Patents

Literature

79results about How to "Reduce level difference" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

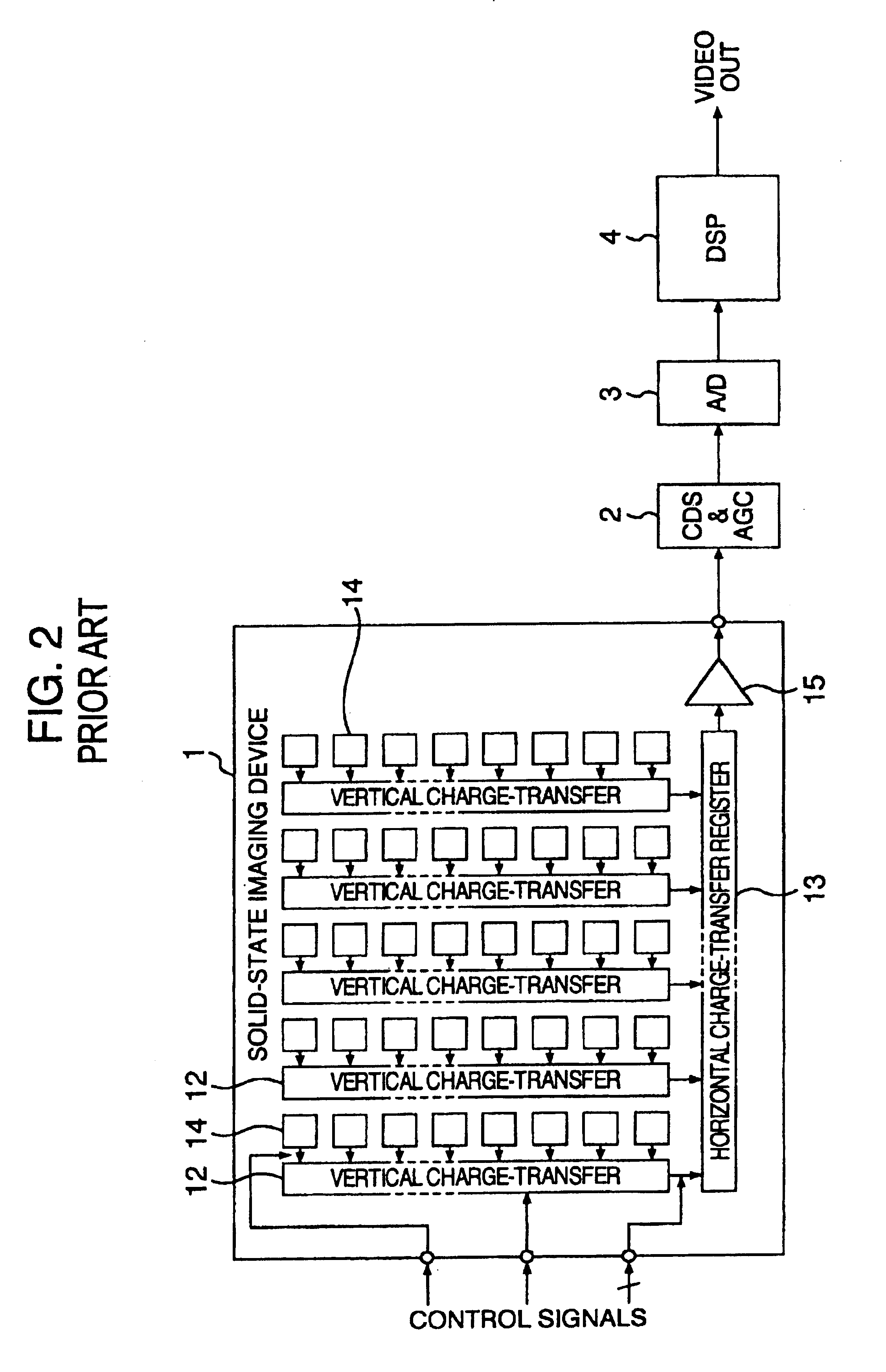

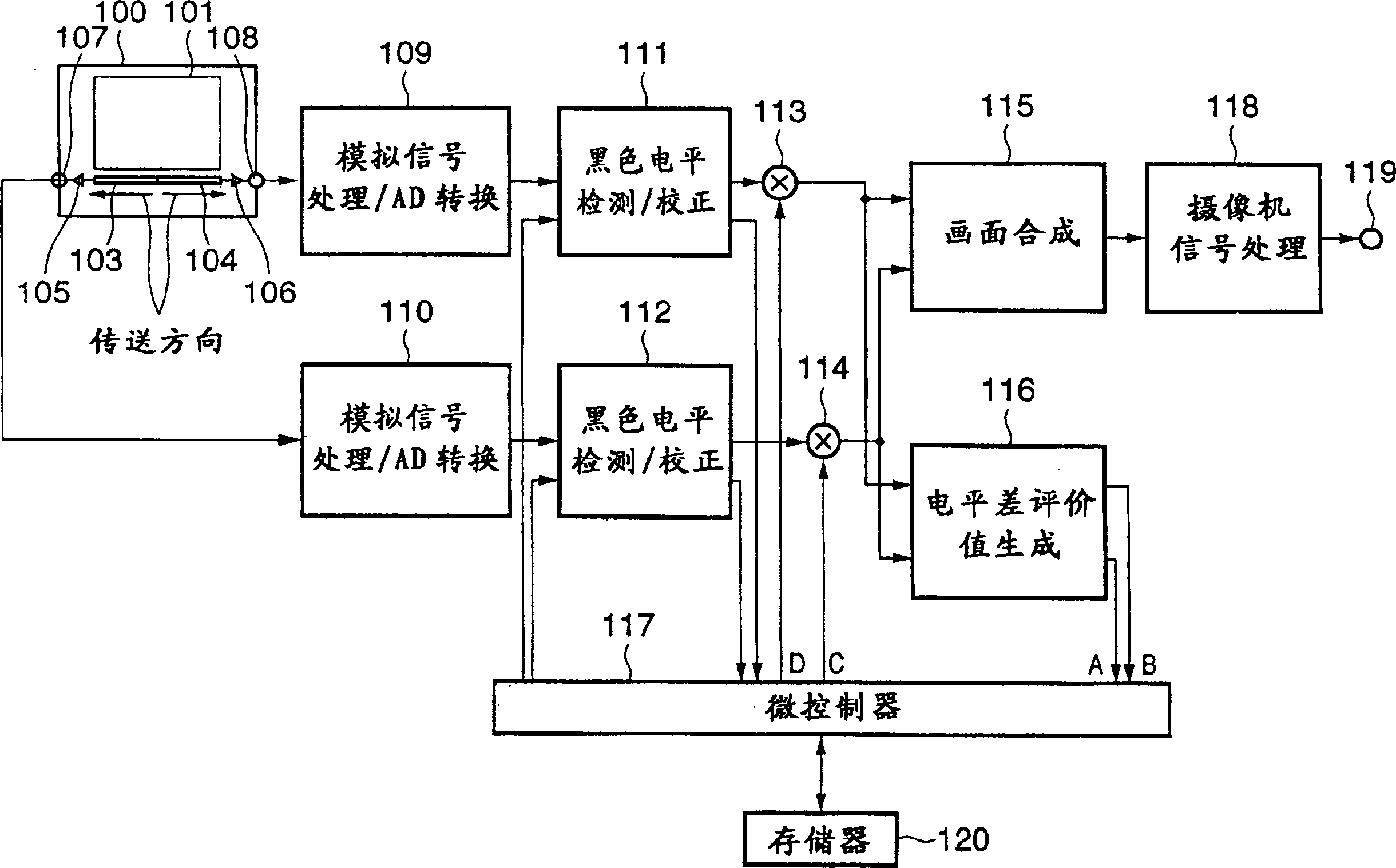

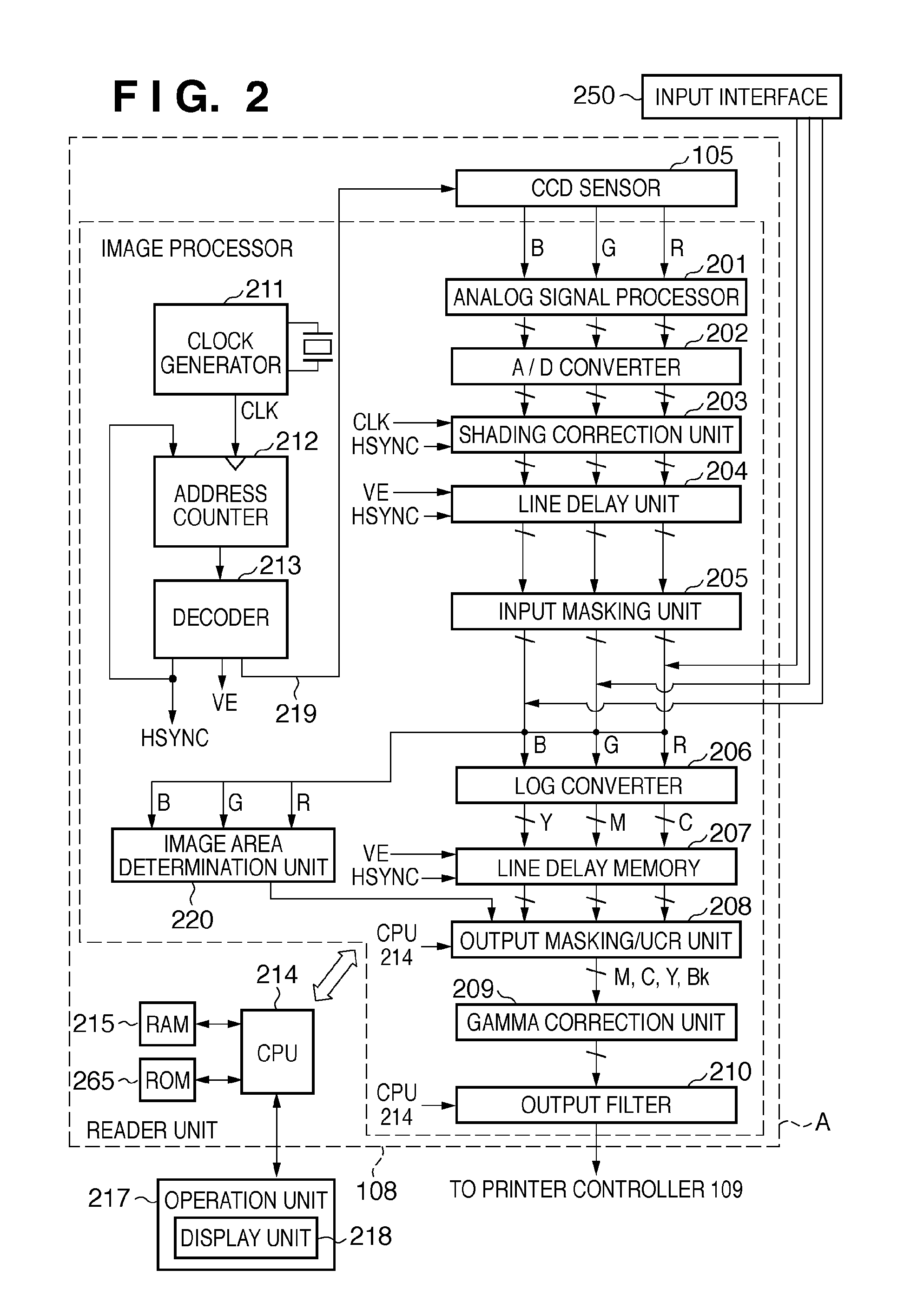

Correction apparatus

InactiveUS7379104B2Respond quicklyAccurate UniformityTelevision system detailsColor television detailsSignal onEngineering

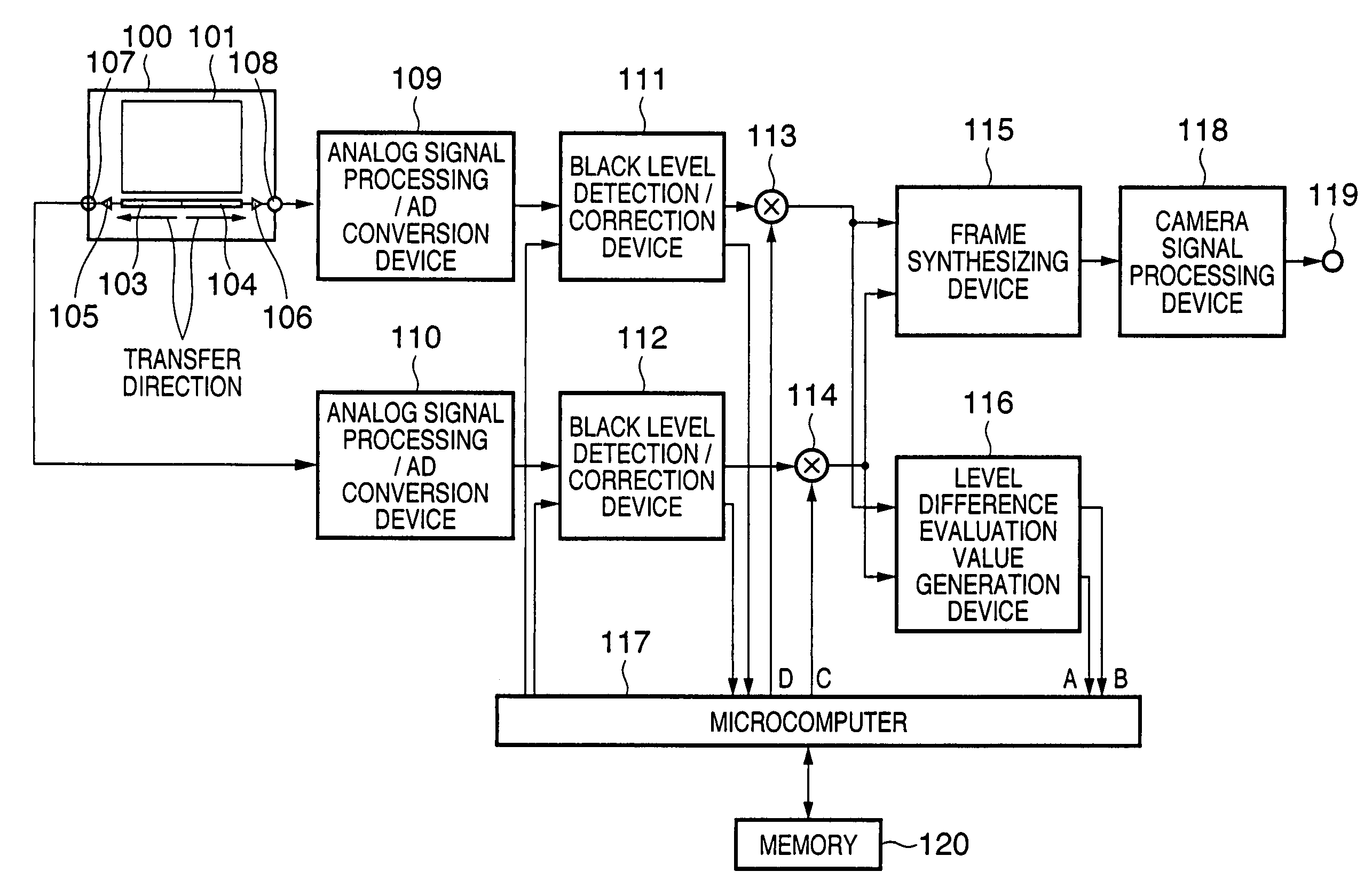

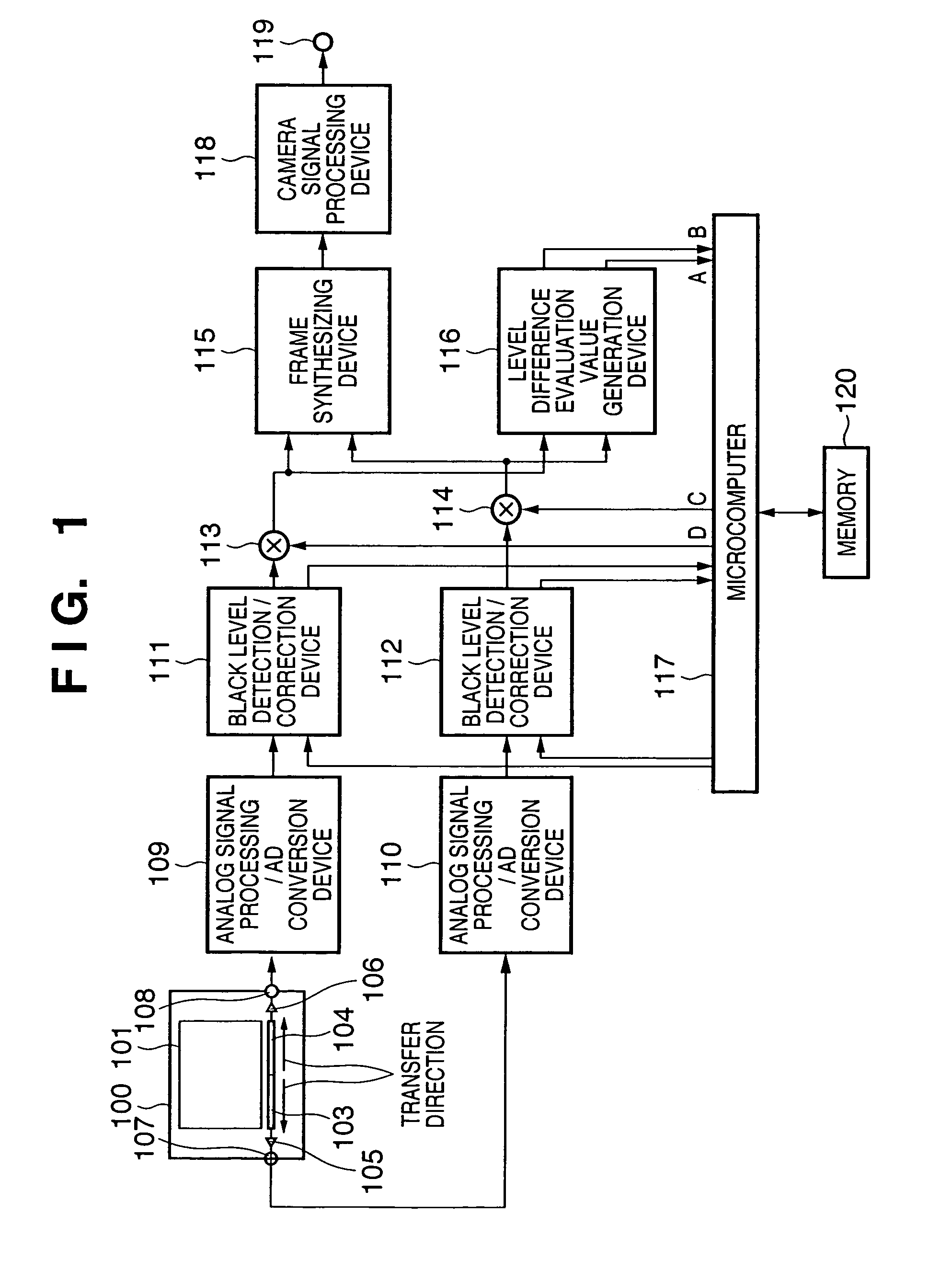

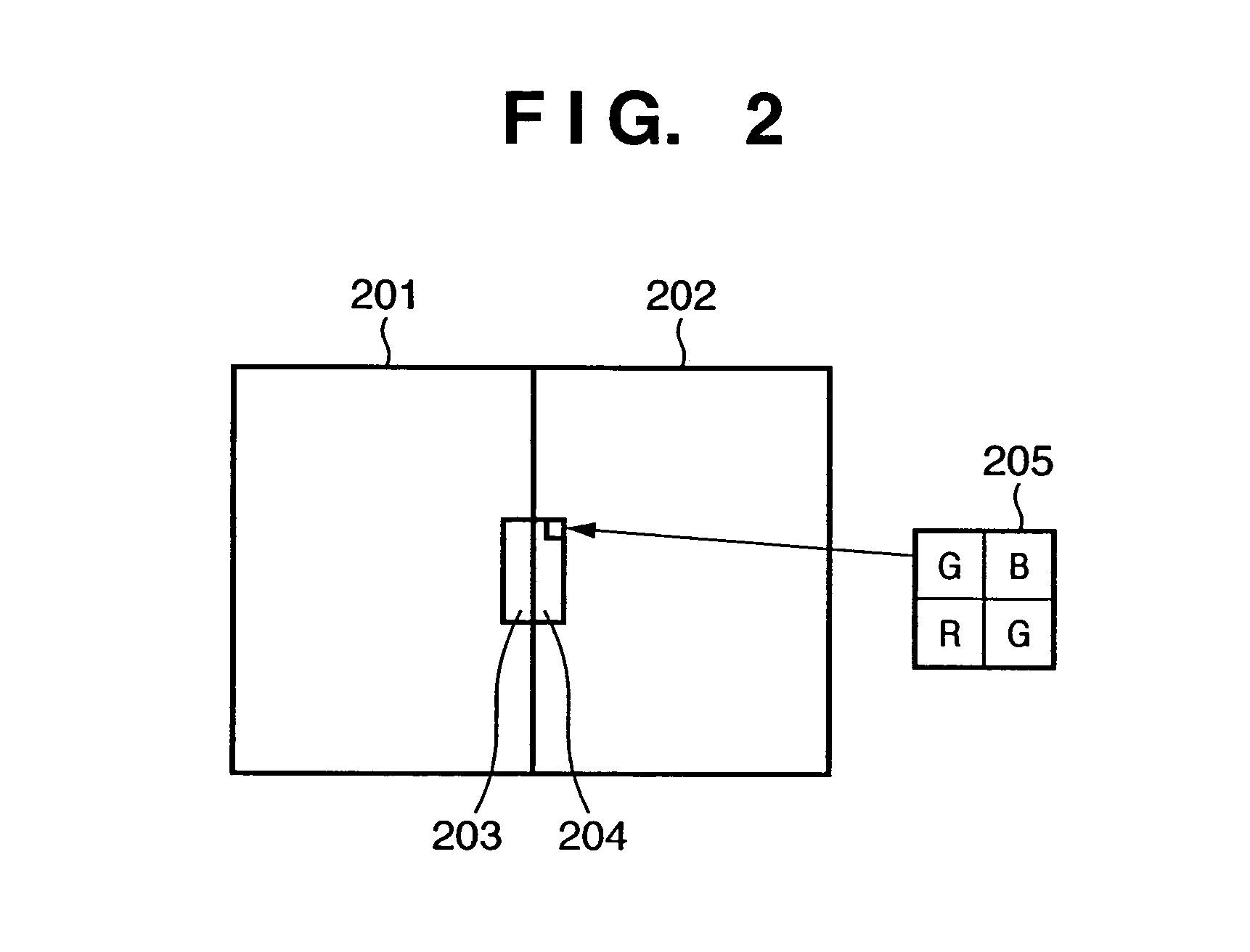

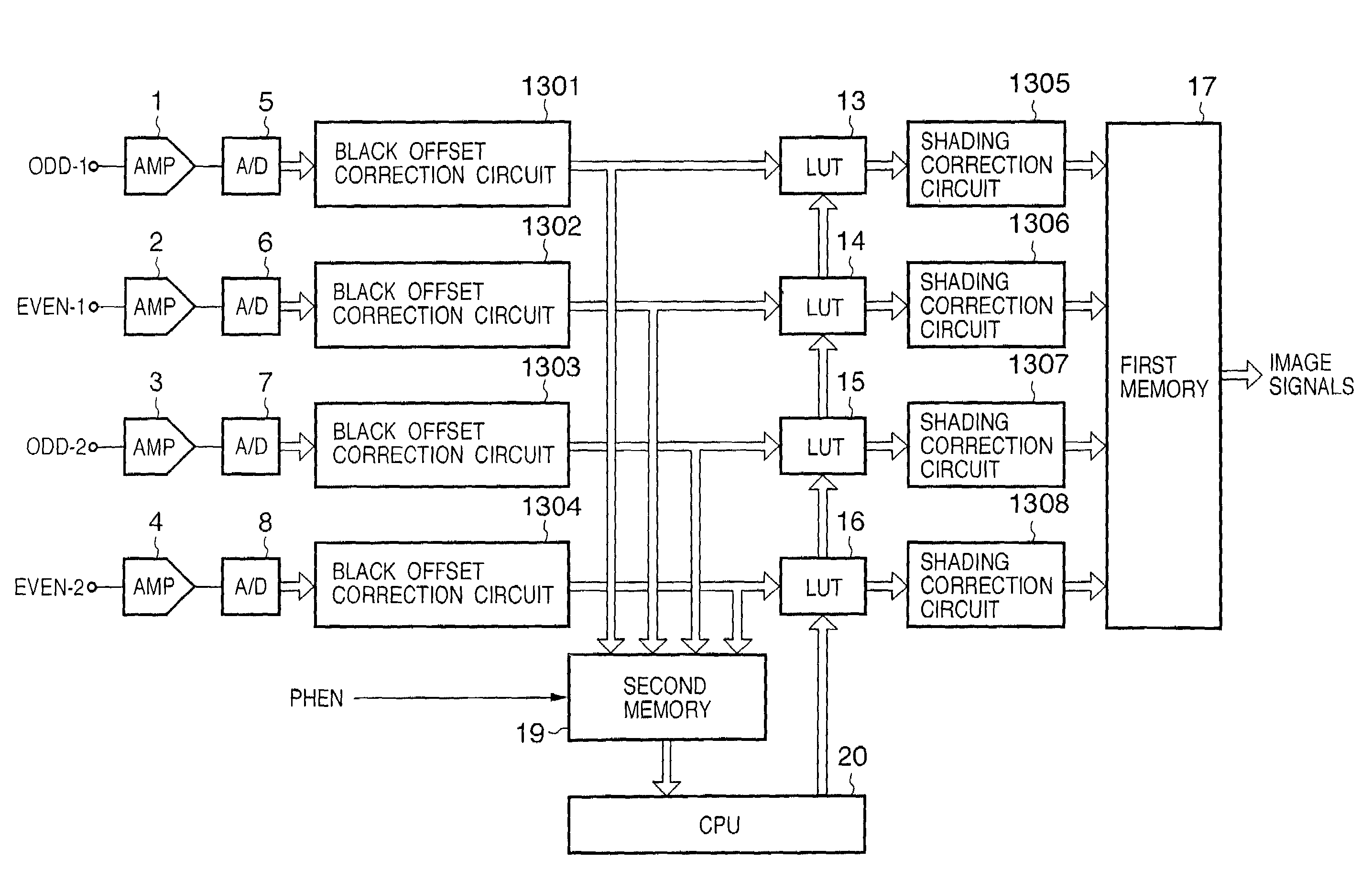

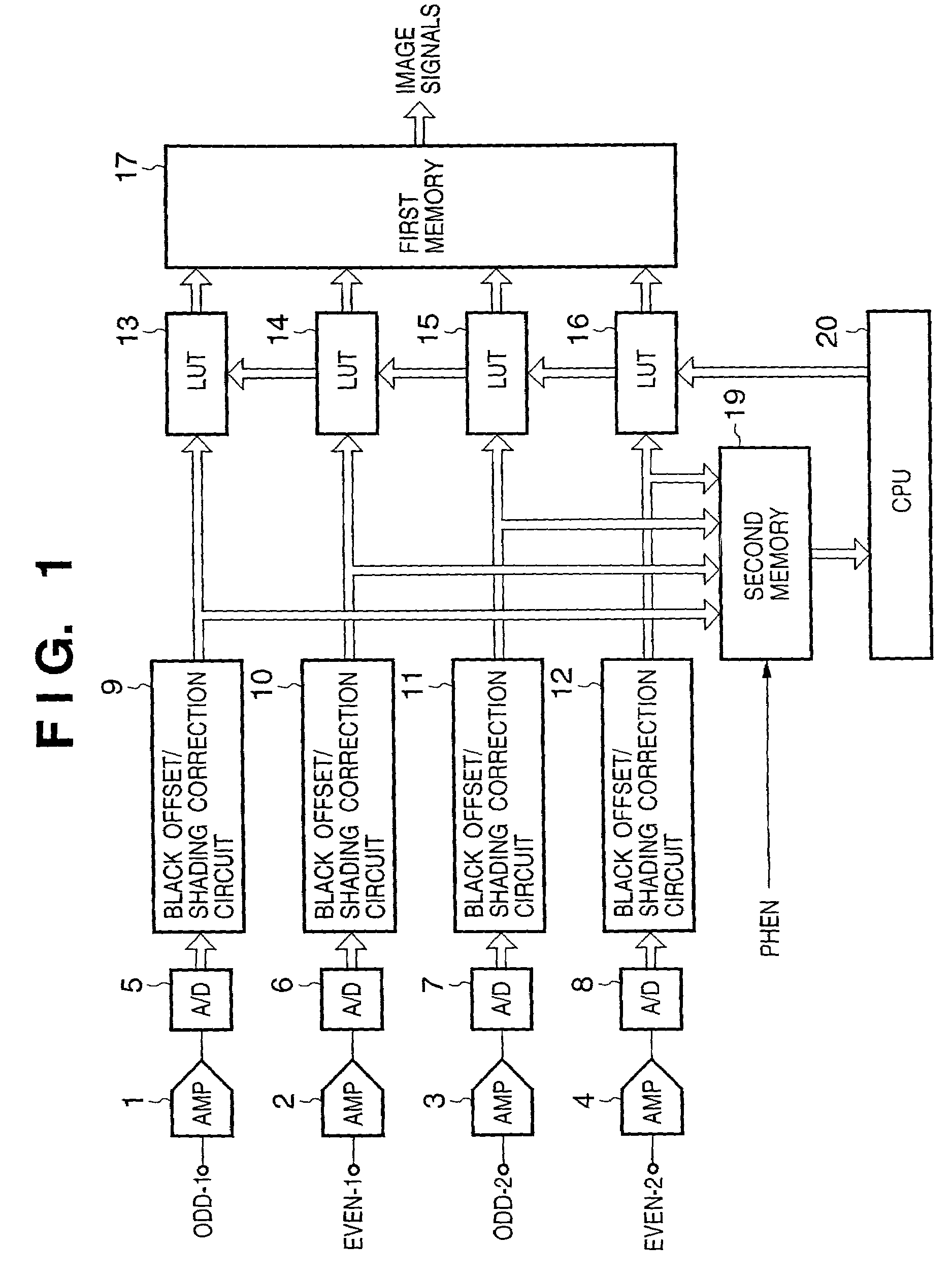

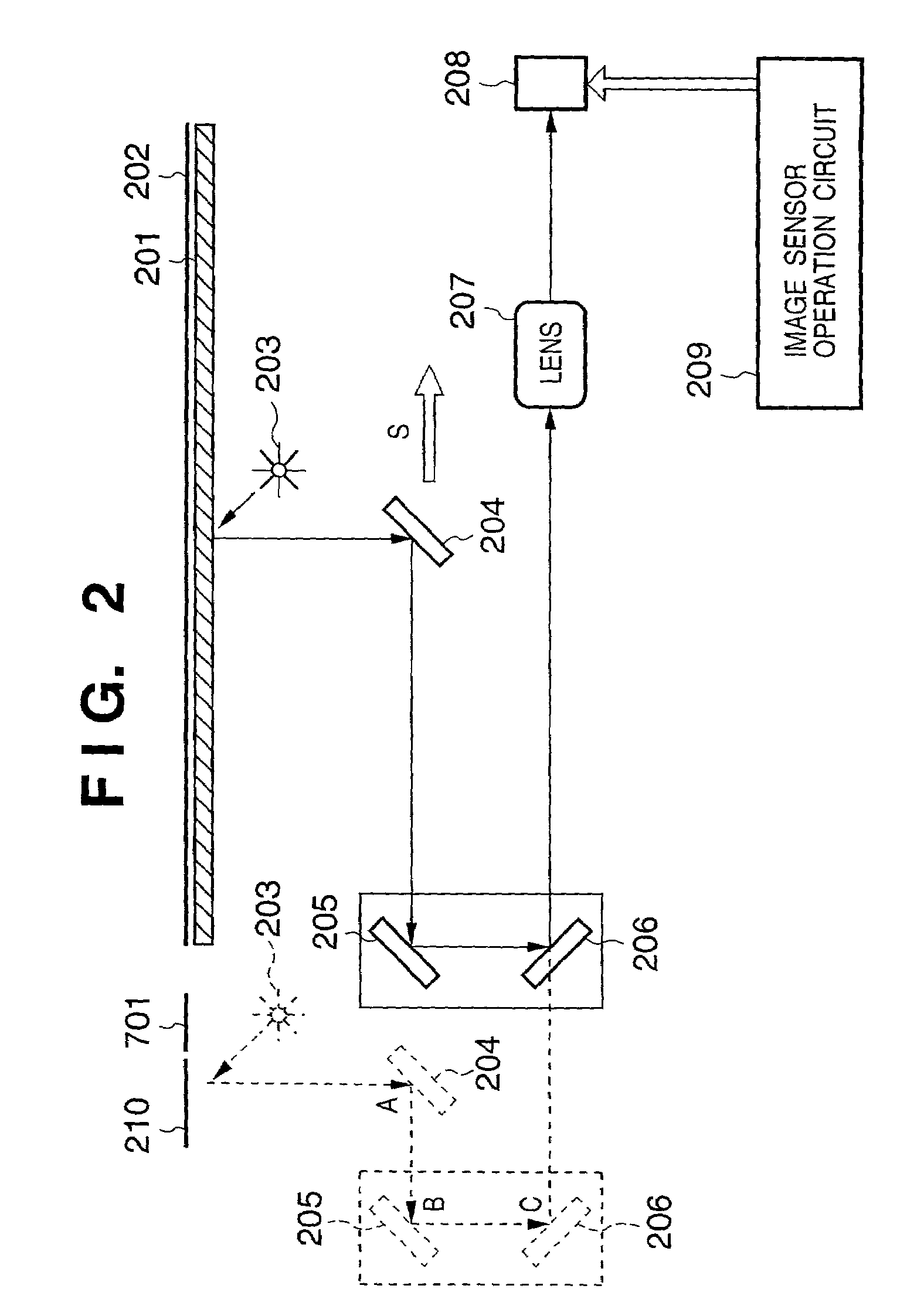

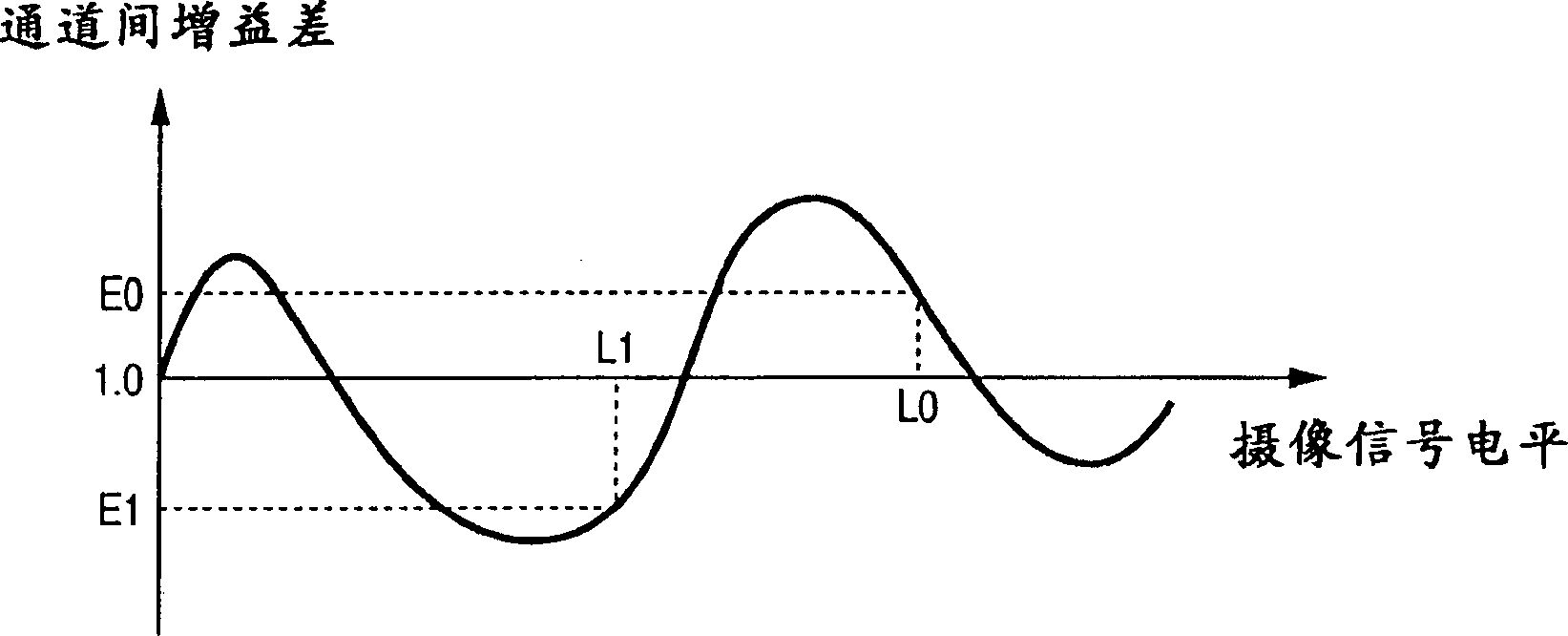

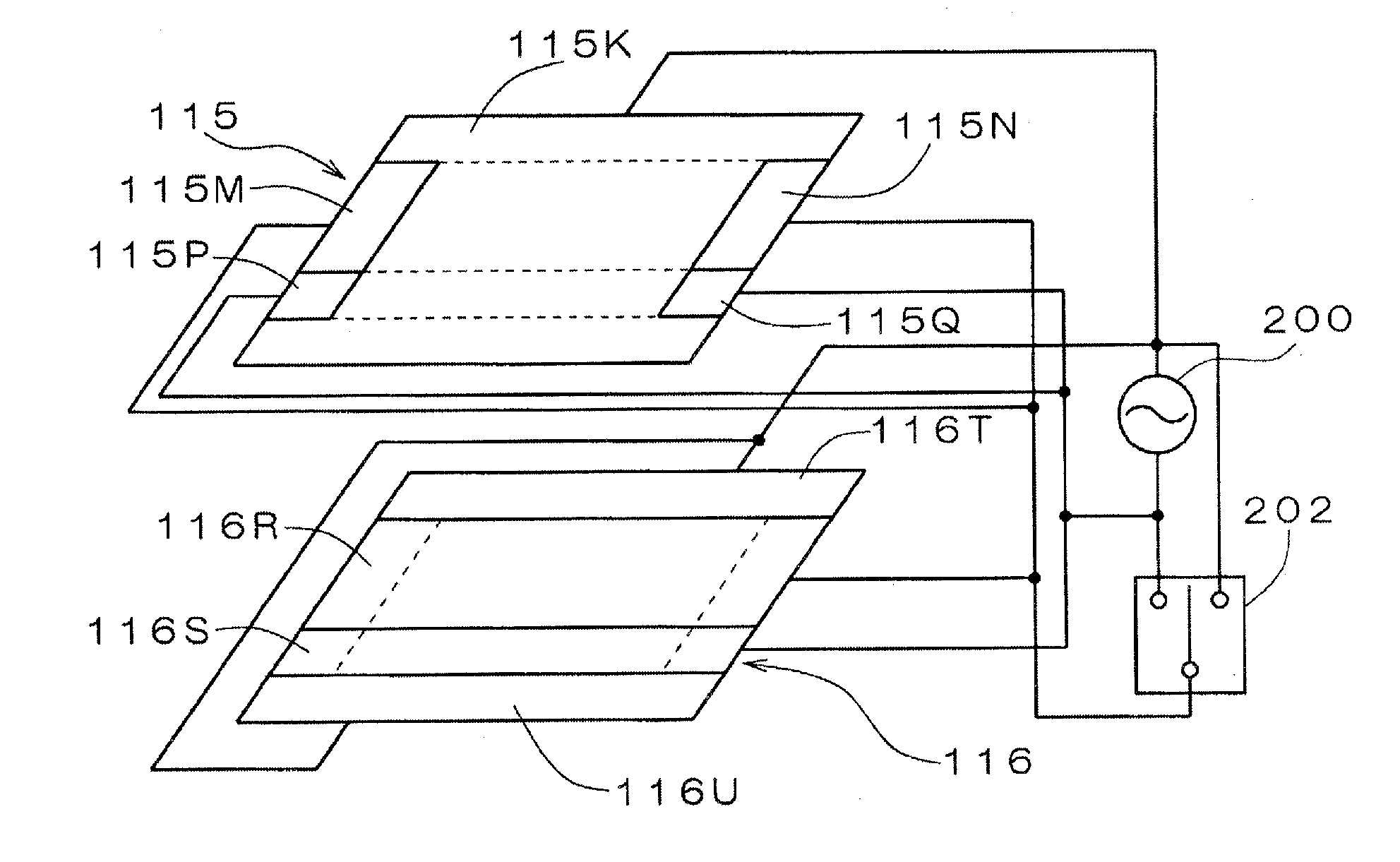

An object of this invention is to correct the non uniformity between a plurality of image sensing regions in real time and cope with even dynamic variations such as temperature variations or variations over time. To achieve this object, a correction apparatus includes a plurality of level adjustment devices which independently adjust the levels of a plurality of image sensing signals output from a plurality of output terminals, an output level detection device which detects the output levels of the plurality of level adjustment devices, and a correction coefficient determination device which determines a correction coefficient for reducing the level difference between the image sensing signals on the basis of the detection result of the output level detection device. The correction coefficient determination device determines the correction coefficient by excluding an object-dependent level difference component in which the level difference between the plurality of image sensing signals exceeds a predetermined level difference. The correction coefficient determination device supplies the determined correction coefficient to the level adjustment devices to perform adjustment so as to reduce the level difference between the image sensing signals.

