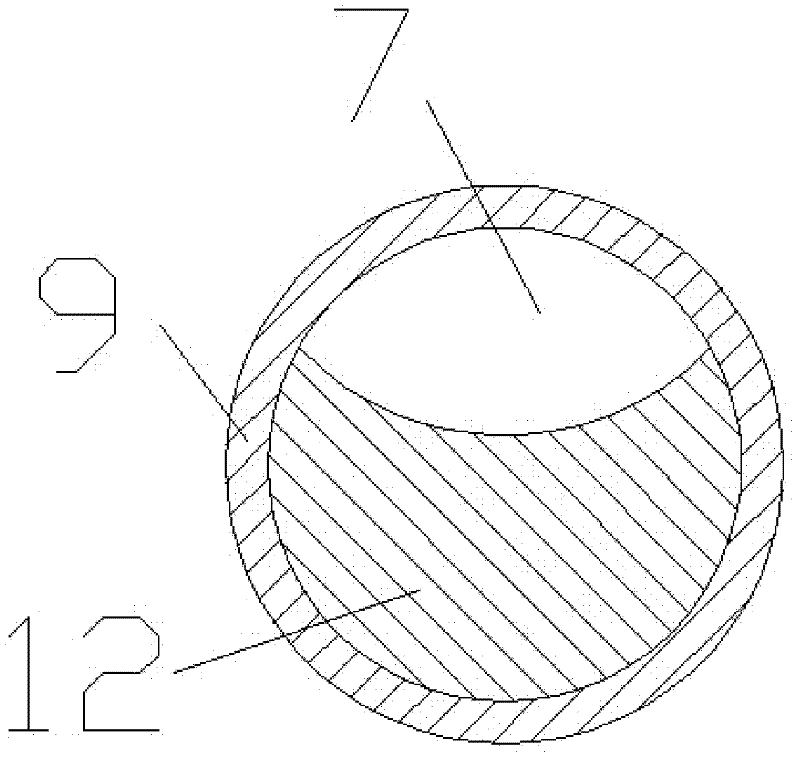

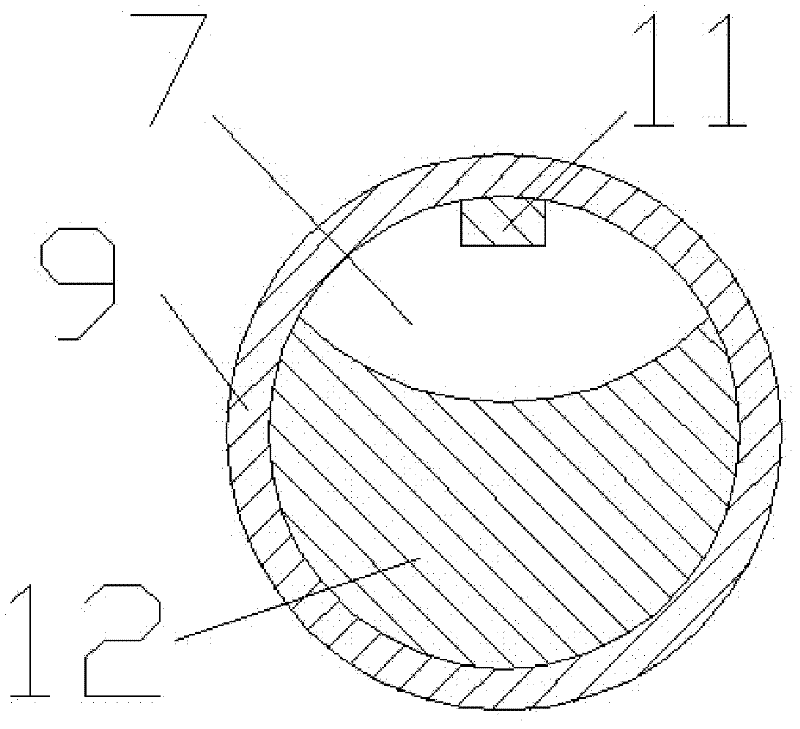

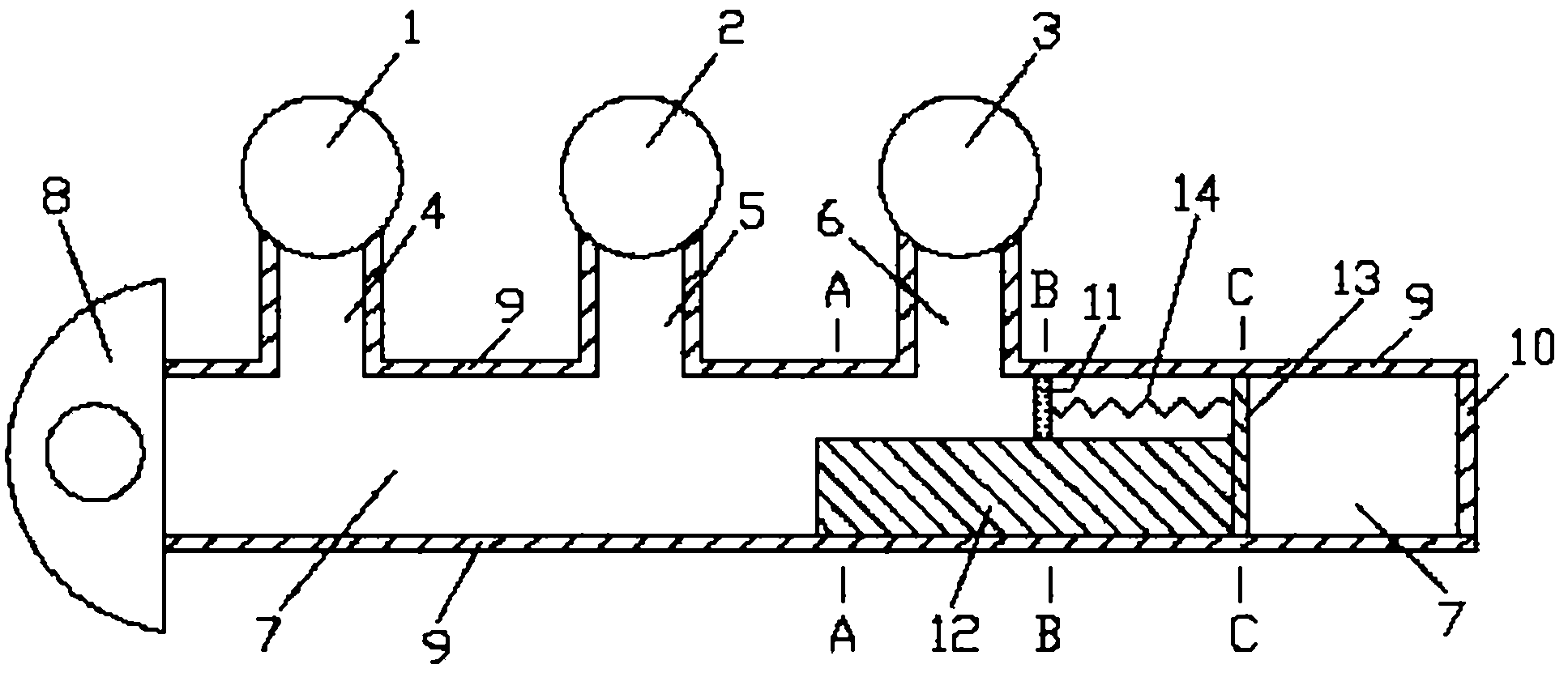

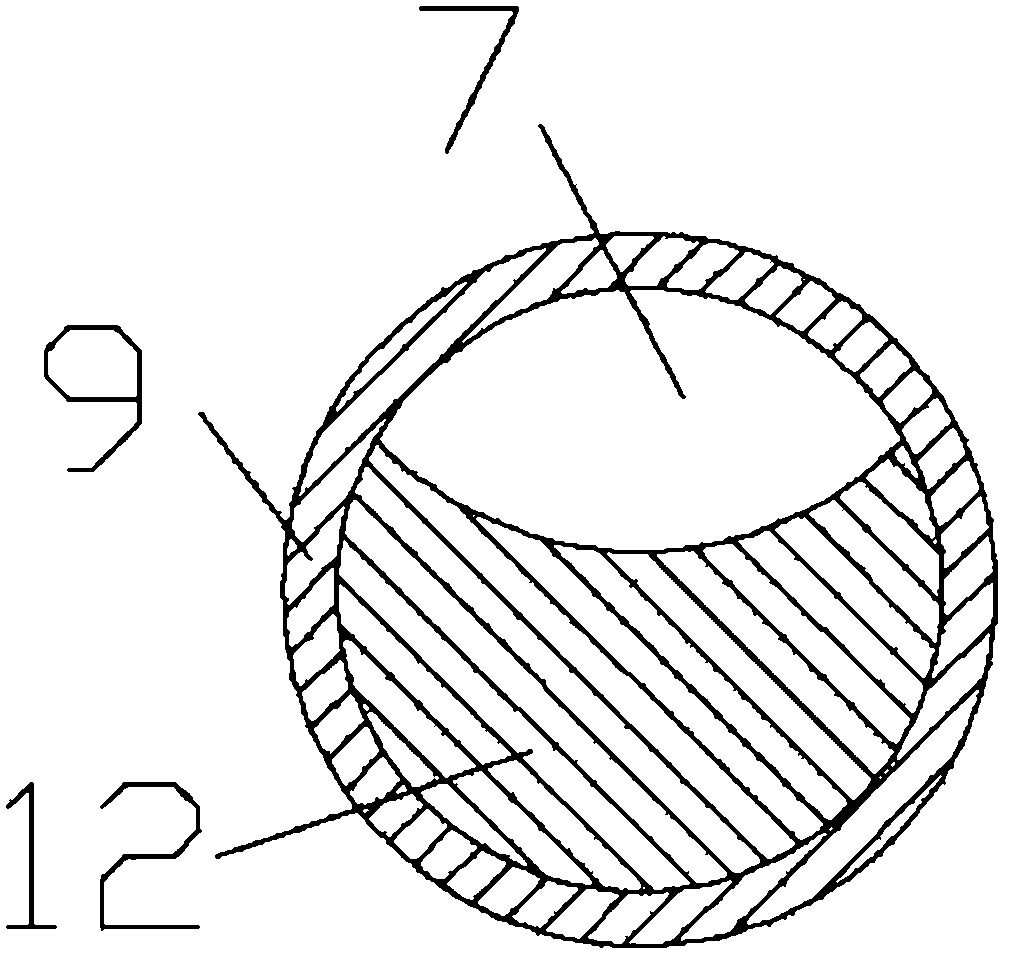

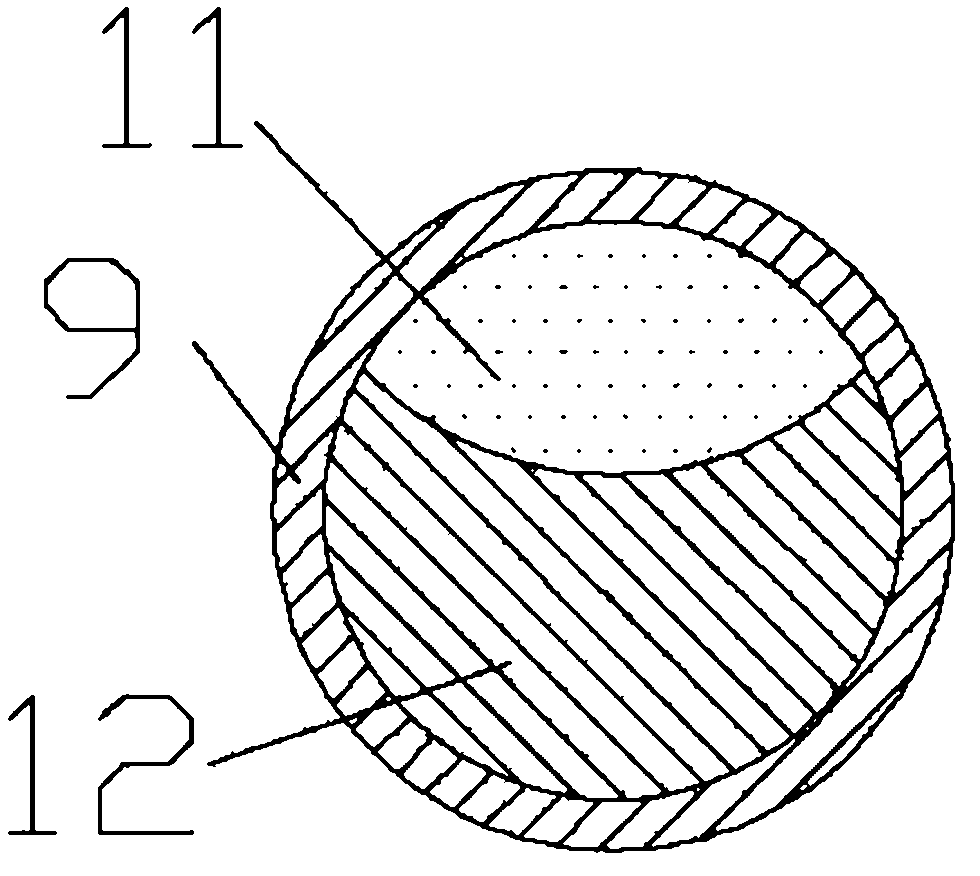

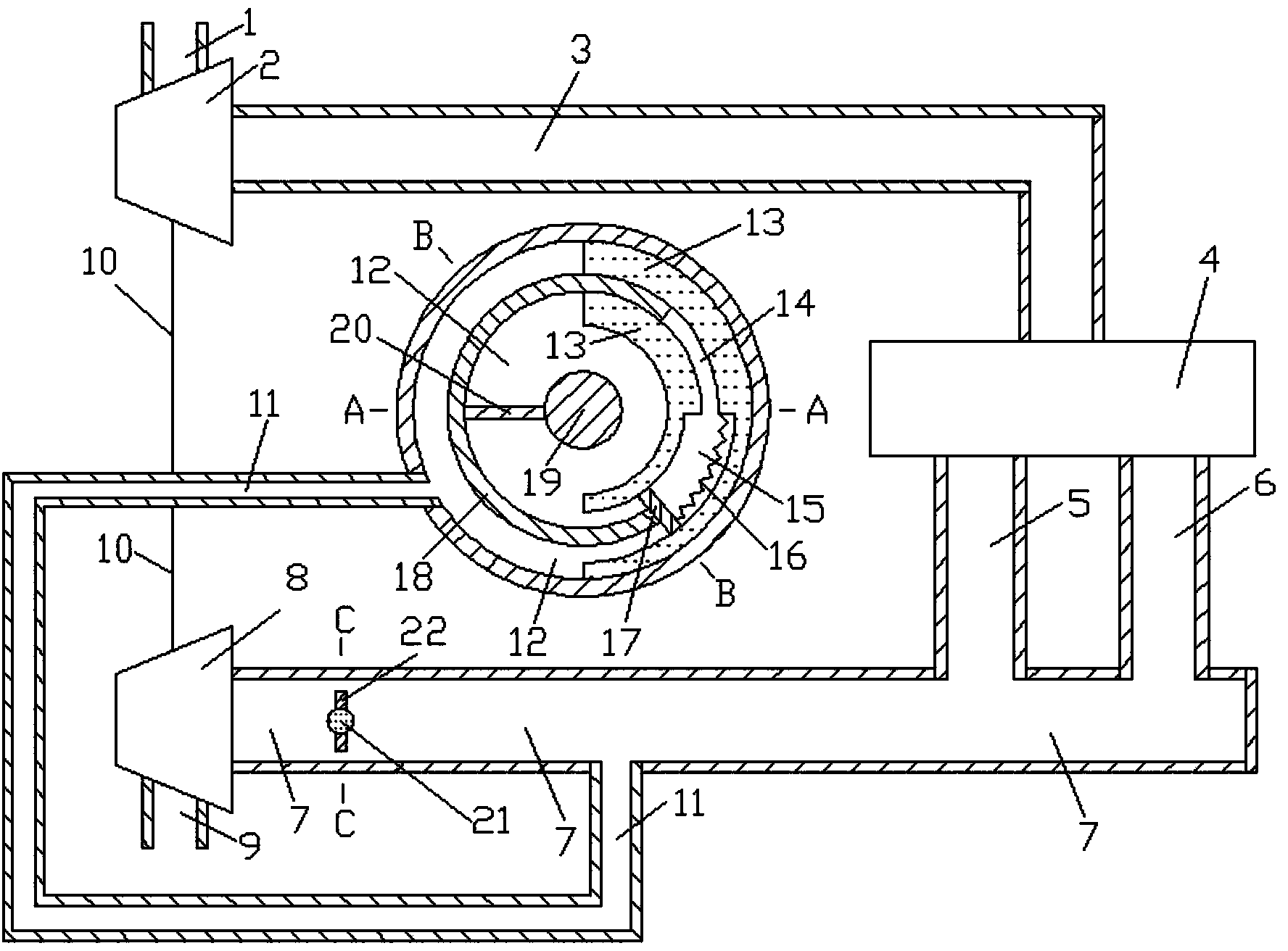

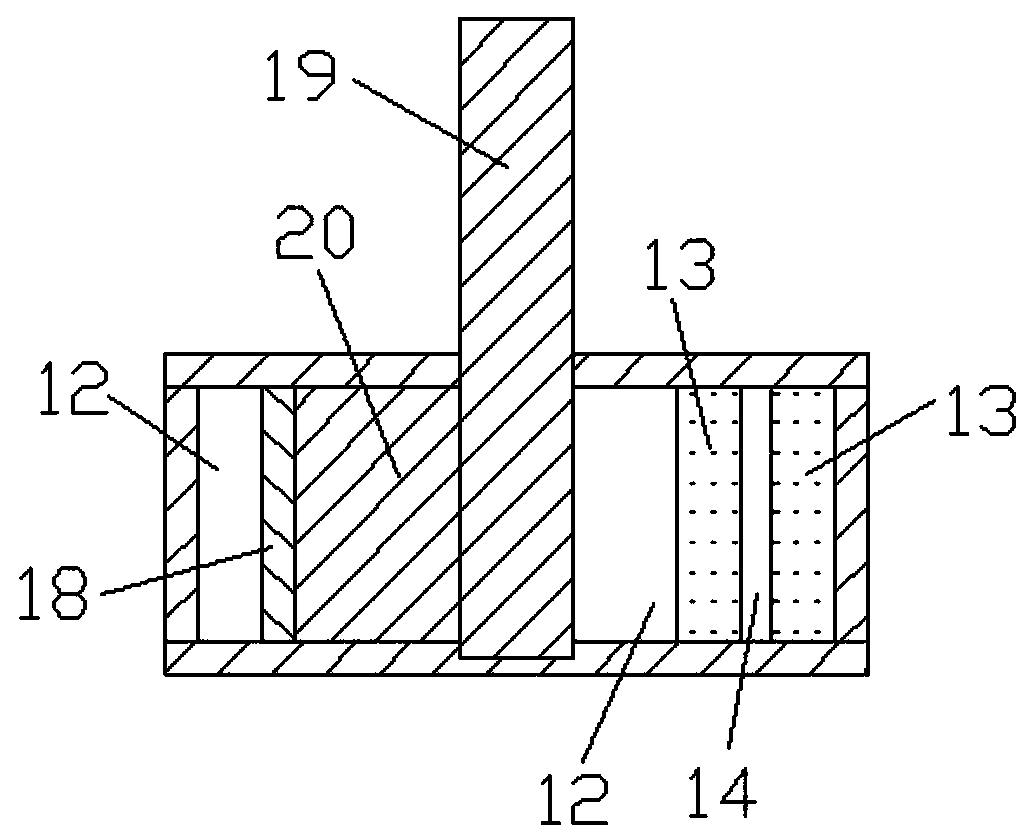

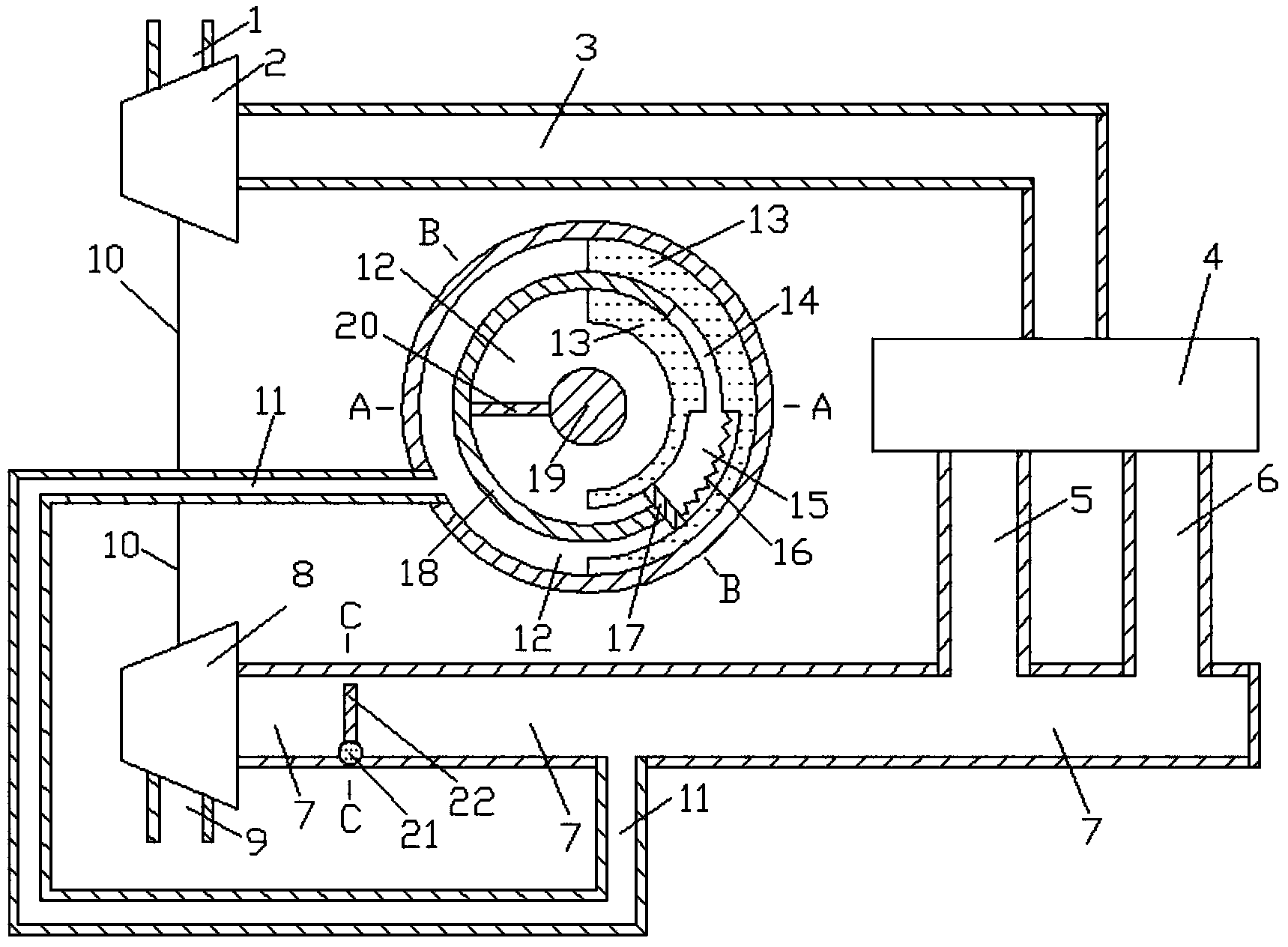

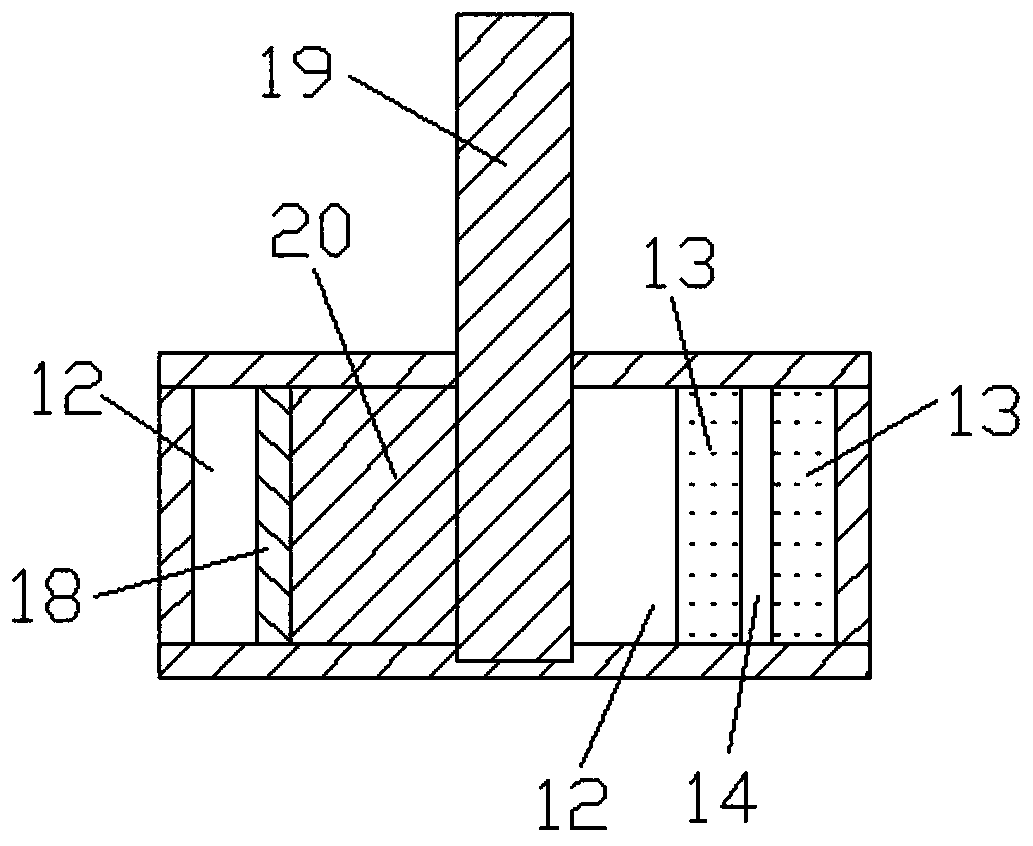

A rotation control type pipeline reducing rate variable device belongs to the technical field of mechanical design and comprises an air compressor, an engine, an air exhaust pipe, a turbine, a volume cavity, a rotation body, a spring, a connection pipe, a rotation rod, a rotation shaft and a rotation plate. The longitudinal sections of the volume cavity and the rotation body are both in arc shapes, the rotation plate is installed in the air exhaust pipe, the rotation plate and the rotation shaft are fixed together, the left wall of the rotation body is connected with the left wall of the volume cavity through the spring, and two ends of the connection pipe are respectively communicated with the right wall of the volume cavity and the air exhaust pipe. When pressure in the air inlet pipe of the engine is high, the rotation body drives the rotation plate to rotate in a counterclockwise mode, pumping loss of the engine is small, and the whole performance is excellent. When pressure in the air inlet pipe of the engine is low, the rotation body drives the rotation plate to rotate in a clockwise mode, available energy in front of the turbine is more, air inlet pressure of the engine is high, and the whole performance is excellent. The rotation control type pipeline reducing rate variable device is reasonable in design, simple in structure and suitable for a turbine single inlet turbocharged system.