Owner:CANON KK

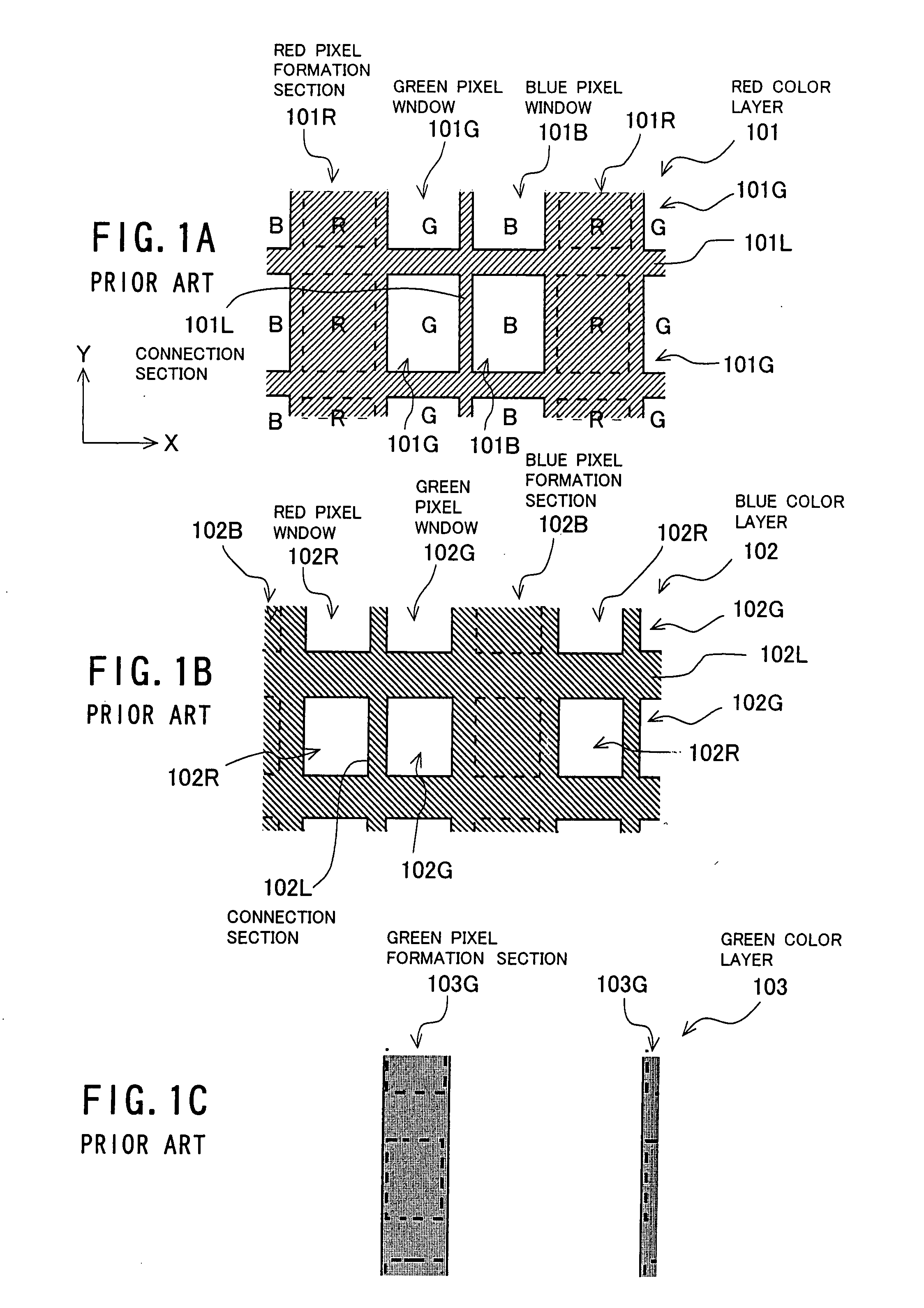

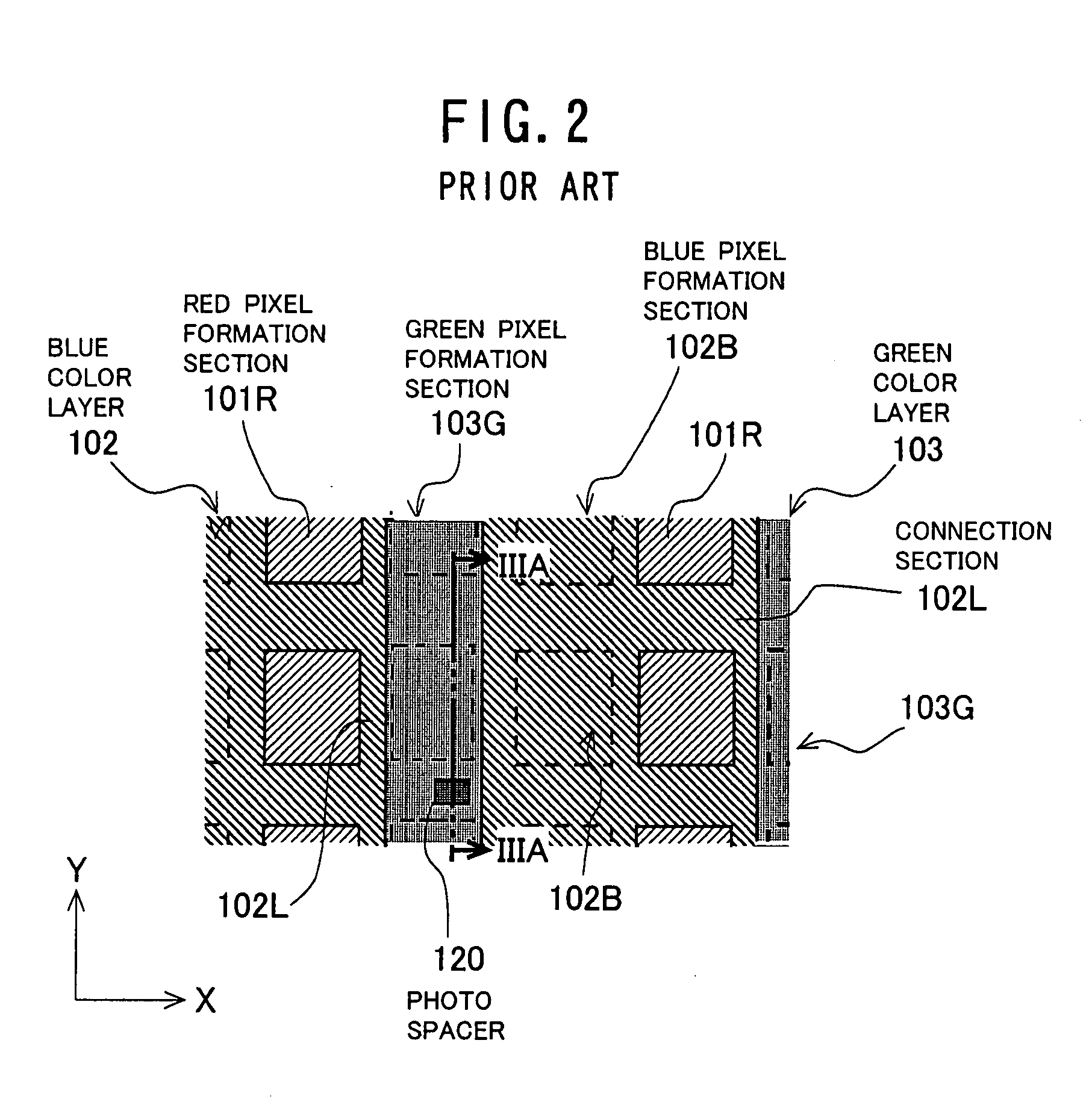

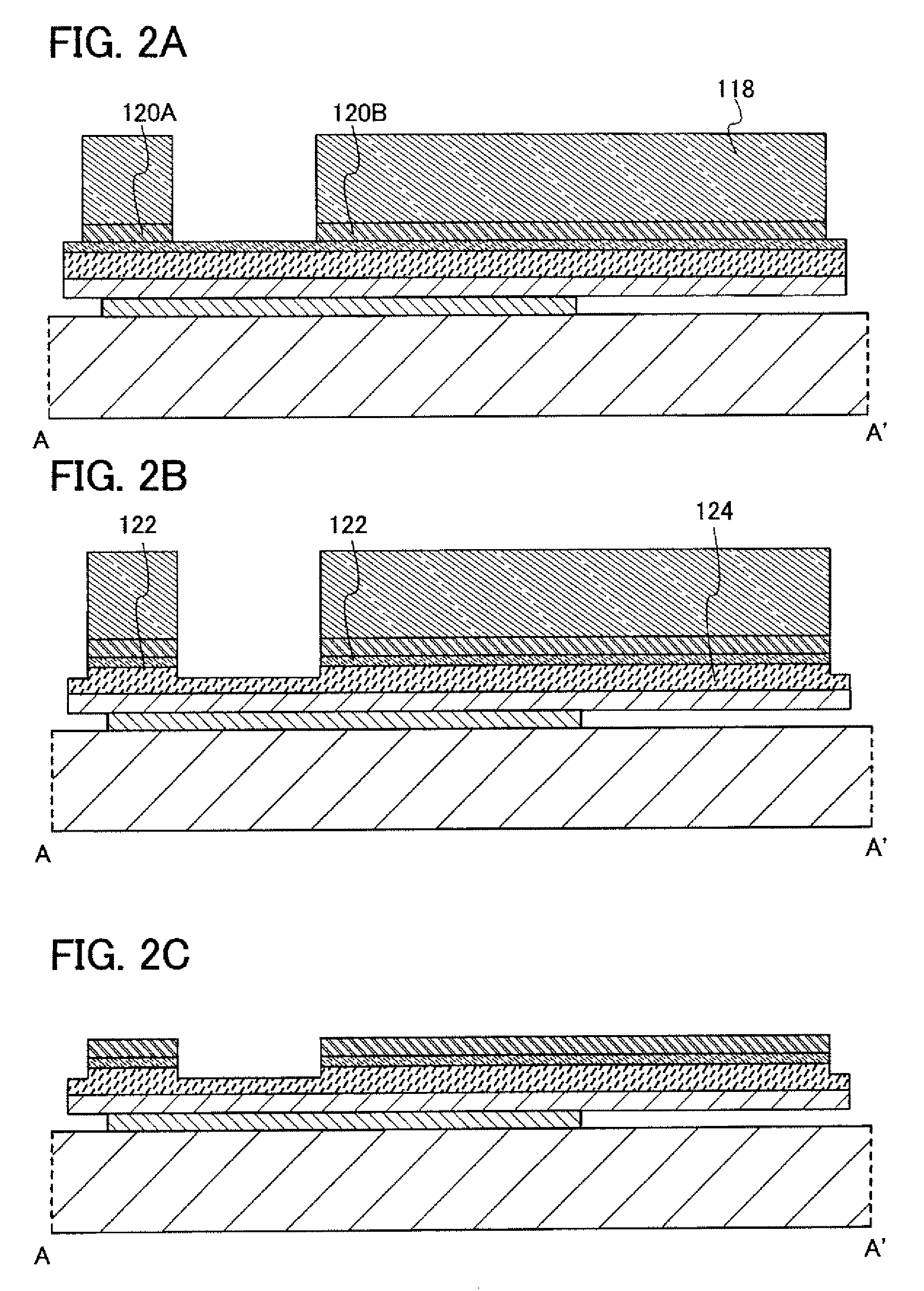

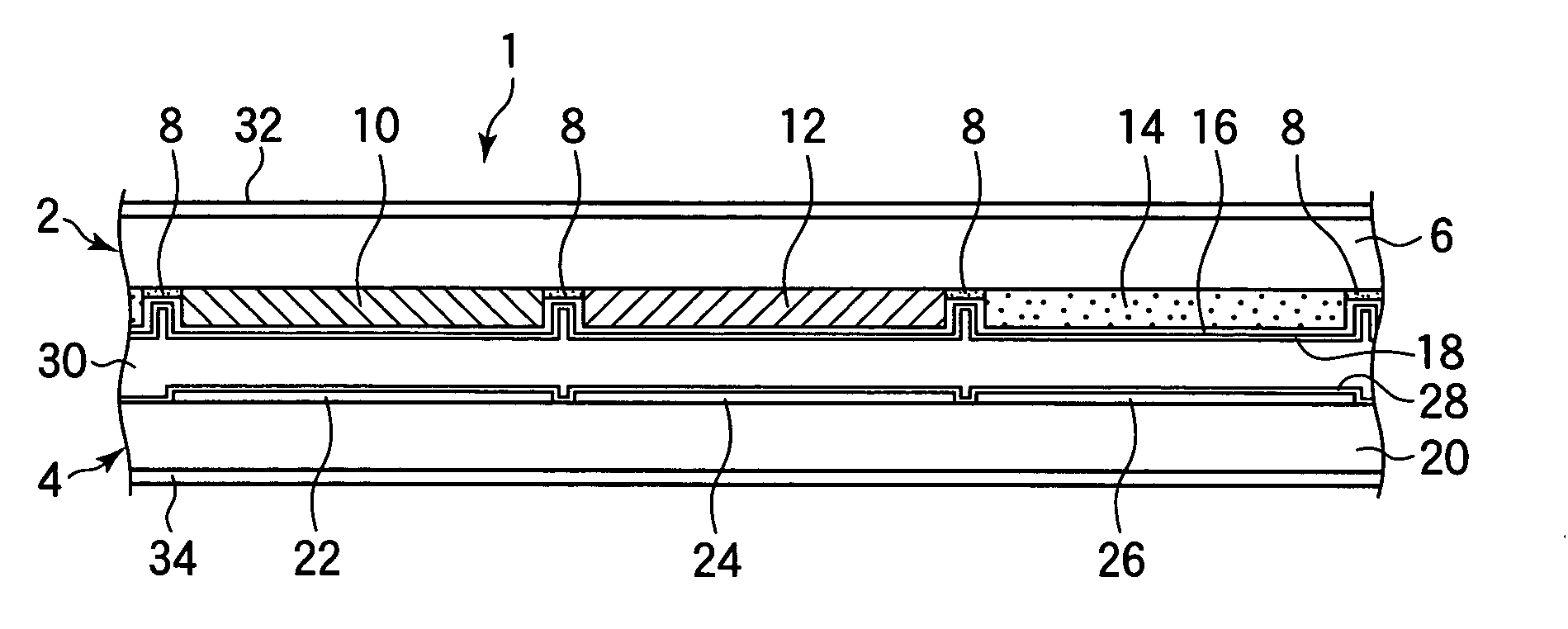

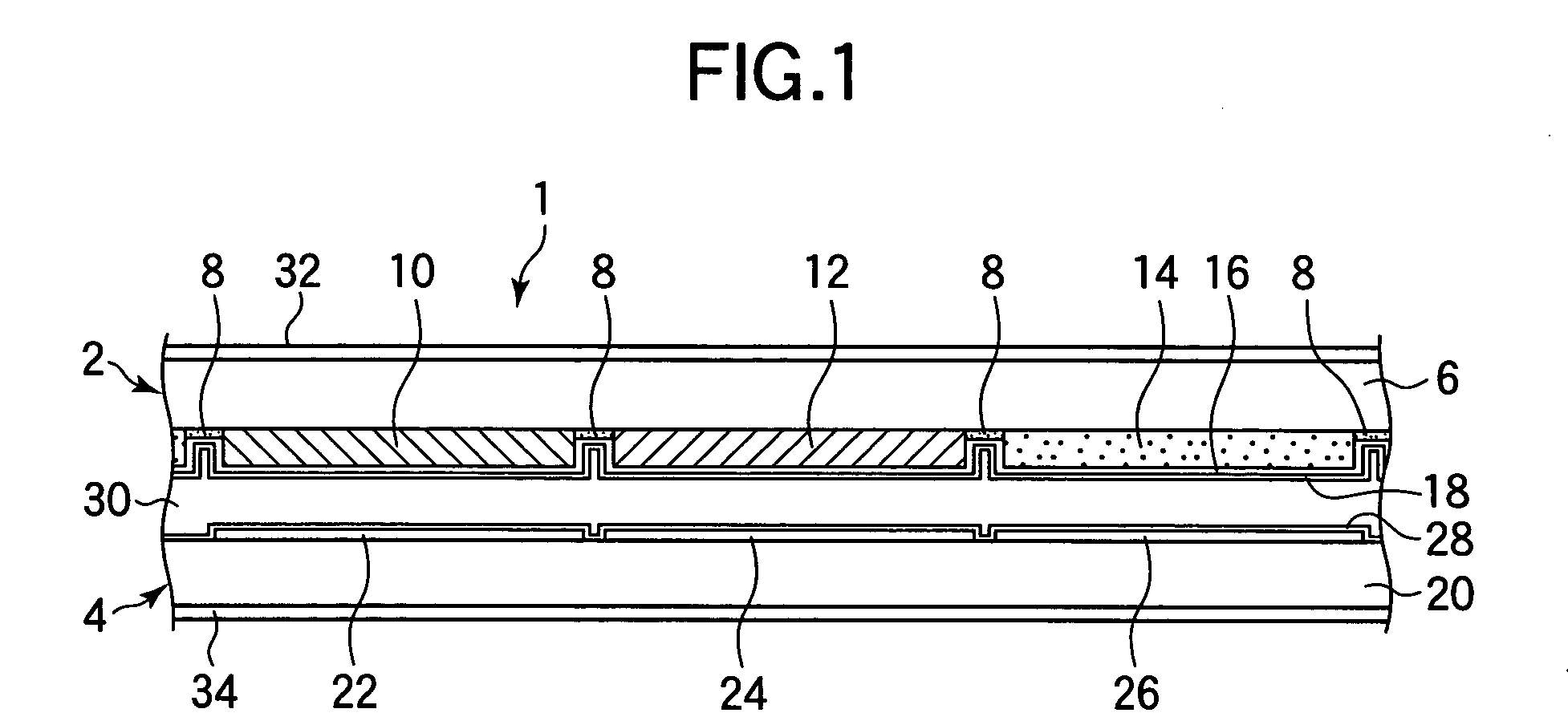

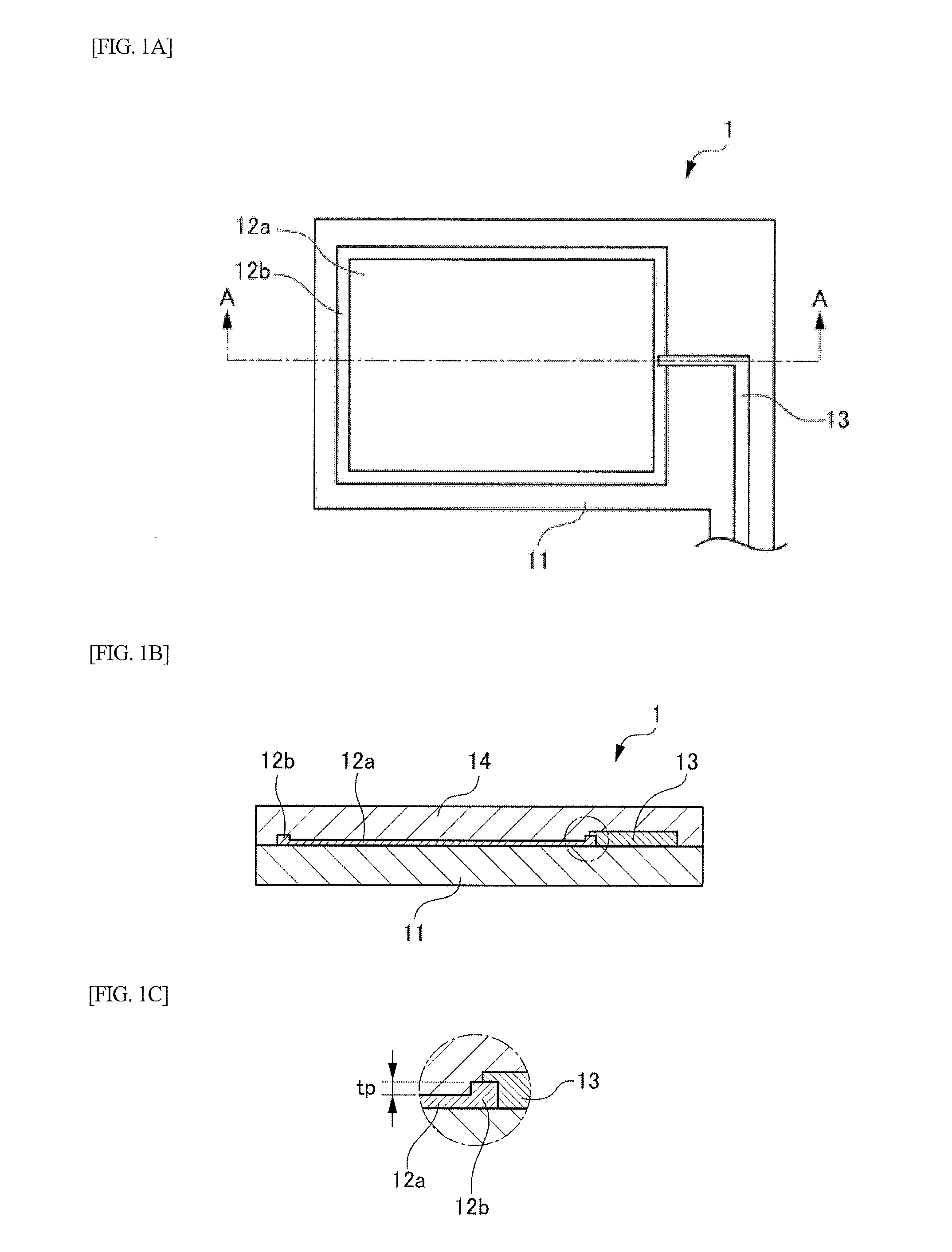

Color filter, method of fabricating the same and Liquid-Crystal Display device

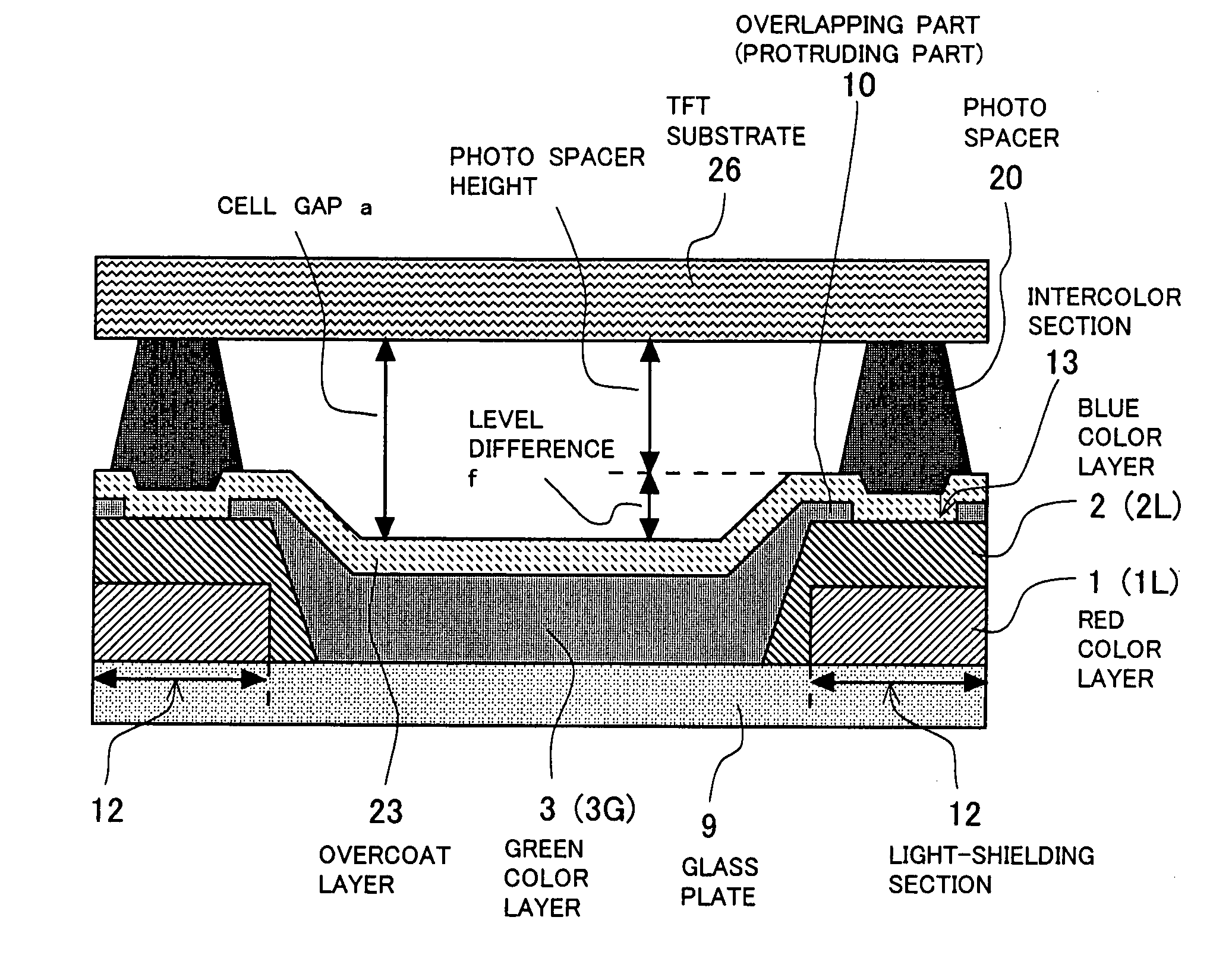

ActiveUS20070216832A1Reduce level differenceEasily removeNon-linear opticsLiquid-crystal displayColor filter array

A color filter having two-layered light-shielding sections without a black matrix is provided, which reduces the level difference from the colored materials for pixels with a simple method and makes it possible to remove the color layer on the said sections. A red color layer having stripe-shaped red pixel formation sections and a blue color layer having stripe-shaped blue pixel formation sections are overlapped to form two-layered light-shielding sections. A green color layer having island-shaped green pixel formation sections is overlapped with the red and blue color layers, placing the green pixel formation sections in the overlapped green pixel windows of the red and blue color layers. Only the peripheries of the green pixel formation sections are placed on the light-shielding sections to facilitate the removal of the peripheries by polishing.

Owner:GOLD CHARM LTD

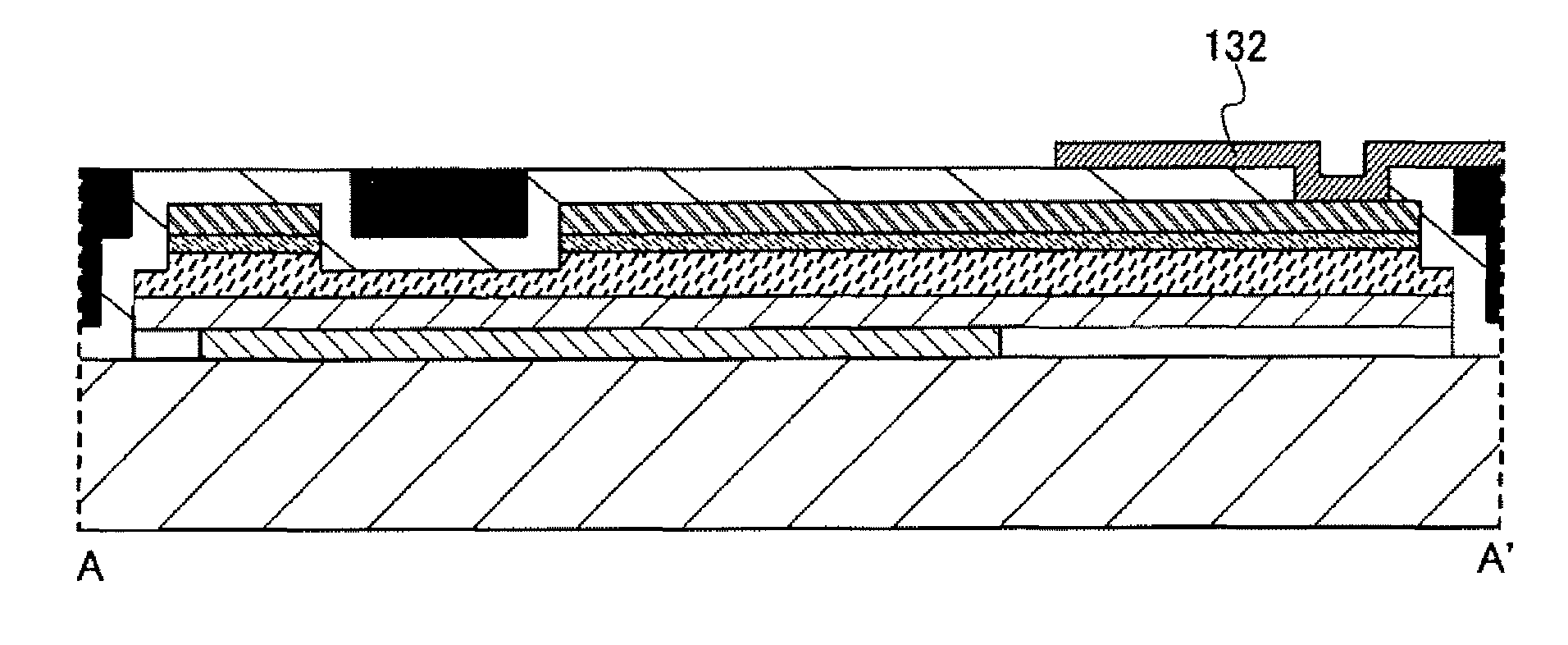

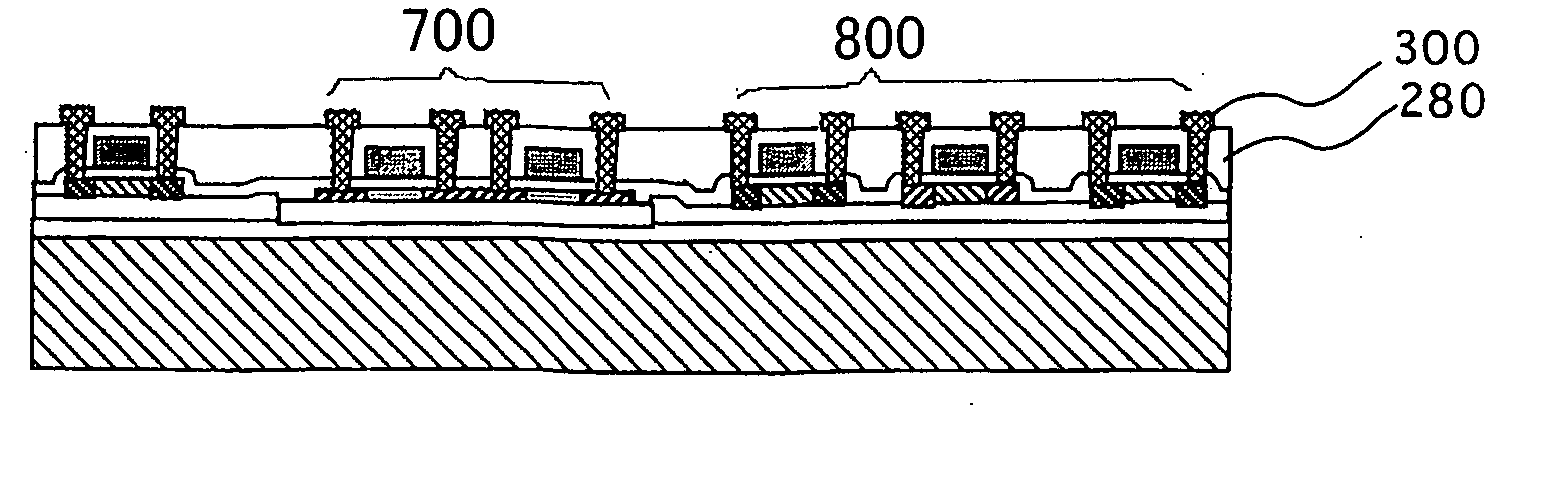

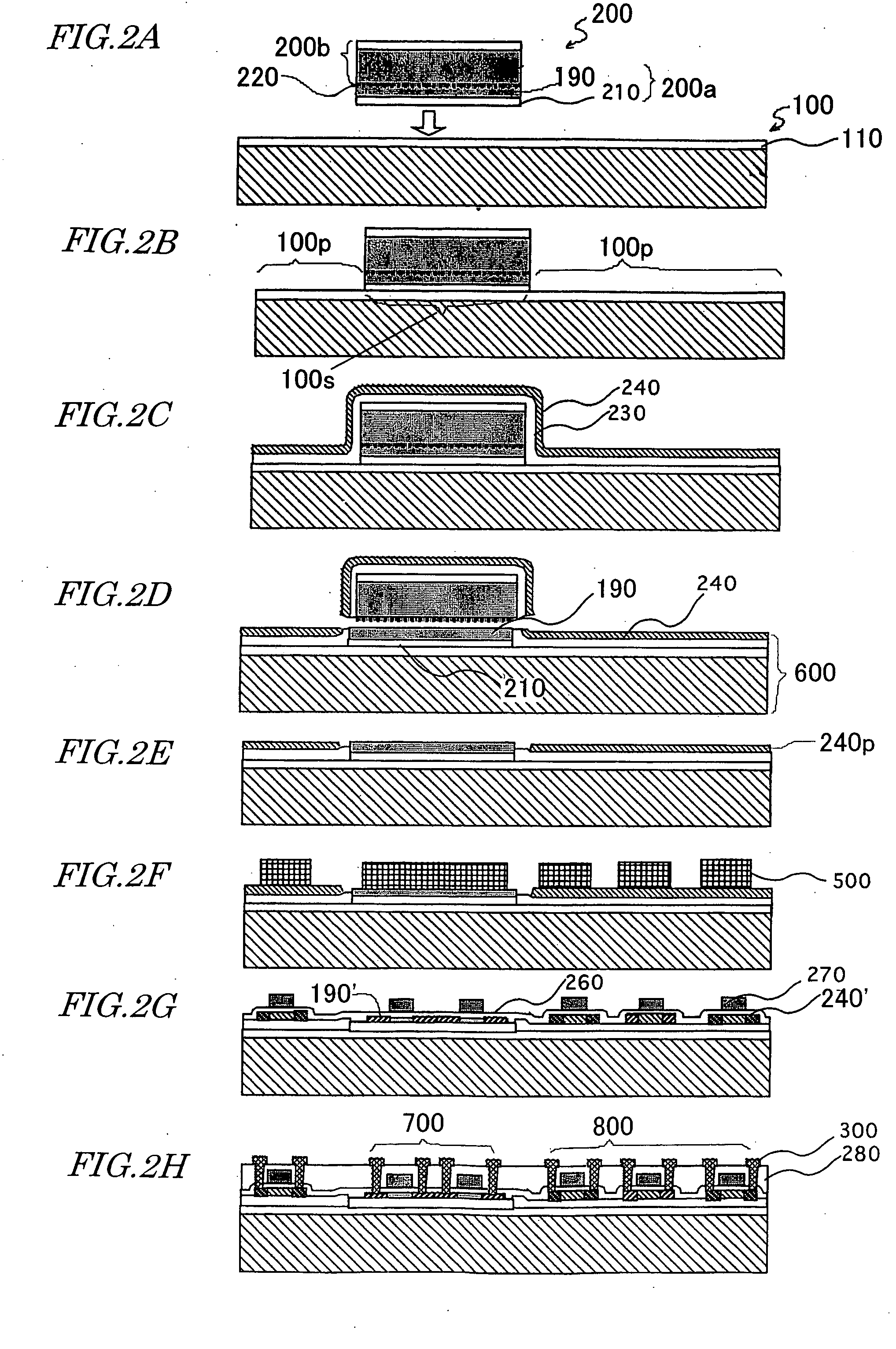

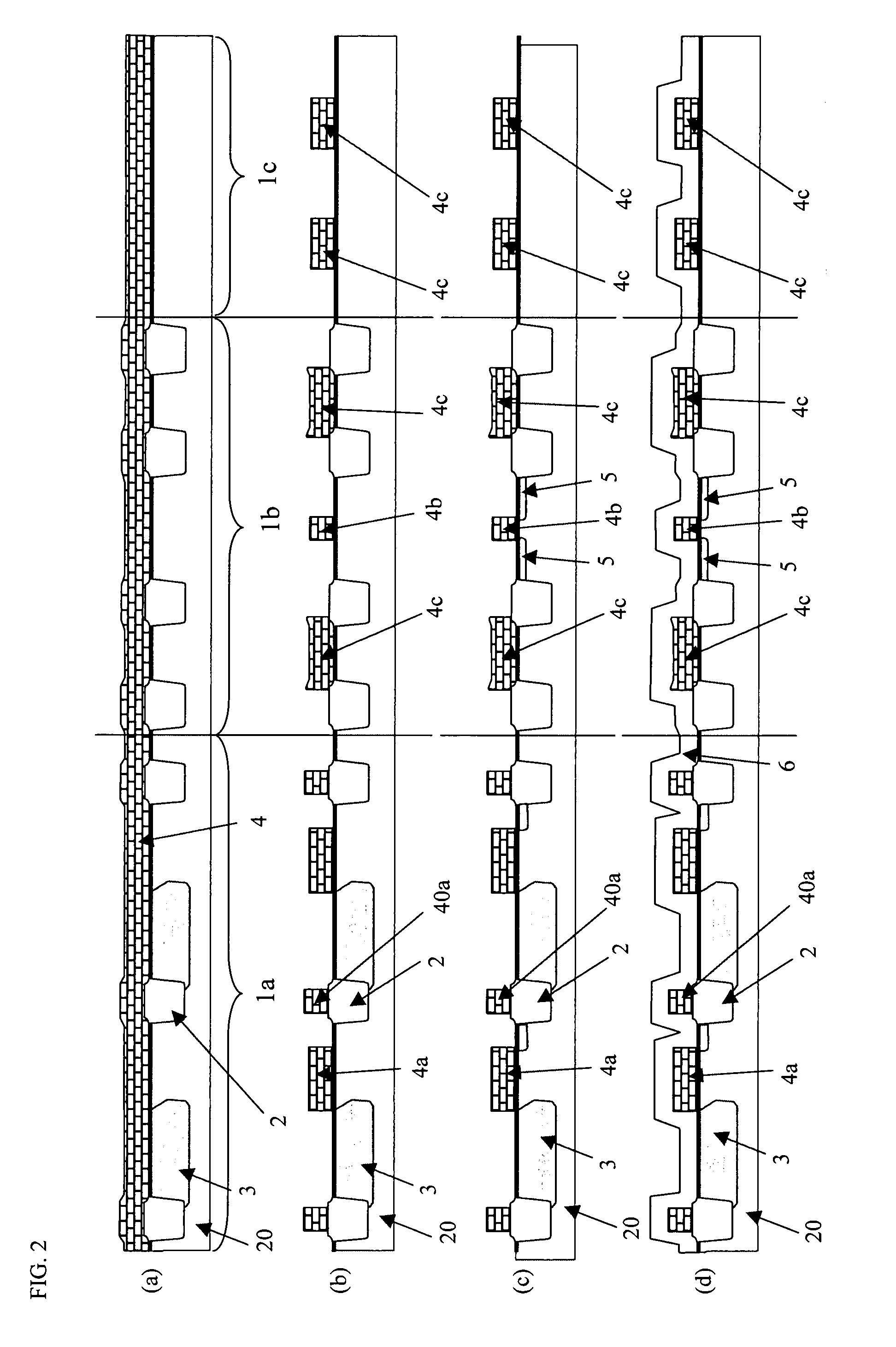

Liquid crystal display device

InactiveUS8049221B2Reduce in quantitySimple processSolid-state devicesSemiconductor/solid-state device manufacturingLiquid-crystal displayEtching

An objective is simplification of a manufacturing method of a liquid crystal display device or the like. In a manufacturing method of a thin film transistor, a stack in which a first conductive film, an insulating film, a semiconductor film, an impurity semiconductor film, and a second conductive film are stacked in this order is formed, and the first conductive film is exposed by first etching and a pattern of the second conductive film is formed by second etching. Further, after thin film transistors are formed, a color filter layer is formed so that unevenness caused by the thin film transistors or the like is relieved; thus, the level difference of the surface where the pixel electrode layer is formed is reduced. Alternatively, a color filter layer is selectively formed utilizing the unevenness caused by thin film transistors or the like.

Owner:SEMICON ENERGY LAB CO LTD

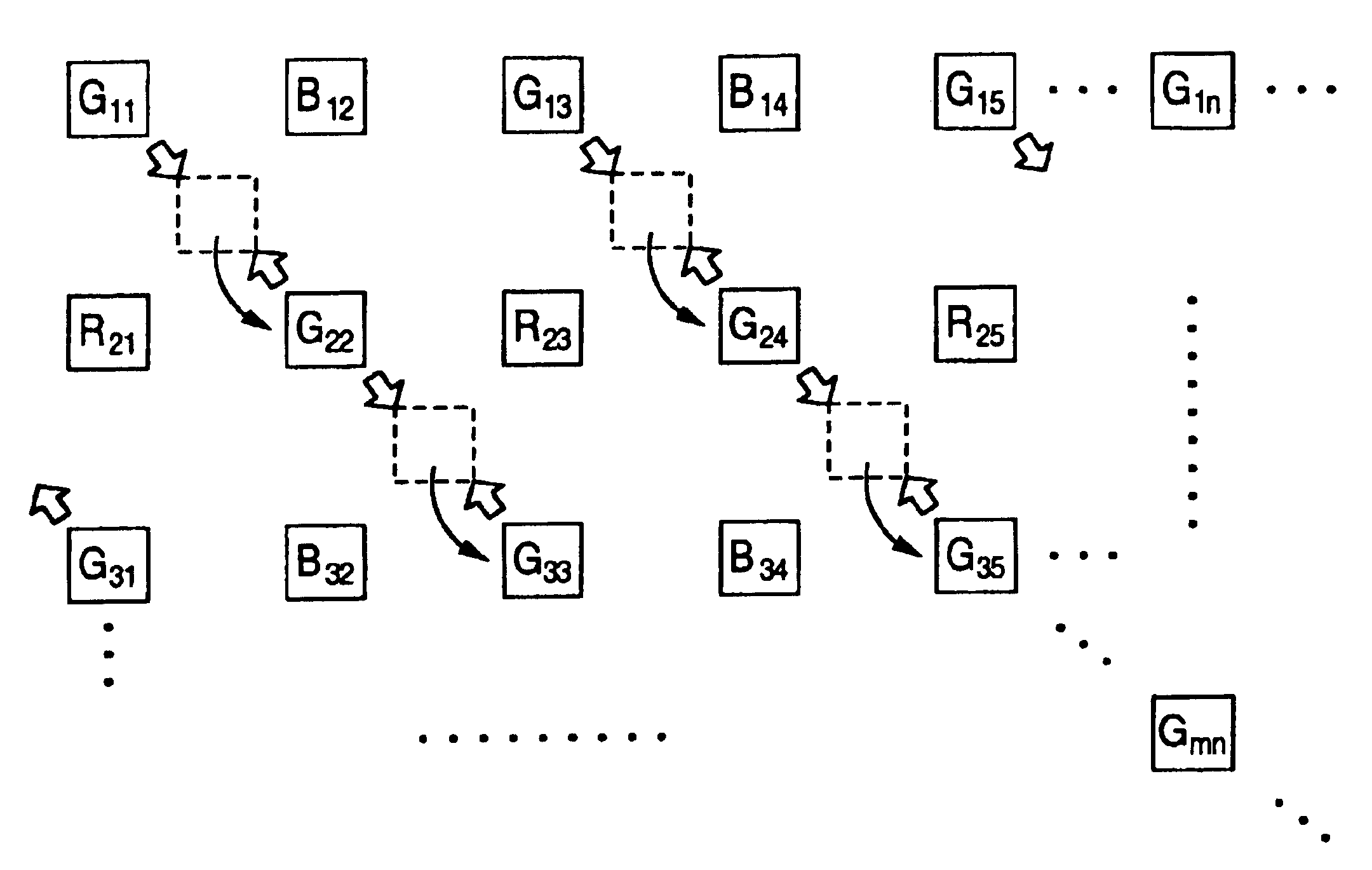

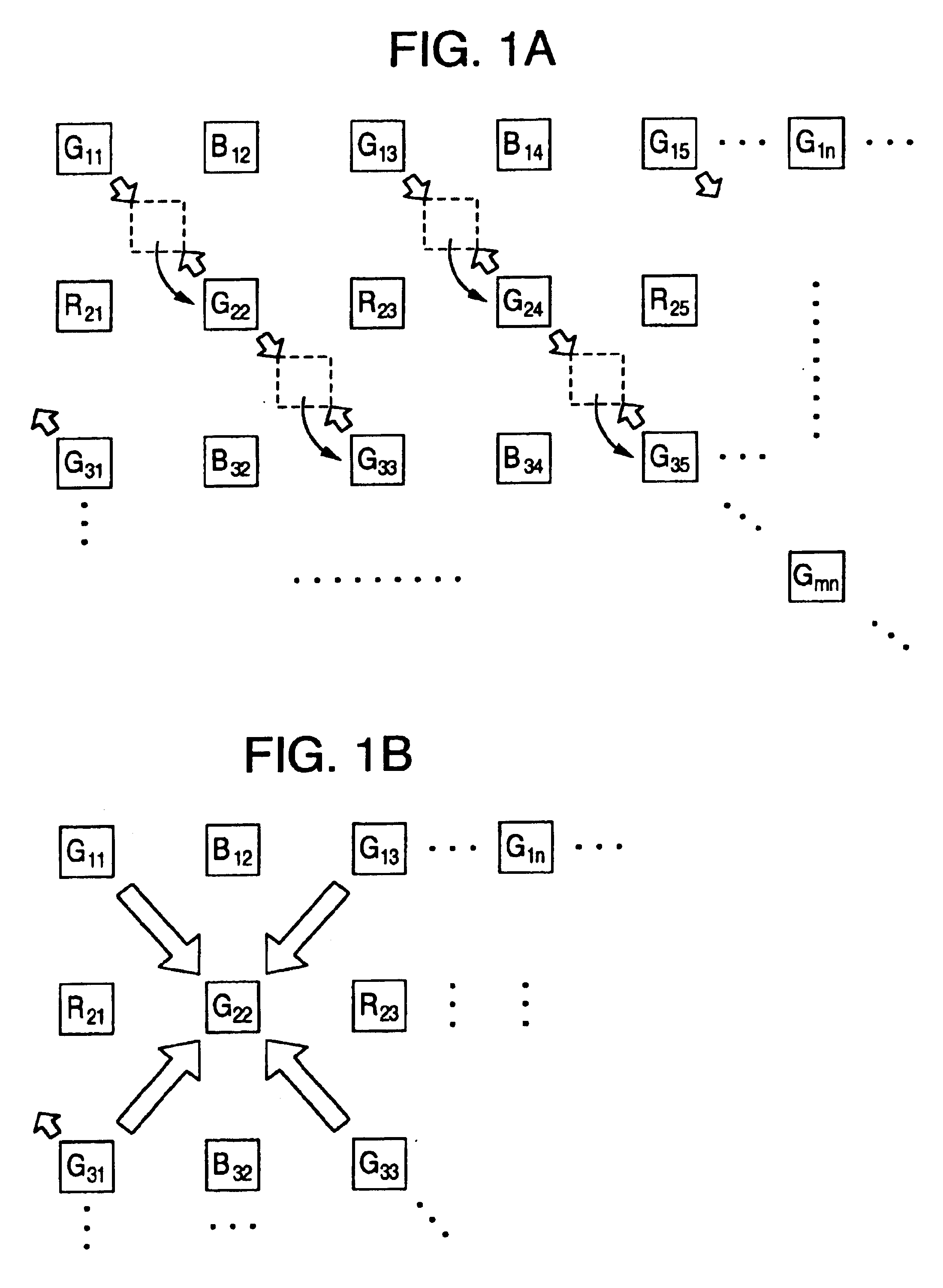

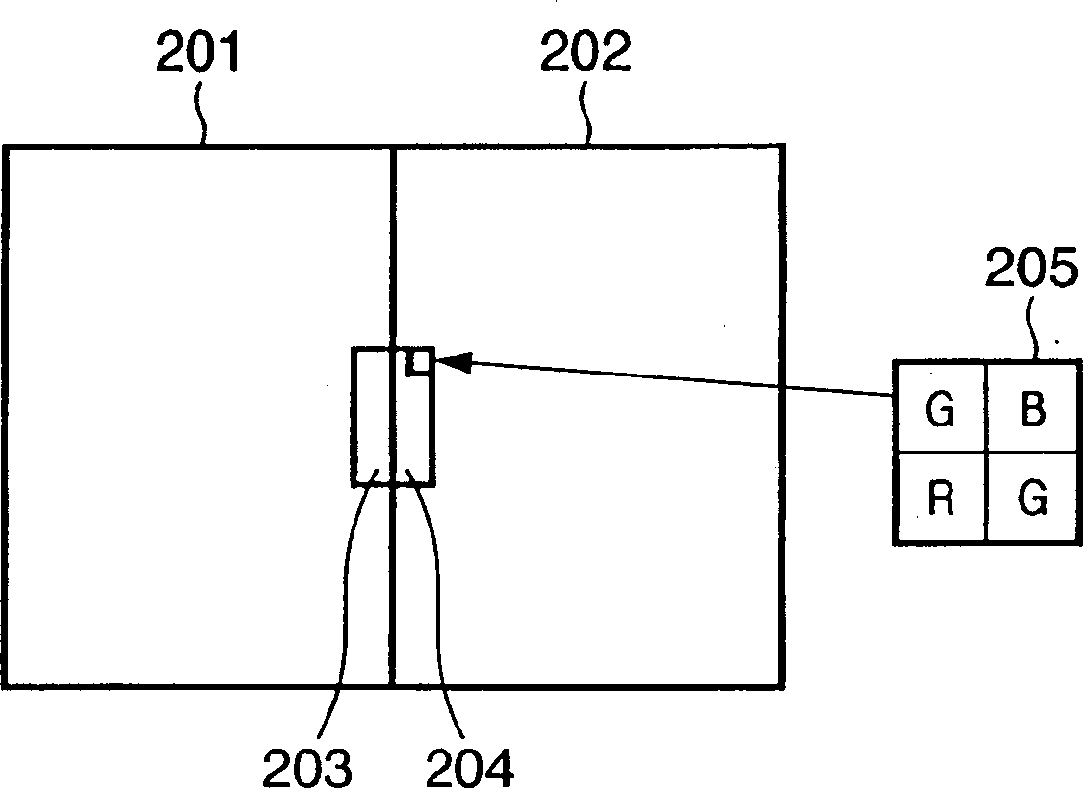

Method of processing image signal from solid-state imaging device, image signal processing apparatus, image signal generating apparatus and computer program product for image signal processing method

InactiveUS6900838B1Preventing Image Quality DeteriorationAvoid height differenceTelevision system detailsTelevision system scanning detailsGreen-lightComputer science

An image signal processing method and an image signal processing apparatus for processing the color component signal obtained from a solid-state image pickup device including an arrangement of a plurality of photoelectric elements and a color filter arranged in the light receiving section of each pixel corresponding to the photoelectric element, an image signal generating apparatus and a computer program product for the image signal processing method. A color component signal is fetched from a designated pixel corresponding to the photoelectric element having a filter that can transmit the green light on a line of the solid-state image pickup device. A color component signal is also fetched from a pixel corresponding to the photoelectric element having a filter for transmitting at least the green light on another line, which pixel is located in the neighborhood of the designated pixel. Further, based on a plurality of the color signals fetched in the foregoing steps, the value of the color component signal of the designated pixel having the filter for transmitting at least the green light is determined.

Owner:KOKUSA ELECTRIC CO LTD

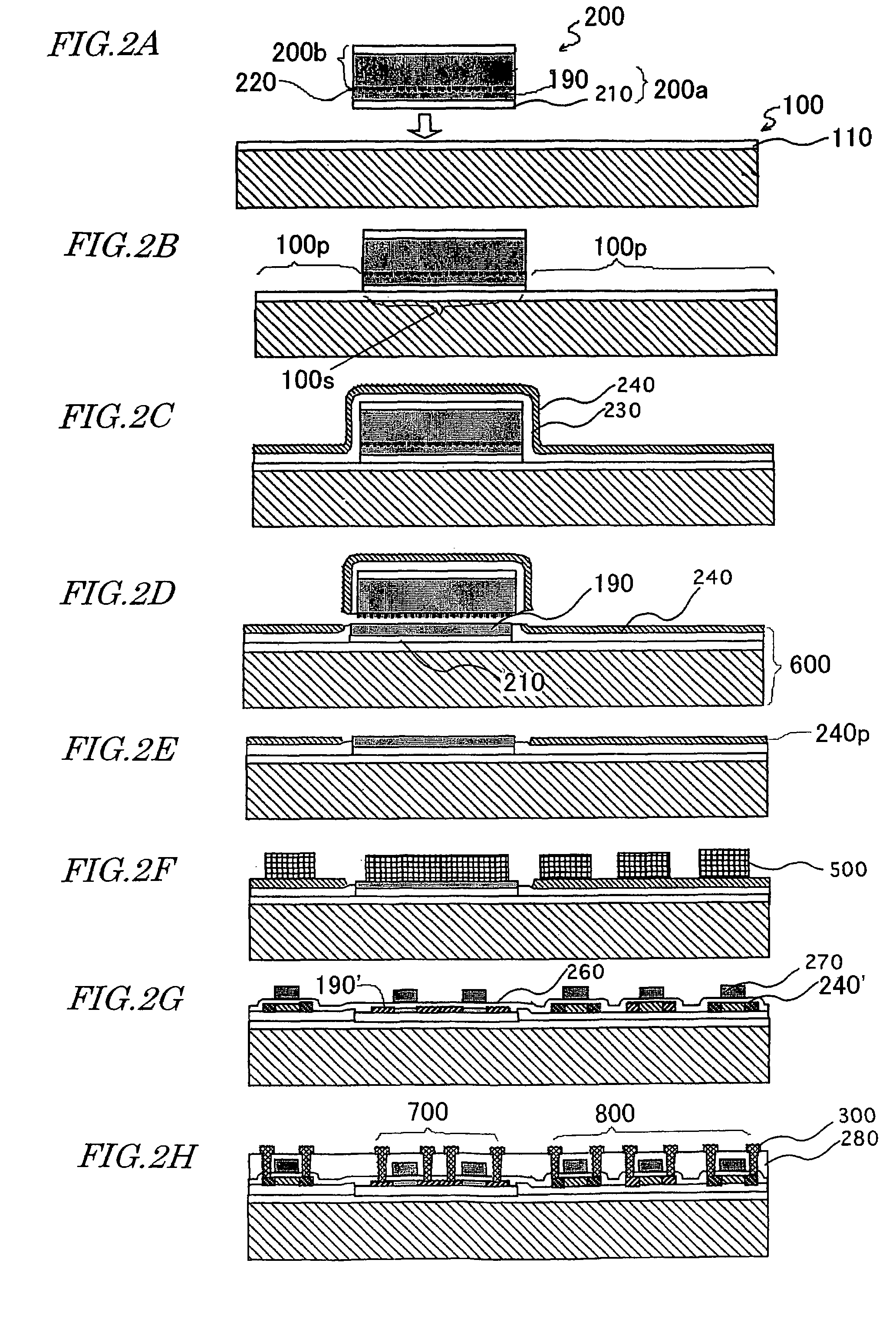

Semiconductor device with single crystal semiconductor layer(s) bonded to insulating surface of substrate

ActiveUS7262464B2Reduce level differenceReduce thicknessTransistorRoller bearingsSingle crystalSemiconductor

A semiconductor device includes a substrate with an insulating surface and a single crystal semiconductor layer, which is bonded to the insulating surface of the substrate. The device further includes a first insulating layer, which is provided between the insulating surface of the substrate and the single crystal semiconductor layer, and a second insulating layer, which has been deposited on the entire insulating surface of the substrate except an area in which the first insulating layer is present.

Owner:SHARP KK

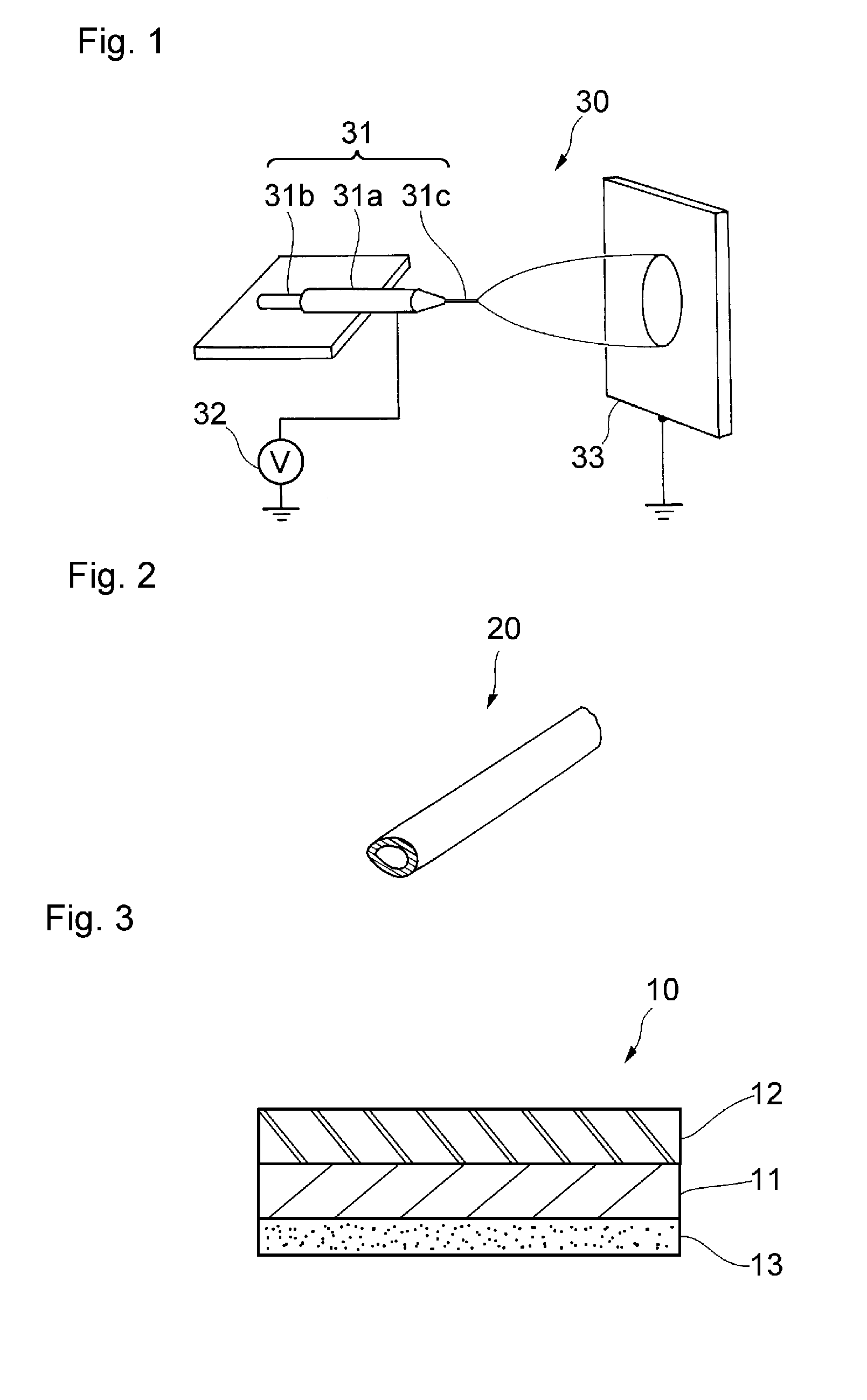

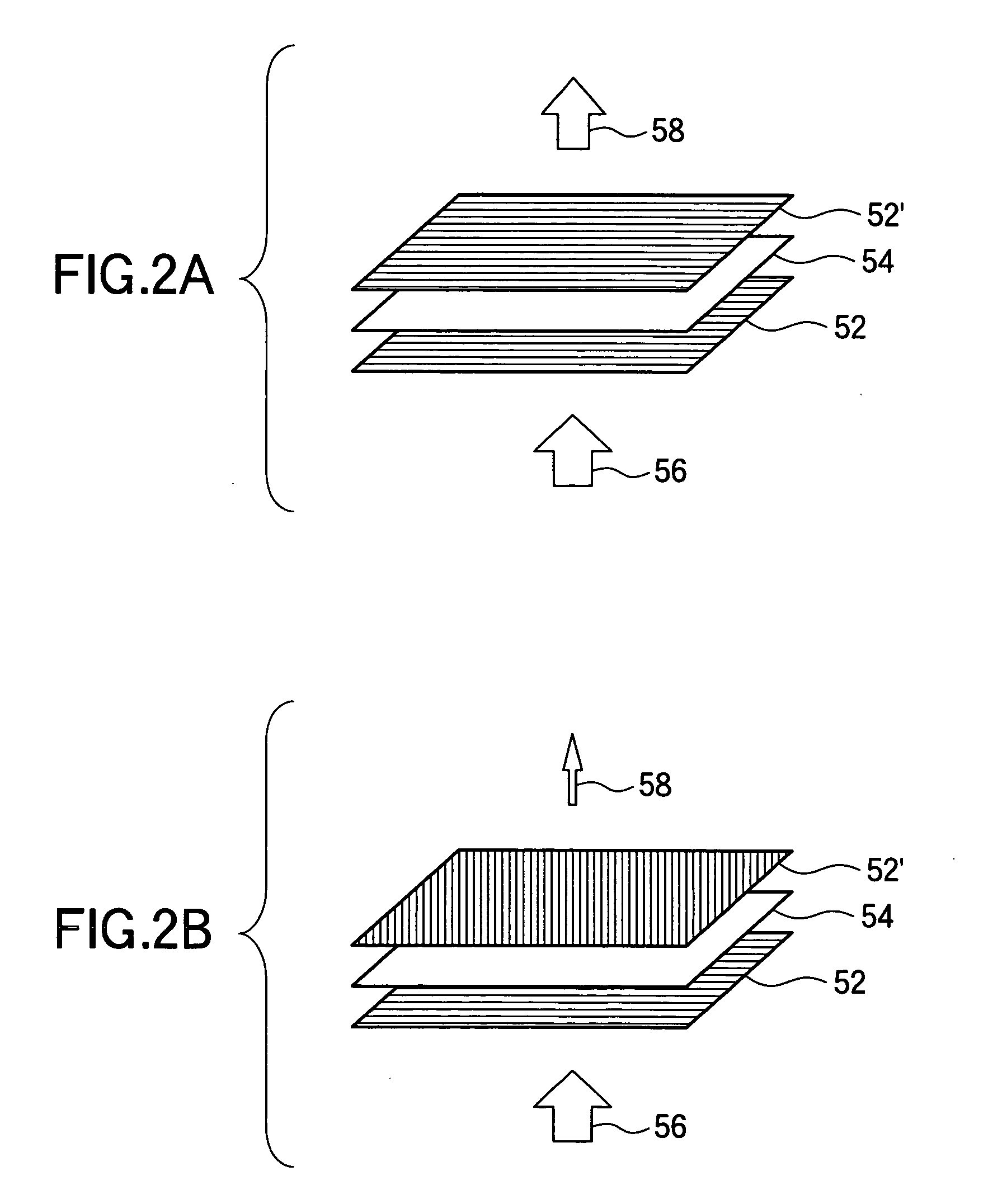

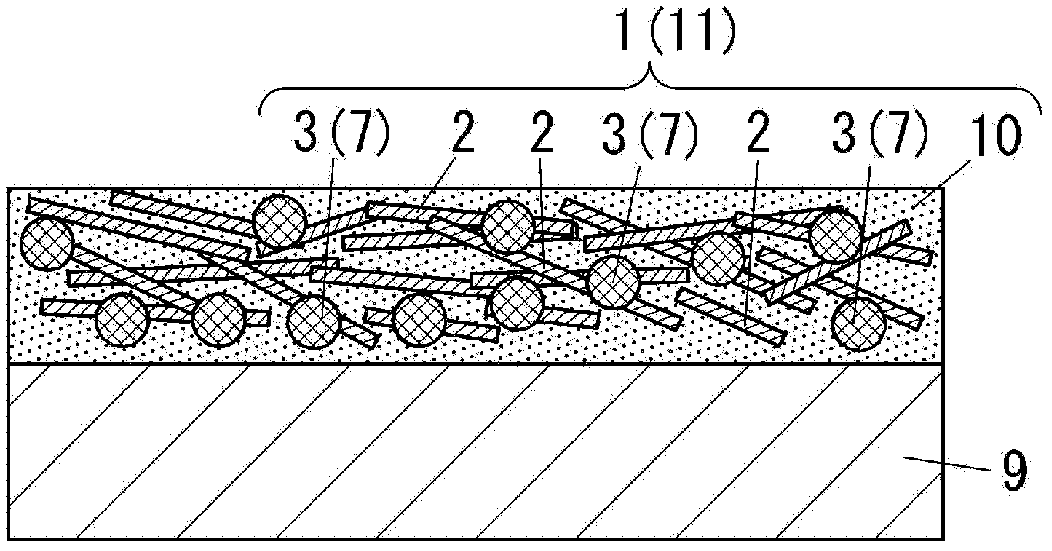

Nanofiber sheet

ActiveUS20110259518A1Reduce level differenceMaterial nanotechnologyAdhesive processes with surface pretreatmentPolymer scienceWater insoluble

A nanofiber sheet including a nanofiber layer containing a polymeric nanofiber, a surface of nanofiber sheet being adhesive. The nanofiber preferably contains an adhesive component and a water insoluble polymer. The nanofiber sheet preferably has a water soluble layer containing a nanofiber containing a water soluble adhesive component and a water insoluble layer containing a nanofiber containing a water insoluble polymer laminated to each other. The nanofiber sheet preferably further includes a base layer located on one side of the nanofiber layer and an adhesive layer located on the other side of the nanofiber layer.

Owner:KAO CORP

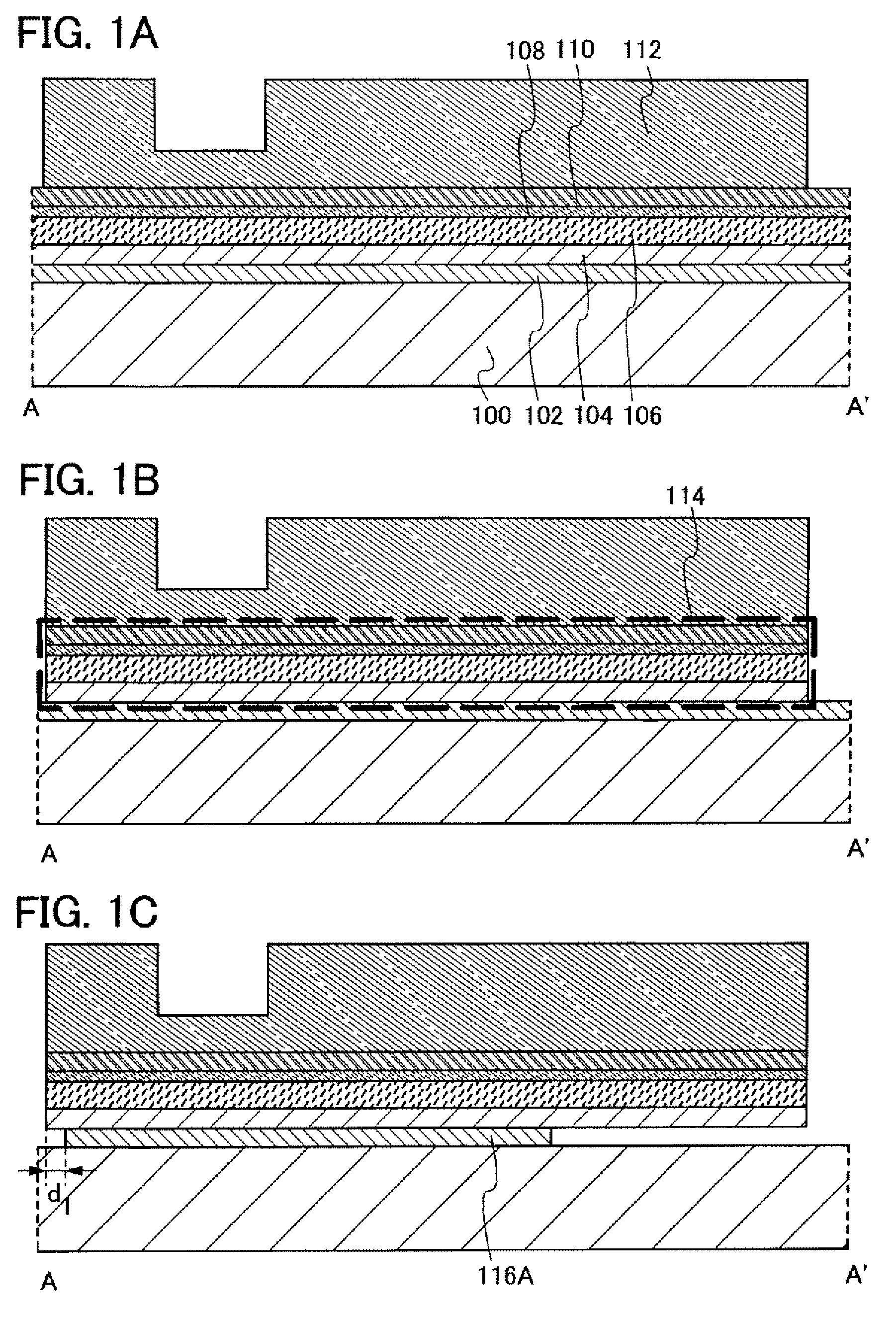

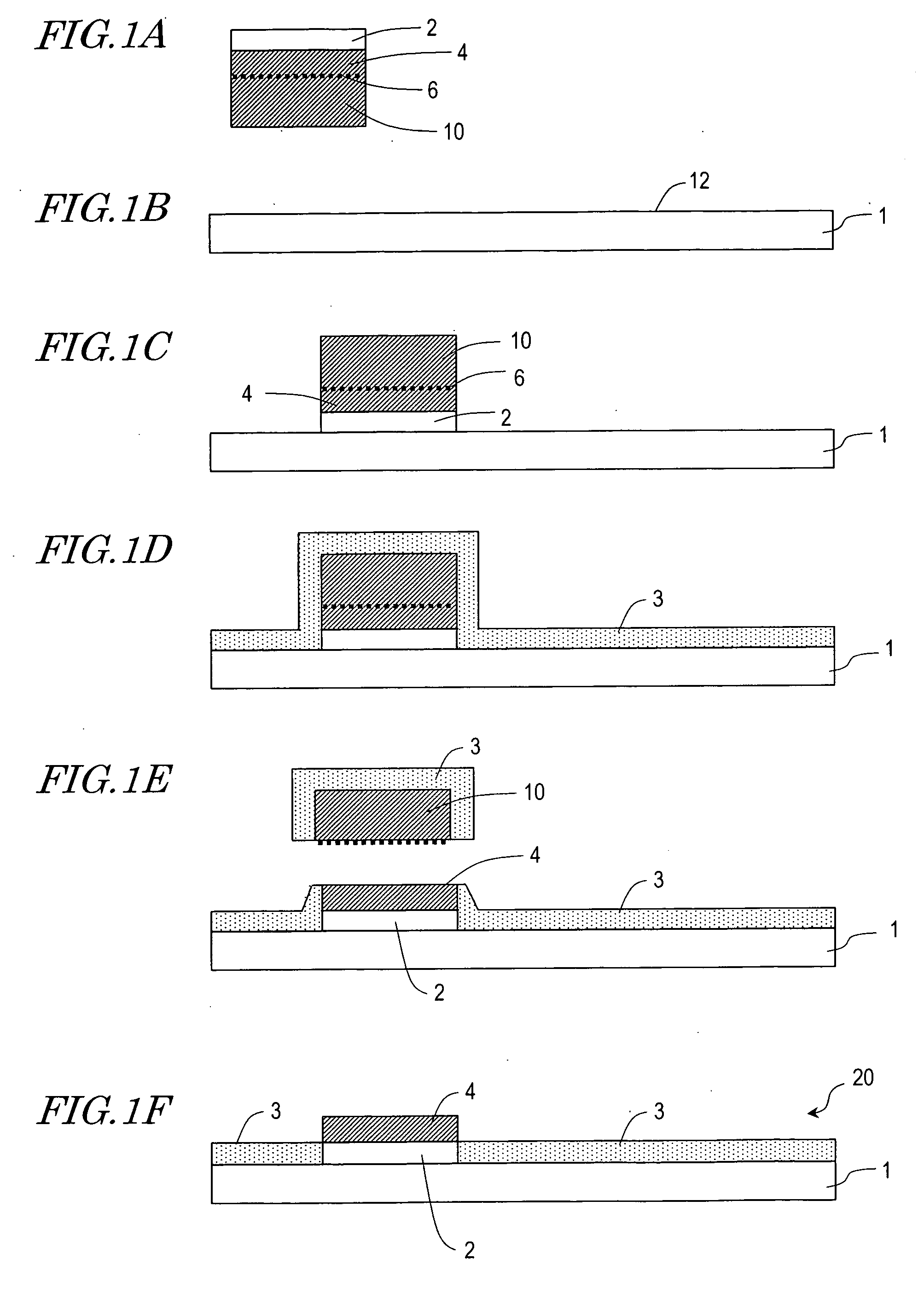

Semiconductor device and method for fabricating the same

ActiveUS20050173761A1Reduce level differenceReduce thicknessTransistorRoller bearingsDevice materialSingle crystal

A semiconductor device includes a substrate with an insulating surface and a single crystal semiconductor layer, which is bonded to the insulating surface of the substrate. The device further includes a first insulating layer, which is provided between the insulating surface of the substrate and the single crystal semiconductor layer, and a second insulating layer, which has been deposited on the entire insulating surface of the substrate except an area in which the first insulating layer is present.