Owner:SUZHOU INTI AUTOMOTIVE TECH CO LTD

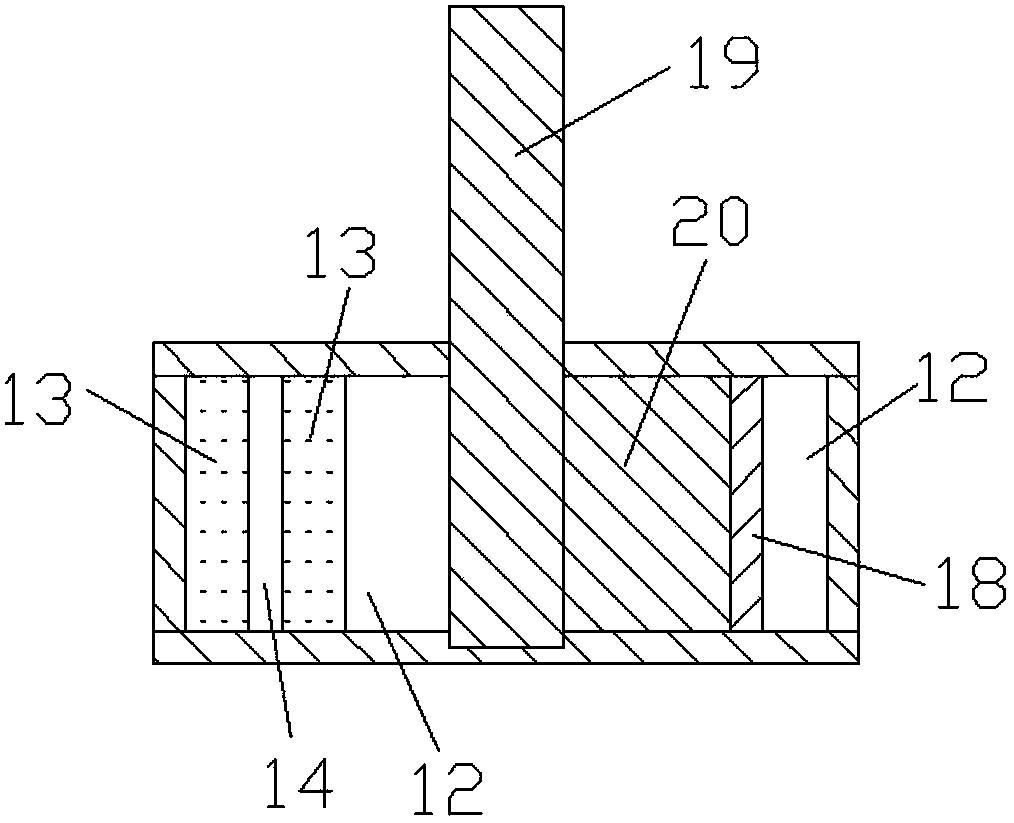

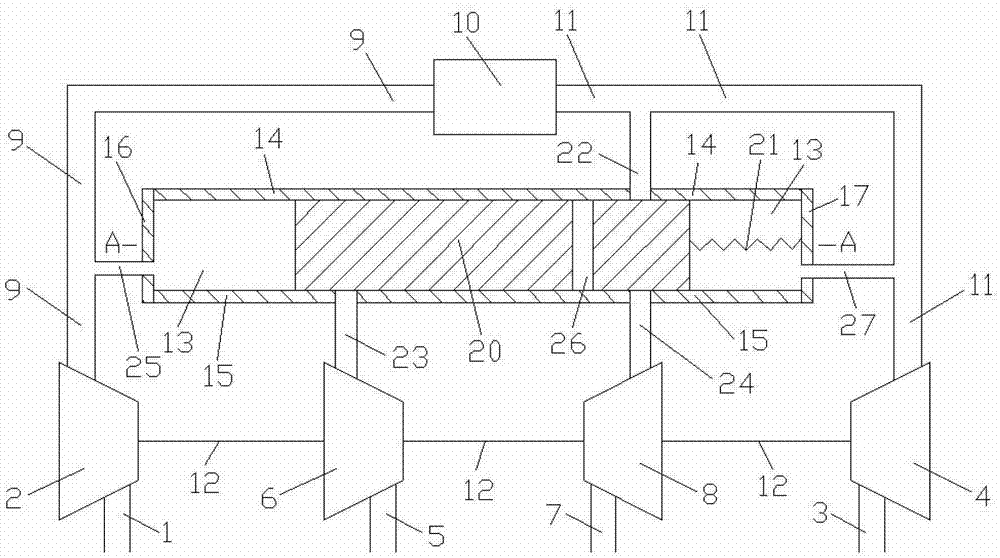

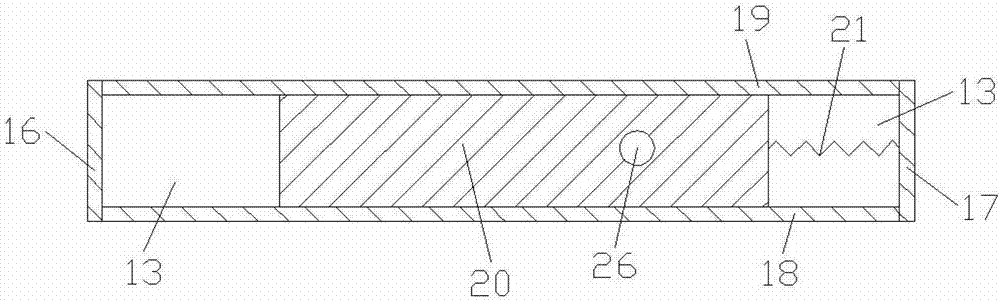

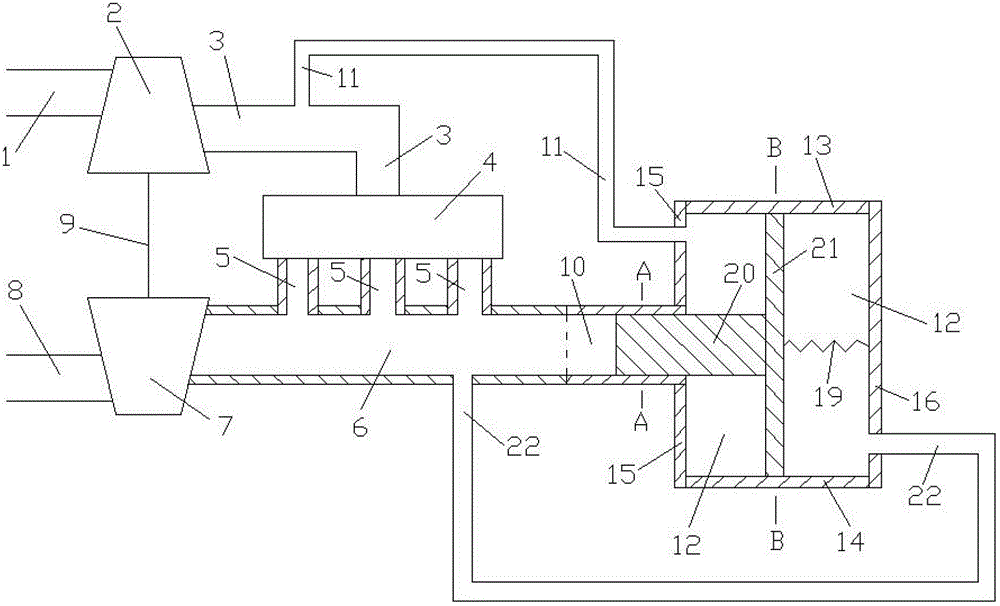

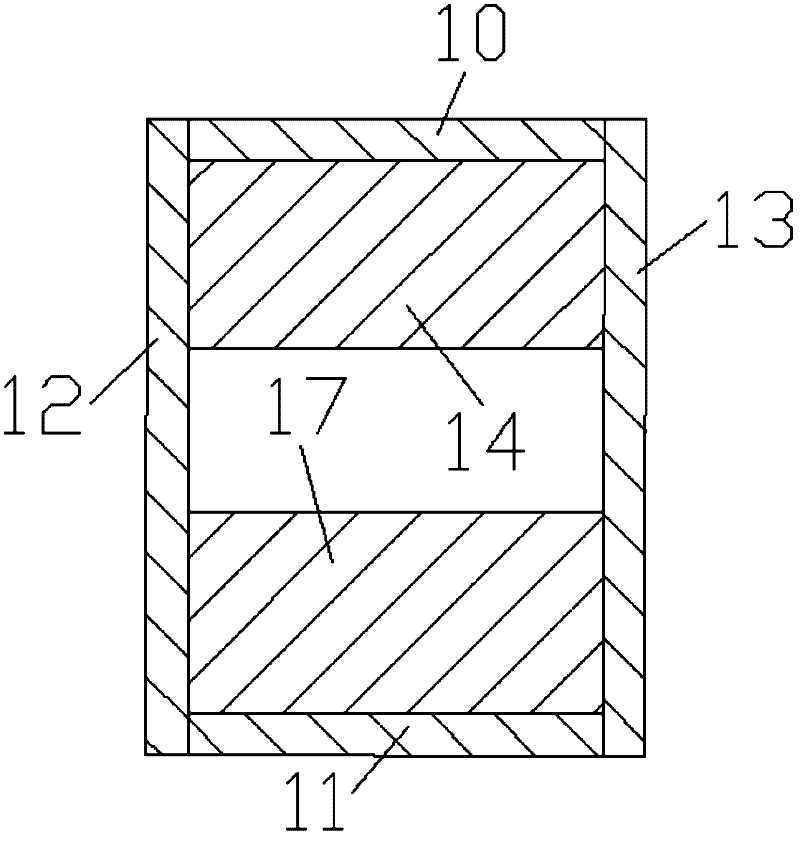

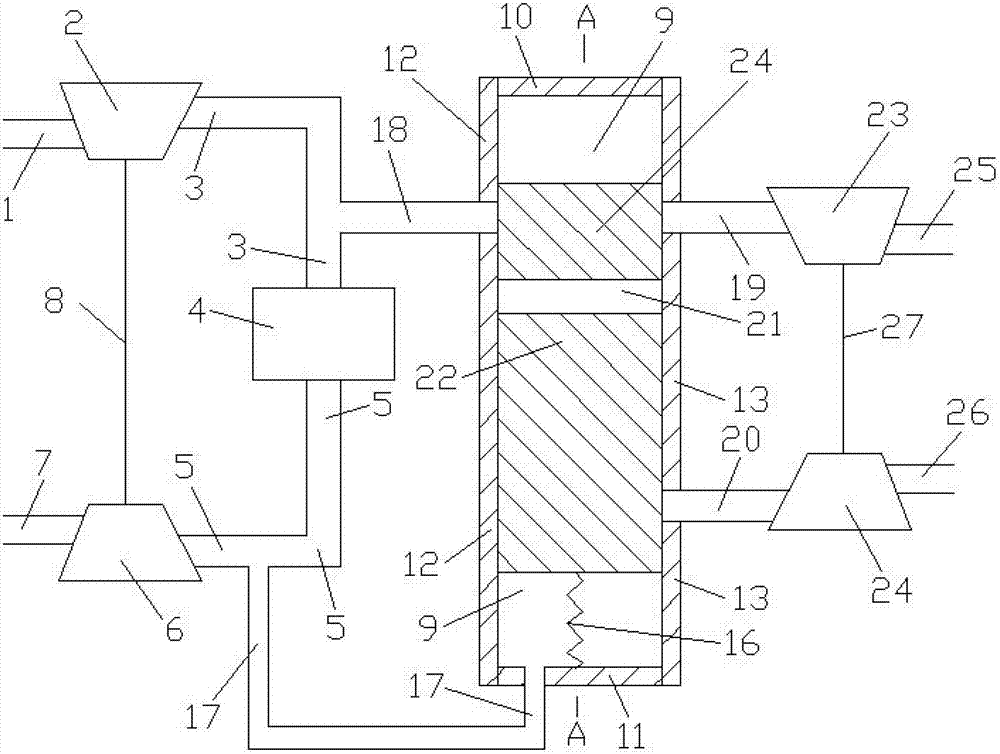

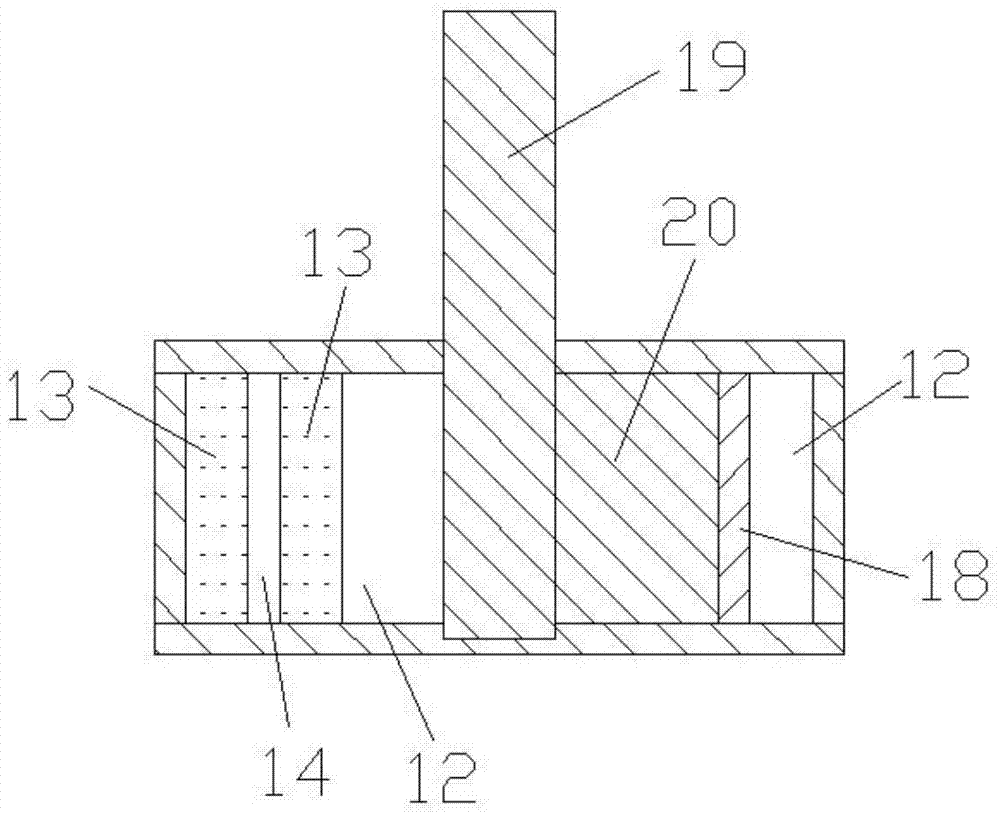

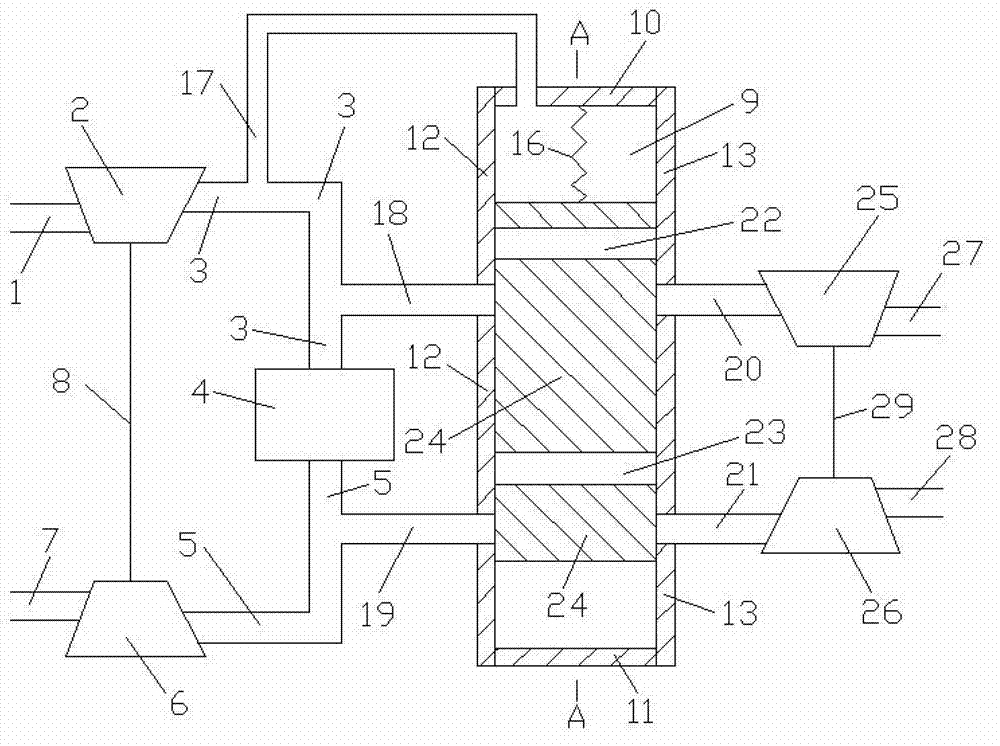

Variable air exhaust through flow area air exhaust pressure control type adjusting mechanism for turbocharged engine

InactiveCN103089411ALarge throat areaIncrease intake pressureInternal combustion piston enginesInlet pressureAir compressor

A variable air exhaust through flow area air exhaust pressure control type adjusting mechanism for a turbocharged engine belongs to the technical field of mechanical design and comprises an air compressor, an engine, a turbine, a volume cavity, a rotation body, a spring, a rotation rod, a rotation shaft and a rotation plate. The longitudinal sections of the volume cavity and the rotation body are both in arc shapes, the rotation plate is installed in an air exhaust pipe, the rotation plate and the rotation shaft are fixed together, the left wall of the rotation body is connected with the left wall of the volume cavity through the spring, and two ends of a connection pipe are respectively communicated with the right wall of the volume cavity and the air exhaust pipe. When pressure in the air exhaust pipe in front of the rotation plate is high, the rotation body drives the rotation plate to rotate in a counterclockwise mode, pumping loss of the engine is small, and the whole performance is excellent. When pressure in the air exhaust pipe in front of the rotation plate is low, the rotation body drives the rotation plate to rotate in a clockwise mode, available energy in front of the turbine is more, air inlet pressure of the engine is high, and the whole performance is excellent. The variable air exhaust through flow area air exhaust pressure control type adjusting mechanism for the turbocharged engine is reasonable in design, simple in structure and suitable for a turbine single inlet turbocharged system.

Owner:SHANGHAI JIAO TONG UNIV

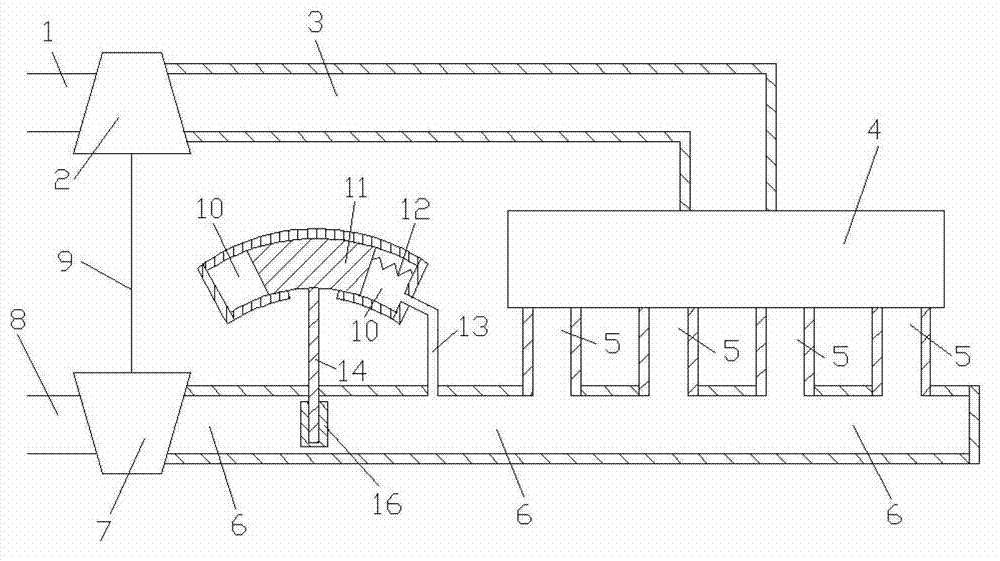

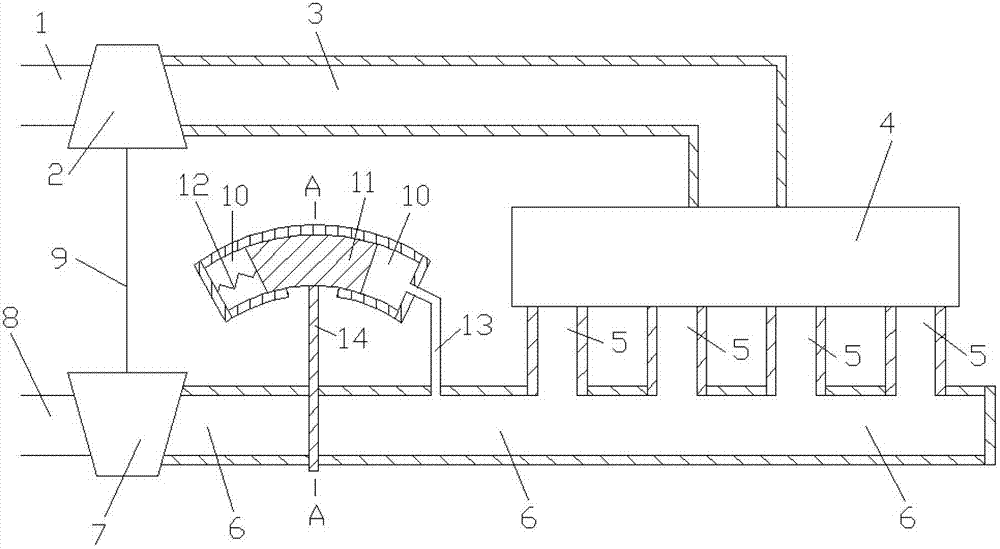

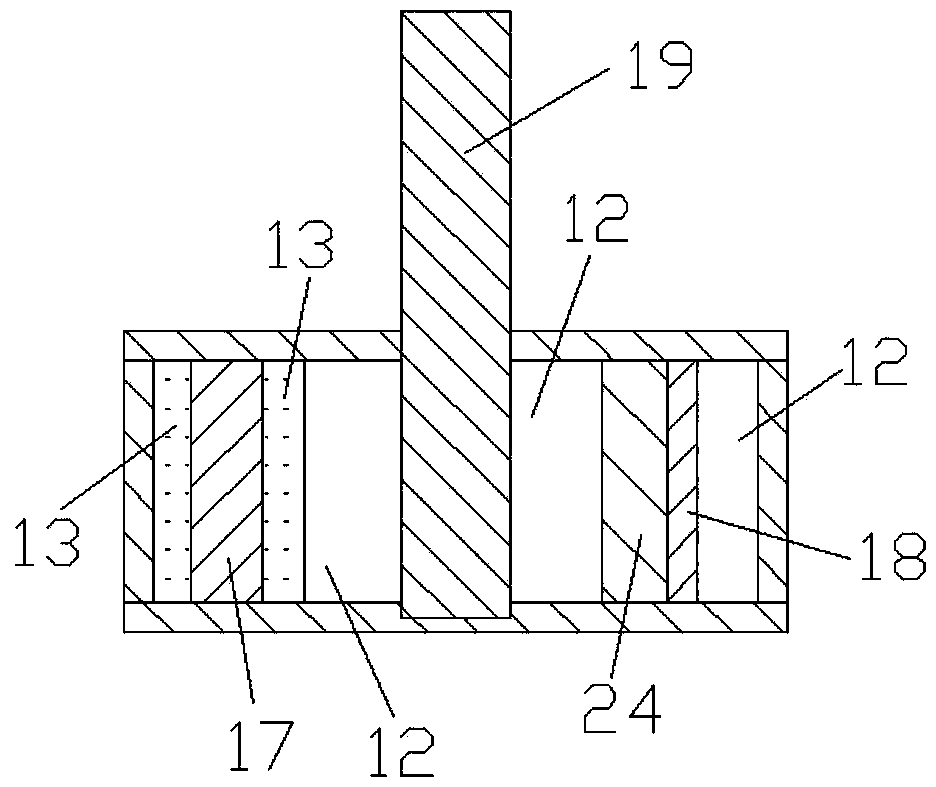

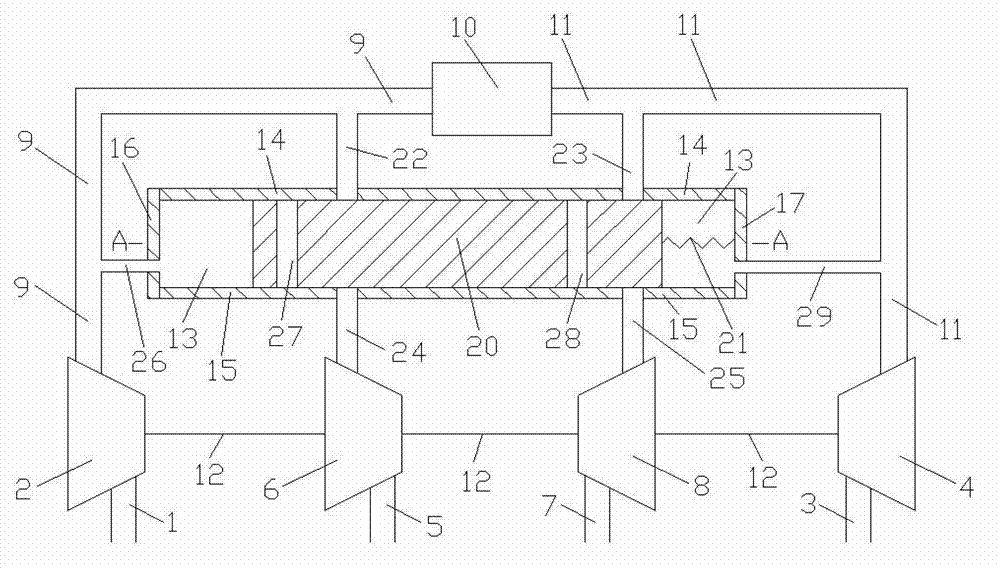

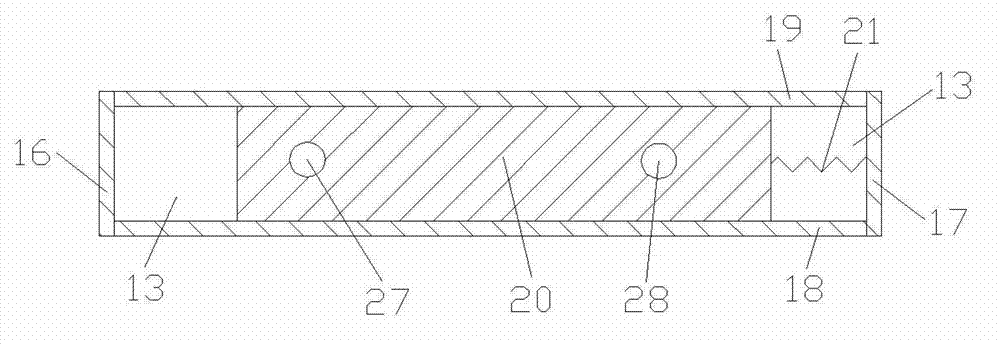

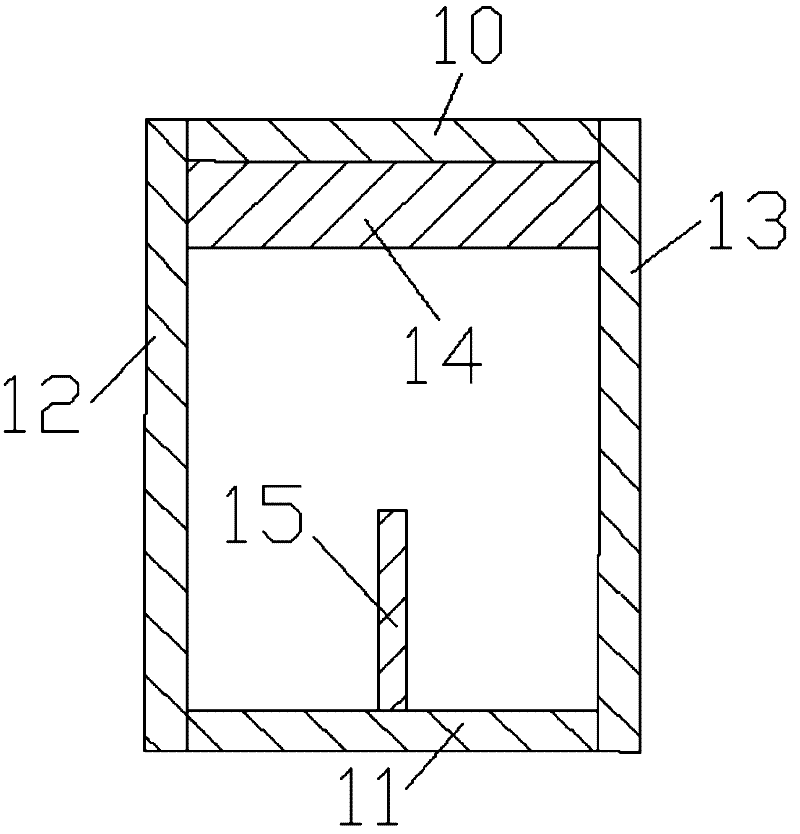

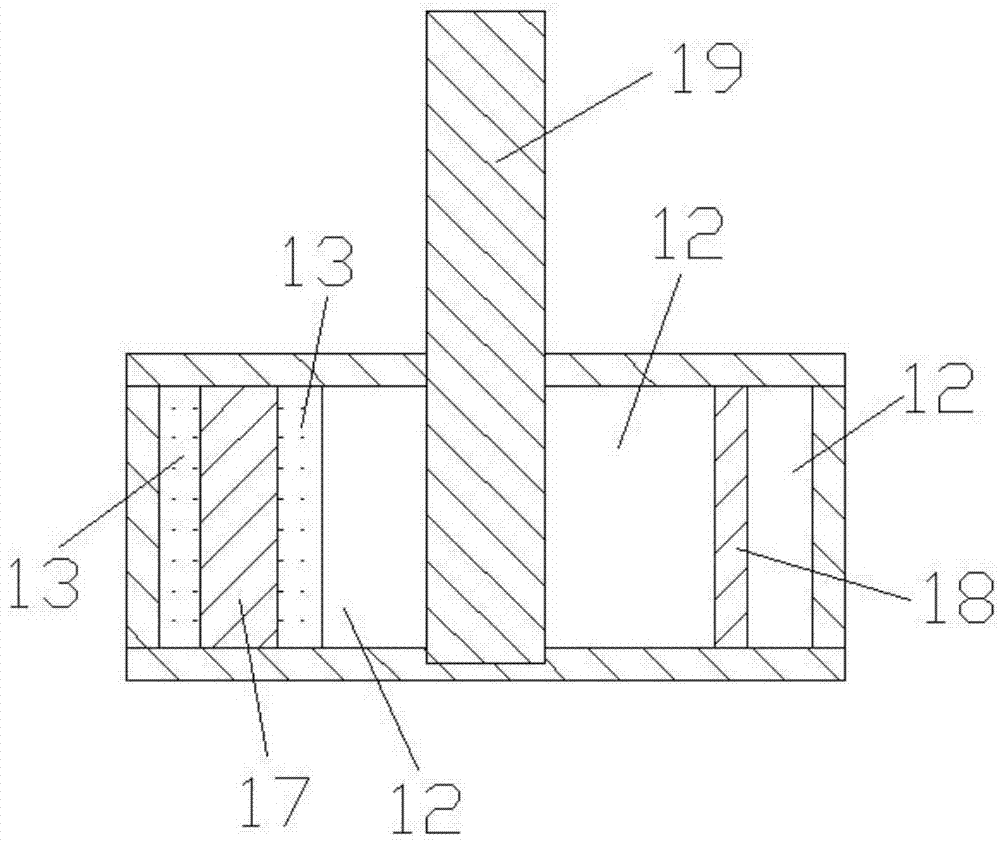

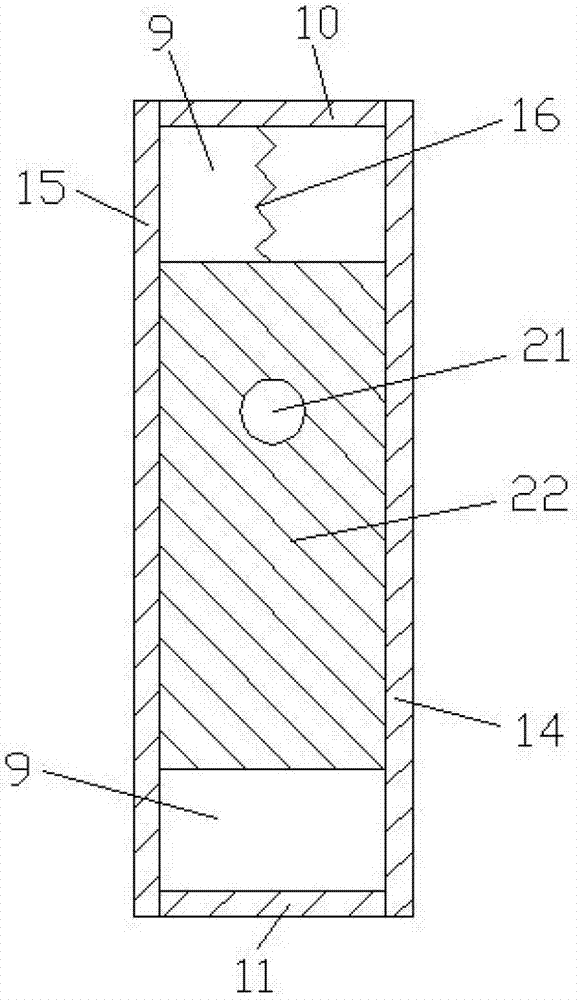

Rotation control type air exhaust pipe outlet area variable device

ActiveCN103089412AReasonable designSimple structureInternal combustion piston enginesIntake pressureMechanical design

A rotation control type air exhaust pipe outlet area variable device belongs to the technical field of mechanical design and comprises an air compressor, an engine, an air exhaust pipe, a turbine, a volume cavity, a rotation body, a spring, a connection pipe, a rotation rod, a rotation shaft and a rotation plate. The longitudinal sections of the volume cavity and the rotation body are both in arc shapes, the rotation plate is installed in the air exhaust pipe, the rotation plate and the rotation shaft are fixed together, the left wall of the rotation body is connected with the left wall of the volume cavity through the spring, and two ends of the connection pipe are respectively communicated with the right wall of the volume cavity and the air exhaust pipe. When pressure in the air exhaust pipe in front of the rotation plate is high, the rotation body drives the rotation plate to rotate in a counterclockwise mode, pumping loss of the engine is small, and the whole performance is excellent. When pressure in the air exhaust pipe in front of the rotation plate is low, the rotation body drives the rotation plate to rotate in a clockwise mode, available energy in front of the turbine is more, air inlet pressure of the engine is high, and the whole performance is excellent. The rotation control type air exhaust pipe outlet area variable device is reasonable in design, simple in structure and suitable for a turbine single inlet turbocharged system.

Owner:SHANGHAI JIAO TONG UNIV

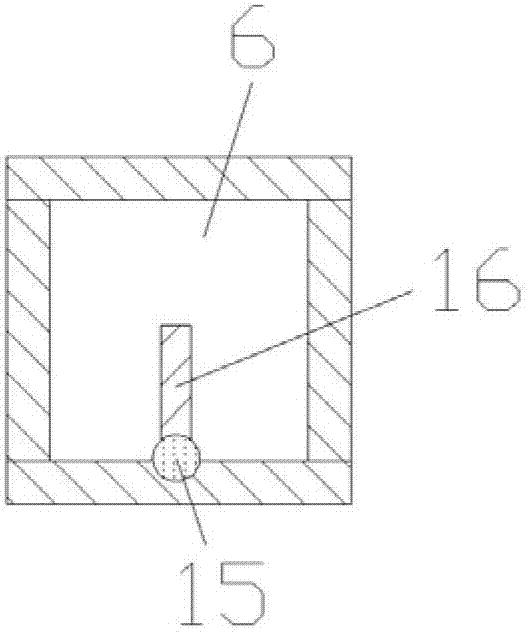

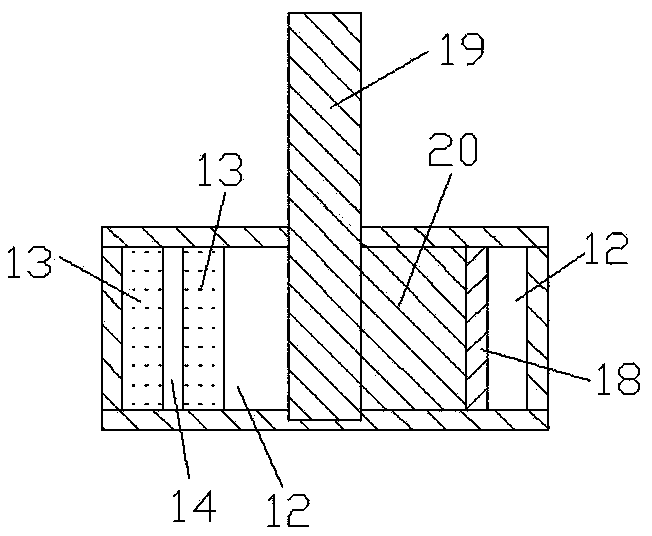

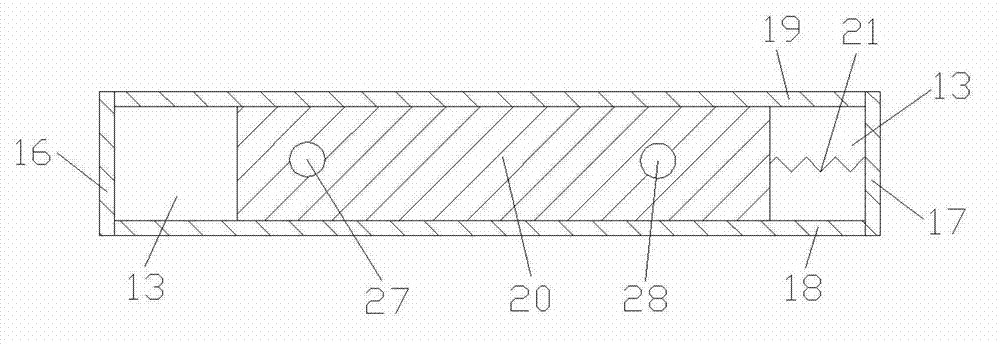

Square tube device with chain

InactiveCN103573389AConsidering both high and low speed conditionsReasonable designInternal combustion piston enginesThroatTurbine