Owner:SHARP KK

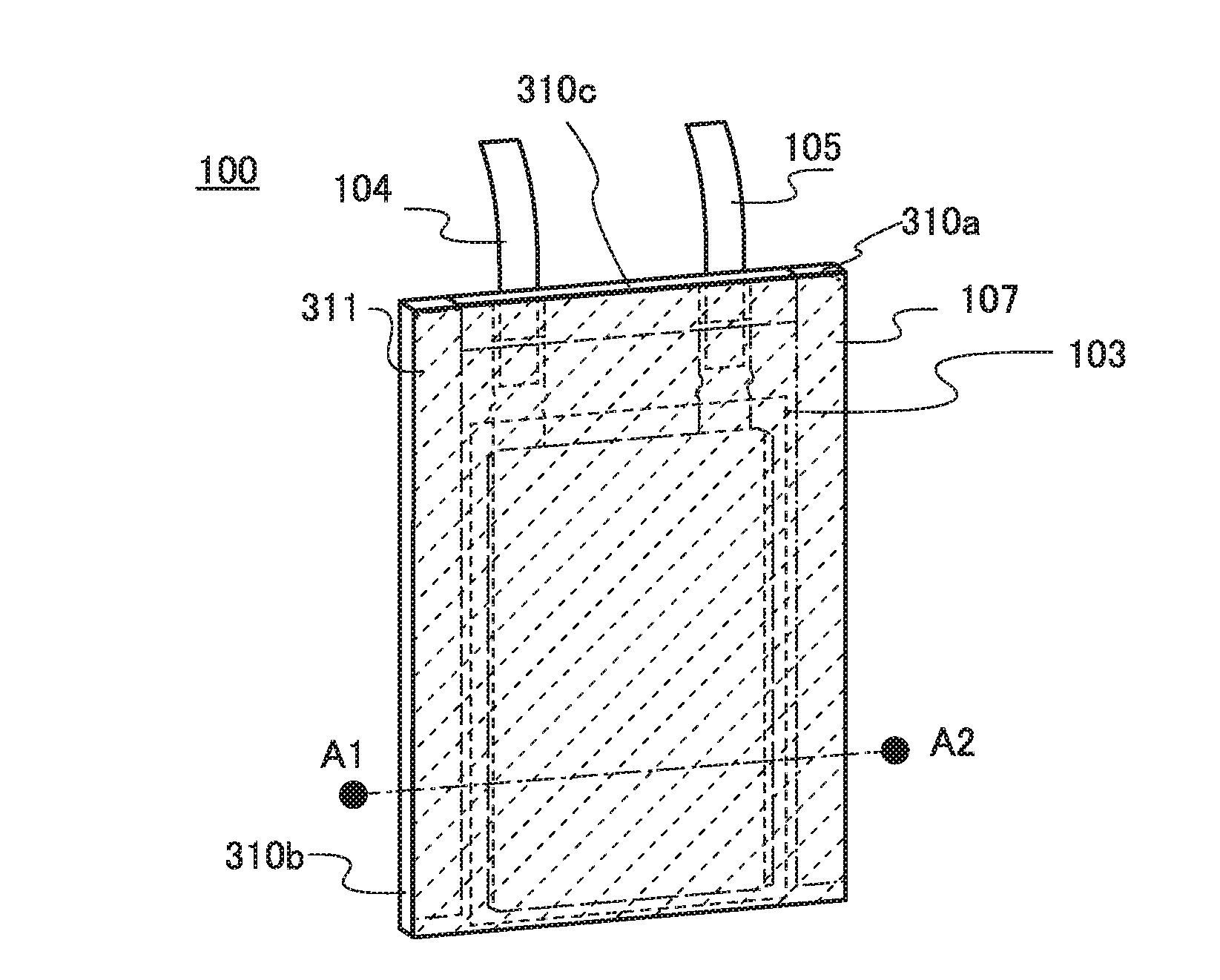

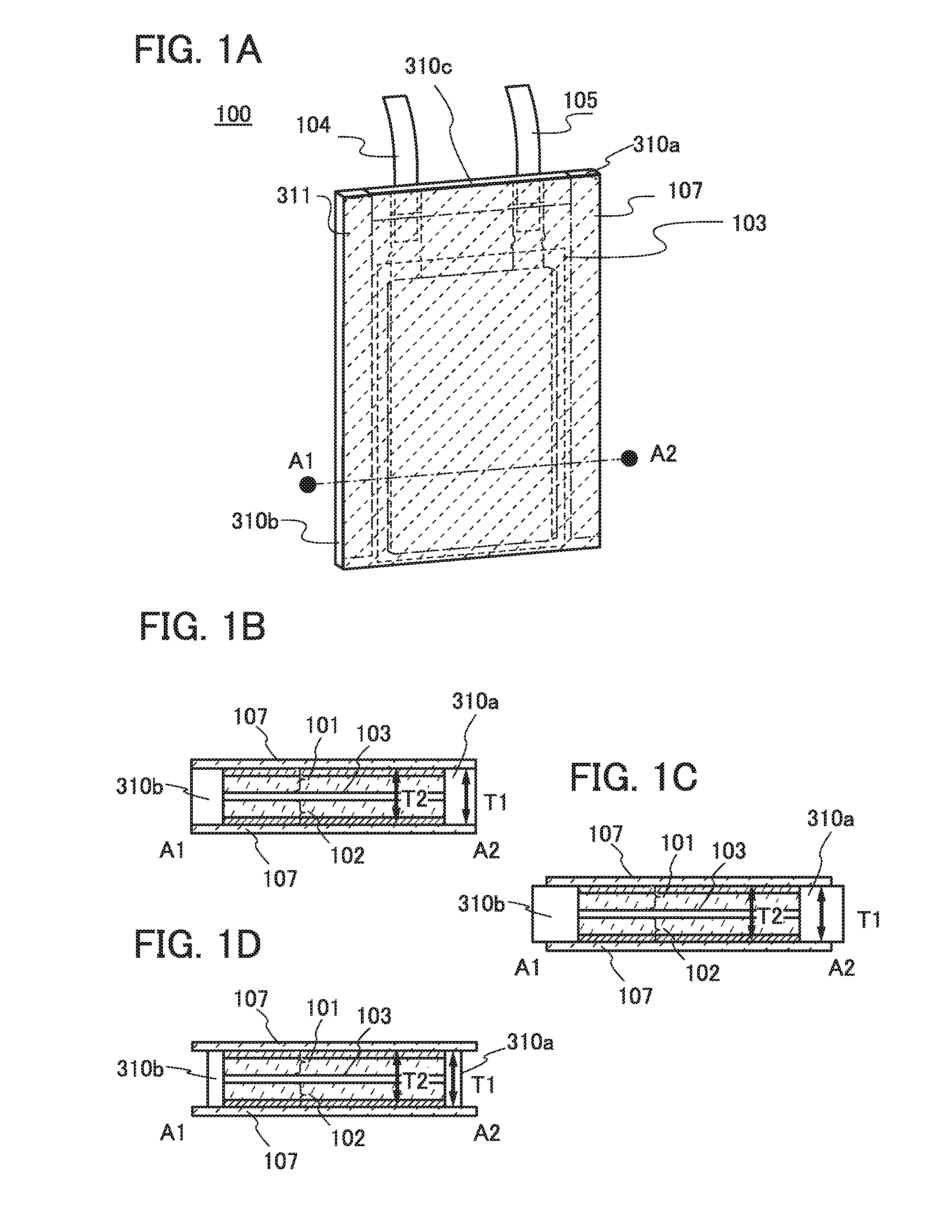

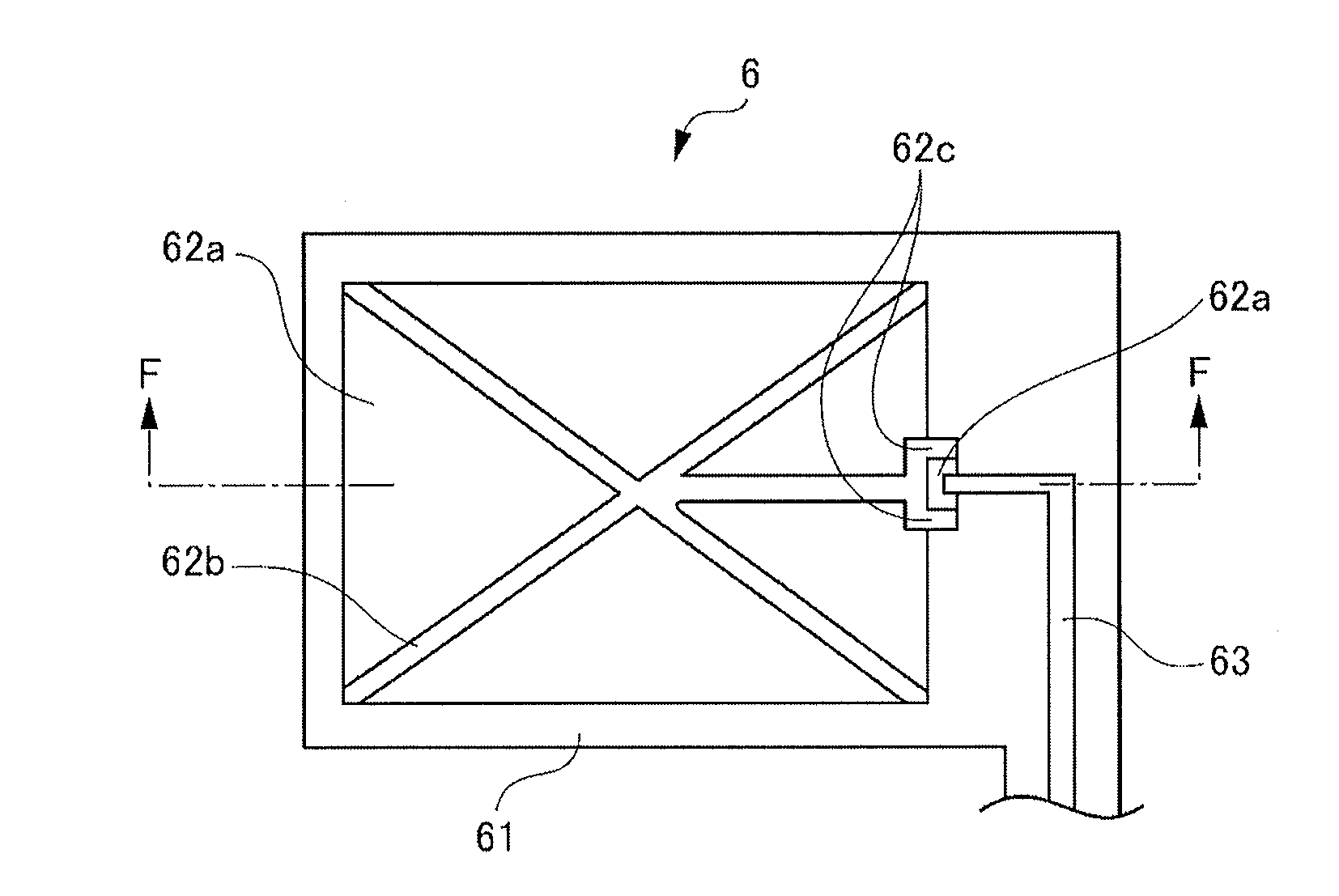

Secondary battery and electronic device

ActiveUS20160218327A1Suppress sharp bendingReduce stress concentrationSmall-sized cells cases/jacketsLarge-sized cells cases/jacketsCushioningElectrical battery

In the case where a film having lower strength than a metal can is used as an exterior body of a secondary battery, a current collector provided in a region surrounded by the exterior body, an active material layer provided on a surface of the current collector, or the like might be damaged when force is externally applied to the secondary battery. A secondary battery resistant to external force is provided. A cushioning material is provided in a region sandwiched by an exterior body of the secondary battery. Specifically, the cushioning material is provided on the periphery of an electrode group including a positive electrode current collector, a positive electrode active material layer formed on at least one surface of the positive electrode current collector, a separator, a negative electrode current collector, and a negative electrode active material layer formed on at least one surface of the negative electrode current collector.

Owner:SEMICON ENERGY LAB CO LTD

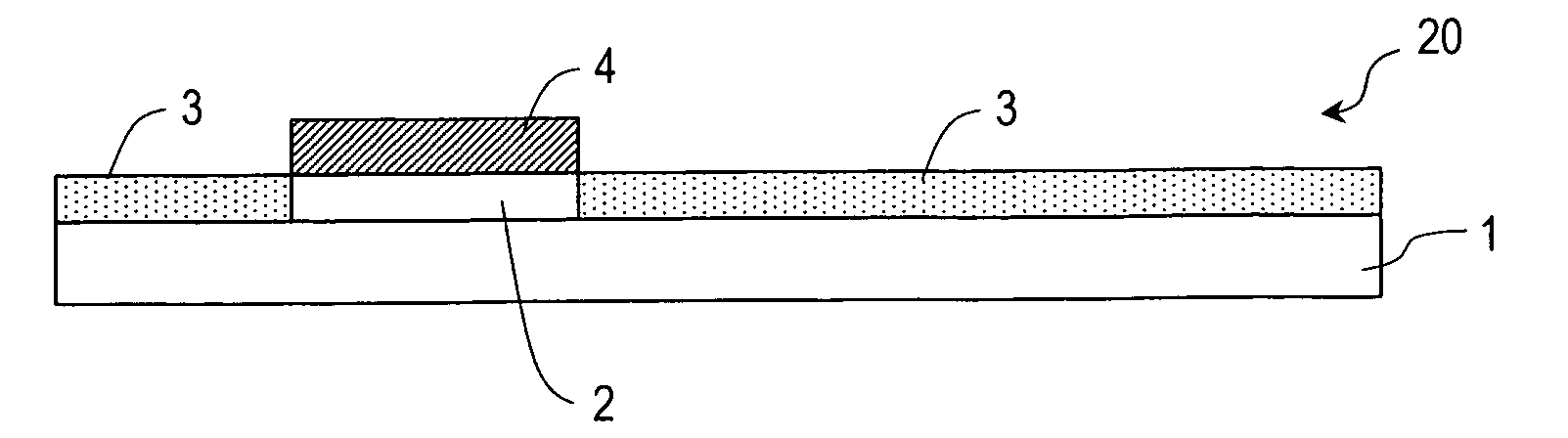

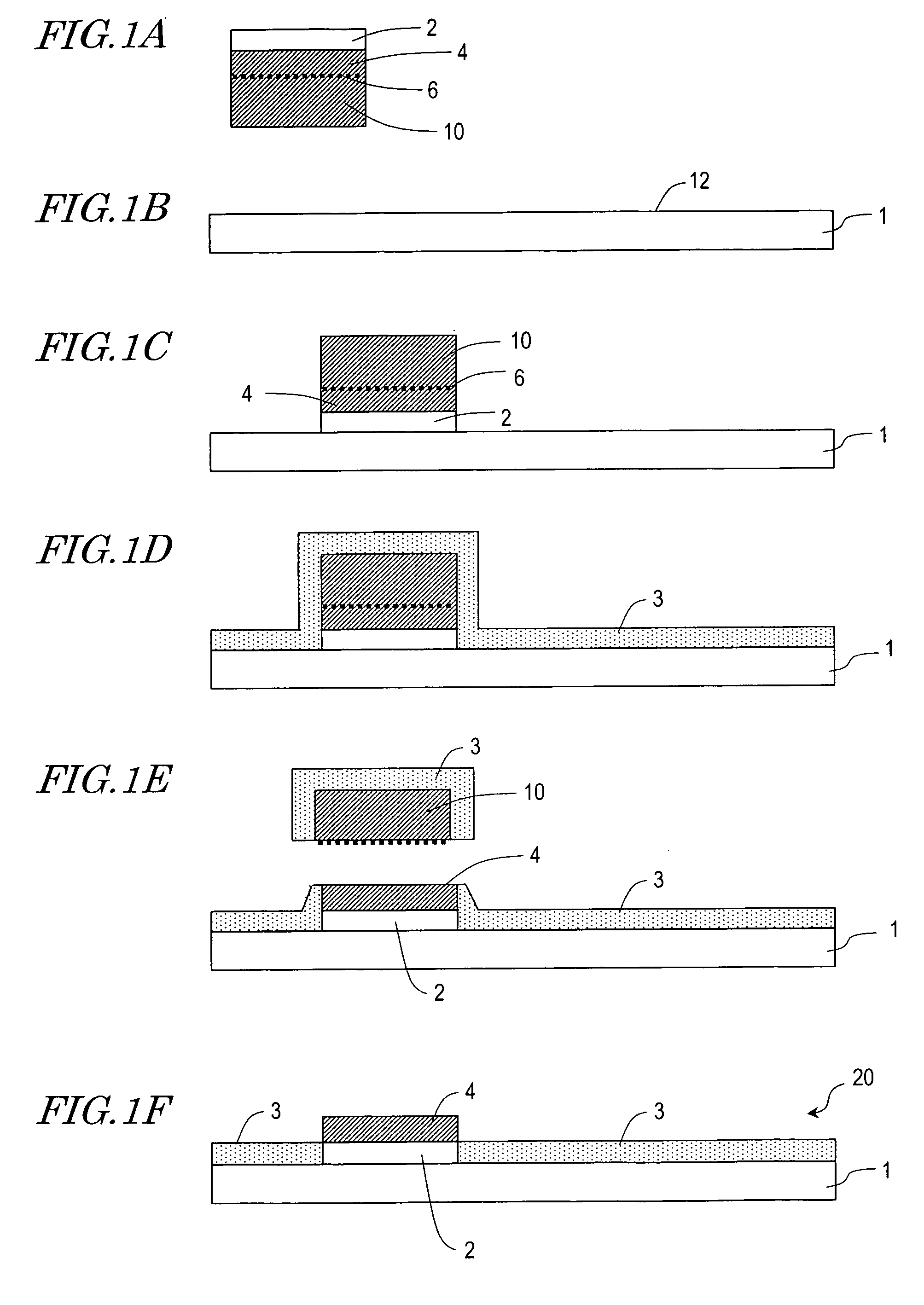

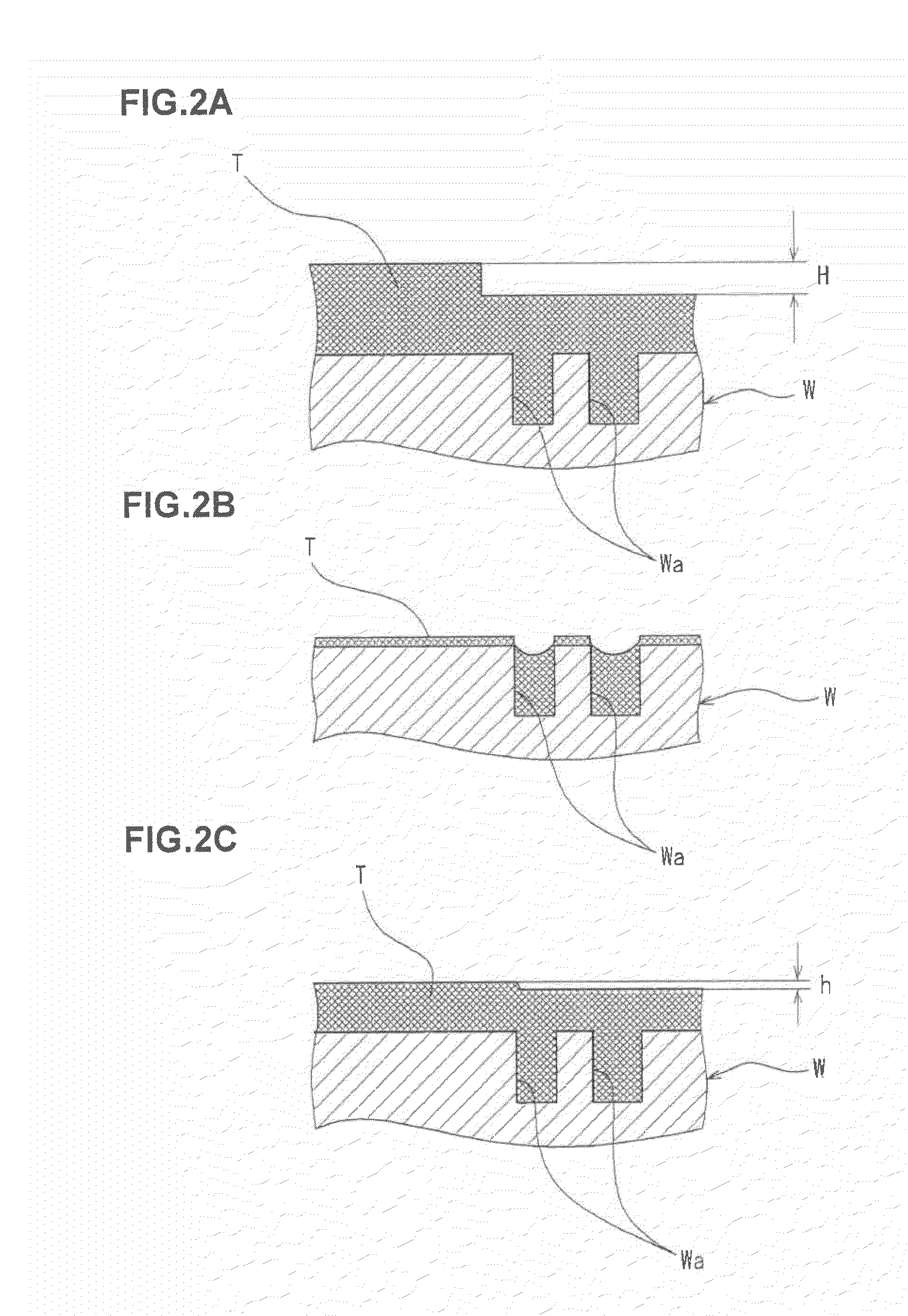

Method of forming buried wiring lines, and substrate and display device using the same

InactiveUS20080239680A1Improve the immunityReduce level differencePrinted circuit aspectsDual purpose resistNanometreCorrosion

An method of forming buried wiring lines makes it possible not to limit usable materials for an insulative plate to those having excellent heat resistance and to improve the corrosion resistance of the terminals provided for the buried wiring lines. The surface of an insulative plate is selectively etched using a mask formed on the surface, thereby forming grooves in the surface. A metallic nanoparticle ink is placed over the whole surface of the plate to fill the grooves with the ink, where the mask is being left. The ink is heated for preliminary curing to form a metallic nanoparticle ink film. The part of the film placed on the mask is selectively removed by detaching the mask, thereby leaving the remainder of the film in the grooves. The remaining film in the grooves is heated for main curing, thereby forming desired buried wiring lines.

Owner:NEC LCD TECH CORP

Liquid crystal display

InactiveUS20050128381A1Maintain whitenessReduce level differenceOptical filtersNon-linear opticsTransmittanceResist

In order to suppress color tint during display of black, chromaticity is changed when black is displayed while maintaining chromaticity when white is displayed. For this purpose, the pigment to be dispersed in a color resist is adjusted in particle size and concentration. Such adjustment is so performed that the chromaticity difference between displayed white and black becomes 0.01 or smaller in the x-y chromaticity coordinates by varying the transmissivity of color pixels during display of black. With such a structure, successfully provided is a color liquid crystal display capable of preventing color tint in displayed black, while keeping white chromaticity at the desired level.

Owner:SHARP KK

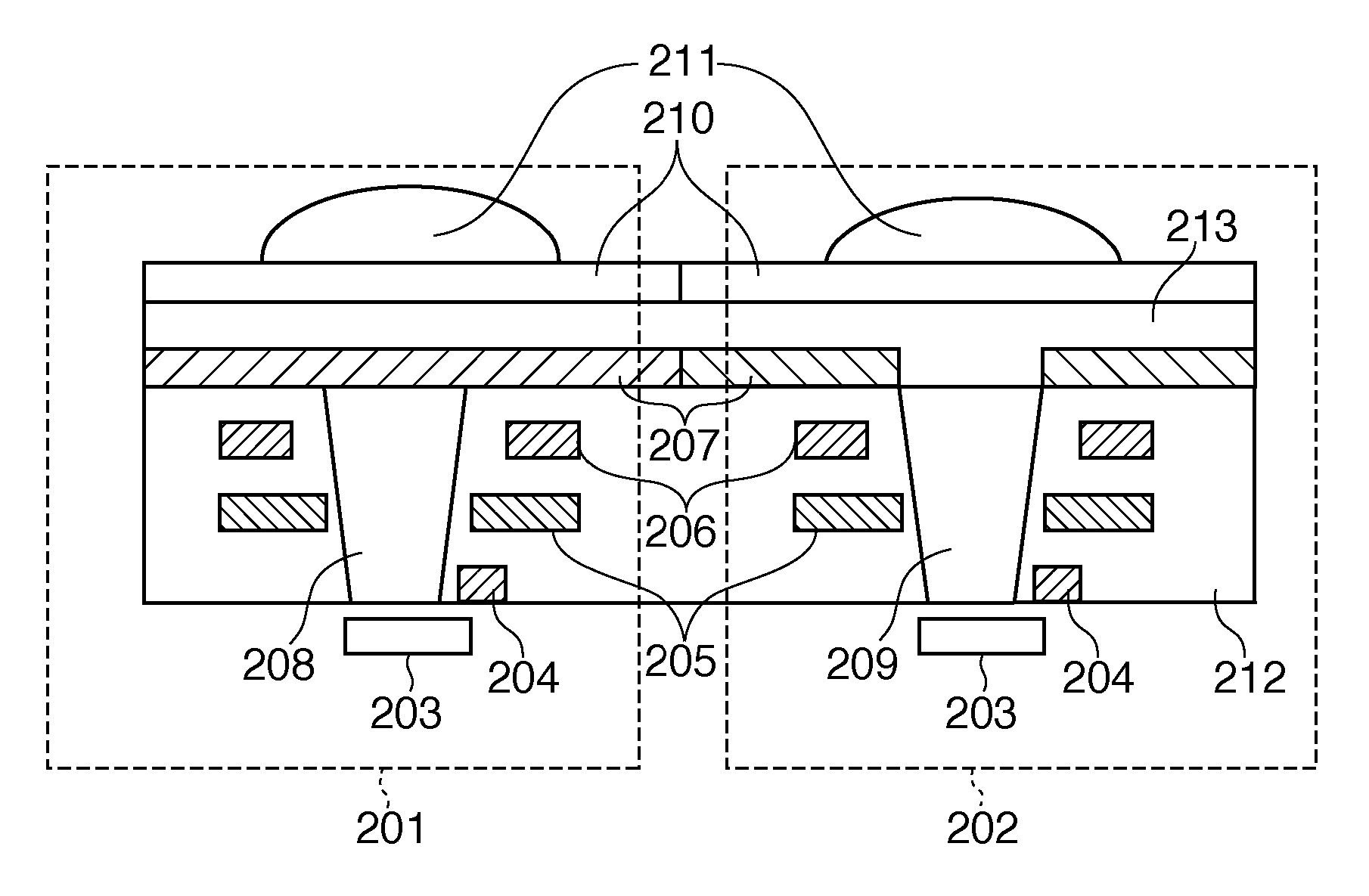

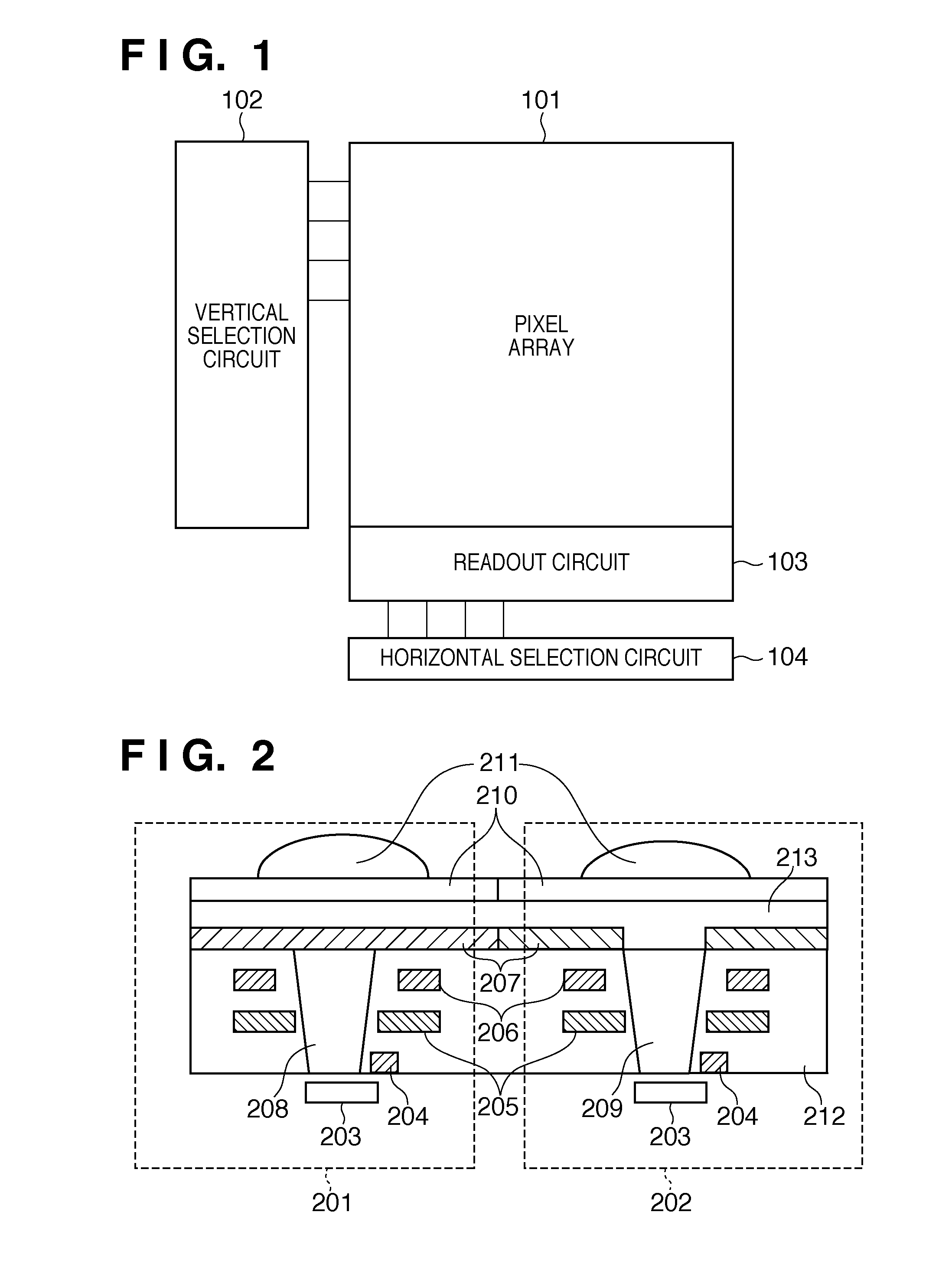

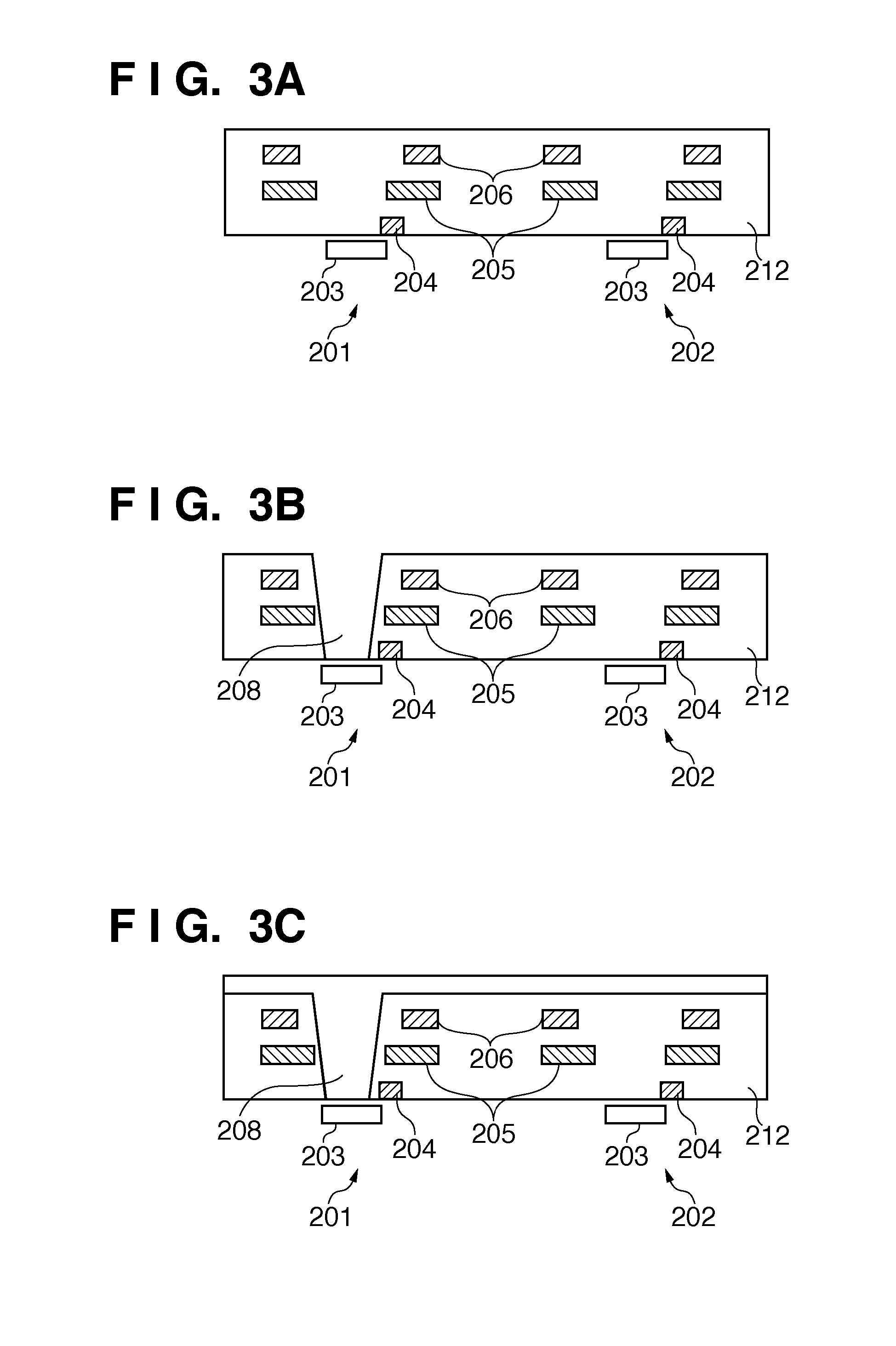

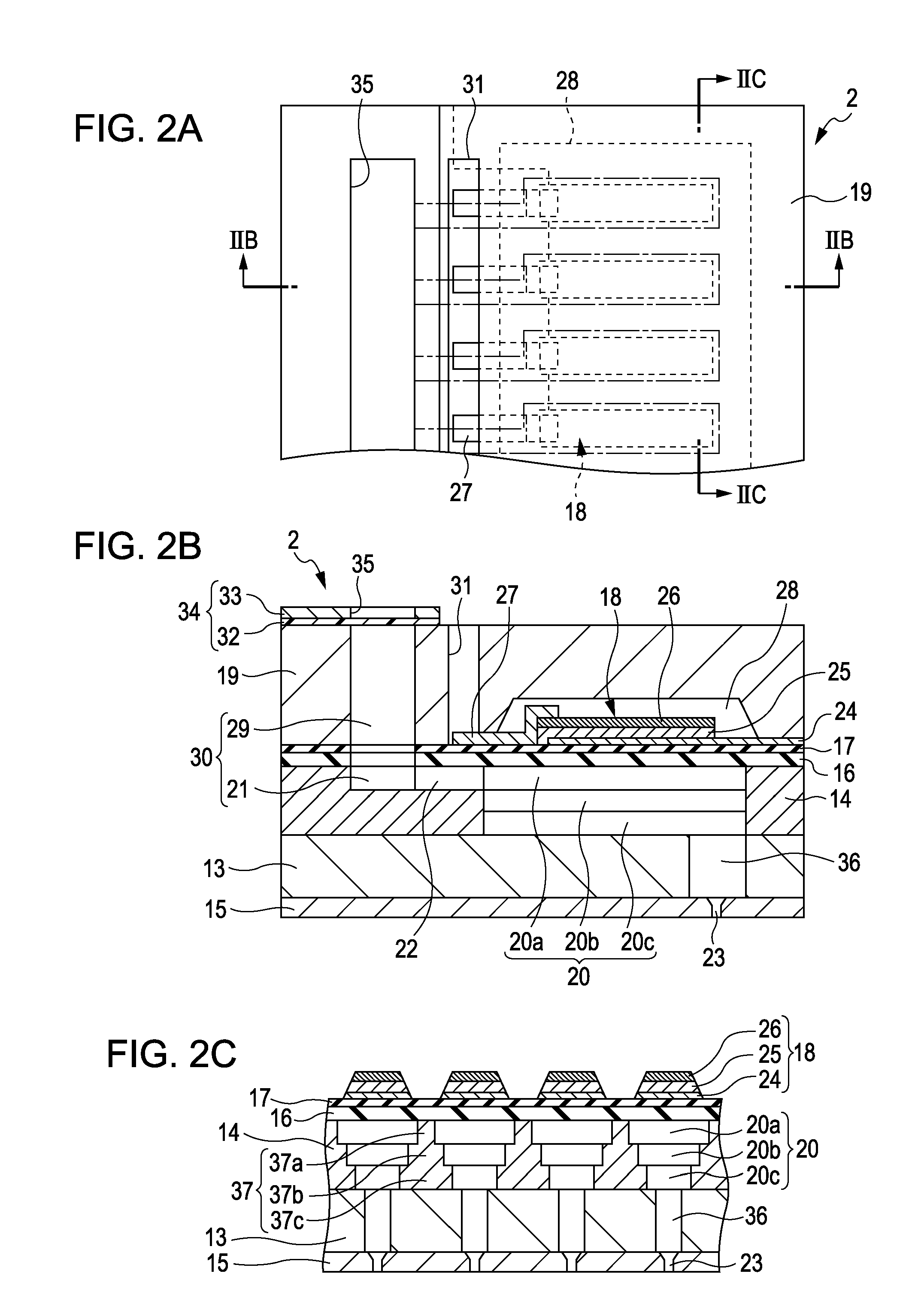

Image sensor and manufacturing method thereof

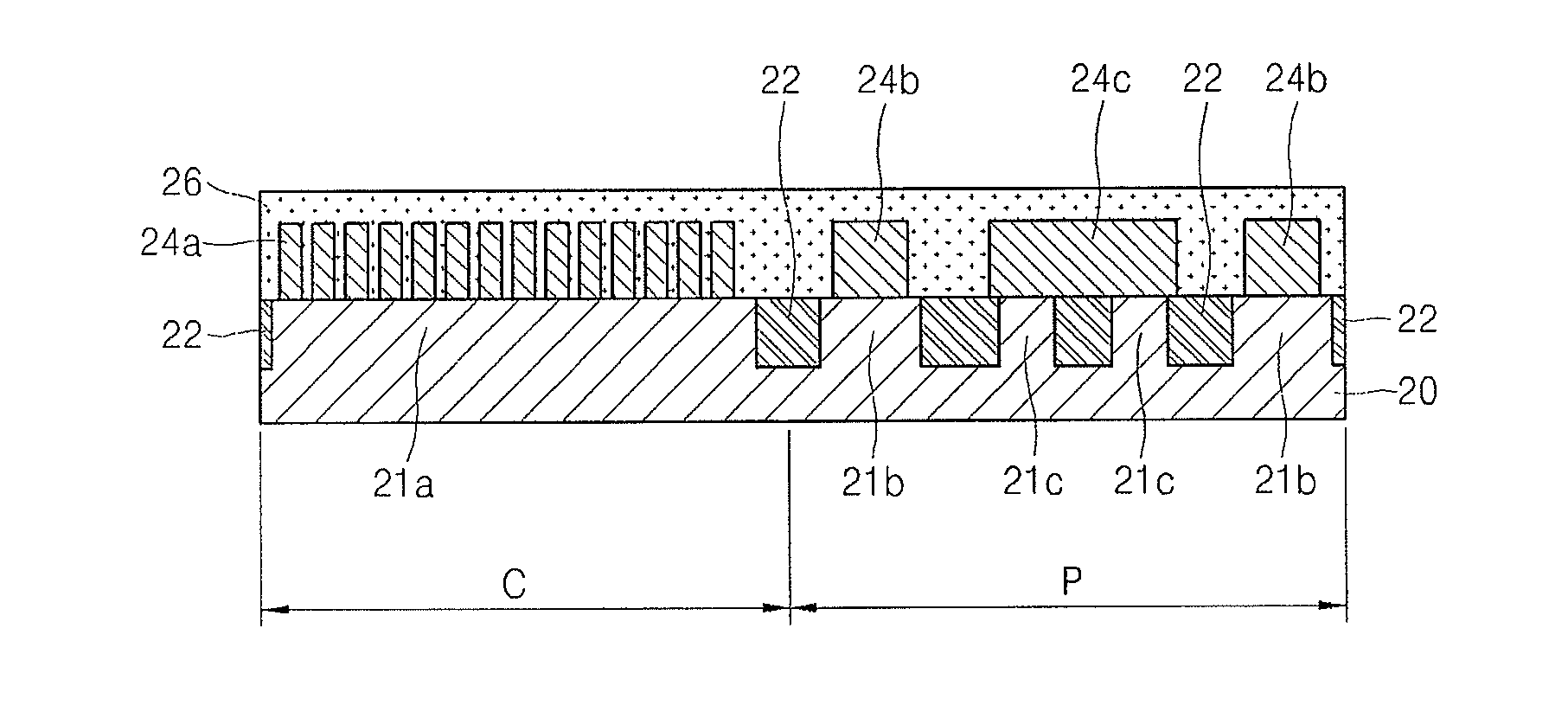

InactiveUS20120012964A1Reduce level differenceTelevision system detailsSolid-state devicesImage sensorEngineering

An image sensor includes: a photoelectric conversion pixel having a photoelectric conversion element that performs photoelectric conversion, and a light guide formed of a first material in an interlayer insulation film above the photoelectric conversion element; and a light-shielded pixel having a photoelectric conversion element that performs photoelectric conversion, a light guide formed of a second material that is different from the first material in an interlayer insulation film above the photoelectric conversion element, and a light-shielding layer formed above the light guide.