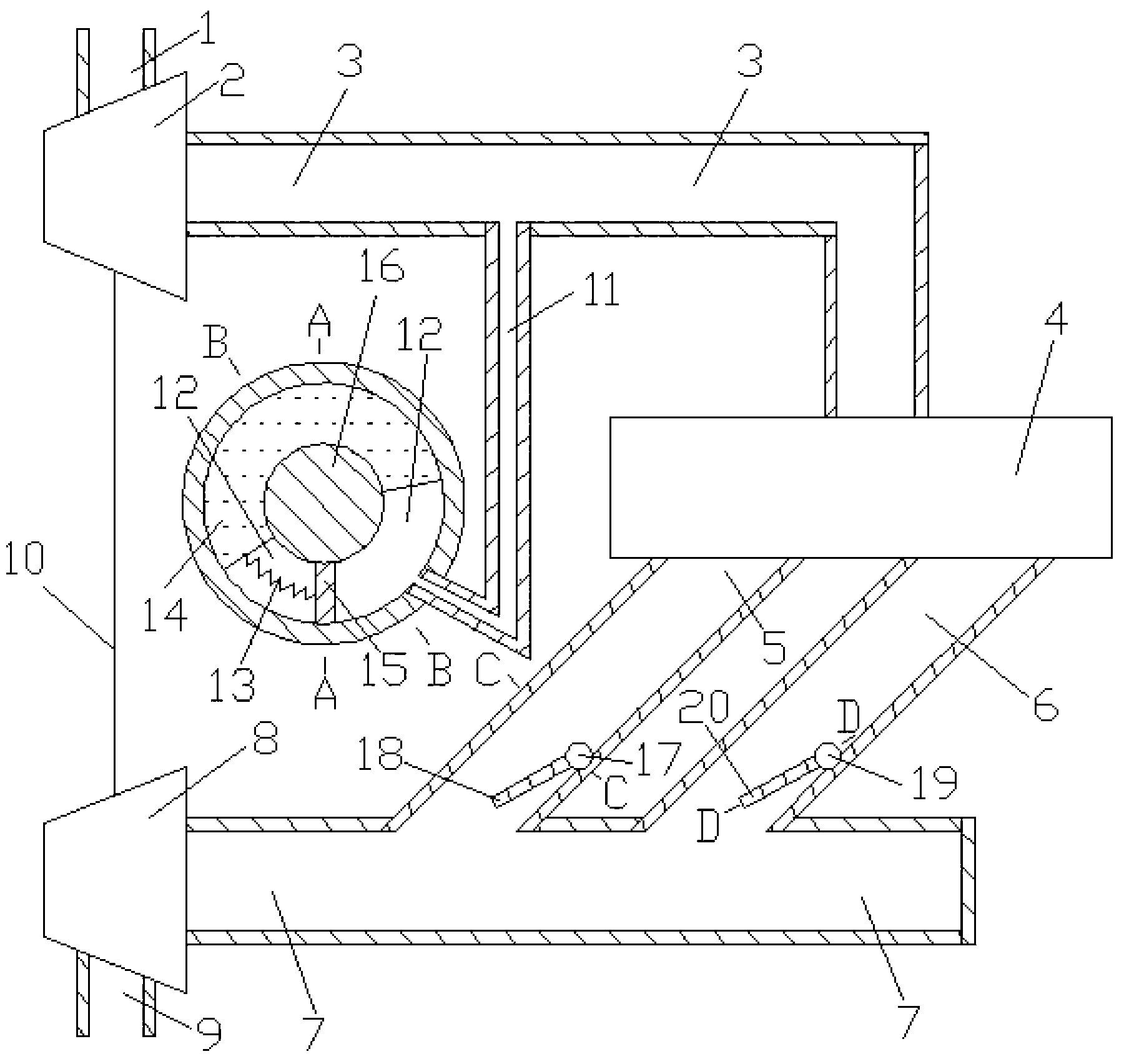

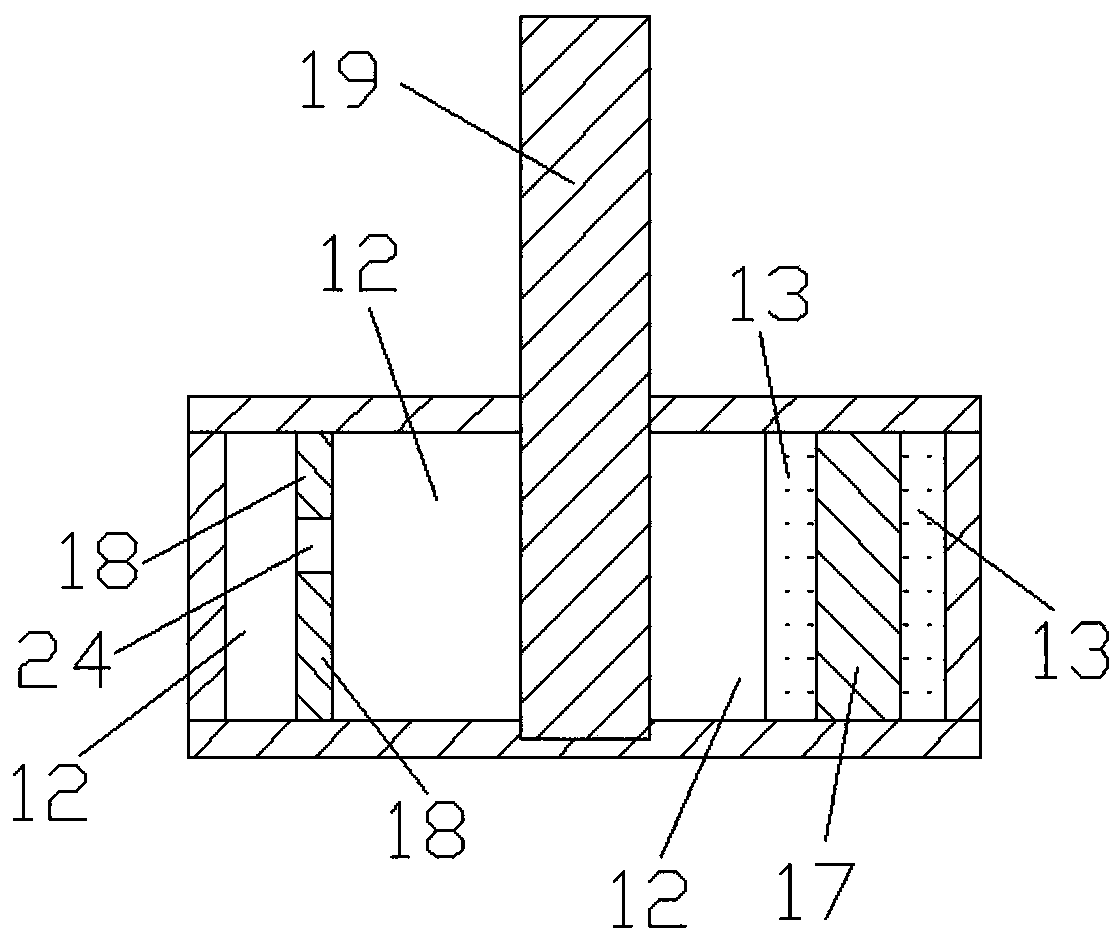

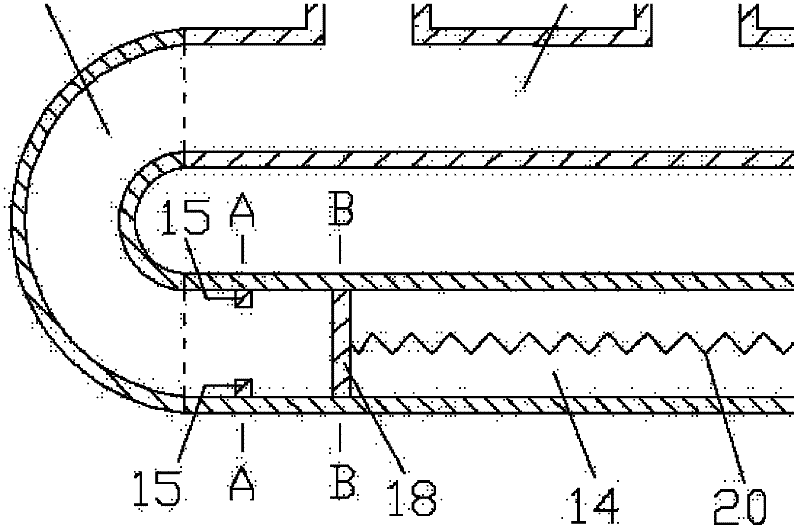

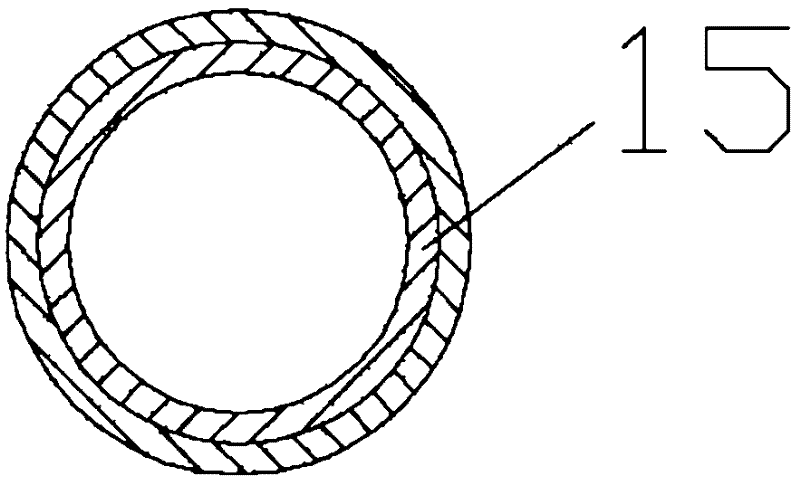

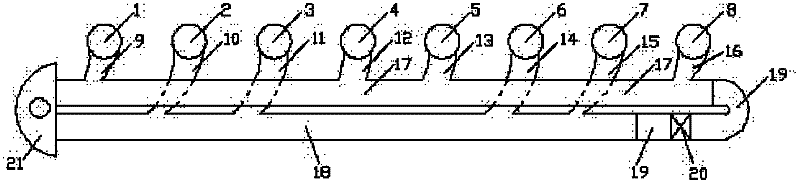

The invention discloses a square tube device with a chain. The square tube device comprises capacity cavities, a rotating body, a clapboard, a rotating shaft, a rotating plate and the chain, wherein the longitudinal section of the capacity cavity is annular; the longitudinal section of the rotating body is arc; an exhaust pipe is a round pipe with a uniform section; one end of a first connecting pipe is communicated with the capacity cavity on the right of the clapboard and the other end is communicated with an air-inlet pipe of an engine; the two ends of a second connecting pipe are respectively communicated with the capacity cavity on the left of the clapboard and the exhaust pipe. When the pressure of the air-inlet pipe of the engine is higher than that in the exhaust pipe, the rotating body drives the rotating plate to rotate counterclockwise, and the area of the throat of the exhaust pipe is relatively large; when the pressure of the air-inlet pipe of the engine is lower than that in the exhaust pipe, the rotating body drives the rotating plate to rotate clockwise, and the area of the throat of the exhaust pipe is relatively small. The square tube device is reasonable in design, simple in structure and applicable to a turbo-charging system with one turbine inlet and a turbine which is laterally arranged.

Owner:SHANGHAI JIAO TONG UNIV

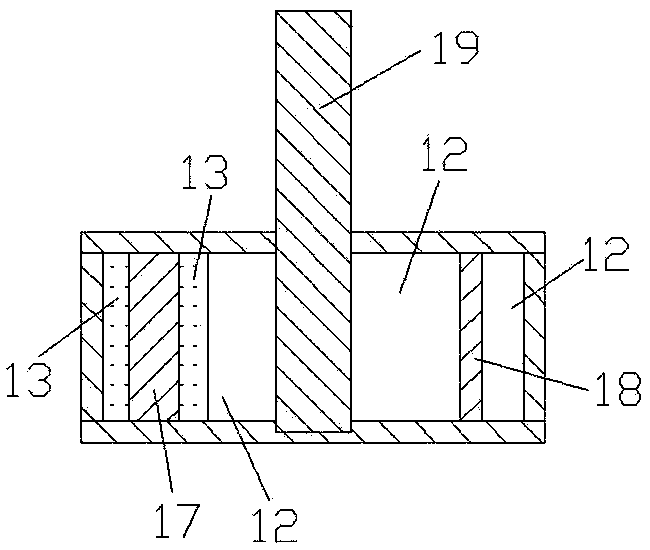

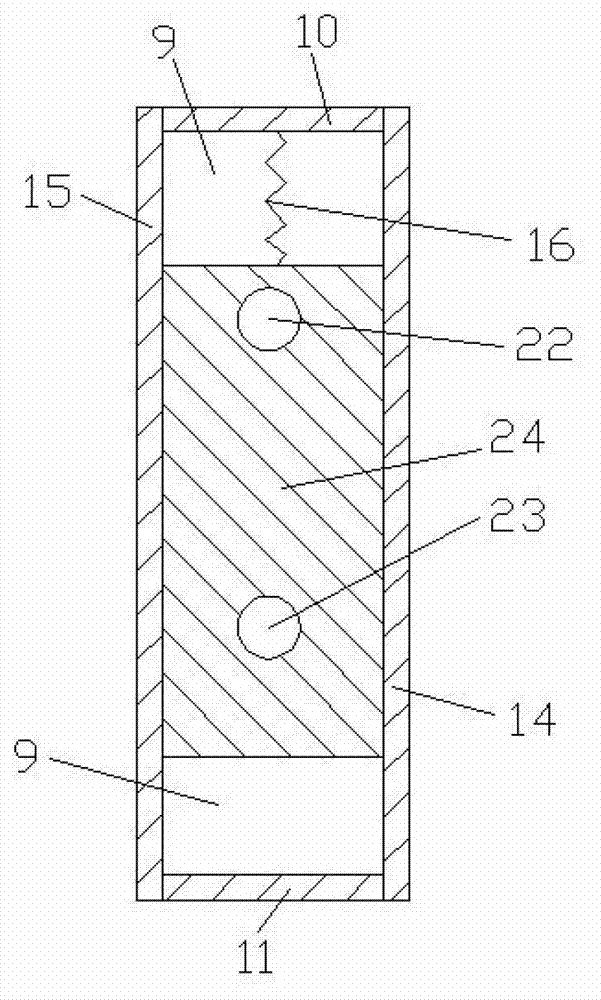

Double through pipe type rotation mechanism

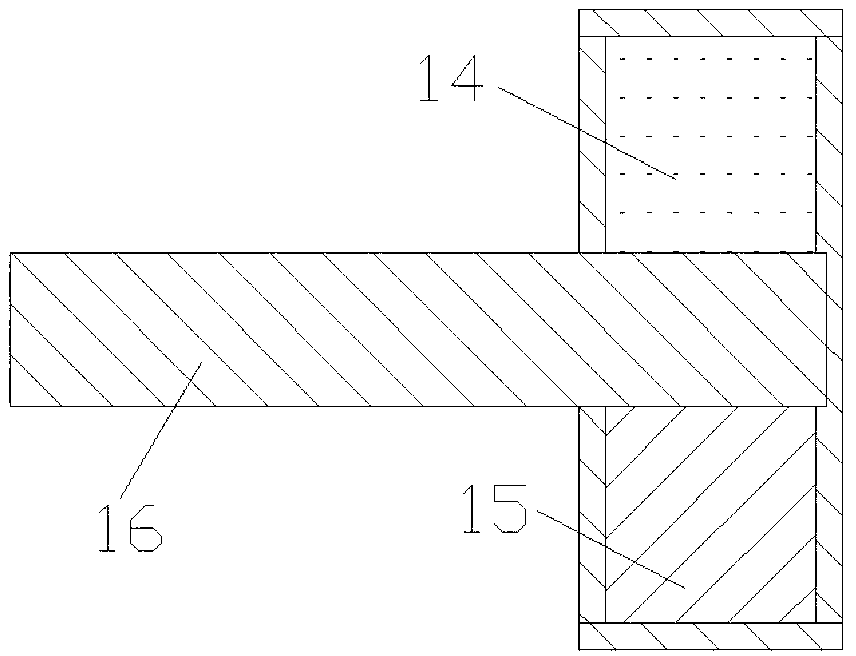

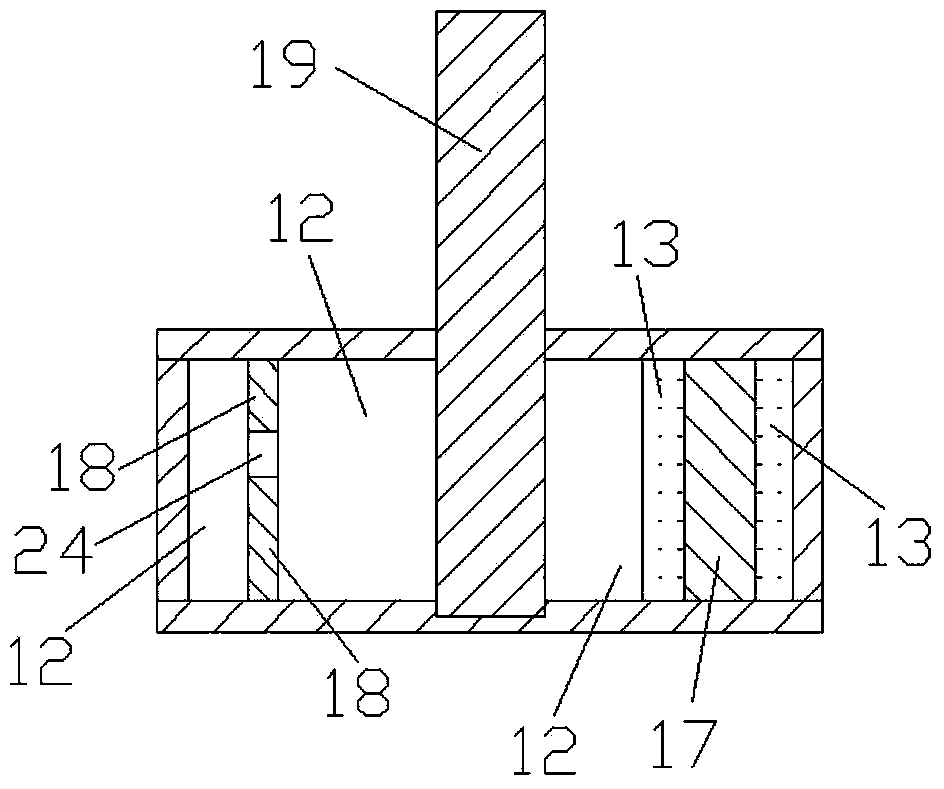

InactiveCN103382886AReduce lossesTake advantage ofInternal combustion piston enginesThroatElastic component

A double through pipe type rotation mechanism in the technical field of mechanical design comprises a capacity cavity, an elastic component, a rotating body, a partition plate, a rotating shaft, a rotating plate and a chain. The vertical section of the capacity cavity is ring-shaped, the vertical section of a fixed body and the vertical section of the rotating body are arc-shaped, exhaust pipes are uniform-section round pipes, a first through pipe and a second through pipe are arranged in the fixed body, and the upper wall surface of the second through pipe is connected with the partition plate through the elastic component. When pressure of an engine intake pipe is high, the rotating body drives the rotating plate to rotate counterclockwise, throat opening areas of the exhaust pipes are large, and engine pumping loss is small; when pressure of the engine intake pipe is small, the rotating body drives the rotating plate to rotate clockwise, throat opening areas of the exhaust pipes are small, pulse energy can be fully utilized, and turbine front available energy is much. The double through pipe type rotation mechanism is reasonable in design, simple in structure and suitable for a turbocharging system with one turbine inlet and a turbine arranged on the side.