Owner:CANON KK

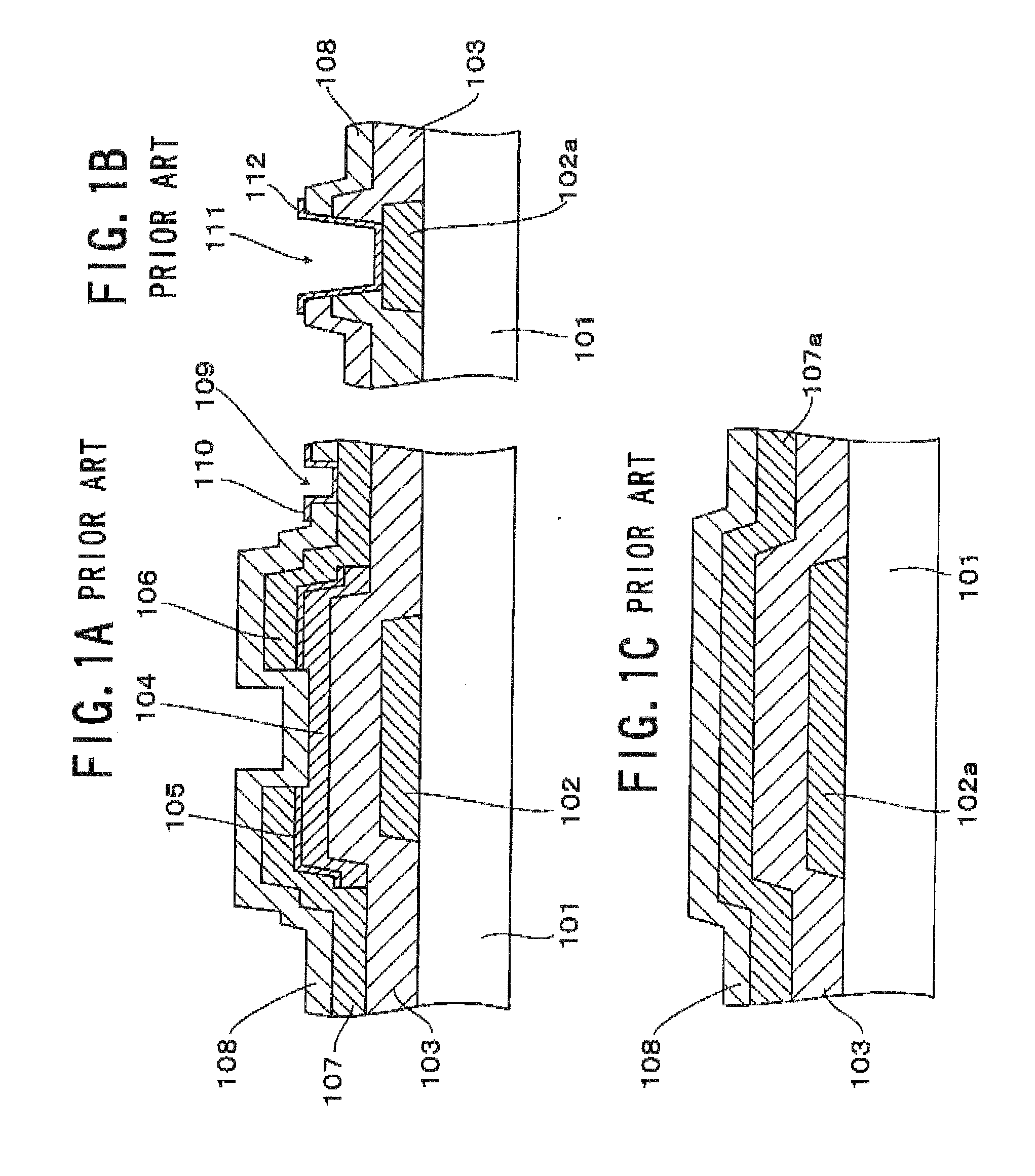

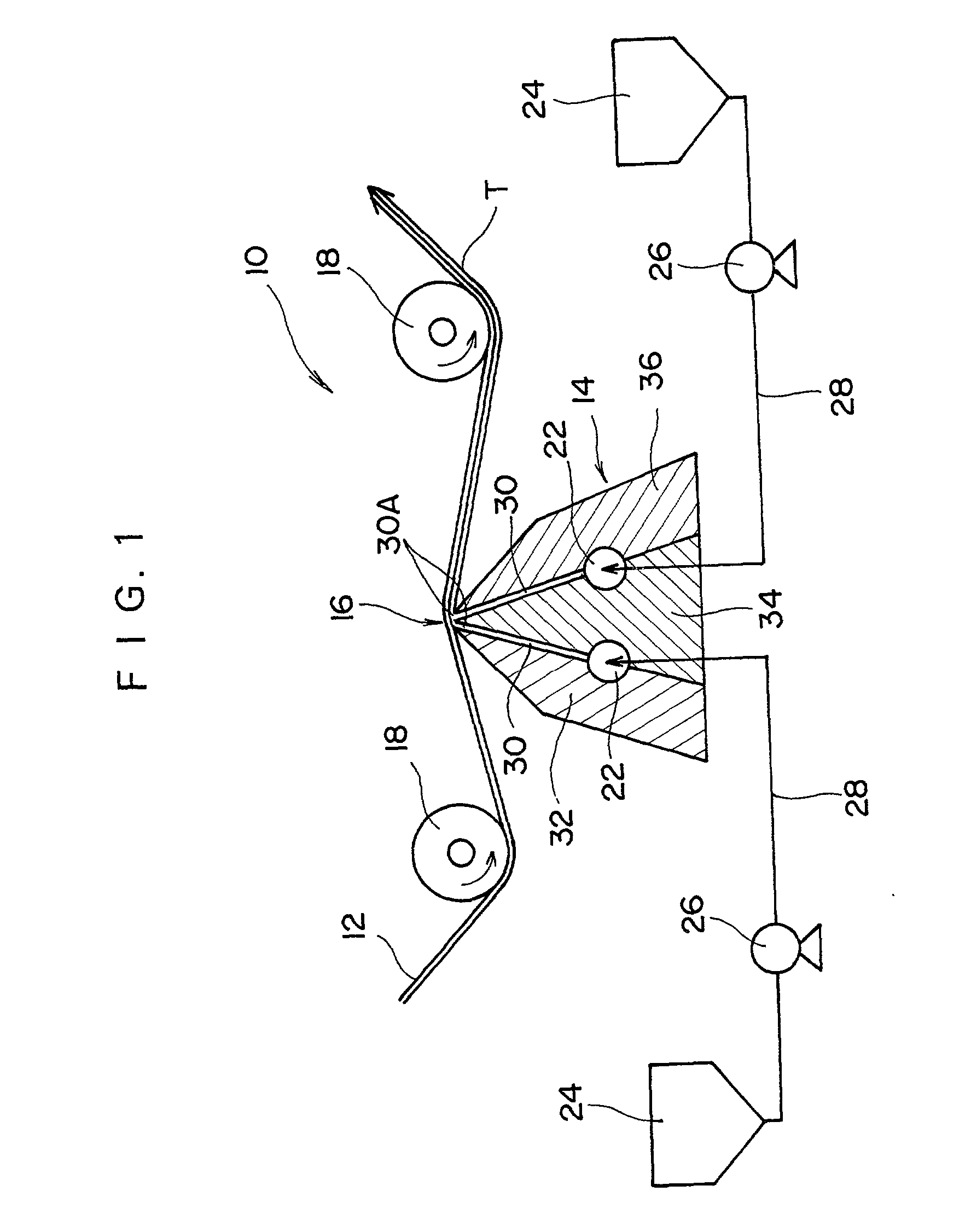

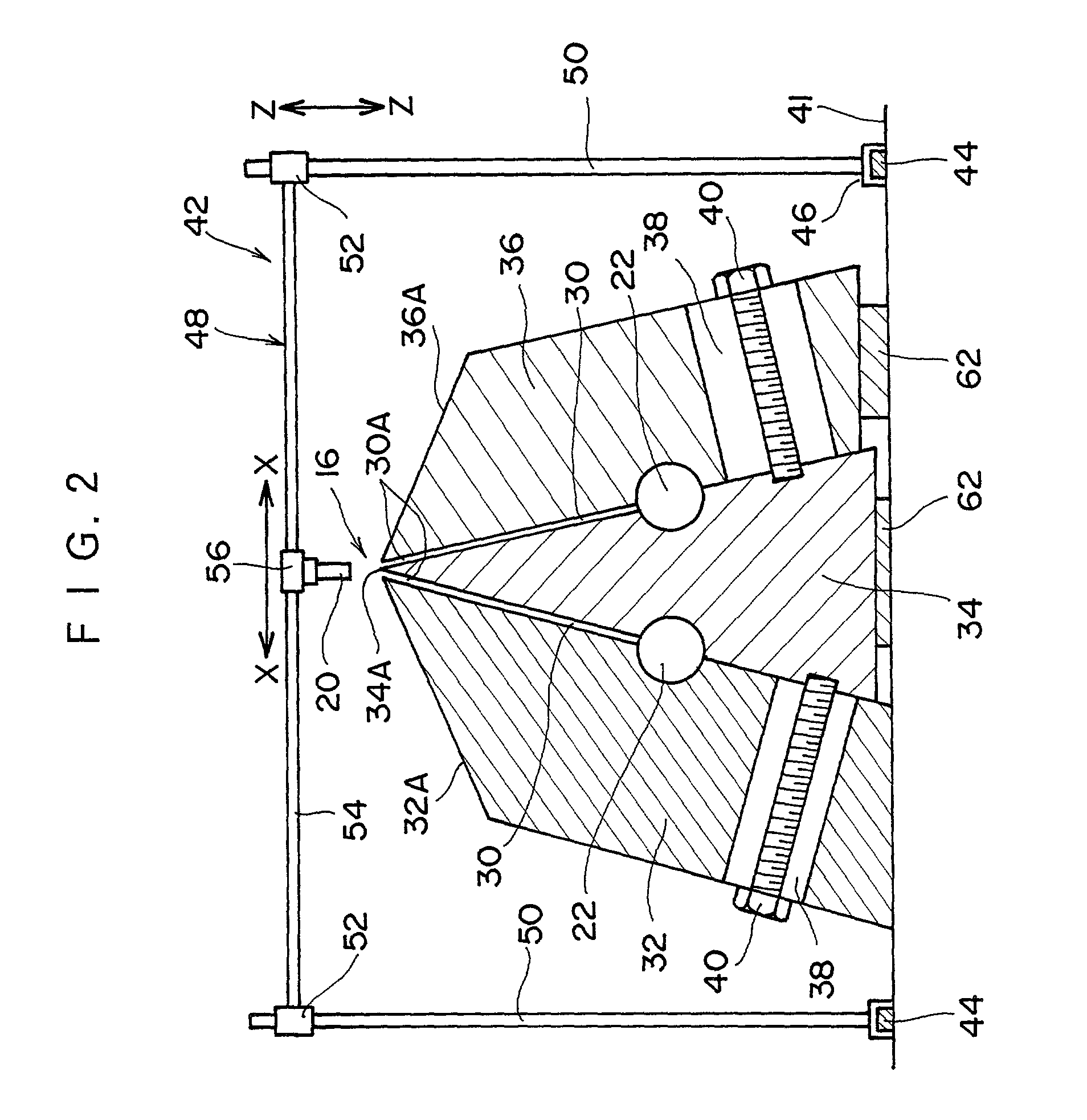

Discrepancy correction method and apparatus for correcting difference in levels of image signals obtained by an image sensor having a multiple output channels

InactiveUS7324236B2Reduce level differenceDigital computer detailsVisual presentationCorrection methodImage signal

Image signals output from a linear image sensor which outputs charges accumulated in pixels in the right-side area and charges accumulated in pixels in the left-side area via different channels are subjected to discrepancy correction. First, a gray reference board is scanned by the linear image sensor while changing charging periods, and look up tables for converting signal levels of the respective channels are generated on the basis of signal levels obtained by scanning the gray reference board. A discrepancy correction is realized by converting levels of image signals output from the two terminals using the look up tables.

Owner:CANON KK

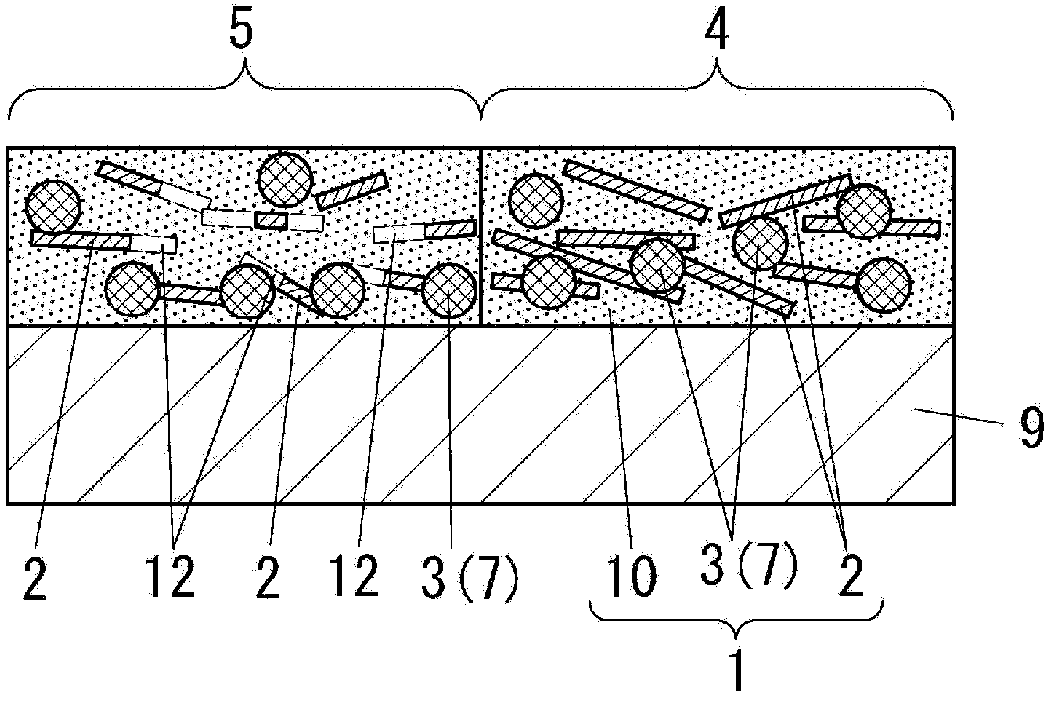

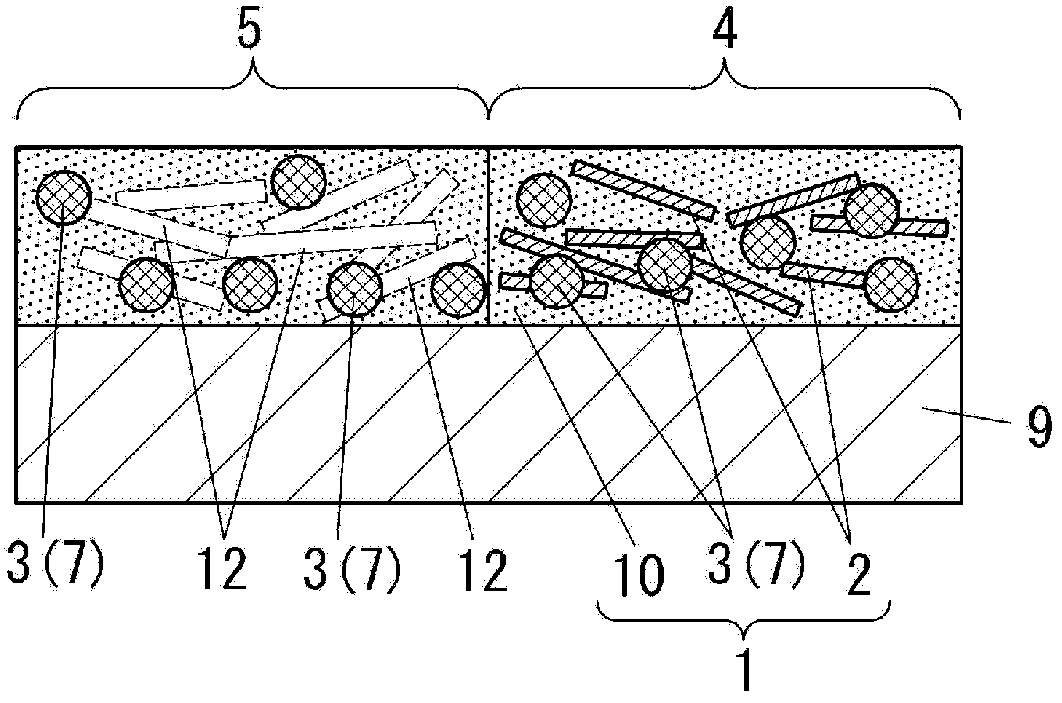

Transparent conductive film, substrate with transparent conductive film, and method for manufacturing same

InactiveCN103460304AReduce aspect ratioReduce the numberMaterial nanotechnologyConductive layers on insulating-supportsNanowireNanoparticle

Provided is a transparent conductive film that is capable of converting a conductive portion to an insulating portion more easily and more quickly than in the past, and also capable of reducing the step between the conductive portion and the insulating portion. A conductive portion (4) and an insulating portion (5) are formed. The conductive portion (4) contains a resin component (10), a metallic nanowire (2), and an insulating reinforcement component (3). The insulating reinforcement component (3) is a nanoparticle with higher light absorbency than the metallic nanowire (2). The insulating portion (5) contains either a resin component (10) and no metallic nanowire (2), or a resin component (10) and a metallic nanowire (2) with a smaller aspect ratio than the abovementioned metallic nanowire (2).

Owner:PANASONIC CORP

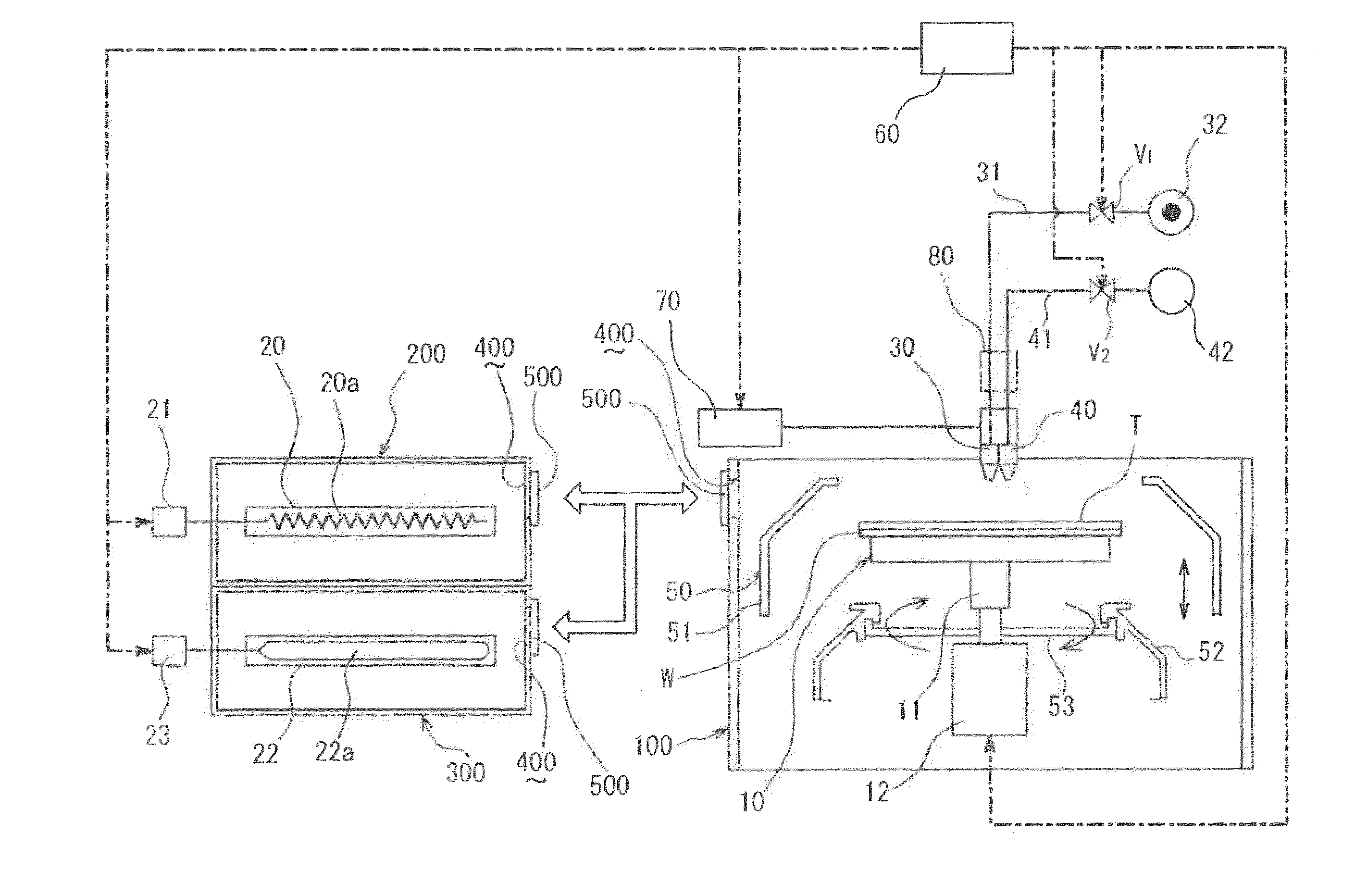

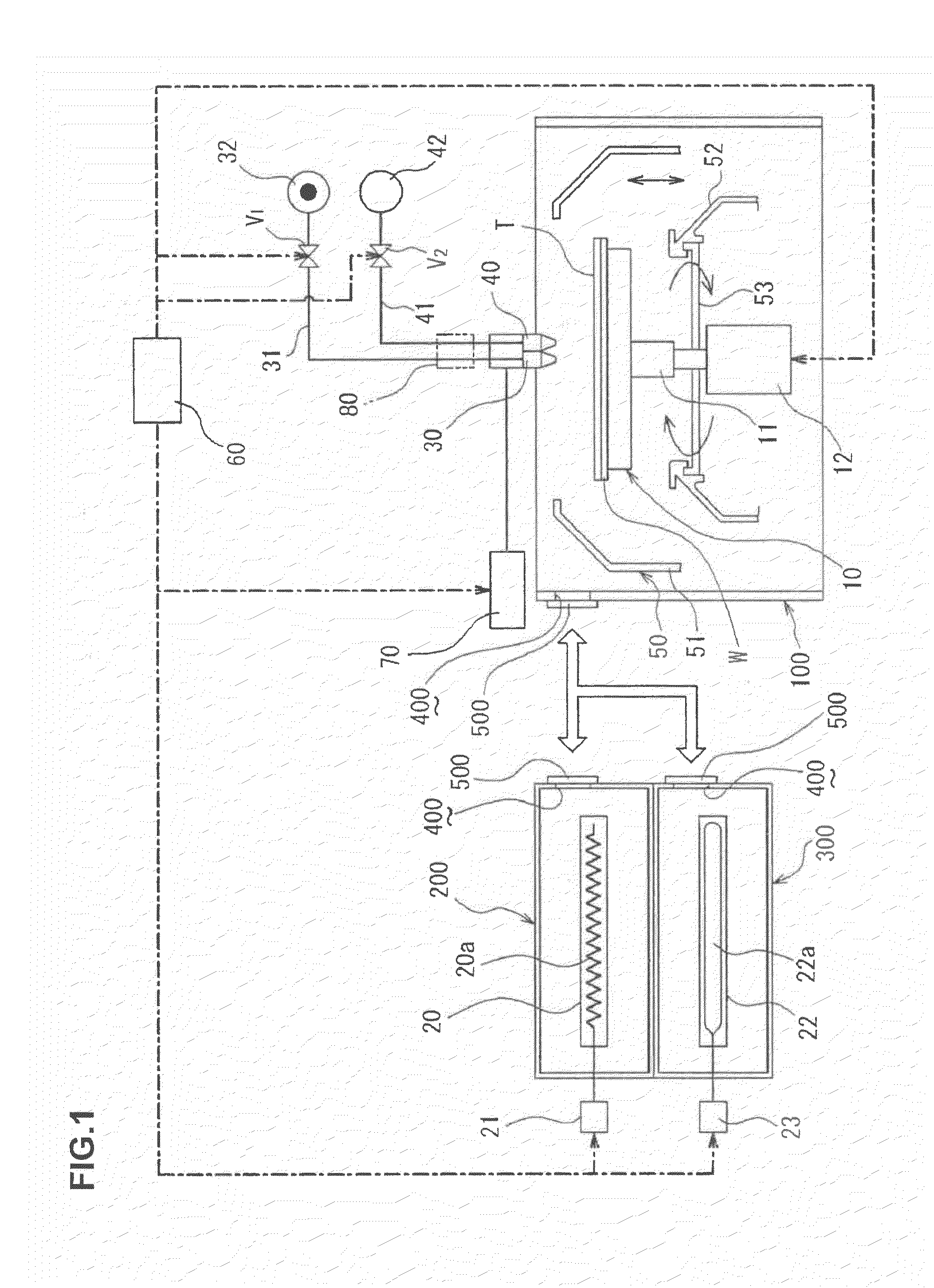

Substrate treatment apparatus and substrate treatment method

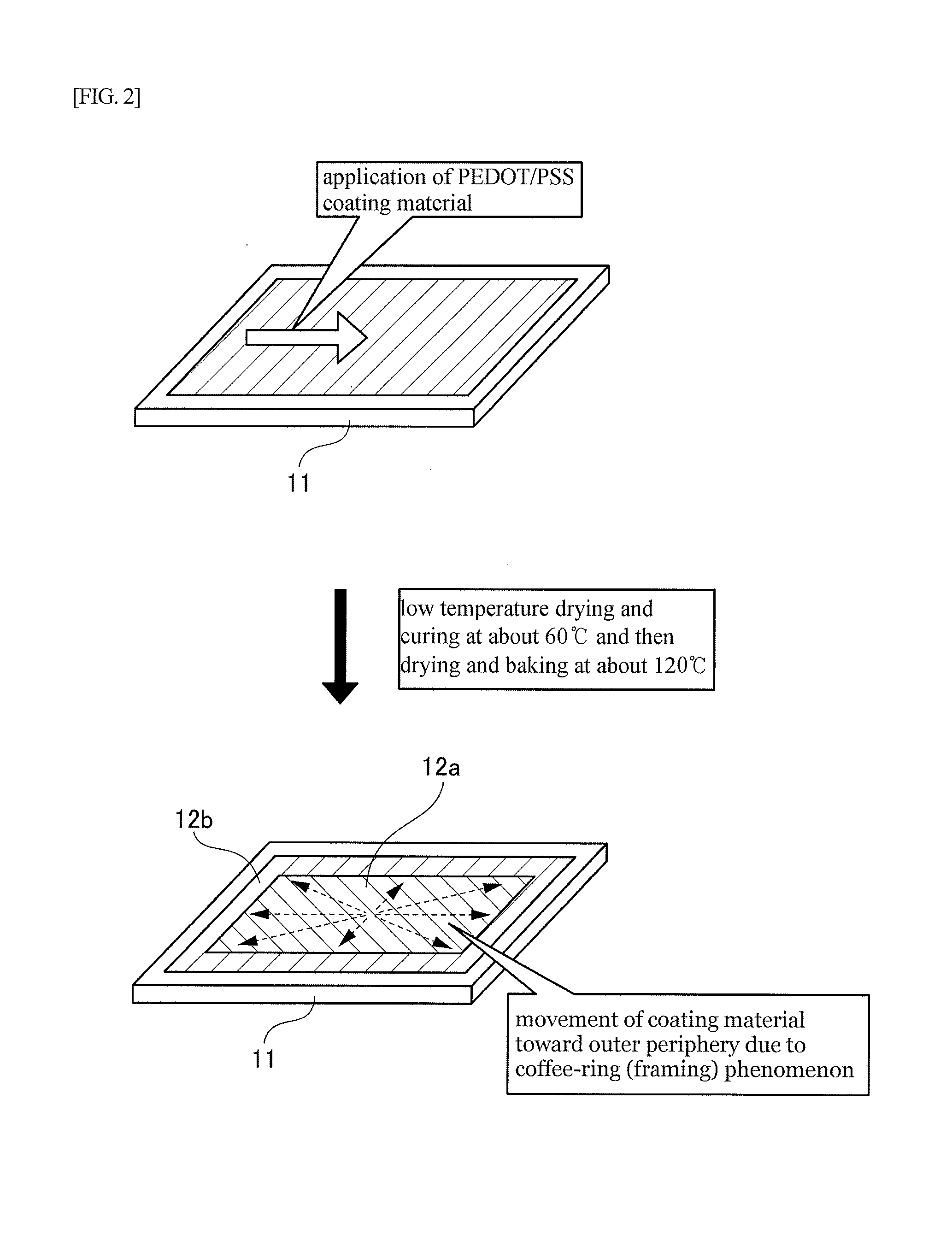

ActiveUS20110030897A1Reduce level differenceLower substrate temperatureLiquid surface applicatorsPhotomechanical apparatusHigh loadNanotechnology

Owner:TOKYO ELECTRON LTD

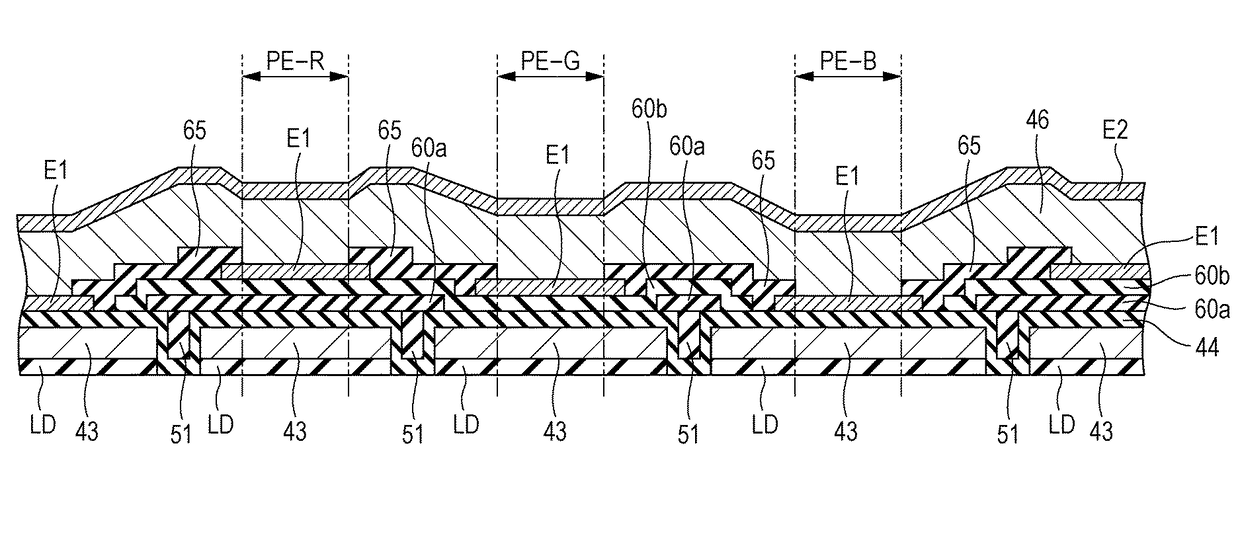

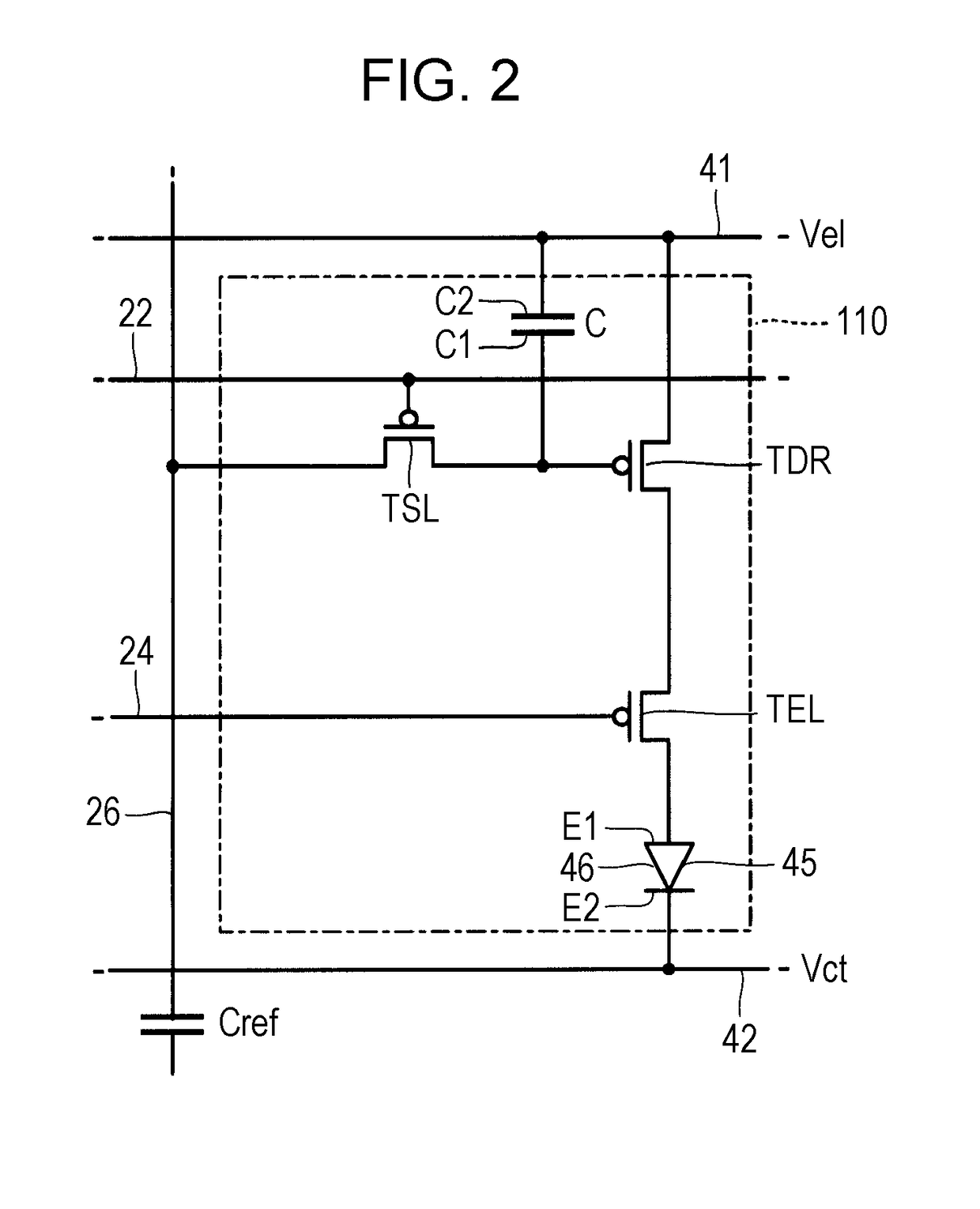

Organic el device, method for manufacturing organic el device, and electronic instrument

ActiveUS20170352842A1High luminosityImprove color stability and reliabilitySolid-state devicesSemiconductor/solid-state device manufacturingOptical pathOptical path length

An organic EL device has at least a first pixel and a second pixel different in the optical path length, in which the first pixel and the second pixel have a reflective layer, a protective layer, an optical path length adjusting layer, a first electrode, a light emitting function layer, and a second electrode, and the optical path length adjusting layer is an insulating layer and has a refractive index higher than a refractive index of the protective layer.

Owner:SEIKO EPSON CORP

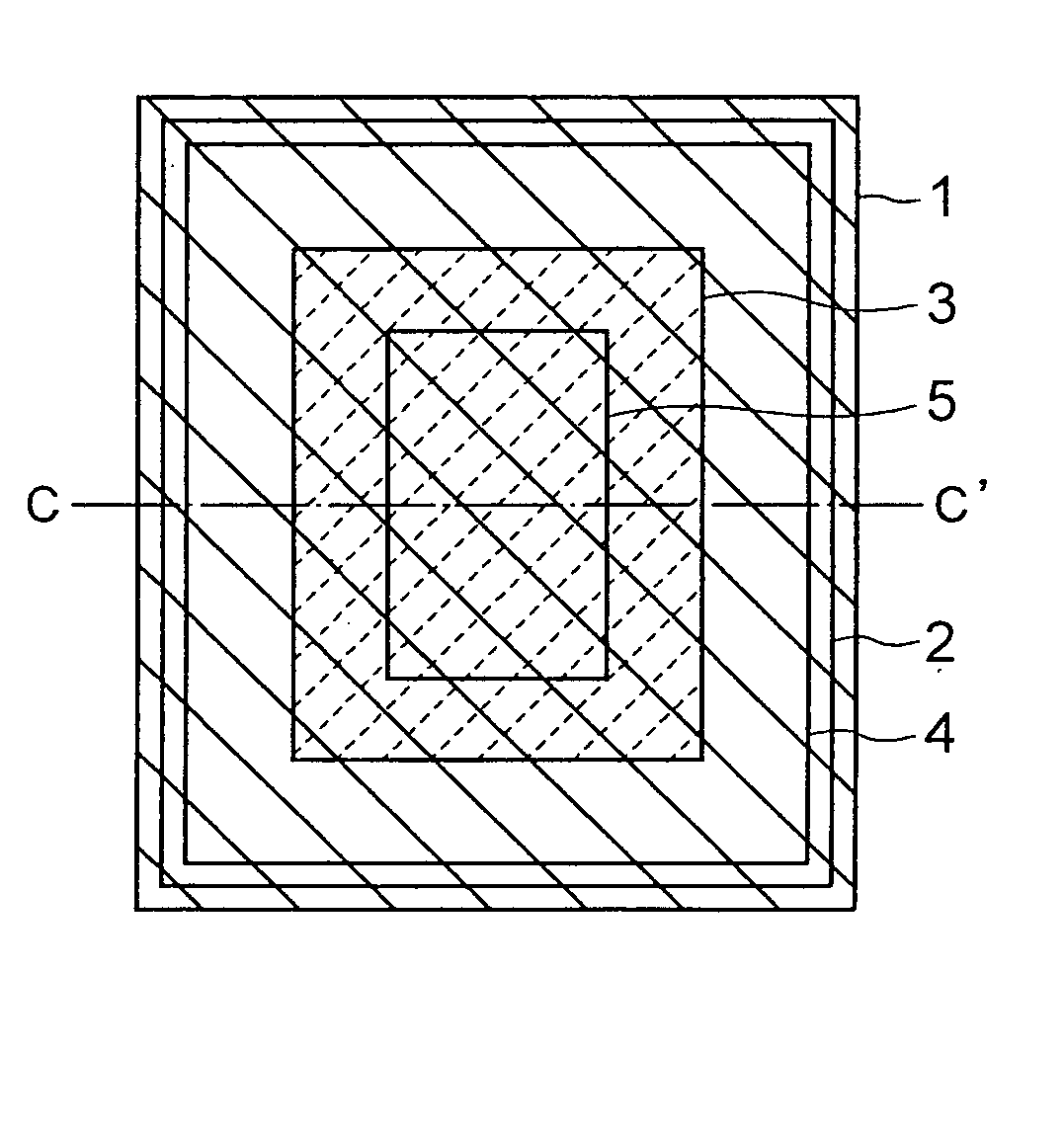

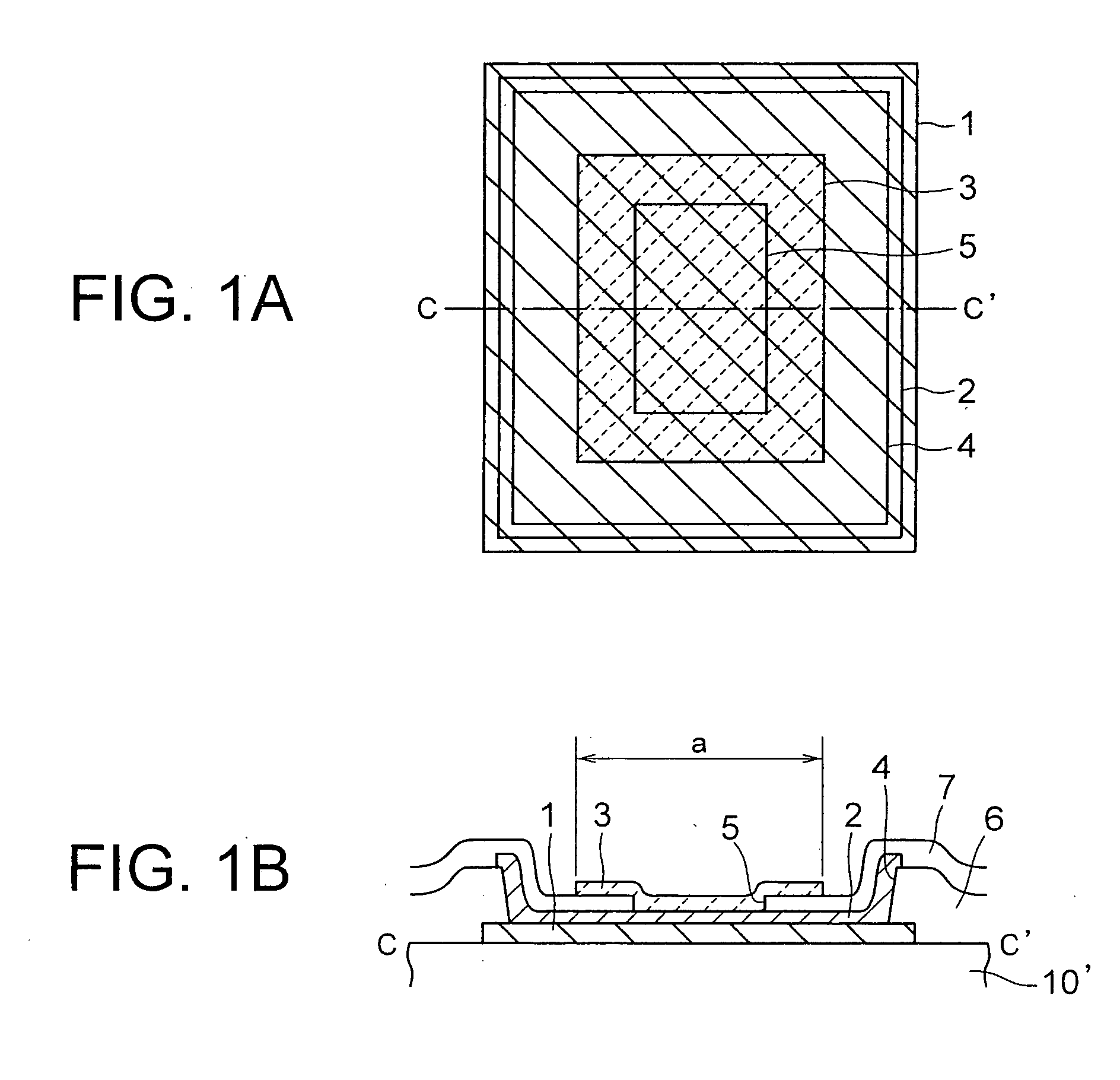

LCD device having a smaller level difference

ActiveUS20040239857A1Reduce level differenceReduce the amount requiredNon-linear opticsRubbingPhysics

The TFT substrate of an LCD device has an array of pixel electrodes defined by a plurality of signal lines and a plurality of scanning lines. Each terminal of the scanning lines includes a first metallic pattern, a second metallic pattern in contact with the first metallic pattern through a first via hole, and an ITO pattern in contact with the second metallic pattern through a second via hole. The ITO pattern has a width smaller than the width of the first via hole and larger than the second via hole, thereby providing the TFT substrate with a smaller level difference. The smaller level difference prevents the dust generated during a rubbing treatment from attaching onto the TFT substrate.