Owner:SHANGHAI JIAO TONG UNIV

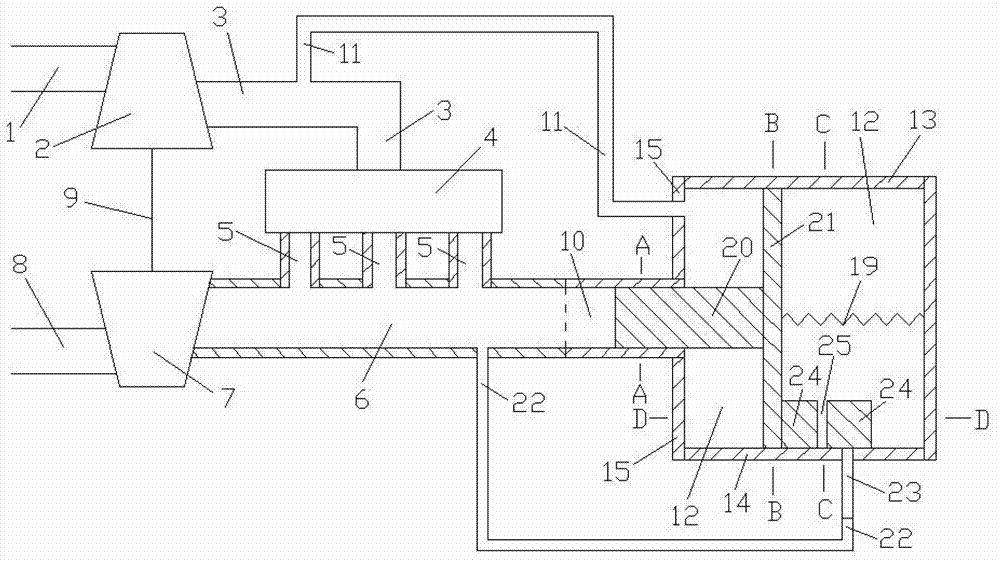

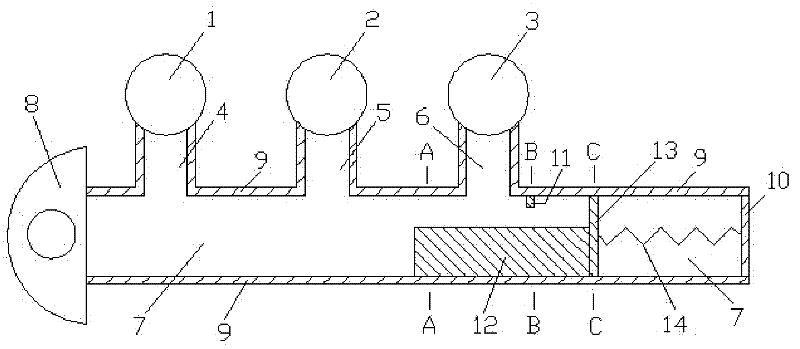

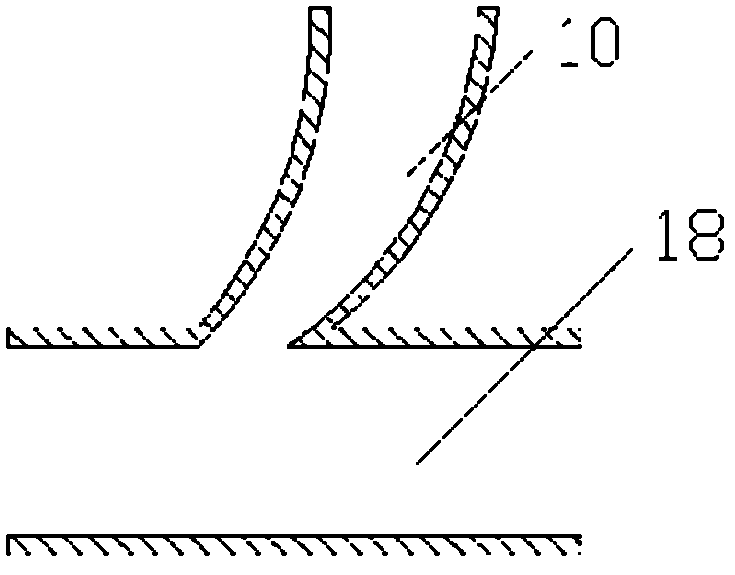

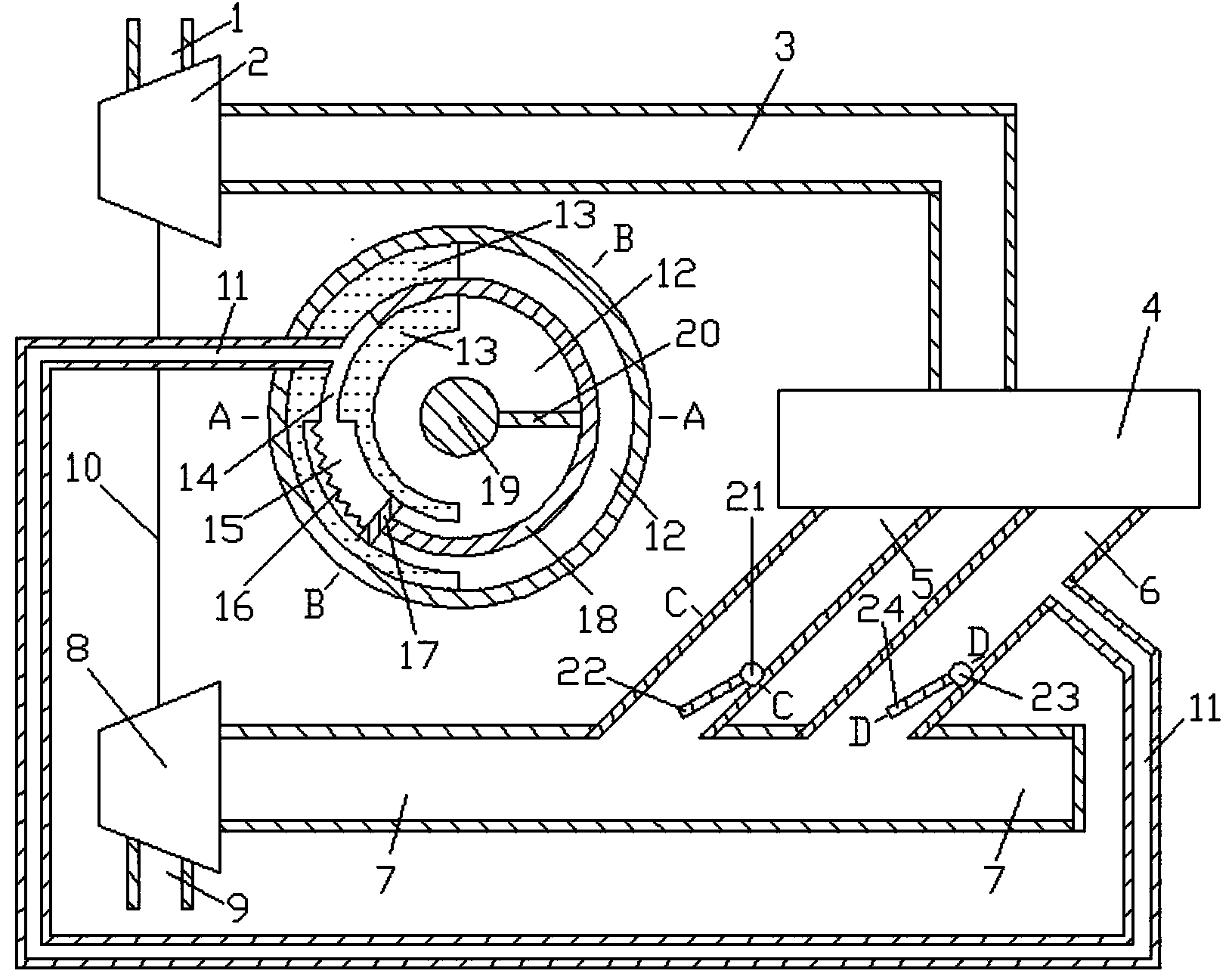

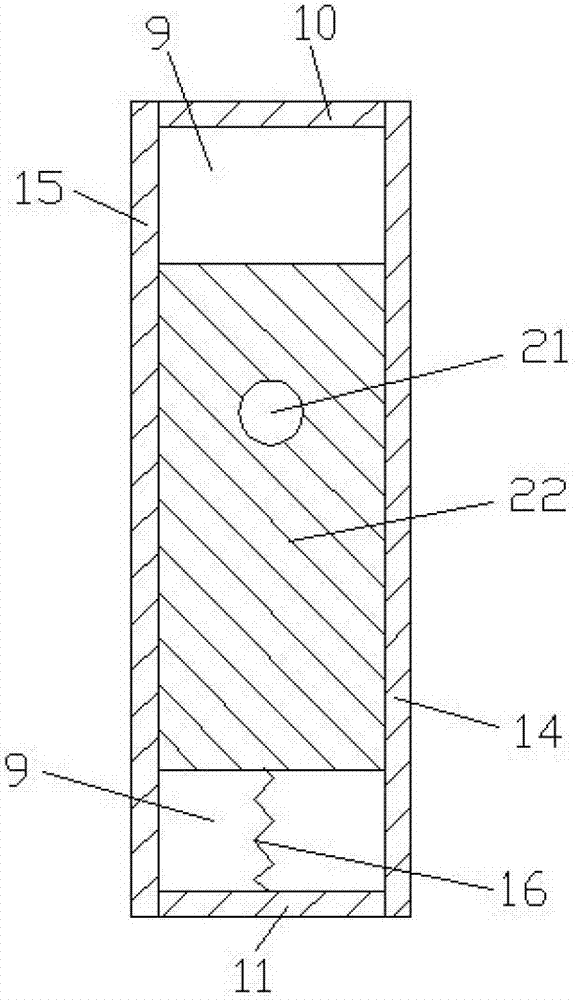

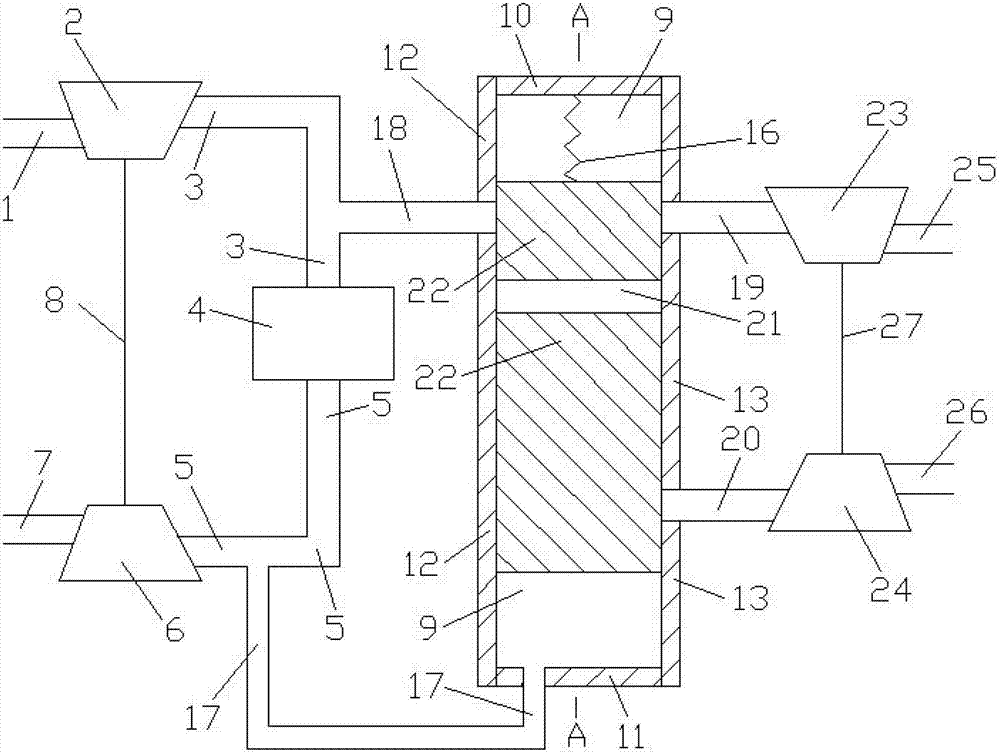

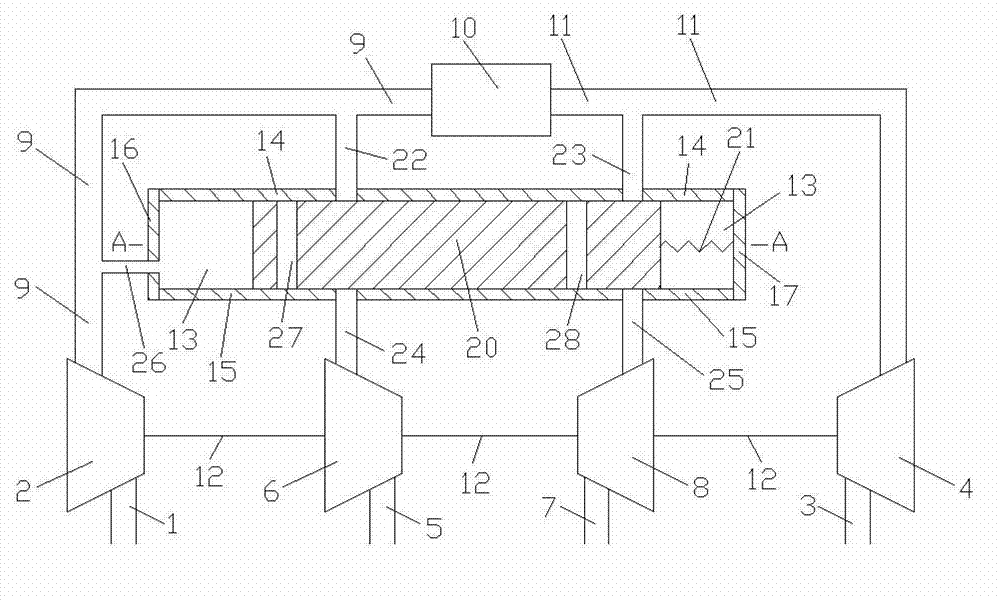

Turbocharging system with two rotating plates in front of turbine inlet

InactiveCN102562271AConsidering both high and low speed conditionsReasonable designInternal combustion piston enginesElastic componentLow speed

A turbocharging system with two rotating plates in front of a turbine inlet belongs to the technical field of internal combustion engines and comprises a cylinder, an exhaust tube, a connecting tube, a turbine, a capacity cavity, the rotating plates, a rotating shaft and an elastic component. An opening end of the capacity cavity is connected with the upper wall surface of the connecting tube, the rotating shaft is mounted between a front wall surface and a rear wall surface of the connecting tube, both the first rotating plate and the second rotating plate are integrally fixedly connected with the rotating shaft, and the second rotating plate is connected with the lower wall surface of the connecting tube via the elastic component. When an engine is in a high-speed working condition, both the two rotating plates rotate clockwise, the area of a throat of the connecting tube is large, so that pumping loss is low, and performances of the total engine are excellent; and when the engine is in a low-speed working condition, both the two rotating plates rotate anticlockwise, the area of the throat of the connecting tube is small, available energy in front of the turbine is sufficient, air inlet pressure of the engine is high, and the performances of the integral engine are excellent. The turbocharging system is reasonable in design and simple in structure. The invention is applicable to a turbocharging system with a side-mounted turbine at a turbine inlet.

Owner:SHANGHAI JIAO TONG UNIV

Switchable turbocharging system

InactiveCN102808688AImprove machine performanceReduce lossesInternal combustion piston enginesAxial compressorCombustion

The invention relates to a switchable turbocharging system, belonging to the technical field of internal combustion engines. The switchable turbocharging system comprises two air compressors, an air inlet pipe, an engine, a gas exhaust pipe, two turbines, a volume chamber, connecting pipes, a moving body, a spring and two penetrating pipes, wherein the moving body is mounted in the volume chamber and is in sealed contact with the internal wall face of the volume chamber, both the first penetrating pipe and the second penetrating pipe penetrate through the left wall face and the right wall face of the moving body, and the upper wall face of the moving body is connected with the upper wall face of the volume chamber through the spring. When the engine is in low-speed working condition, the moving body moves upwards, only the first air compressor and the first turbine work, pulse energy is fully utilized, the inlet air pressure of the engine is higher, and the whole performance of the engine is better; and when the engine is in high-speed working condition, the moving body moves downwards, the first air compressor, the second air compressor, the first turbine and the second turbine simultaneously work, the pumping loss of the engine is less, and the whole performance of the engine is better. The switchable turbocharging system is reasonable in design and simple in structure and is applicable to a turbocharging system with two turbochargers.

Owner:SHANGHAI JIAO TONG UNIV

Chain transmission system with double-arc structure

InactiveCN103382887AConsidering both high and low speed conditionsReasonable designInternal combustion piston enginesPulse energyTurbine

The invention discloses a chain transmission system with a double-arc structure and relates to the technical field of mechanical design. The chain transmission system comprises a containing cavity, an elastic part, a rotary body, a clapboard, a rotating shaft, a rotating board and a chain. The longitudinal section of the containing cavity is circular, longitudinal sections of a fixing body and the rotating body are arc-shaped, the cross section of an exhaust pipe is rectangular, a first through pipe and a second through pipe are both distributed in the fixing body, a fixing board is fixedly combined with the rotating body, and the right wall surface of the fixing body is connected with the fixing plate through the elastic part. When the pressure of an air inlet pipe of an engine is high, the rotating body drives the rotating board to rotate anticlockwise, the area of a throat portion of the exhaust pipe is relatively large, and pumping loss of the engine is less. When pressure of the air inlet pipe of the engine is relatively low, the rotating body drives the rotating board to rotate clockwise, the area of the throat portion of the exhaust pipe is relatively small, pulse energy can be fully used, and turbine-front available energy is more. The chain transmission system with the double-arc structure is reasonable in design, simple in structure and suitable for a turbine boosting system with one turbine inlet and a turbine laterally arranged.