Owner:HANNSTAR DISPLAY CORPORATION

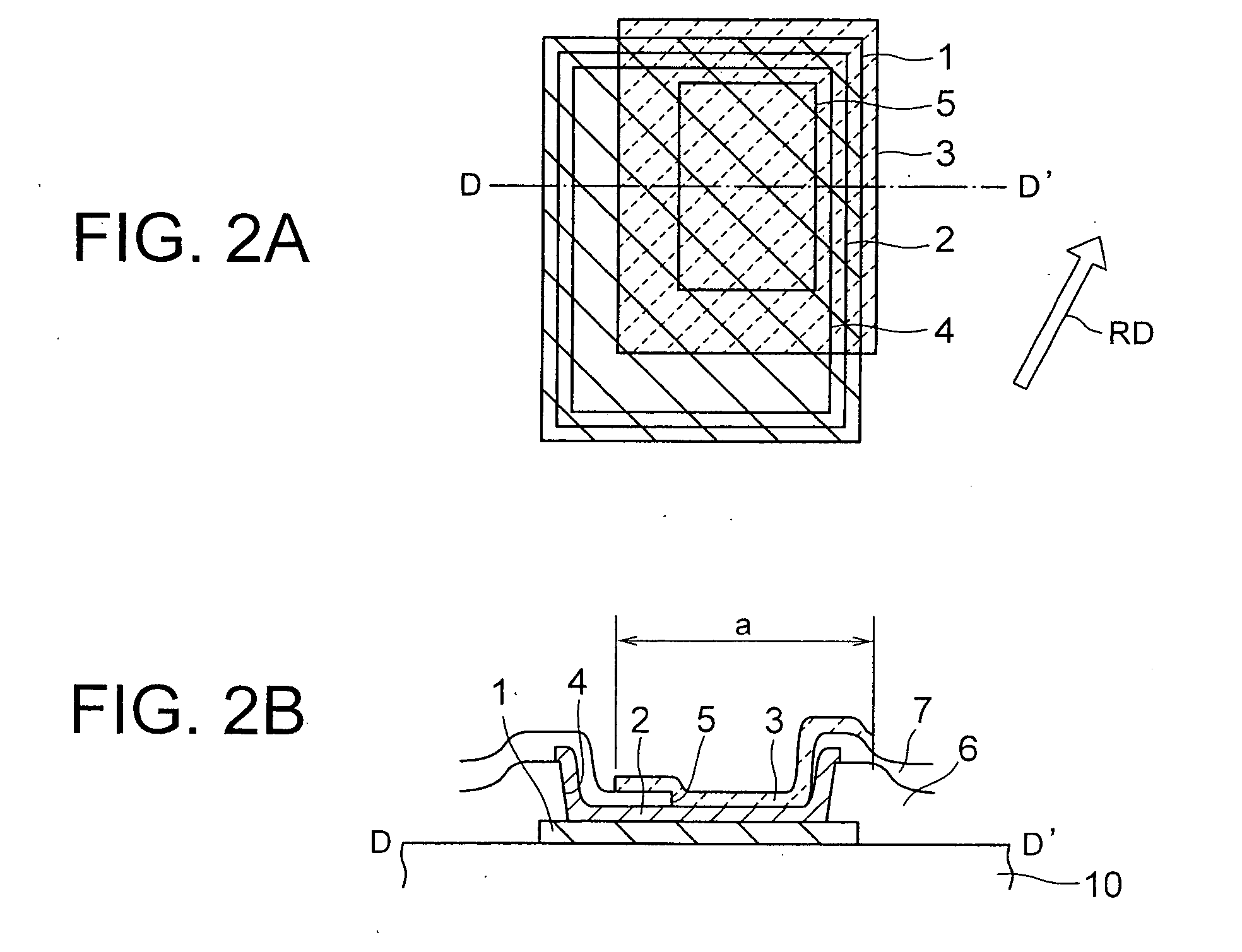

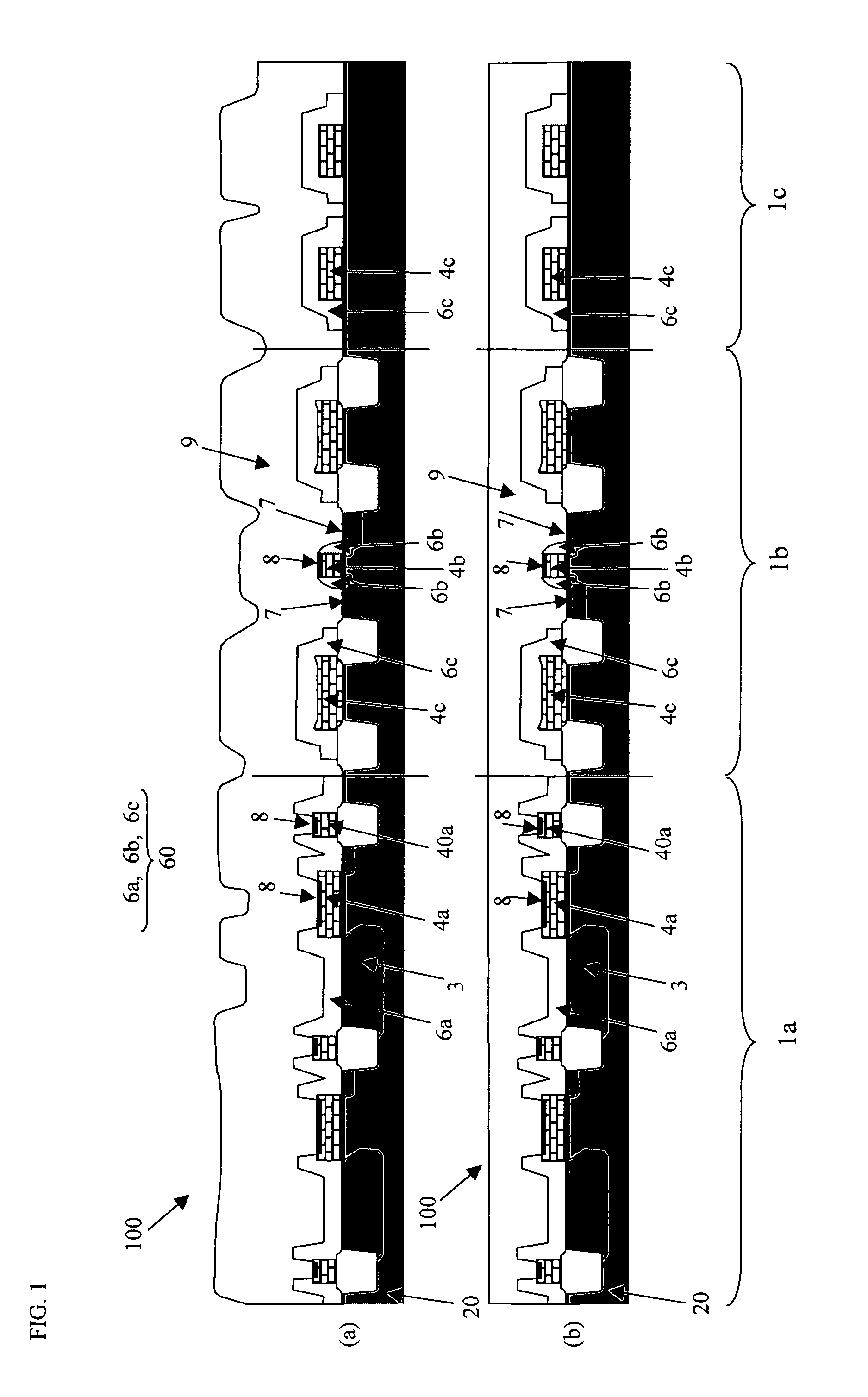

Solid-state imaging device and method for fabricating the same

ActiveUS20080087976A1High resolutionReduce level differenceSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringPhotodiode

A method for fabricating a solid-state imaging device comprises: a step of forming a photodiode protection insulation film 6a; a step of forming a dummy protection insulation film 6c corresponding to the photodiode protection insulation film 6a both in the peripheral circuit region 1b and the scribe lane region 1c; and a step of forming an interlayer insulation film 9 for covering all three regions of a pixel region 1a in which pixels and the photodiode protection insulation film 6a are formed, a peripheral circuit region 1b in which a driving circuit and the dummy protection insulation film 6c are formed, and a scribe lane region 1c in which the dummy protection insulation film 6c is formed, wherein the dummy protection insulation film 6c causes an average height of a surface of the interlayer insulation film 9 included in each of the peripheral circuit region 1b and the scribe lane region 1c to be close to an average height of a surface of the interlayer insulation film 9 included in the pixel region 1a, before a CMP is performed on an entirety of the surface thereof.

Owner:PANNOVA SEMIC

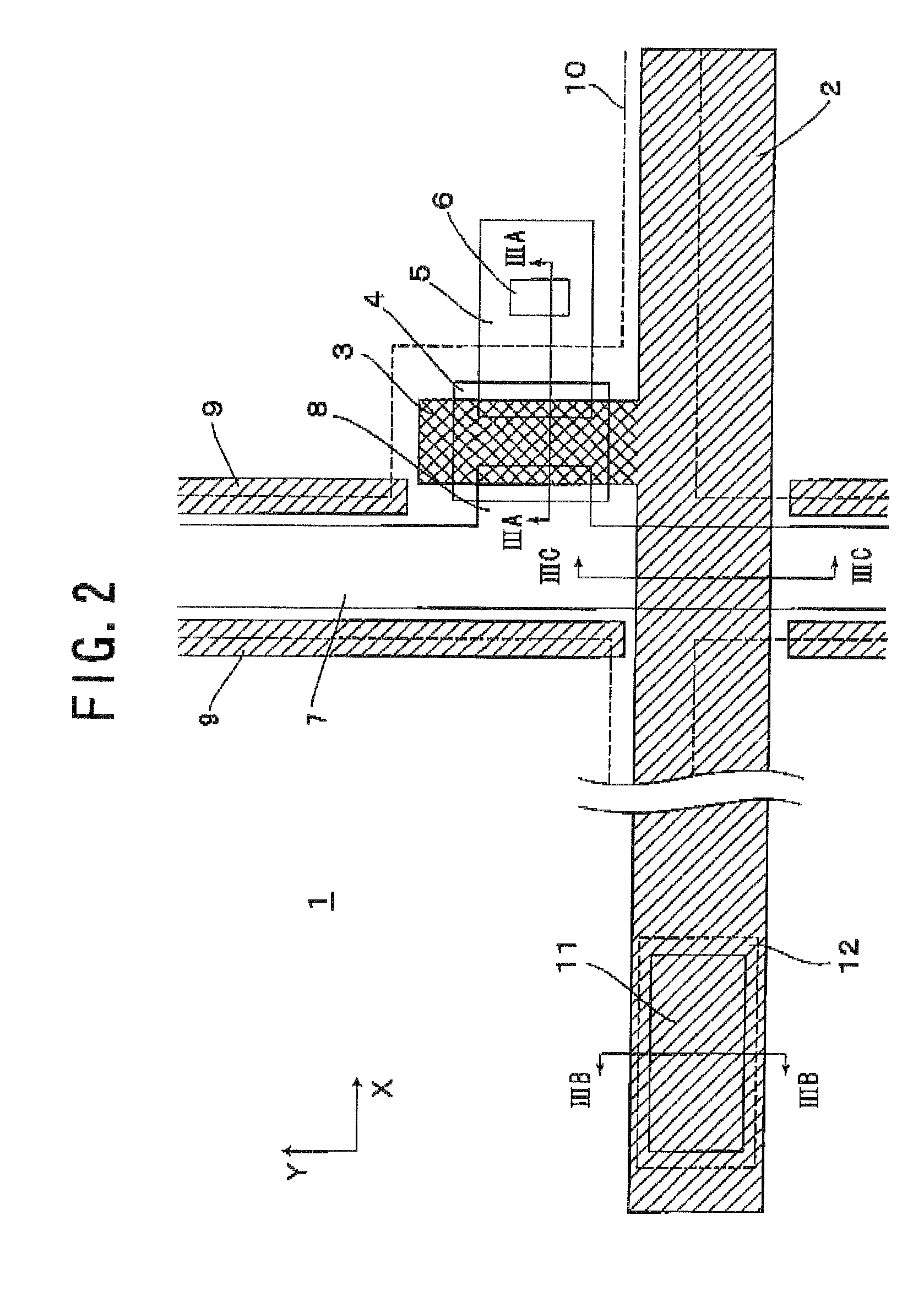

Correction apparatus

InactiveCN1543198AReduce level differenceTelevision system detailsColor television detailsSignal onEngineering

An object of this invention is to correct the non uniformity between a plurality of image sensing regions in real time and cope with even dynamic variations such as temperature variations or variations over time. To achieve this object, a correction apparatus includes a plurality of level adjustment devices which independently adjust the levels of a plurality of image sensing signals output from a plurality of output terminals, an output level detection device which detects the output levels of the plurality of level adjustment devices, and a correction coefficient determination device which determines a correction coefficient for reducing the level difference between the image sensing signals on the basis of the detection result of the output level detection device. The correction coefficient determination device determines the correction coefficient by excluding an object-dependent level difference component in which the level difference between the plurality of image sensing signals exceeds a predetermined level difference. The correction coefficient determination device supplies the determined correction coefficient to the level adjustment devices to perform adjustment so as to reduce the level difference between the image sensing signals.

Owner:CANON KK

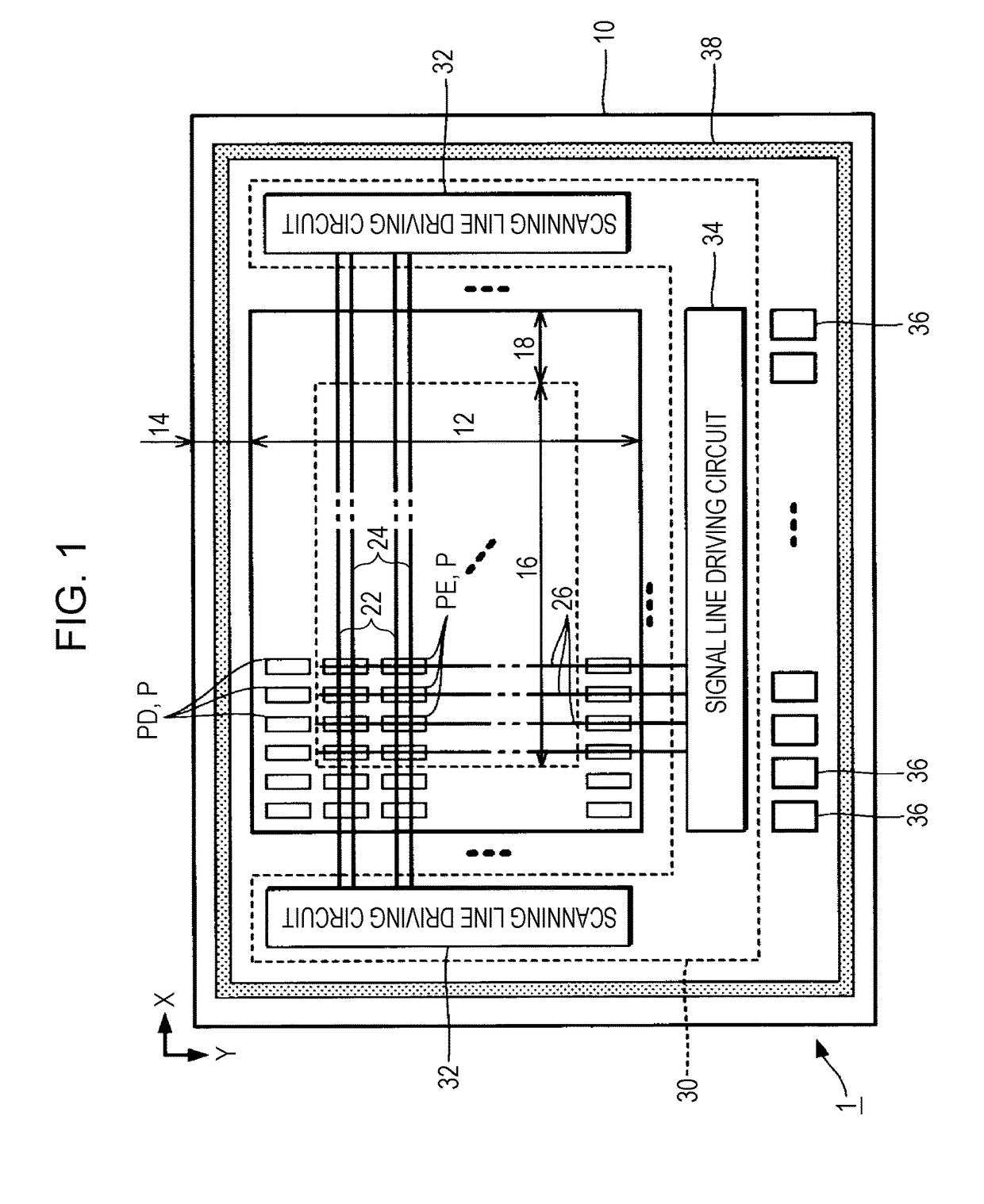

Display device

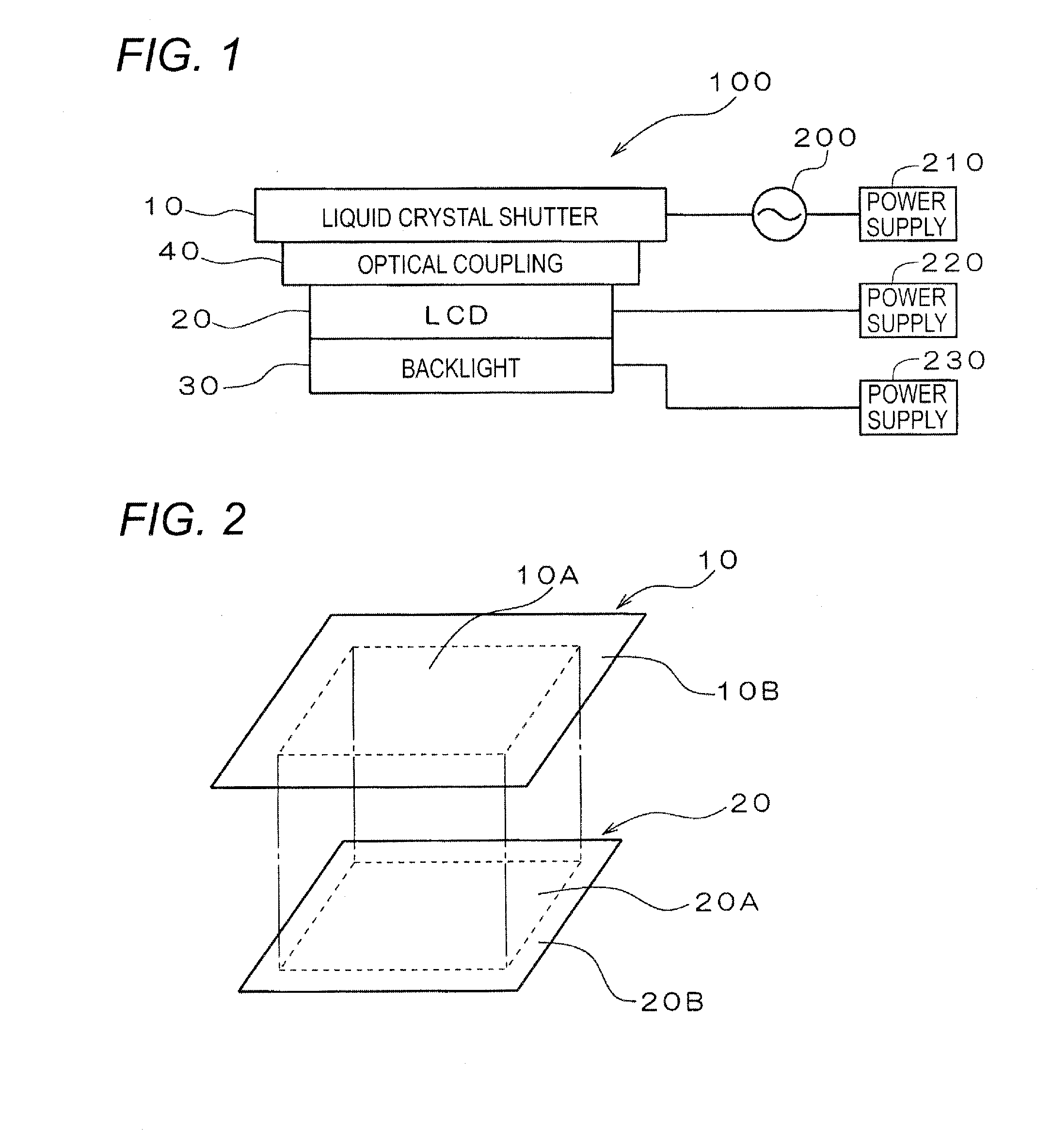

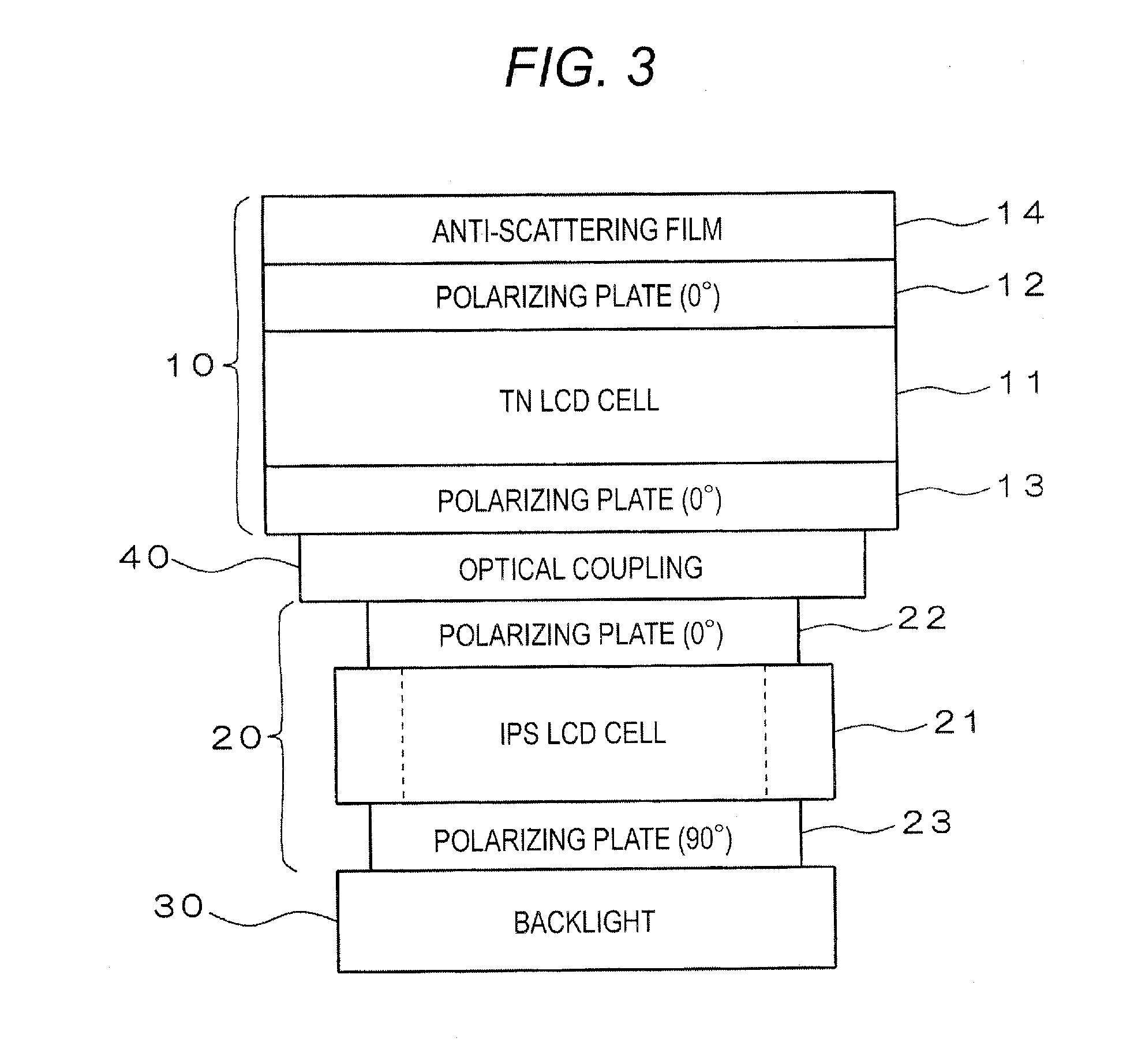

ActiveUS20160209684A1Reduce level differenceReduce in optical propertyStatic indicating devicesNon-linear opticsLiquid-crystal displayDisplay device

A display device includes a liquid crystal display device that has a display area and a hidden area surrounding the display area; a liquid crystal shutter that is layered on the liquid crystal display device and has a first area corresponding to the display area and a second area corresponding to the hidden area; and a control unit that sets the first and second areas to a transparent state and an opaque state, respectively, when the display area is active, and sets the first and second areas to the opaque state when the display area is not active.

Owner:ALPINE ELECTRONICS INC

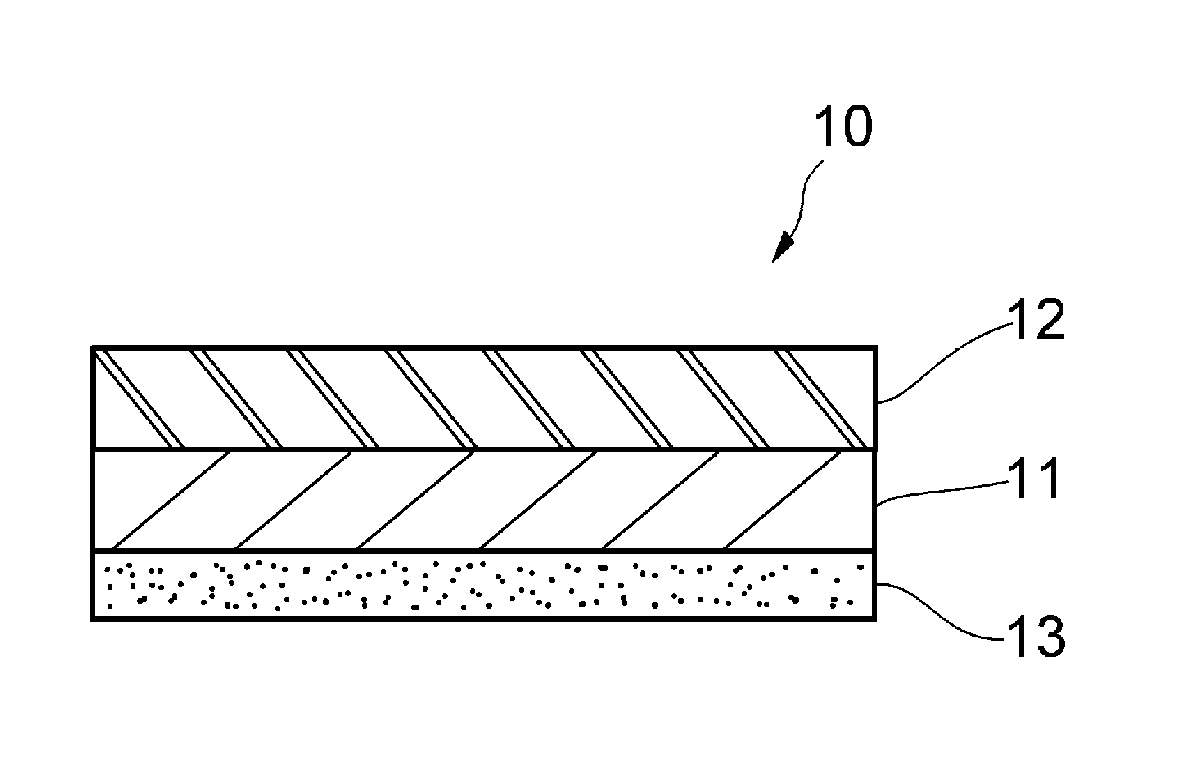

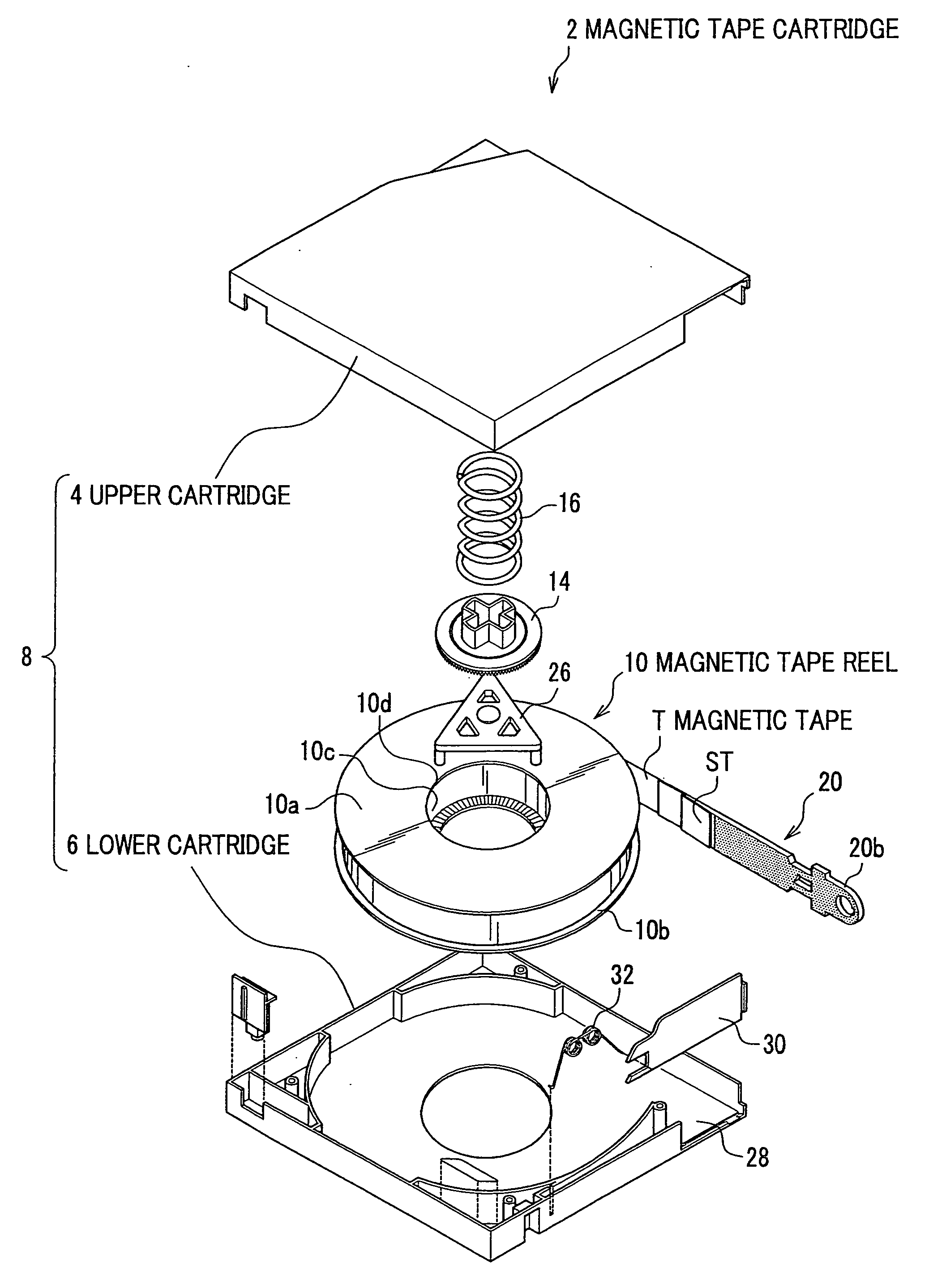

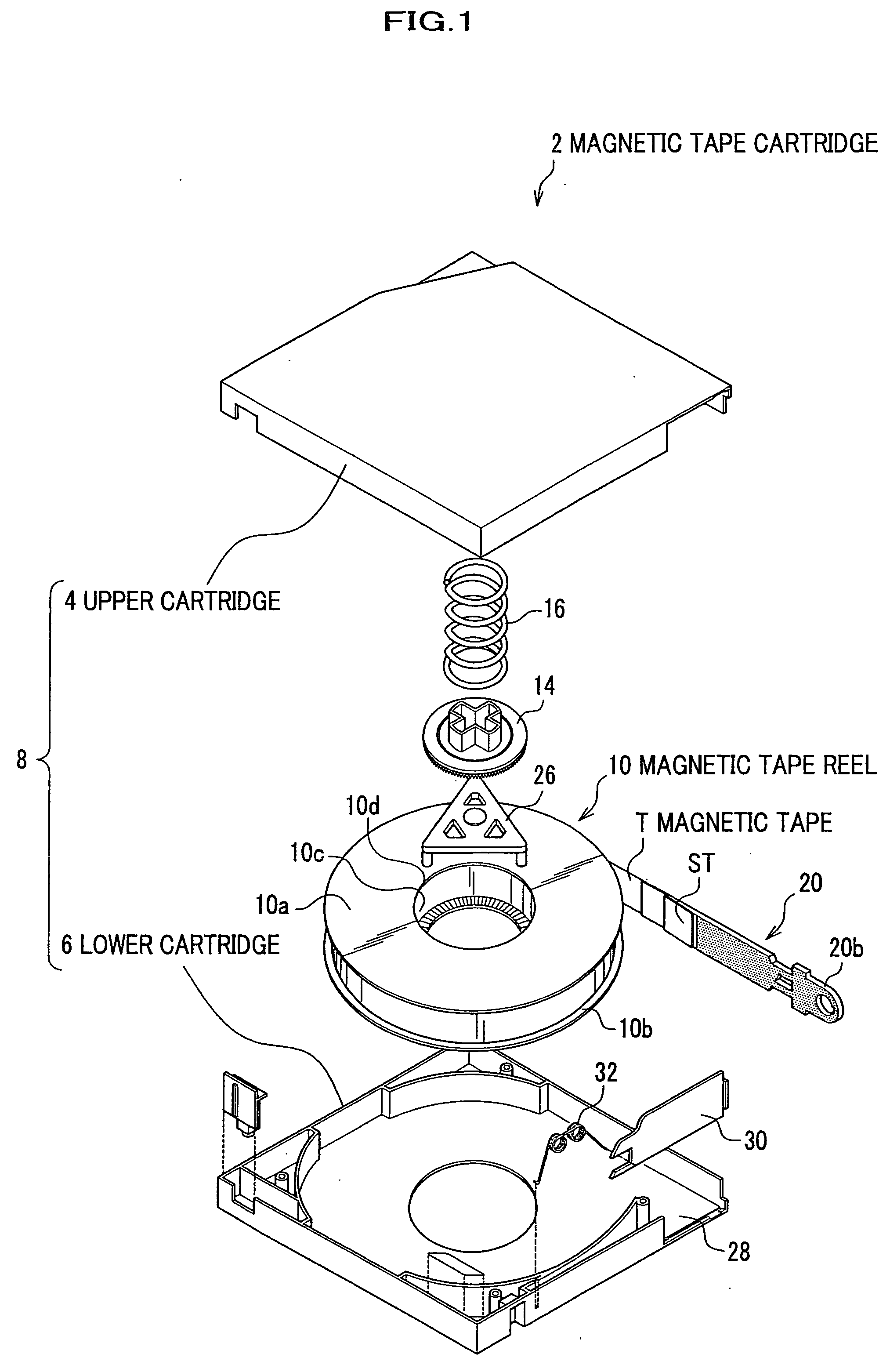

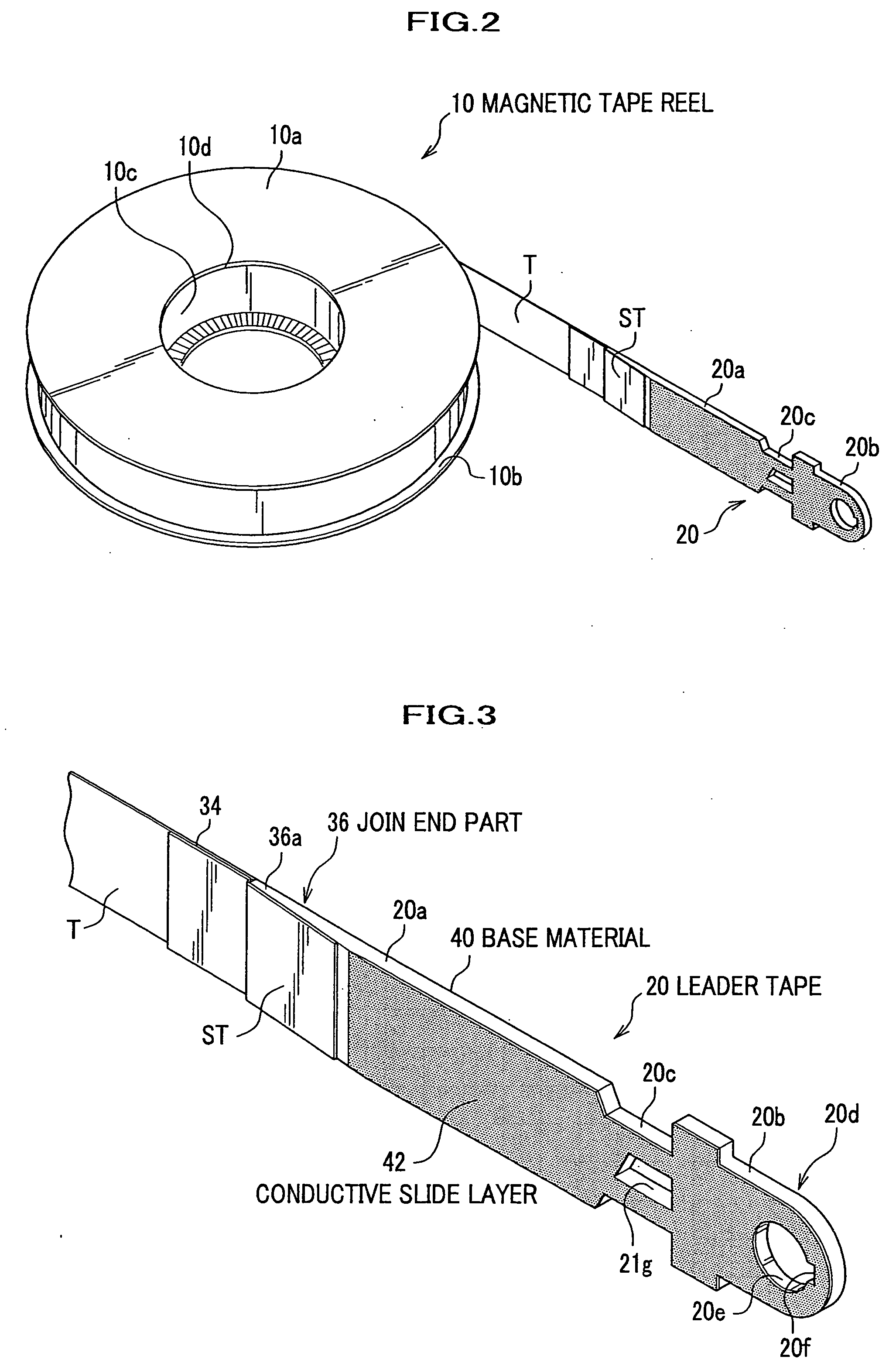

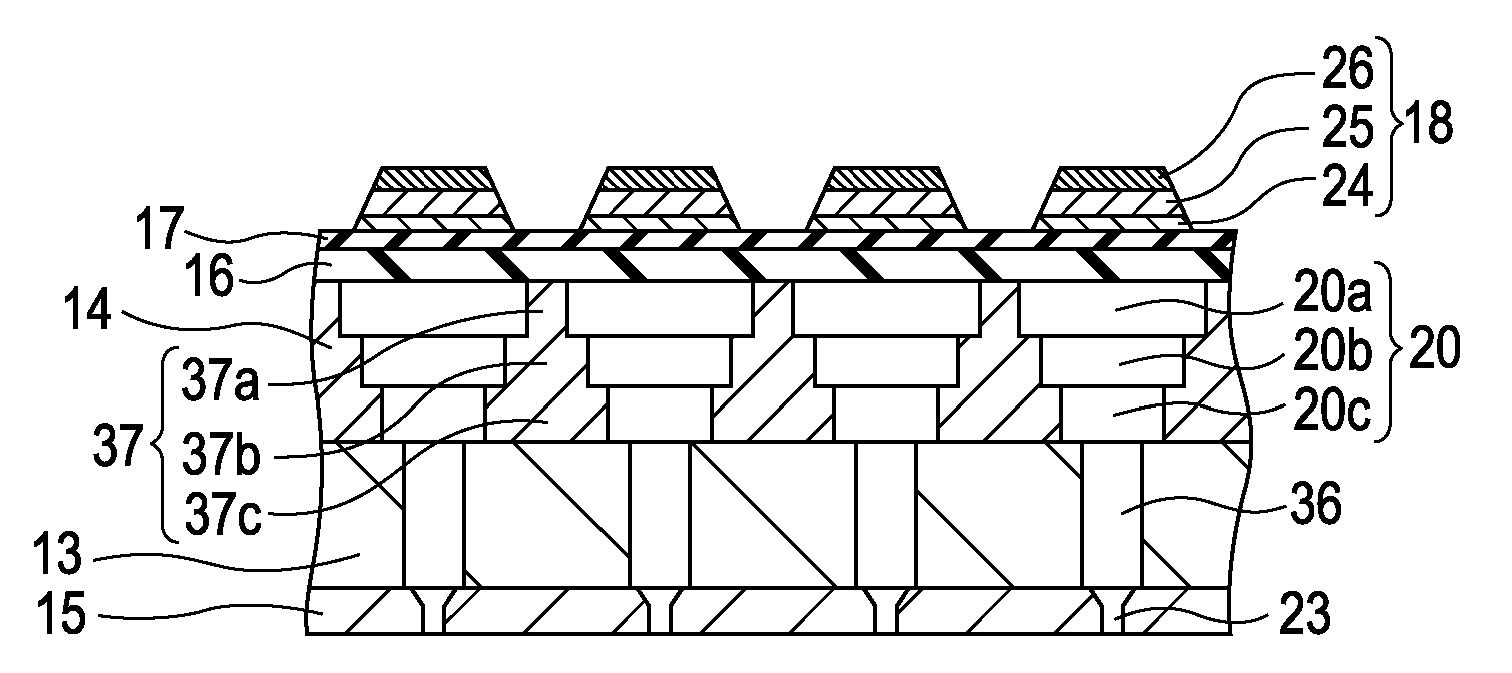

Leader tape, method for manufacturing the same, and magnetic tape cartridge

ActiveUS20060032959A1Avoid accumulationReduce decreasePicture changing apparatusProjector film strip handlingMagnetic tapeSurface roughness

The present invention provides a leader tape, method for manufacturing the same, and a magnetic tape cartridge with a leader tape having surface properties and conductive properties for securing slide durability suitable for a magnetic tape drive using a magnetic tape cartridge of one reel cartridge. A leader tape joined to a starting end of a magnetic tape wound around a magnetic tape reel of a one reel cartridge, comprising: a base material; and a conductive slide layer formed on at least one surface of the base material, the surface of the conductive slide layer having a surface electrical resistance value of 102 Ω / square to 1010 Ω / square and a surface roughness Ra of 0.5 μm to 1.5 μm.