Owner:SHANGHAI JIAO TONG UNIV

Synchronous double-moving-body moving device

InactiveCN102767418AGood machine performanceReduce lossesInternal combustion piston enginesCombustionLow speed

The invention relates to a synchronous double-moving-body moving device in the technical field of internal-combustion engines, which comprises a gas-inlet pipe, a gas compressor, an engine, a gas-discharging pipe, a turbine, a volume cavity, a connecting pipe, moving bodies, a moving plate and a spring, wherein one end of one moving body extends into a first connecting pipe, the other end of the moving body and the left wall surface of the moving plate are fixedly connected into a whole, and the right wall surface of the moving plate is connected with the right wall surface of the volume cavity through the spring. When the engine is under a low-speed working condition, the moving plate moves towards a direction which is close to the left wall surface of the volume cavity, so that the volume of the gas-discharging pipe is relatively smaller, pulse energy can be fully utilized, the gas-inlet pressure of the engine is higher, and the overall performance of the engine is more excellent; and when the engine is under a high-speed working condition, the moving plate moves towards a direction which is close to the right wall surface of the volume cavity, so that the volume of the gas-discharging pipe is relatively larger, pumping loss is smaller, and the overall performance of the engine is more excellent. The synchronous double-moving-body moving device has a reasonable design and a simple structure and is applicable to turbo-charging systems with single turbine inlets.

Owner:SHANGHAI JIAO TONG UNIV

Triaxial synchronous type variable exhaust branch reducing rate system

InactiveCN103291433AShrinkage rate is largeShrinkage rate is smallExhaust apparatusSilencing apparatusPulse energyTurbine

The invention relates to the technical field of mechanical design and relates to a triaxial synchronous type variable exhaust branch reducing rate system comprising a volumetric cavity, an elastic member, a rotor, a partition, rotary shafts, rotary plates and a chain. The longitudinal section of the volumetric cavity is circular. The longitudinal section of the rotor is arc-shaped. One end of a third connecting shaft passes through the volumetric cavity and is embedded on the side wall of the volumetric cavity, and one end of the first rotary shaft passes through a first exhaust branch and is embedded on the side wall of the first exhaust branch. When the pressure of an intake pipe of an engine is high, the rotor drives the rotary plates to rotate anticlockwise, outlet area of the exhaust branch is large, and pumping loss of the engine is low; when the pressure of the intake pipe of the engine is low, the rotor drives the rotary plates to rotate clockwise, outlet area of the exhaust pipe is small, pulse energy can be fully utilized, and turbine inlet available energy is high. The triaxial synchronous type variable exhaust branch reducing rate system is reasonable in design, simple in structure, and applicable to a turbocharging system with one turbine inlet and a side turbine.

Owner:SHANGHAI JIAO TONG UNIV

Double-shaft synchronous control mechanism for exhaust pipe throat area

InactiveCN103382888AConsidering both high and low speed conditionsReasonable designInternal combustion piston enginesElastic componentSynchronous control

The invention belongs to the technical field of mechanical design and discloses a double-shaft synchronous control mechanism for an exhaust pipe throat area. The double-shaft synchronous control mechanism for the exhaust pipe throat area comprises a volume chamber, an elastic component, a rotating body, a separation plate, rotating shafts, a rotating plate and a chain; the longitudinal section of the volume chamber is in an annular shape; the longitudinal section of the rotating body is in an arc shape; an exhaust pipe is a round pipe with uniform sections; one end of a second rotating shaft penetrate the exhaust pipe to be embedded on the side wall of the exhaust pipe; the rotating plate which is arranged inside the exhaust pipe is fixedly connected into a whole with the second rotating shaft. When the pressure of an air inlet pipe of an engine is high, the rotating body drives the rotating plate to rotate in an anticlockwise mode, the exhaust pipe throat area is large relatively, and the engine pumping loss is small. When the pressure of the air inlet pipe of the engine is low, the rotating body drives the rotating plate to rotate in a clockwise mode, the exhaust pipe throat area is small relatively, the pulse energy can be fully utilized, and the available energy before a turbine is large. The double-shaft synchronous control mechanism for the exhaust pipe throat area is reasonable in design, simple in structure and suitable for a turbocharging system which is provided with one turbine inlet and the side turbine.

Owner:SHANGHAI JIAO TONG UNIV

Parallel gas path system with switching mechanism

InactiveCN102767423AConsidering both high and low speed conditionsReasonable designInternal combustion piston enginesIntake pressurePulse energy

A parallel gas path system with a switching mechanism in the technical field of internal combustion engines comprises gas compressors, a gas inlet tube, an engine, an exhaust tube, turbines, a containing cavity, connecting tubes, a moving body, a spring and a through tube. The moving body is mounted in the containing cavity and is in sealing contact with the inner wall surface of the containing cavity, the through tube penetrates through the right wall surface and the left wall surface of the moving body, and the lower wall surface of the moving body is connected with the lower wall surface of the containing cavity. When the engine is in a low-speed working condition, the moving body moves upwards, only the first gas compressor and the first turbine work, pulse energy is fully utilized, inlet pressure of the engine is high, and the performance of the whole engine is excellent; and when the engine is in a high-speed working condition, the moving body moves downwards, the first gas compressor, the second gas compressor, the first turbine and the second turbine work simultaneously, pumping loss of the engine is less, and the performance of the whole engine is excellent. The parallel gas path system with the switching mechanism is reasonable in design, simple in structure and applicable to a turbo-charging system with two turbochargers.

Owner:SHANGHAI JIAO TONG UNIV

Turbocharger system with movable body arranged in air exhaust pipe

InactiveCN102518505AConsidering both high and low speed conditionsReasonable designInternal combustion piston enginesExhaust apparatusElastic componentLow speed

A turbocharger system with a movable body arranged in an air exhaust pipe belongs to the technical field of combustion motor and comprises an air cylinder, the air exhaust pipe, a turbine, a blocking plate, the movable body and an elastic component. The movable body is fixedly and integrally connected with the rear wall of the movable body, the movable body and the rear wall of the movable body are both installed in the air exhaust pipe, and the rear wall of the movable body is connected with the rear wall of the air exhaust through the elastic component. When a motor is on the low speed work condition, the movable body and the rear wall of the movable move towards the direction far away from the rear wall of the air exhaust pipe, the volume of exhausted air in the air exhaust pipe is relatively small, pulse energy can be fully used, air inlet pressure of the motor is high, and the whole machine performance of the motor is excellent. When the motor is on the high speed work condition, the movable body and the rear wall of the movable move towards the direction close to the rear wall of the air exhaust pipe, the volume of exhausted air in the air exhaust pipe is relatively large, pumping loss is small, and the whole machine performance of the motor is excellent. The turbocharger system is reasonable in design, simple in structure and suitable for turbine systems with one turbine inlet and a laterally arranged turbine.

Owner:SHANGHAI JIAO TONG UNIV

Turbo-charging system provided with moving part in exhaust pipe

InactiveCN102410076AExhaust occupies a small volumeIncrease intake pressureInternal combustion piston enginesCombustionLow speed

The invention relates to a turbo-charging system provided with a moving part in an exhaust pipe, belonging to the technical field of combustion engines. The turbo-charging system comprises an air cylinder, the exhaust pipe, a turbine, a baffle, the moving part and an elastic part, wherein the moving part and the back wall of the moving part are arranged in the exhaust pipe; and the back wall of the moving part is connected with the back wall of the exhaust pipe by the elastic part. When an engine is in a low-speed working condition, the moving part and the back wall of the moving part move together toward a direction far way from the back wall of the exhaust pipe, the occupied volume of exhaust gas in the exhaust pipe is relatively smaller, the pulse energy can be fully used, the intake pressure of the engine is higher, and the overall performance of the engine is superior; when the engine is in a high-speed working condition, the moving part and the back wall of the moving part move together toward a direction close to the back wall of the exhaust pipe, the volume of the exhaust gas in the exhaust pipe is relatively more, the pumping loss is lesser, and the overall performance ofthe engine is superior. The invention is reasonable in design and simple in structure and is suitable for the combustion engine with a turbine inlet and a side-arranged turbine.

Owner:SHANGHAI JIAO TONG UNIV

Air inlet pressure main control type pipeline device

InactiveCN102889121AReasonable designSimple structureInternal combustion piston enginesIntake pressureMechanical design

The invention discloses an air inlet pressure main control type pipeline device, and belongs to the technical field of mechanical design. The air inlet pressure main control type pipeline device comprises air compressors, an air inlet pipe, an engine, an air exhaust pipe, turbines, a volume cavity, a connection pipe, a moving body, a spring and penetration pipes, wherein the moving body is arranged in the volume cavity and is in sealing contact with the inner wall surface of the volume cavity; the first penetration pipe and the second penetration pipe penetrate through the upper wall surface and the lower wall surface of the moving body; and the right wall surface of the moving body is connected with the right wall surface of the volume cavity through the spring. When the engine is in a high-speed working condition, the moving body moves rightwards, the first air compressor, the second air compressor, the first turbine and the second turbine work synchronously, the air pumping loss of the engine is relatively low, and the overall performance of the engine is relatively high; and when the engine is in a low-speed working condition, the moving body moves leftwards, only the first air compressor and the first turbine work, pulse energy is fully used, the air inlet pressure of the engine is relatively high, and the overall performance of the engine is relatively high. The air inlet pressure main control type pipeline device is rational in design, simple in structure and suitable for turbine pressurization systems with double turbines and double air compressors.

Owner:SHANGHAI JIAO TONG UNIV

Pipeline system capable of controlling intake pressure and exhaust pressure synchronously and mainly

InactiveCN102877933AConsidering both high and low speed conditionsReasonable designInternal combustion piston enginesLow speedPulse energy

A pipeline system capable of controlling intake pressure and exhaust pressure synchronously and mainly belongs to the technical field of mechanical design, and comprises air compressors, an air intake pipe, an engine, an exhaust pipe, turbines, a volume cavity, a connecting pipe, a moving body, a spring and a penetrating pipe, wherein the moving body is mounted in the volume cavity and in sealed contact with the inner wall of the volume cavity; the penetrating pipe penetrates the upper wall and the lower wall of the moving body; and the right wall of the moving body is connected with the right wall of the volume cavity through the spring. When the engine is in a high-speed working condition, the moving body moves rightwards, a first air compressor, a second air compressor, a first turbine and a second turbine work simultaneously, so that the pumping loss of the engine is lower, and the performance of the whole engine is better; and when the engine is in a low-speed working condition, the moving body moves leftwards, only the first air compressor and the first turbine work, so that pulse energy can be utilized fully, the intake pressure of the engine is higher, and the performance of the whole engine is better. The pipeline system is designed reasonably, simple in structure, and suitable for a turbo-charging system with double turbines and double air compressors.

Owner:SHANGHAI JIAO TONG UNIV

Exhaust pipe pressure control device with chain

InactiveCN103452644AReasonable designSimple structureInternal combustion piston enginesMechanical designPulse energy

The invention relates to an exhaust pipe pressure control device with a chain in the technical field of mechanical design. The exhaust pipe pressure control device comprises a volume cavity, an elastic component, a rotating body, a separating plate, a rotating shaft, a rotating plate and a chain, wherein the longitudinal section of the volume cavity is in a circular ring shape, the longitudinal sections of a fixing body and the rotating body are respectively in a circular arc shape, an exhaust pipe is a uniform-section round pipe, a first penetrating pipe and a second penetrating pipe are respectively arranged in the fixing body, and the upper wall surface of the second penetrating pipe is connected with the separating plate through the elastic component. When the pressure in an exhaust pipe of an engine is higher, the rotating body drives the rotating plate to anticlockwise rotate, the throat opening area of the exhaust pipe is relatively larger, and the pumping loss of the engine is less; and when the pressure of the exhaust pipe of the engine is lower, the rotating body drives the rotating plate to clockwise rotate, the throat opening area of the exhaust pipe is relatively smaller, the pulse energy can be fully utilized, and the available energy in front of a turbine is more. The exhaust pipe pressure control device has the advantages that the design is reasonable, the structure is simple, and the engine system is applied to a turbocharging system with one turbine inlet and lateral turbine arrangement.

Owner:SHANGHAI JIAO TONG UNIV

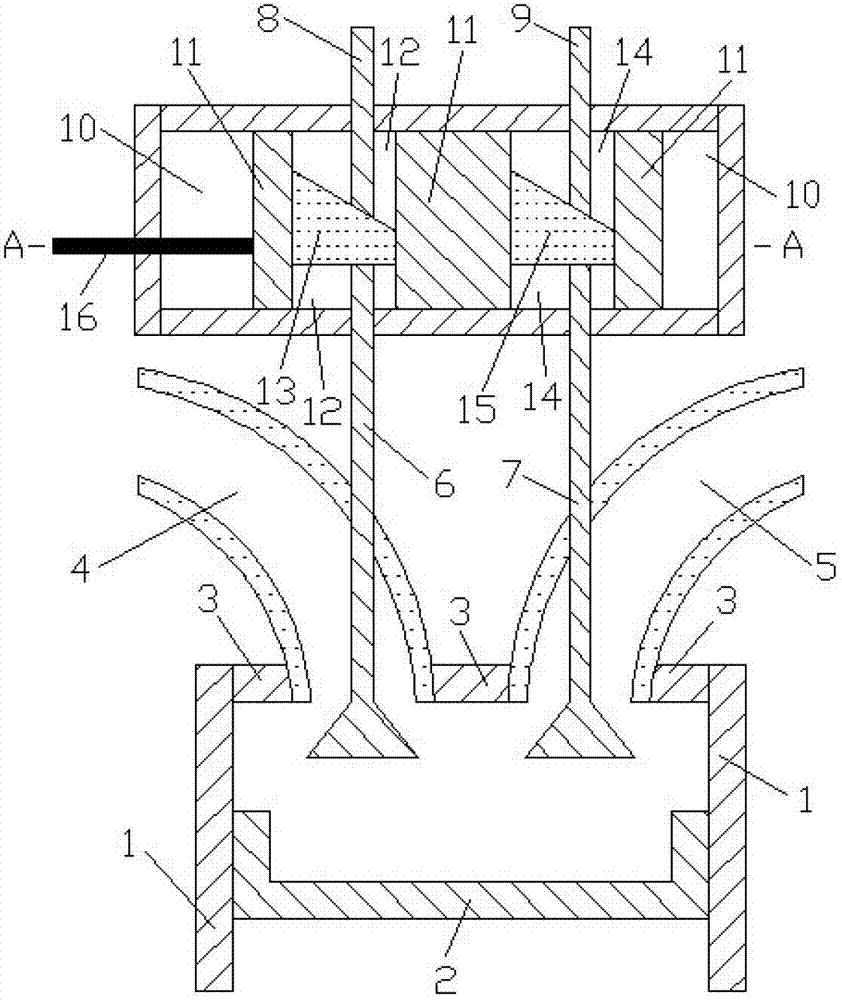

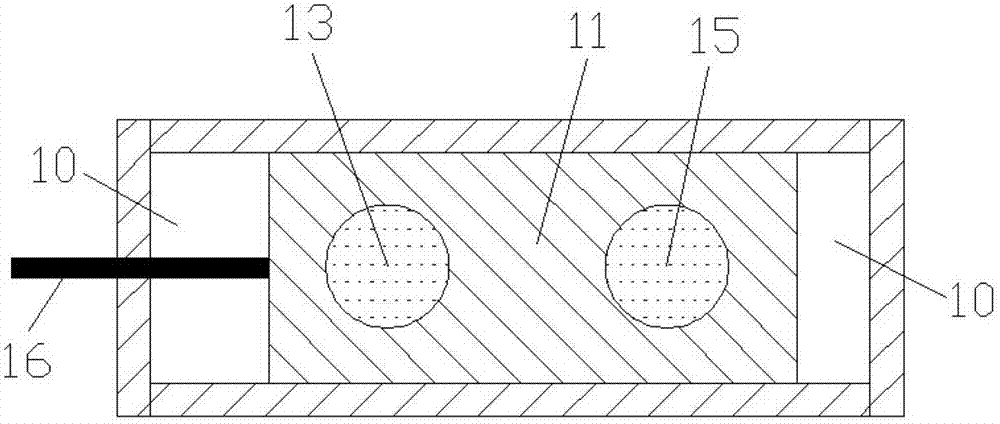

Turbocharging system with exhaust pipe with variable volume

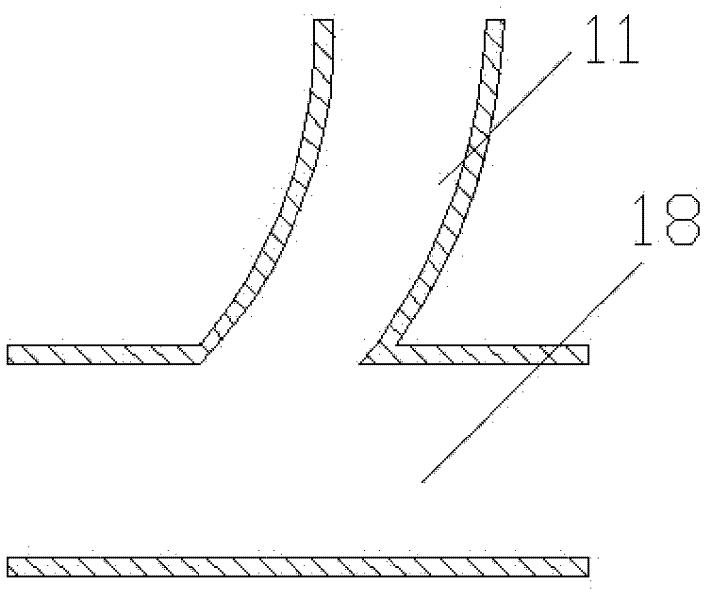

InactiveCN102418590AConsidering both high and low speed conditionsReasonable designInternal combustion piston enginesExhaust apparatusCombustionLow speed

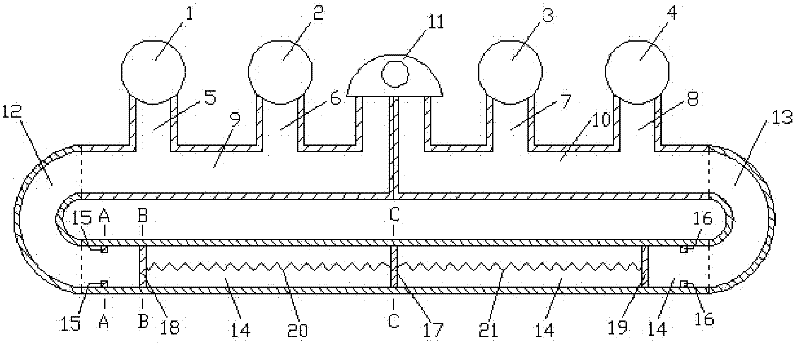

The invention discloses a turbocharging system with an exhaust pipe with a variable volume in the technical field of internal-combustion engines. The turbocharging system comprises air cylinders, the exhaust pipe, a turbine, elbow pipes, a connection pipe, baffle plate rings, movement plates, partition plates and elastic parts; the tail part of the exhaust pipe is connected with the connection pipe through the elbow pipes; the baffle plate rings, the movement plates, the partition plates and the elastic parts are arranged in the connection pipe; and the elastic parts are arranged between the movement plates and the partition plates. When an engine is in a low-speed working condition, the movement plates move toward the baffle plate rings, the volume of the exhaust pipe is relatively small, pulse energy can be fully utilized, the inlet pressure of the engine is very high and the whole engine has excellent performance; and when the engine is in a high-speed working condition, the movement plates can move far away from the baffle plate rings, the volume of the exhaust pipe is relatively large, pumping loss is low, and the whole engine has good performance. The turbocharging system has a reasonable design and a simple structure, and the invention is suitable for the turbocharging system which is provided with two turbine inlets and of which the middle part is provided with the turbine.