Owner:FUJIFILM CORP +1

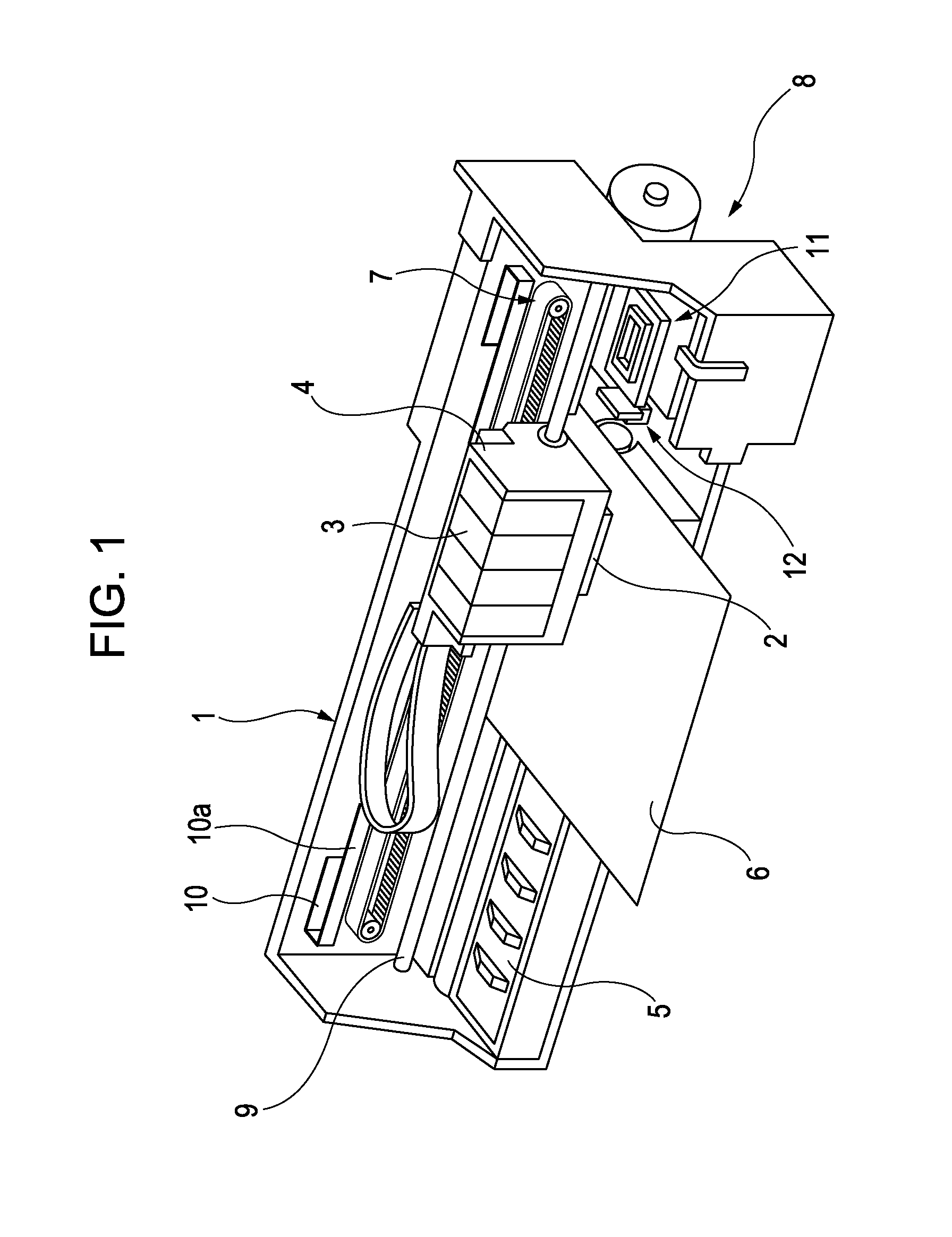

Liquid ejecting head and liquid ejecting apparatus

A liquid ejecting head, in which a plurality of pressure chambers that communicate with corresponding nozzles are formed by partitions, that ejects a liquid through the nozzles that communicate with the pressure chambers by causing an active surface (an elastic membrane) that seals an opening surface of the pressure chambers to deform using a piezoelectric element and thus causing the pressure of the liquid within the pressure chambers to fluctuate. The partitions that separate adjacent pressure chambers from each other are formed having a plurality of levels, the plurality being three or more, so that the partitions become thicker from the side on which the active surface is present toward the side on which the nozzles are present.

Owner:SEIKO EPSON CORP

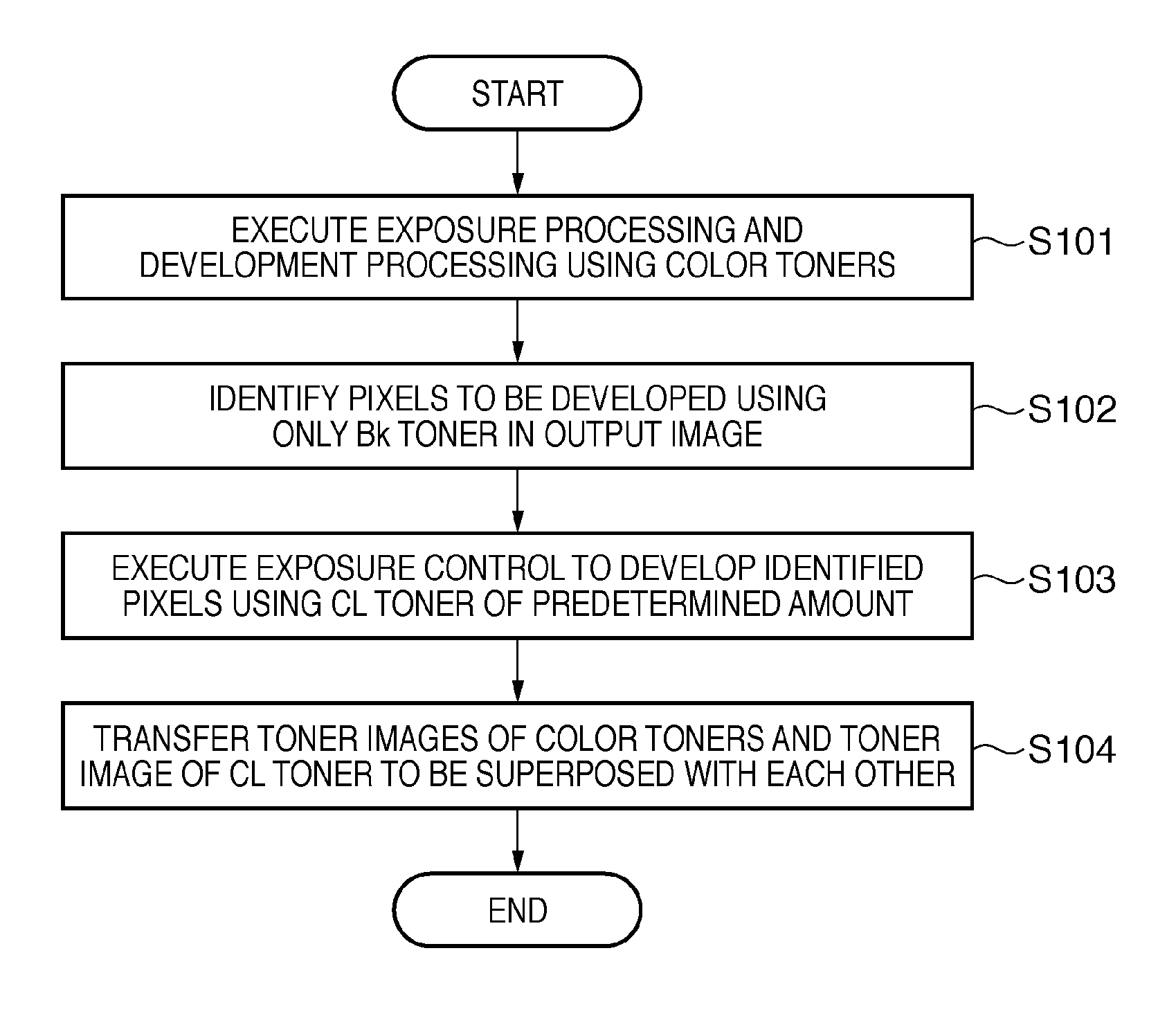

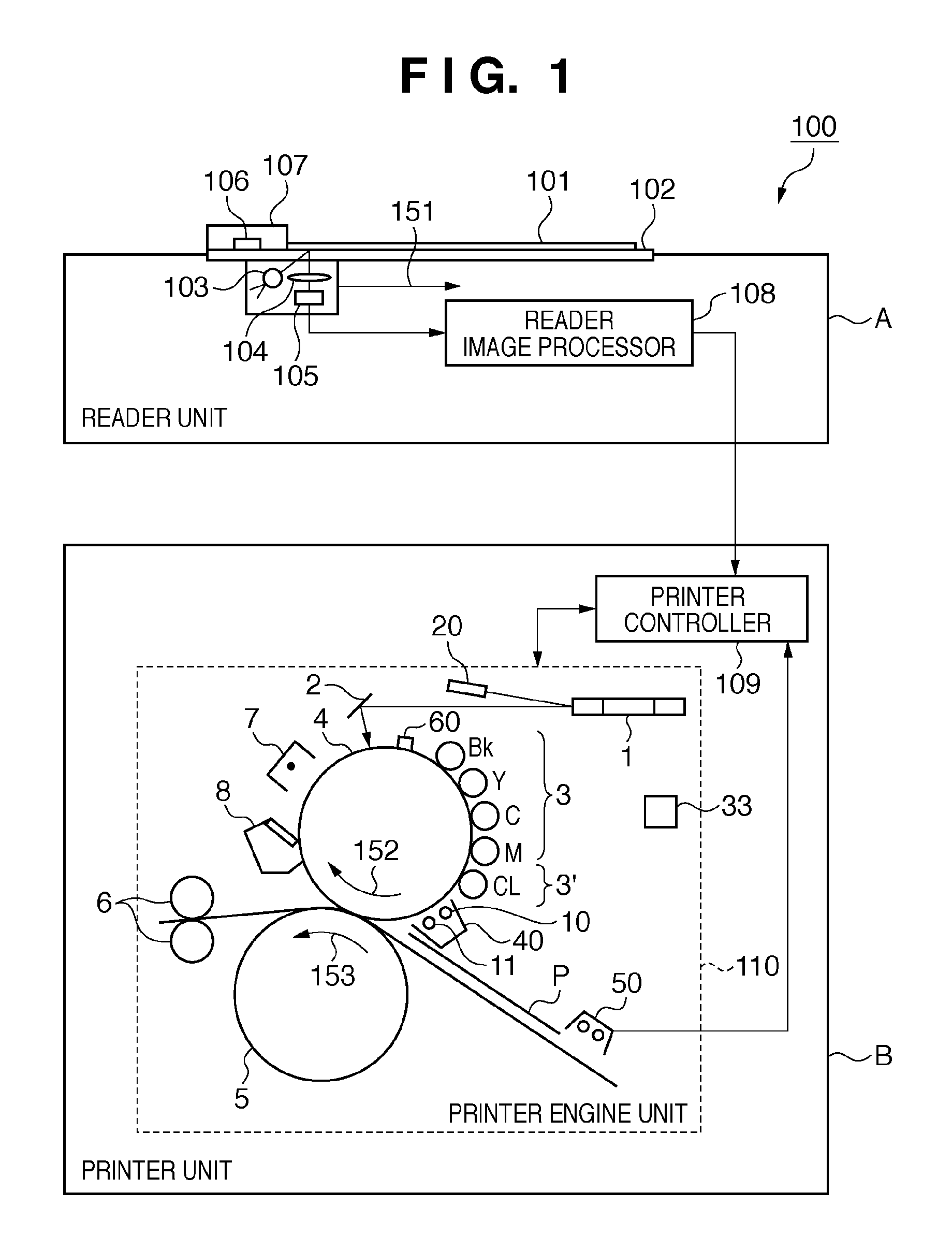

Image forming apparatus and control method thereof

InactiveUS20110206395A1Prevent having different gloss levelUniform glossElectrographic process apparatusComputer graphics (images)Image formation

This invention provides an image forming apparatus, which attains a uniform gloss level of an overall image by preventing regions having different gloss levels from being generated on the image to be formed upon execution of image formation using a transparent toner, and a control method thereof. To accomplish this, an image forming apparatus of this invention identifies pixels to be developed using only a black toner of colored toners from an image signal of an image to be formed on a printing material upon execution of image formation using the transparent toner. Furthermore, the image forming apparatus executes exposure control so as to perform development using the transparent toner in an amount required to reduce a gloss level difference between the pixels to be developed using only the black toner and those to be developed using the colored toners other than the black toner.

Owner:CANON KK

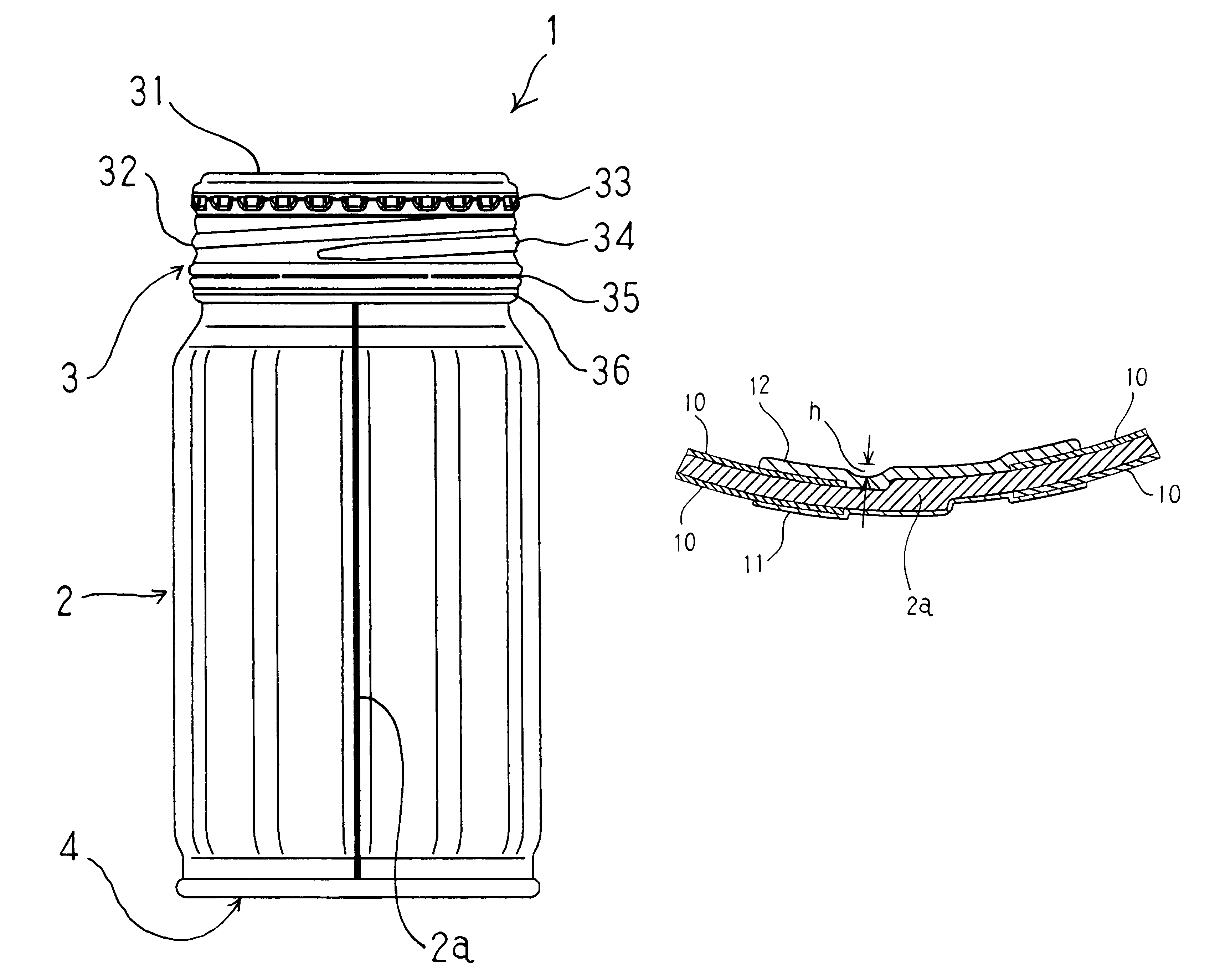

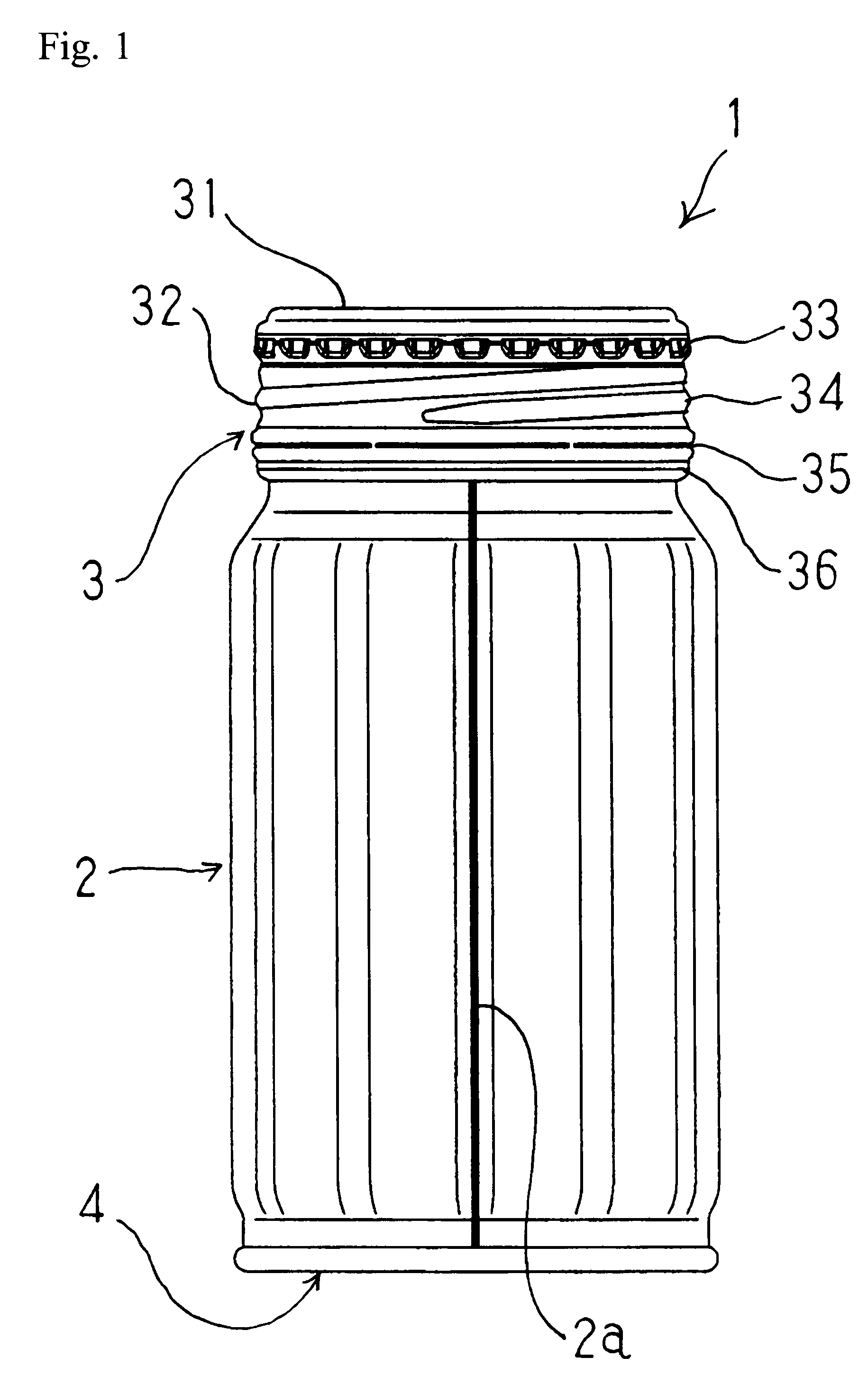

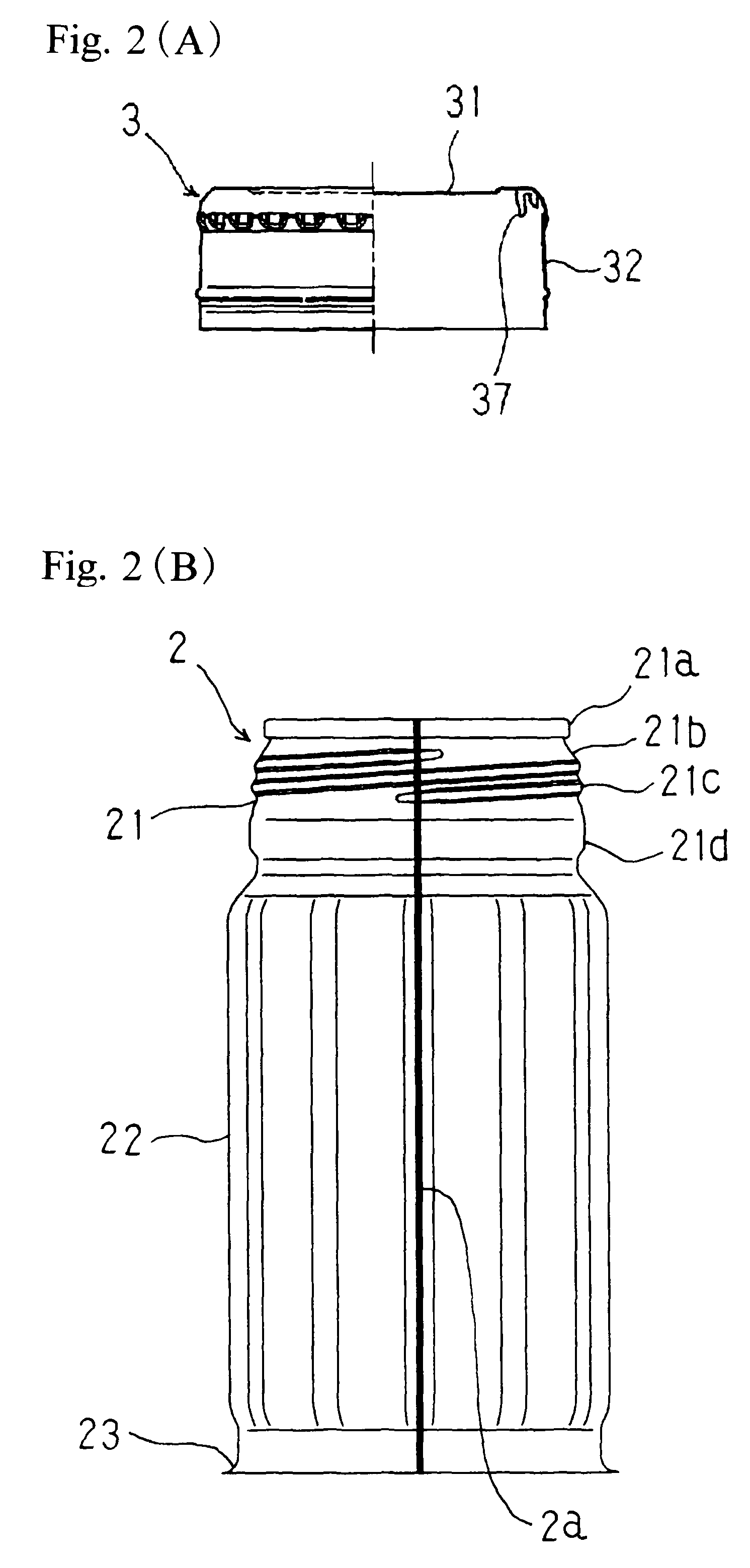

Can container

InactiveUS8181814B2Sufficient sealing abilityMinimize the differenceClosure capsRigid containersEngineeringWelding

To ensure sealing ability of a resealable can container formed of a welded can body between a curled portion of container mouth and a resin sealing liner, without degrading productivity and easiness to open the closure.The can body 2 is prepared by rolling a steel sheet and welding overlapped longitudinal edges of the steel sheet. In order to achieve the above-mentioned objective, a level difference of a welded portion 2a on the surface of a curled portion 21a is reduced smaller than that on the trunk portion 22, specifically, kept within the range of 15 to 100 μm, and a durometer hardness of the resin sealing liner is kept within the range of HDA 30 to 70 according to ISO 868 (or JIS-K7215).

Owner:DAIWA CAN

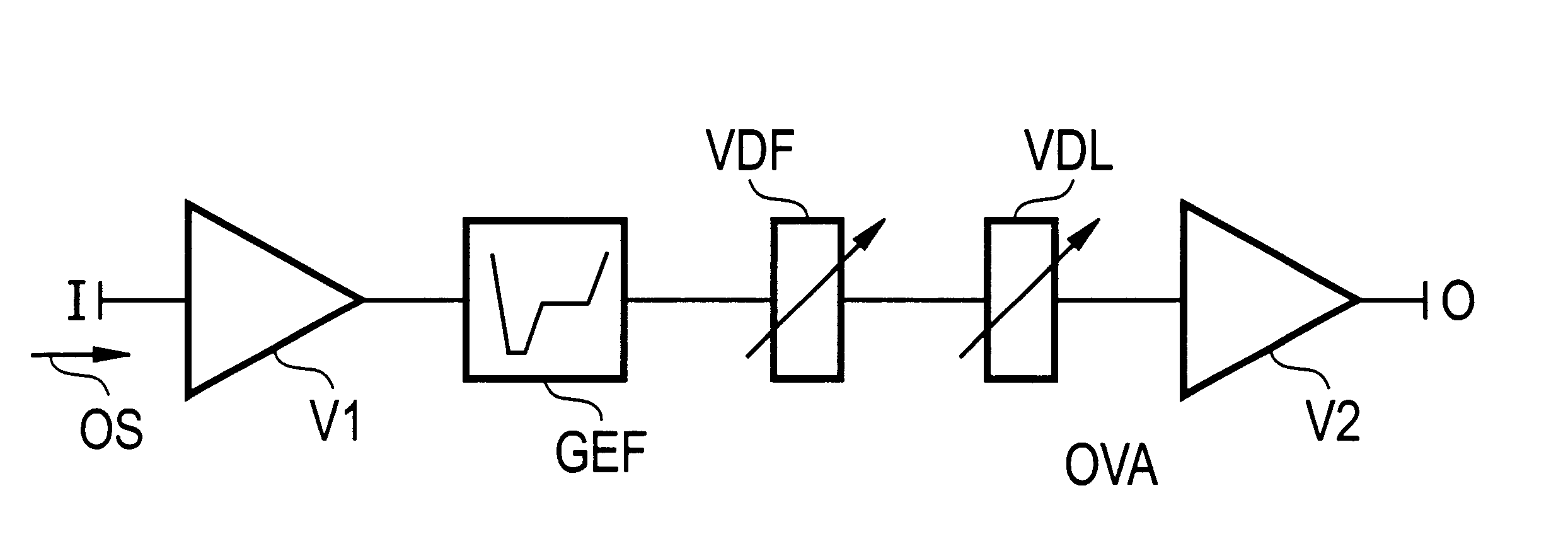

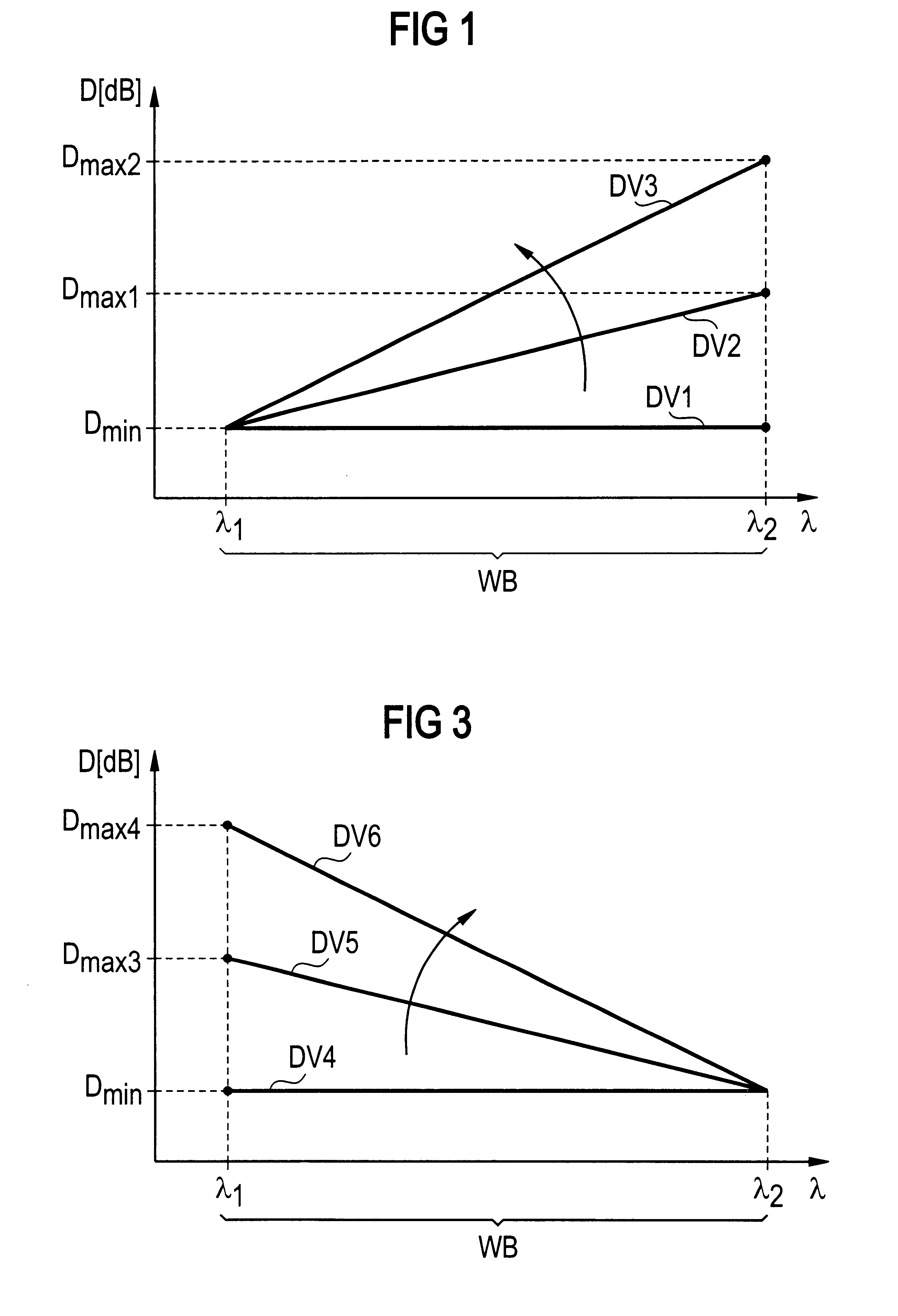

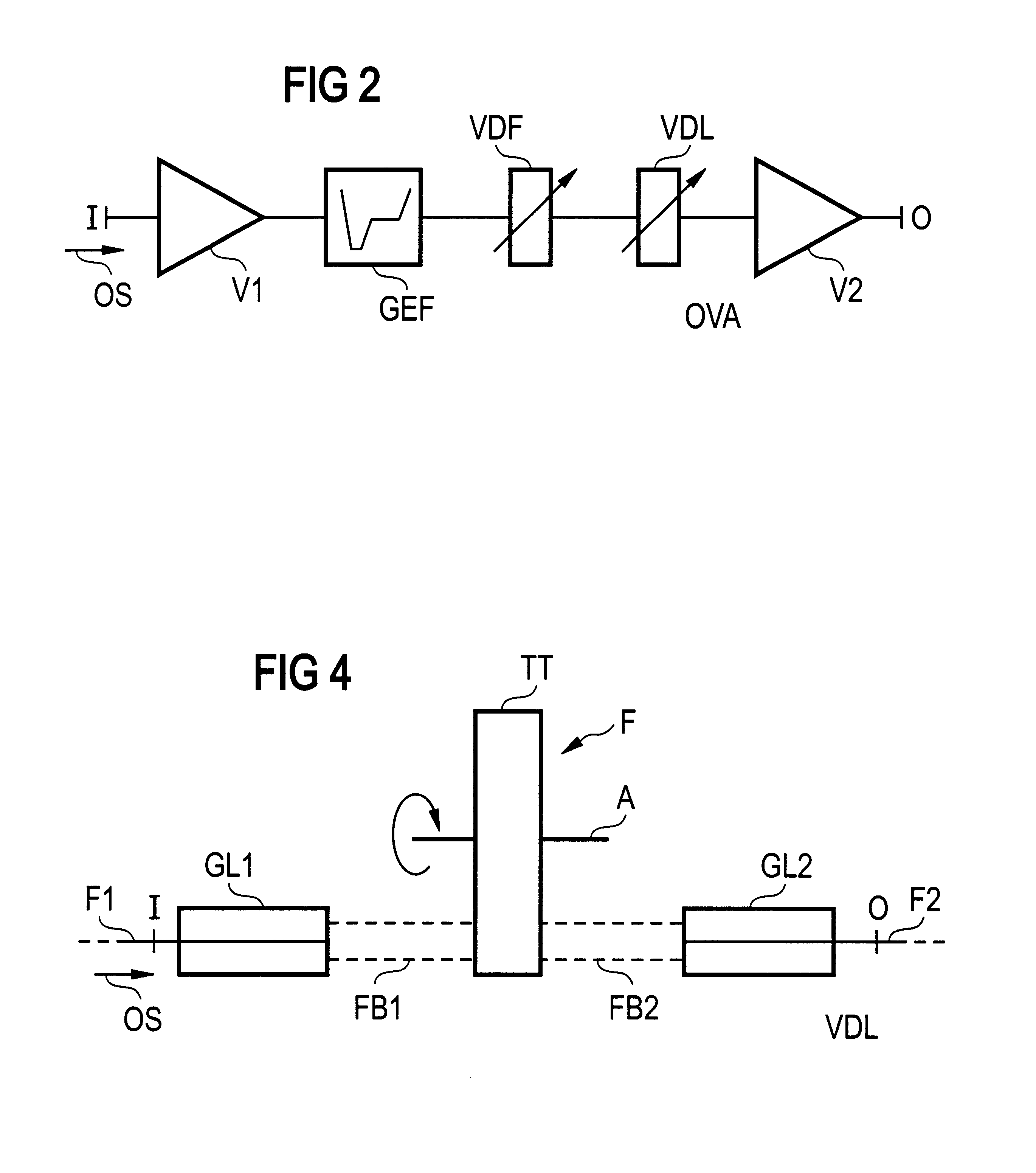

Optical amplifier arrangement having a variably settable attenuator

InactiveUS6768579B2Reduce level differenceReduce tiltFibre transmissionActive medium shape and constructionUltrasound attenuationOptical amplifier

An optical amplifier arrangement having at least one optical amplifier stage (V1, V2) and a variably settable attenuator (VDL), whose attenuation spectrum (DV2, DV3, DV5, DV6) assumes an attenuation profile (DV2, DV3, DV5, DV6) that increases or decreases proportionally to wavelength. To reduce tilt of the channel level spectrum of an optical transmission signal, the profile of the attenuation spectrum (DV2, DV3, DV5, DV6) is variably settable. An advantageous structure of the variably settable attenuator according to the invention is furthermore specified.

Owner:XIEON NETWORKS SARL

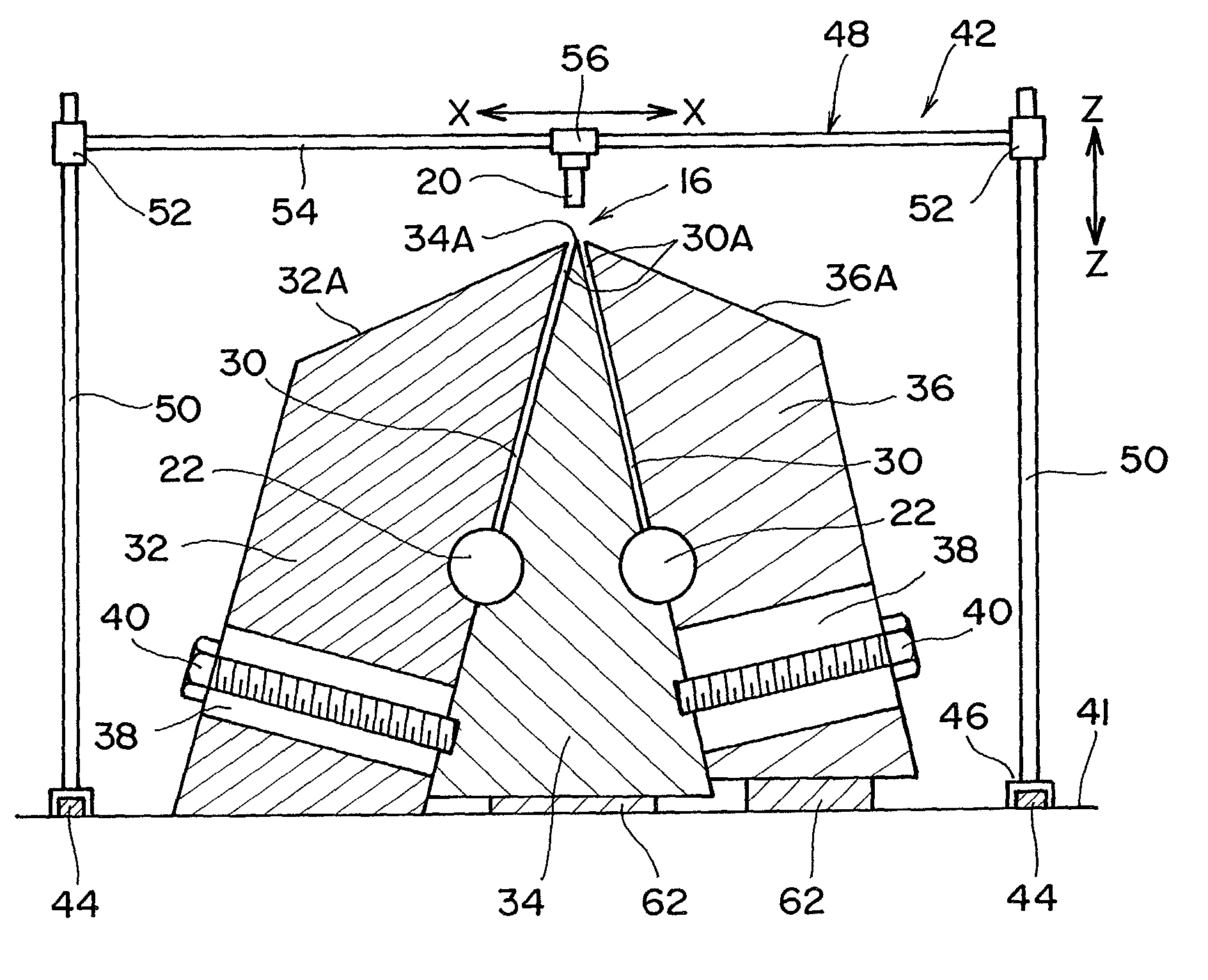

Extrusion-type coating method and apparatus

InactiveUS20020023584A1Reduce level differenceReduce varianceCoating by extrusionPretreated surfacesMeasurement deviceElectrical and Electronics engineering

Edge faces with level differences are formed by assembling blocks constructing a coating head, and level difference variances in the width direction of a web are measured by a level difference variance measurement device. Then, the level difference variances are adjusted with reference to measured results, so that the level difference variances can be reduced. Therefore, coating layers can be uniformly formed on the web.

Owner:FUJIFILM CORP +1

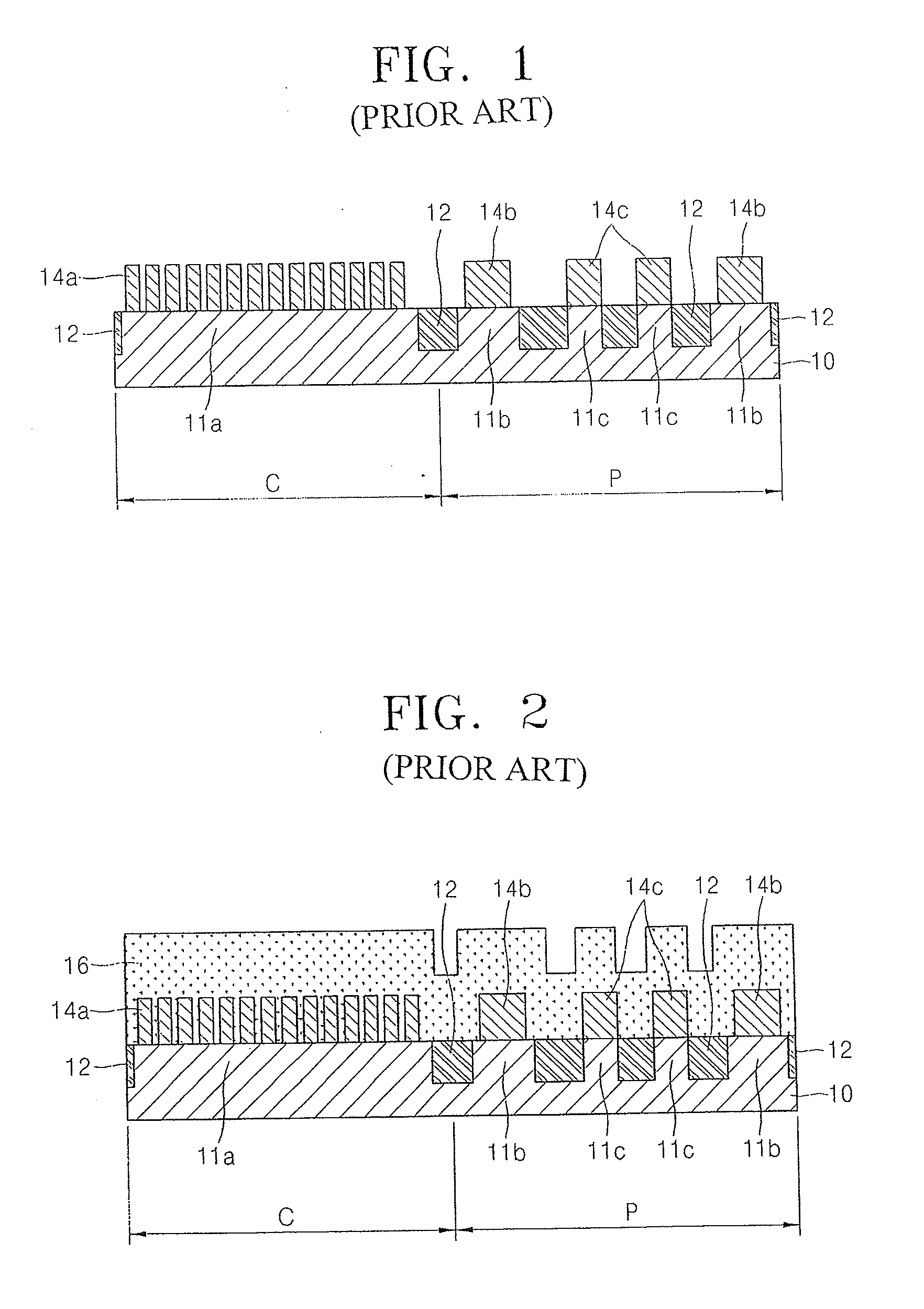

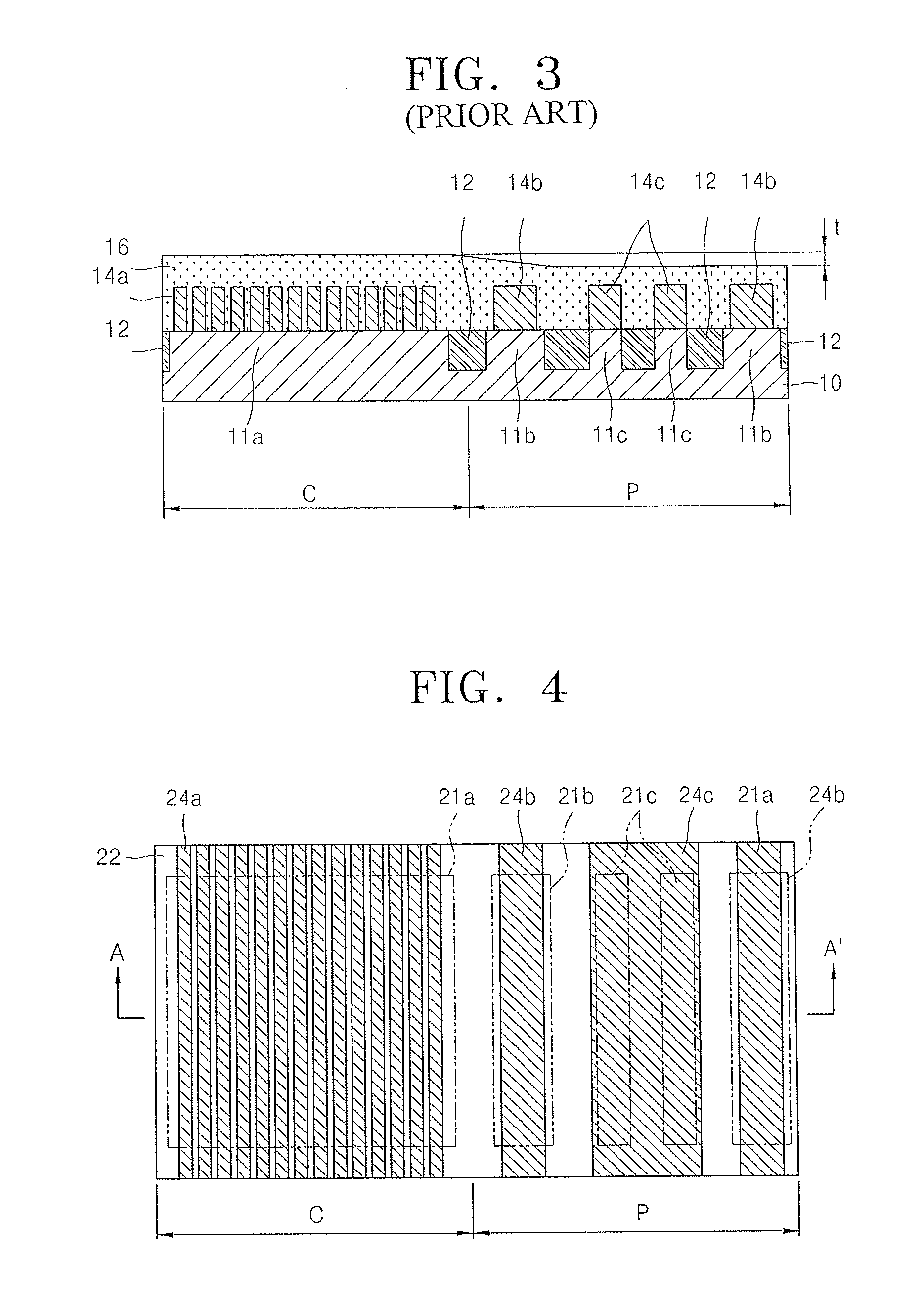

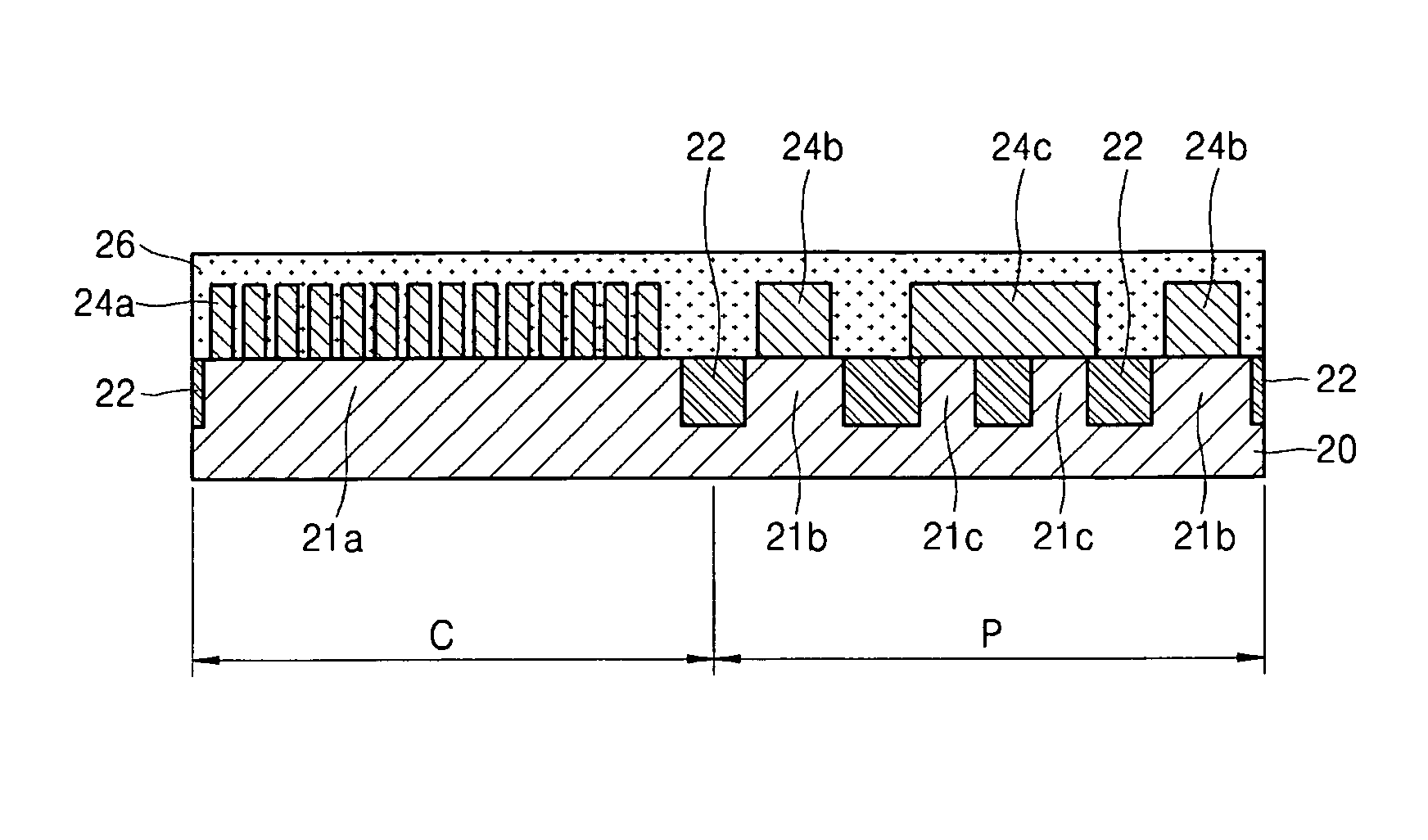

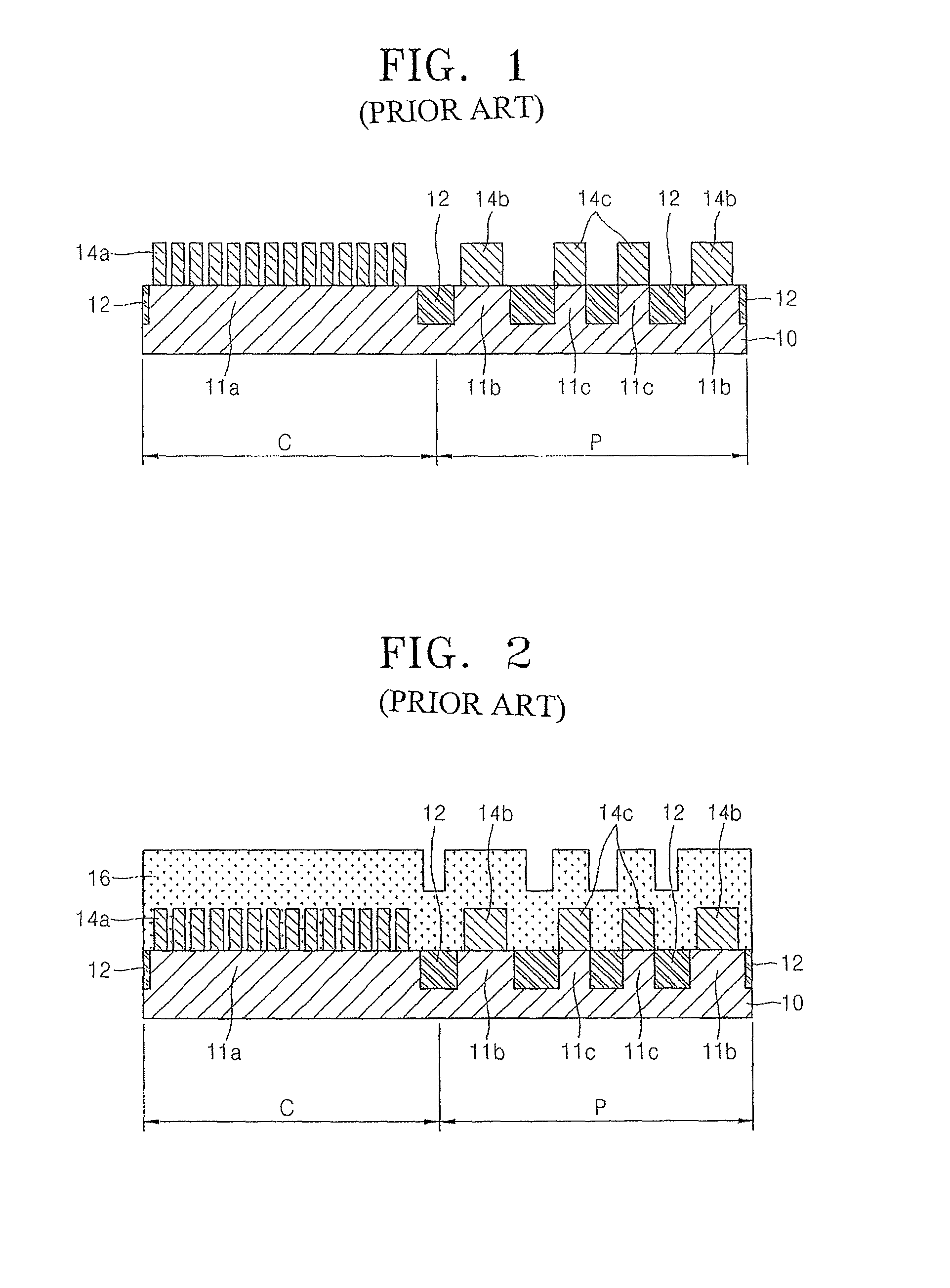

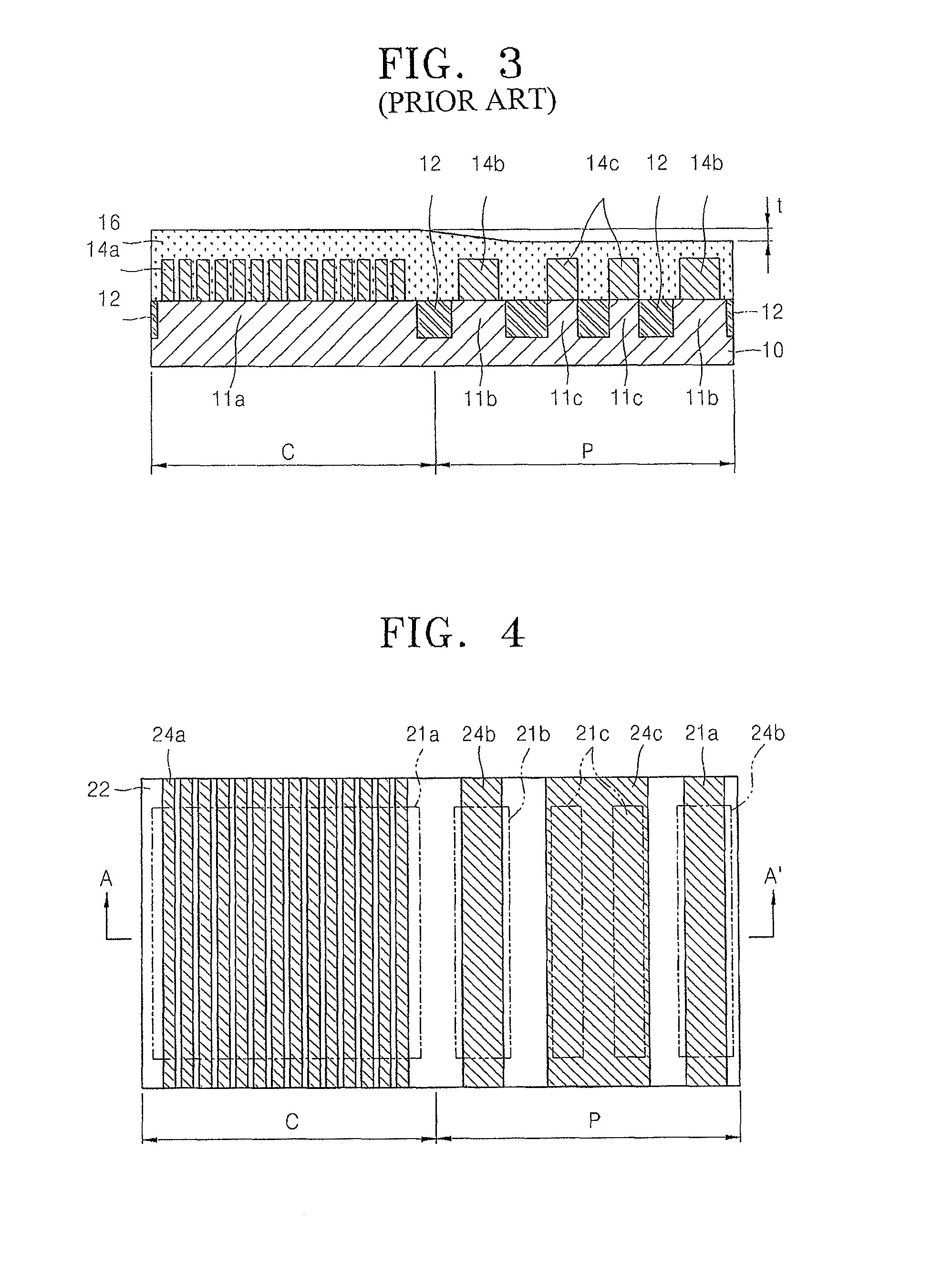

Semiconductor device including dummy gate part and method of fabricating the same

ActiveUS20120028435A1Reduce the differenceDifference in levelSolid-state devicesSemiconductor/solid-state device manufacturingCell regionDevice material

In a reliable semiconductor device and a method of fabricating the semiconductor device, a difference in height between upper surfaces of a cell region and a peripheral region (also referred to as a level difference) is minimized by optimizing dummy gate parts. The semiconductor device includes a semiconductor substrate including a cell region and a peripheral region surrounding the cell region, a plurality of dummy active regions surrounded by a device isolating region and formed apart from each other, and a plurality of dummy gate parts formed on the dummy active regions and on the device isolating regions located between the dummy active regions, wherein each of the dummy gate parts covers two or more of the dummy active regions.

Owner:SAMSUNG ELECTRONICS CO LTD

Semiconductor device including dummy gate part and method of fabricating the same

ActiveUS8053845B2Reduce the differenceDifference in levelSolid-state devicesSemiconductor/solid-state device manufacturingDevice materialCell region

In a reliable semiconductor device and a method of fabricating the semiconductor device, a difference in height between upper surfaces of a cell region and a peripheral region (also referred to as a level difference) is minimized by optimizing dummy gate parts. The semiconductor device includes a semiconductor substrate including a cell region and a peripheral region surrounding the cell region, a plurality of dummy active regions surrounded by a device isolating region and formed apart from each other, and a plurality of dummy gate parts formed on the dummy active regions and on the device isolating regions located between the dummy active regions, wherein each of the dummy gate parts covers two or more of the dummy active regions.

Owner:SAMSUNG ELECTRONICS CO LTD

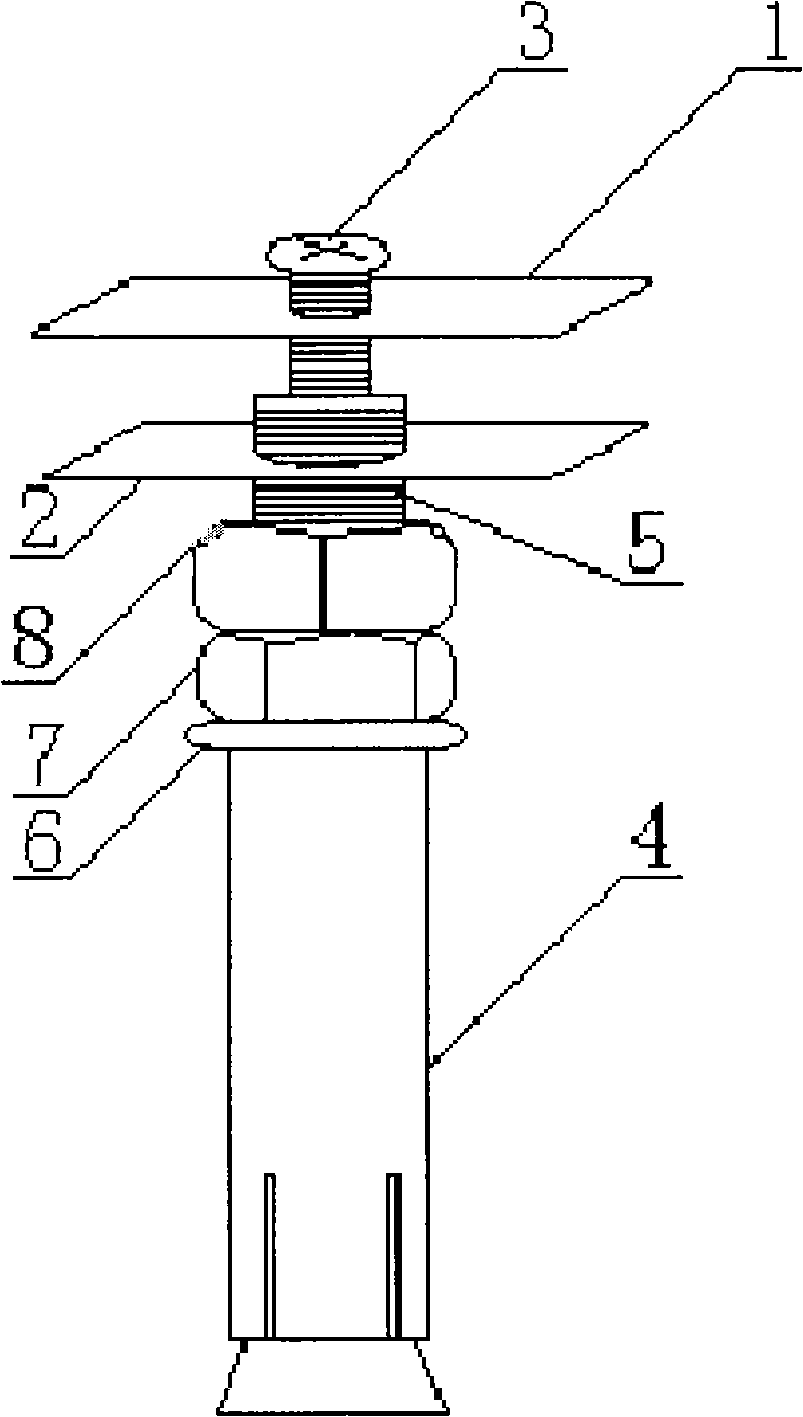

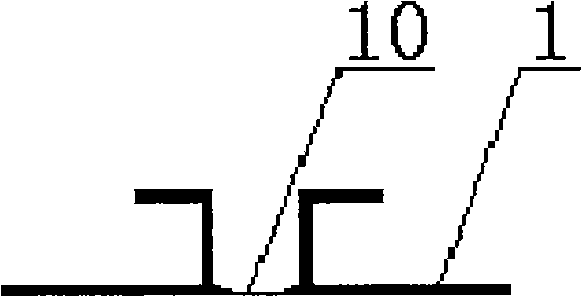

Keel-free direct hanging fastener

The invention relates to a non-keel dry-hanging fastener which belongs to the technical field of parts or structures especially used as fixing material during decorating walls of buildings. The non-keel dry-hanging fastener solves the problem that thermal-insulation decoration plates have no keel dry-hangings and comprises a clip and a fastening piece, wherein, the clip is an expansion bolt, and the center of the threaded rod of the expansion bolt is provided with an inner-threaded round hole; the fastening piece is connected with the threaded rod of the expansion bolt by a screw. The fastening piece consists of a top plate and a base plate which are respectively provided with a round hole. The fastener provided by the invention is made of stainless steel or metal, the surface of which is treated to resist against corrosion, and realizes that thermal-insulation decoration plates have no keel dry-hangings, so that thermal-insulation decoration plates can be perfectly fixed on walls. The fastener is applicable to various wall materials, such as concrete, solid and hollow walls and can make constructions and maintenance convenient and quick. The fastener has high loading capacity, high bearing pressure and good tension-resistance performance; besides, the fastener can prevent the impact damage, reduce the loading of a whole building, provide 3-5 cm horizontal adjustment differences for the distorted surfaces of walls, and provide flat surfaces for wall decoration.

Owner:张俊尧

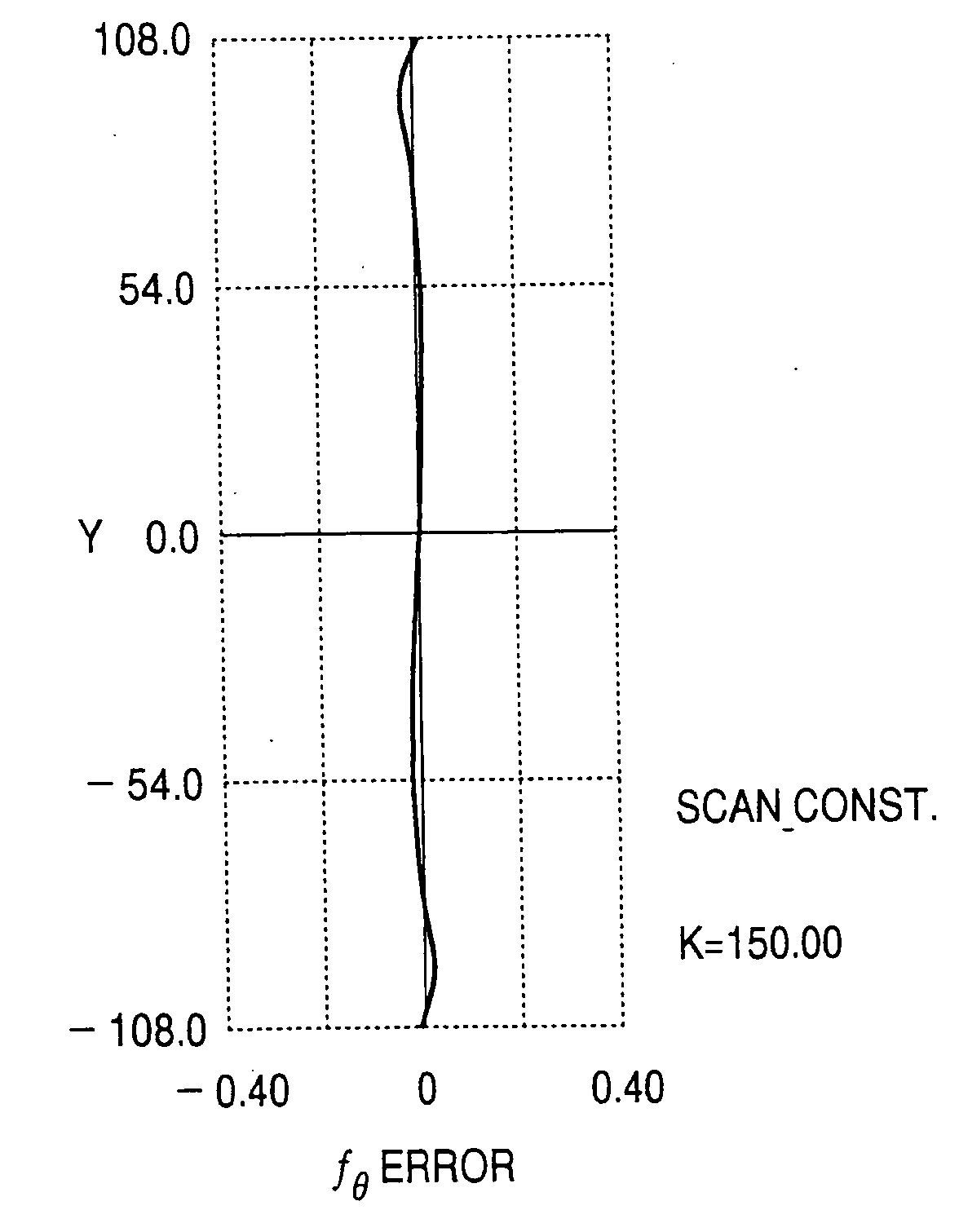

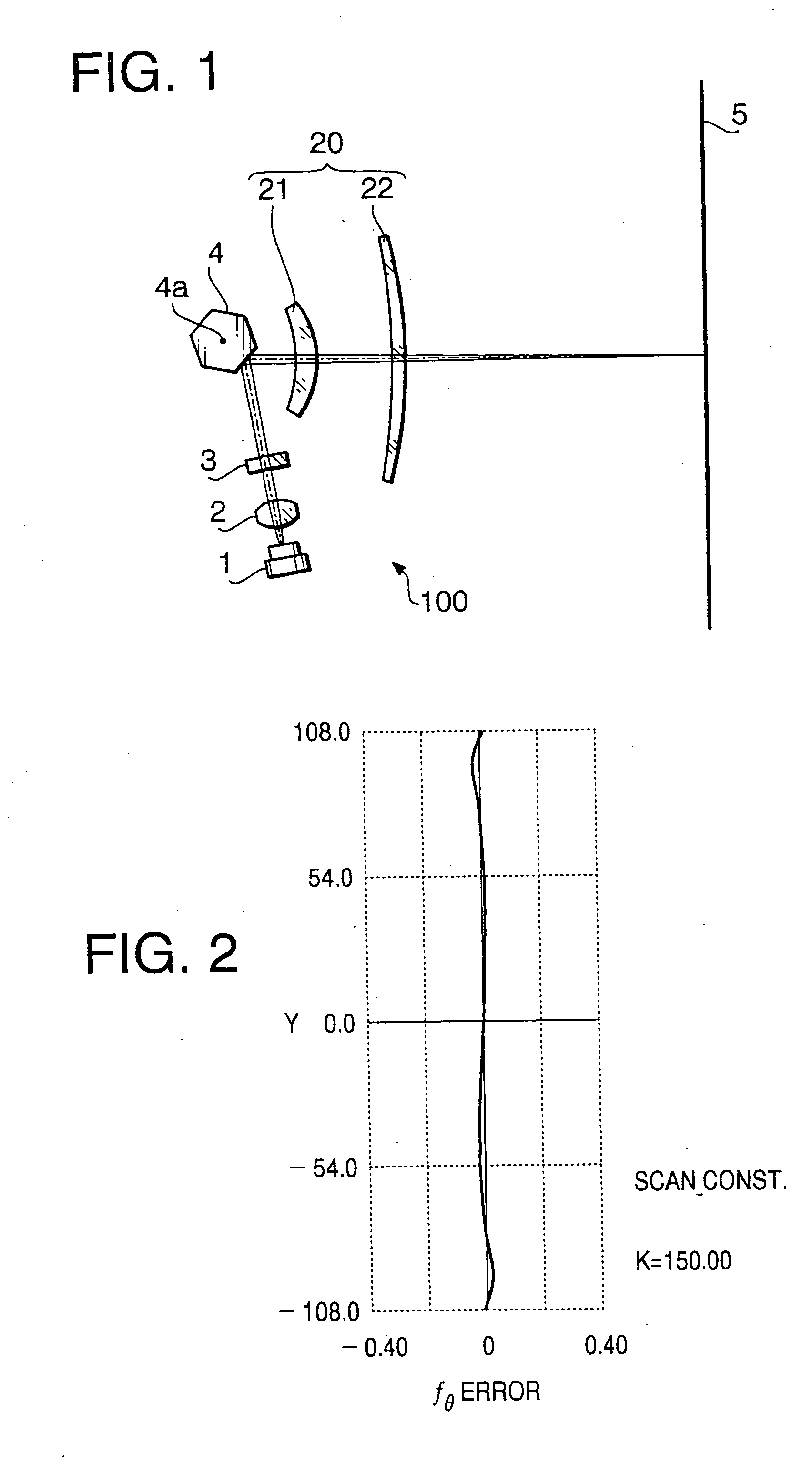

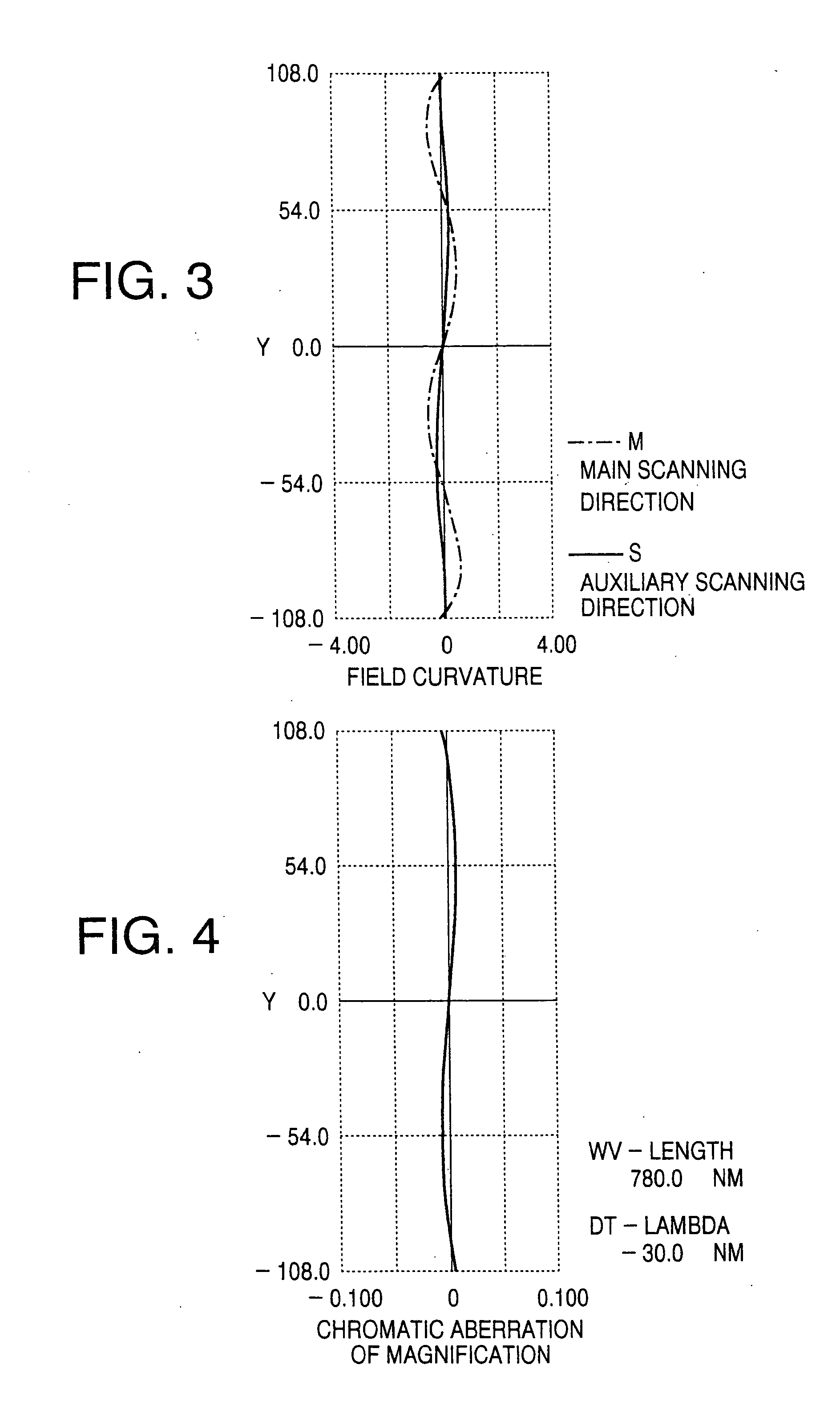

Scanning optical system

InactiveUS20060023971A1Deterioration in diffraction efficiencyDeterioration in efficiencyInking apparatusCharacter and pattern recognitionLight beamImage formation

A scanning optical system comprises: a light source which emits a beam of light; a deflecting system that dynamically deflects the beam emitted by the light source with its deflecting surface; and a scan lens group including a molded resin lens, which focuses the beam dynamically deflected and scanned in a main scanning direction by the deflecting system on an image formation surface. In the scanning optical system, the molded resin lens has a diffracting lens surface which is provided with a diffractive level difference structure formed on a base curve having refractive power, and a following condition is satisfied: 18<WL / P<28 where “W” denotes an effective scan width (mm) on the image formation surface, “L” denotes a distance (mm) from the deflecting surface to the molded resin lens, and “P” denotes a distance (mm) from the deflecting surface to the image formation surface.

Owner:ASAHI KOGAKU KOGYO KK

Transparent electrode capacitance sensor and process for manufacturing the same

ActiveUS20160266707A1Improve reliabilitySecures wide viewable areaResistance/reactance/impedenceInput/output processes for data processingAuxiliary electrodeCapacitance transducer

A transparent electrode capacitance sensor includes a transparent resin substrate; at least one transparent electrode formed on the transparent resin substrate; a pseudo auxiliary electrode formed in at least a portion of an outer periphery of the transparent electrode; and a lead wire connected to the pseudo auxiliary electrode, wherein the pseudo auxiliary electrode is thicker than the transparent electrode, and includes the same material as the transparent electrode.

Owner:SHIN-ETSU POLYMER CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com