Owner:SHANGHAI JIAO TONG UNIV

Two-valve stroke synchronously-variable device

ActiveCN102926835AReasonable designSimple structureValve arrangementsMachines/enginesMechanical designEngineering

The invention relates to a two-valve stroke synchronously-variable device which belongs to the technical field of mechanical design. The two-valve stroke synchronously-variable device comprises an inlet channel, an exhaust channel, an inlet valve lower segment, an exhaust valve, an inlet valve upper segment, a volume cavity, a movable body, a through tube, a movable block and a movable rod, wherein the movable body is arranged in the volume cavity and is hermetically contact with the inner wall surface of the volume cavity; the through tube penetrates through the upper wall surface and the lower wall surface of the movable body; the movable block is arranged in the through tube and is hermetically contact with the inner wall surface of the through tube; the lower end surface of the movable block forms a plane, and the upper end surface of the movable block forms a slope; the inlet valve upper segment penetrates through the upper wall surface of the volume cavity and extends into the through tube, and the lower end surface of the inlet valve upper segment is hermetically contact with the upper end surface of the movable block. When the movable body moves towards right, the strokes of inlet and exhaust valves are lengthened, when the movable body moves towards left, the strokes of the inlet and exhaust valves are shortened, and the continuous variation of the strokes of the inlet and exhaust valves can be realized. The two-valve stroke synchronously-variable device disclosed by the invention is reasonable in design, simple in structure and suitable for the inlet and exhaust valve stroke variable system of an engine.

Owner:SHANGHAI JIAO TONG UNIV

Turbocharging system with exhaust pipe having variable outlet area

InactiveCN102505984AConsidering both high and low speed conditionsReasonable designInternal combustion piston enginesLow speedCombustion

A turbocharging system with an exhaust pipe having variable outlet area belongs to the technical field of internal combustion engines and comprises cylinders, the exhaust pipe, a turbine, a cavity, moving plates and an elastic component. The cavity is a uniform-section pipe and mounted in front of the exhaust pipe, the moving plates are mounted inside the cavity, and the first moving plate is connected with the second moving plate through the elastic component. When an engine is in a low-speed running state, the moving plates move to the direction distant from the back wall of the cavity, the outlet area of the exhaust pipe is small relatively, available energy in the front of the turbine is high, intake pressure of the engine is high, and the integral performance of the engine is excellent. When the engine is in a high-speed running state, the moving plates move to the direction close to the back wall of the cavity, the outlet area of the exhaust pipe is larger relatively, pumping loss is lower, and the integral performance of the engine is excellent. The turbocharging system is reasonable in design, simple in structure, and suitable for turbocharging systems with one turbine inlet and laterally arranged turbine.

Owner:SHANGHAI JIAO TONG UNIV

Mechanically telescopic device with three connection pipes

InactiveCN102720581AImprove machine performanceReduce lossesInternal combustion piston enginesLow speedCombustion

The invention relates to the technical field of internal combustion engines and discloses a mechanically telescopic device with three connection tubes. The device comprises a gas inlet pipe, a gas compressor, an engine, a gas exhaust pipe, a turbine, a volume cavity, connecting pipes, a moving body, a moving plate and a spring, wherein one end of the moving body stretches into the first connecting pipe; the other end of the moving body is fixedly connected with the left wall surface of the moving plate to form a whole; and the right wall surface of the moving plate is connected with the right wall surface of the volume cavity through the spring. When the engine is in a low-speed working condition, the moving plate moves to the left wall surface of the volume cavity, the volume of the gas exhaust pipe is relatively small, the pulse energy can be fully utilized, the gas inlet pressure of the engine is relatively high, and the overall performance of the engine is relatively good; and when the engine is in a high-speed working condition, the moving plate moves to the right wall surface of the volume cavity, the gas exhaust volume is relatively large, the pumping loss is relatively low, and the overall performance of the engine is relatively good. The device is rational in design and simple in structure and is applied to a turbocharging system with a single turbine inlet.

Owner:SHANGHAI JIAO TONG UNIV

Variable geometry exhaust pipe turbocharging system

InactiveCN102418587AConsidering both high and low speed conditionsThe maximum exhaust temperature difference is smallInternal combustion piston enginesExhaust apparatusCombustionLow speed

The invention relates to a variable geometry exhaust pipe turbocharging system in the technical field of internal combustion engines. The system comprises cylinders, exhaust branch pipes, exhaust pipes, a connecting pipe, a valve and a turbine, wherein the two ports of the connecting pipe are connected with the tail parts of a first exhaust pipe and a second exhaust pipe; the valve is arranged on the connecting pipe; the cross section areas of a first exhaust branch pipe, a second exhaust branch pipe, a seventh exhaust branch pipe and an eighth exhaust branch pipe are gradually reduced from the cylinders to the exhaust pipes; and a third exhaust branch pipe, a fourth exhaust branch pipe, a fifth exhaust branch pipe and a sixth exhaust branch pipe are constant-section pipes. When the valve is closed, a pulse charging mode is adopted, so that pulse energy can be fully utilized, the maximum exhaust temperature difference of each cylinder is small, and an engine has high performance under the low-speed working condition and the transient working condition; and when the valve is opened, a quasi-constant pressure charging mode is adopted, so that pumping loss is low, and the engine has high performance under the high-speed working condition. The invention is reasonable in design, simple in structure and suitable for the turbocharging system of which the turbine is provided with two inlets and is laterally arranged.

Owner:SHANGHAI JIAO TONG UNIV

Mechanical exhaust pipe pressure regulating system

InactiveCN103452649AConsidering both high and low speed conditionsReasonable designInternal combustion piston enginesElastic componentTurbocharger

The invention discloses a mechanical exhaust pipe pressure regulating system in the technical field of mechanical design. The mechanical exhaust pipe pressure regulating system comprises a volume cavity, an elastic component, a rotating body, a division plate, a rotating shaft, a rotating plate and a chain, wherein the longitudinal section of the volume cavity is circular, the longitudinal sections of a fixed body and the rotating body are arc-shaped, an exhaust pipe is a uniform-section round pipe, a first through pipe and a second through pipe are both arranged in the fixed body, and the upper wall surface of the second through pipe and the division plate are connected together through the elastic component. When the pressure of an engine exhaust pipe is higher, the rotating body drives the rotating plate to rotate anticlockwise, the throat area of the exhaust pipe is relatively large, and the pumping loss of an engine is less; when the pressure of the engine exhaust pipe is lower, the rotating body drives the rotating plate to rotate clockwise, the throat area of the exhaust pipe is relatively small, the pulse energy can be utilized fully, and more available energy in front of a turbine exists. The mechanical exhaust pipe pressure regulating system is reasonable in design, simple in structure, and applicable to a turbocharger system with one turbine inlet and a side turbine.

Owner:SHANGHAI JIAO TONG UNIV

Turbocharging system with moving plate in front of turbine inlet

InactiveCN102444468AReasonable designSimple structureInternal combustion piston enginesIntake pressureLow speed

The invention provides a turbocharging system with a moving plate in front of a turbine inlet, belonging to the technical field of internal combustion engines. The system comprises cylinders, an exhaust pipe, a connecting pipe, a turbine, a moving plate and an elastic component, wherein a fixed body is fixedly connected with an upper side wall of the connecting pipe as a whole; the sectional area of the fixed body is gradually reduced along the exhaust flow direction; the moving plate is installed in the connecting pipe; and a fixed plate is connected with the moving plate by the elastic component. When an engine is in a high-speed working condition, the moving plate moves leftward, the throat area of the connecting pipe becomes larger, the pumping loss is lower, and the overall performance of the engine is better; and when the engine is in a low-speed working condition, the moving plate moves rightward under the action of the elastic component, the throat area of the connecting pipe becomes smaller, more available energy exists in front of the turbine, the inlet pressure of the engine is higher, and the overall performance of the engine is better. The turbocharging system provided by the invention has the advantages of reasonable design and simple structure and is suitable to be provided with one side turbine at the turbine inlet.

Owner:SHANGHAI JIAO TONG UNIV

Exhaust manifold circulation area self-regulation type engine system

InactiveCN103452646AConsidering both high and low speed conditionsReasonable designInternal combustion piston enginesElastic componentTurbocharger

The invention discloses an exhaust manifold circulation area self-regulation type engine system in the technical field of mechanical design. The exhaust manifold circulation area self-regulation type engine system comprises a volume cavity, an elastic component, a rotating body, a division plate, a rotating shaft, a rotating plate and a chain, wherein the longitudinal section of the volume cavity is circular, the longitudinal sections of a fixed body and the rotating body are arc-shaped, an exhaust pipe is a uniform-section round pipe, a first through pipe and a second through pipe are both arranged in the fixed body, and the upper wall surface of the second through pipe and the division plate are connected together through the elastic component. When the pressure in an engine exhaust manifold is higher, the rotating body drives the rotating plate to rotate anticlockwise, the necking rate of the exhaust manifold is relatively large, and the pumping loss of an engine is less; when the pressure in the engine exhaust manifold is lower, the rotating body drives the rotating plate to rotate clockwise, the necking rate of the exhaust pipe is relatively small, the pulse energy can be utilized fully, and more available energy in front of a turbine exists. The exhaust manifold circulation area self-regulation type engine system is reasonable in design, simple in structure, and applicable to a turbocharger system with one turbine inlet and a side turbine.

Owner:SHANGHAI JIAO TONG UNIV

Partitioning device for connecting pipes

InactiveCN102767420AConsidering both high and low speed conditionsReasonable designInternal combustion piston enginesCombustionLow speed

The invention discloses a partitioning device for connecting pipes in the technical field of internal combustion engines. The device comprises air compressors, an admission pipe, an engine, an exhaust pipe, turbines, a volume cavity, the connecting pipes, a moving body, a spring and a through pipe, wherein the moving body is arranged in the volume cavity, and contacts the inner wall surface of the volume cavity in a sealed way; the through pipe penetrates through the left and right wall surfaces of the moving body; and the lower wall surface of the moving body is connected with the lower wall surface of the volume cavity through the spring. When the engine is under a low speed working condition, the moving body moves downwards, only the first air compressor and the first turbine work, pulse energy is fully utilized, the admission pressure of the engine is high, and the overall performance of the engine is high; and when the engine is under a high speed working condition, the moving body moves upwards, the first and second air compressors and the first and second turbines work at the same time, the pumping loss of the engine is low, and the overall performance of the engine is high. The device is rational in design, simple in structure and applicable to a turbocharging system with two turbochargers.

Owner:SHANGHAI JIAO TONG UNIV

Mechanism with multiple synchronously rotating components

InactiveCN103573394AConsidering both high and low speed conditionsReasonable designInternal combustion piston enginesPulse energyTurbine

The invention discloses a mechanism with multiple synchronously rotating components. The mechanism comprises a capacity cavity, a rotating body, a clapboard, a rotating shaft, a rotating plate and a chain, wherein the longitudinal section of the capacity cavity is annular; the longitudinal sections of a fixing body and the rotating body are arc; an exhaust pipe is a round pipe with a uniform section; first through pipes and second through pipes are uniformly arranged in the fixing body. When the pressure of the air-inlet pipe of an engine is relatively high, the rotating body drives the rotating plate to rotate counterclockwise, the area of the throat of the exhaust pipe is relatively large, and air pumping loss of the engine is relatively low; when the pressure of the air-inlet pipe of the engine is relatively low, the rotating body drives the rotating plate to rotate clockwise, the area of the throat of the exhaust pipe is relatively small, pulse energy can be fully used, and available energy before a turbine is relatively much. The mechanism is reasonable in design, simple in structure and applicable to a turbo-charging system with one turbine inlet and one turbine which is laterally arranged.

Owner:SHANGHAI JIAO TONG UNIV

Communication device for circulating air course

InactiveCN102767424AImprove machine performanceReduce lossesInternal combustion piston enginesLow speedCombustion

The invention discloses a communication device for a circulating air course in the technical field of internal combustion engines. The device comprises air compressors, an admission pipe, an engine, an exhaust pipe, turbines, a volume cavity, connecting pipes, a moving body, a spring and a through pipe, wherein the moving body is arranged in the volume cavity, and contacts the inner wall surface of the volume cavity in a sealed way; the through pipe penetrates through the left and right wall surfaces of the moving body; and the upper wall surface of the moving body is connected with the upper wall surface of the volume cavity through the spring. When the engine is under a low speed working condition, the moving body moves downwards, only the first air compressor and the first turbine work, pulse energy is fully utilized, the admission pressure of the engine is high, and the overall performance of the engine is high; and when the engine is under a high speed working condition, the moving body moves upwards, the first and second air compressors and the first and second turbines work at the same time, the pumping loss of the engine is low, and the overall performance of the engine is high. The device is rational in design, simple in structure and applicable to a turbocharging system with two turbochargers.

Owner:SHANGHAI JIAO TONG UNIV

Engine system with airway switching device

InactiveCN102817702AConsidering both high and low speed conditionsReasonable designInternal combustion piston enginesIntake pressurePulse energy

The invention provides an engine system with an airway switching device in the technical field of an internal combustion engine, comprising air compressors, an air inlet pipe, an engine, an air exhaust pipe, turbos, a volume chamber, connection pipes, a moving body, a spring and penetration pipes, wherein the moving body is installed in the volume chamber and further contacts with the inner wall face of the volume chamber in a sealing way; the first penetration pipe and the second penetration pipe penetrate through the left wall face and the right wall face of the moving body; and the upper wall face of the moving body is connected with the upper wall face of the volume chamber through the spring. When the engine is located under the low speed working condition, the moving body moves upward; only the first air compressor and the first turbo work; the pulse energy is fully utilized; the air inlet pressure of the engine is higher; and the overall performance of the engine is better. When the engine is located in the high speed working condition, the moving body moves downward; the first air compressor, the second air compressor, the first turbo and the second turbo simultaneously work; the pumping loss of the engine is less; and the overall performance of the engine is better. The engine system with the airway switching device is rational in design, simple in structure and applicable for a turbo charging system with two turbo superchargers.

Owner:SHANGHAI JIAO TONG UNIV

Double-turbine coaxially-connected device

InactiveCN102926859AReduce pumping lossImprove machine performanceInternal combustion piston enginesLow speedCombustion

The invention relates to a double-turbine coaxially-connected device which belongs to the technical field of internal-combustion engines. The double-turbine coaxially-connected device comprises air compressors, an air inlet pipe, an engine, an air exhaust pipe, turbines, a volume cavity, a connecting pipe, a movable body, a spring and through tubes, wherein the movable body is arranged in the volume cavity and is hermetically contact with the inner wall surface of the volume cavity; the first through tube and the second through tube both penetrate through the upper wall surface and the lower wall surface of the movable body; and the right wall surface of the movable body is connected with the right wall surface of the volume cavity through the spring. When the engine is under a high-speed working condition, the movable body moves towards right, the first air compressor, the second air compressor, the first turbine and the second turbine work simultaneously, and the engine is lower in pumping loss, so that the engine is better in overall machine performance; when the engine is under a low-speed working condition, the movable body moves towards left, only the first air compressor and the first turbine work, pulse energy is sufficiently utilized, and the engine is higher in inlet pressure, so that the engine is better in overall machine performance. The double-turbine coaxially-connected device is reasonable in design, simple in structure and suitable for a turbocharging system with double turbines and double air compressors.

Owner:SHANGHAI JIAO TONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com