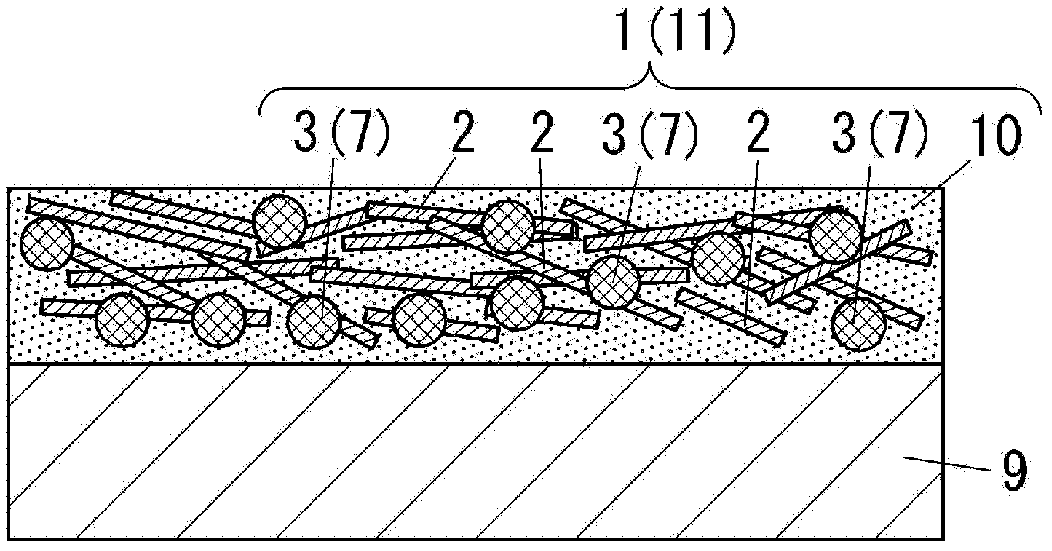

Transparent conductive film, substrate with transparent conductive film, and method for manufacturing same

A technology of transparent conductive film and transparent substrate, which can be used in the removal of conductive materials by light, printed circuit manufacturing, cable/conductor manufacturing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

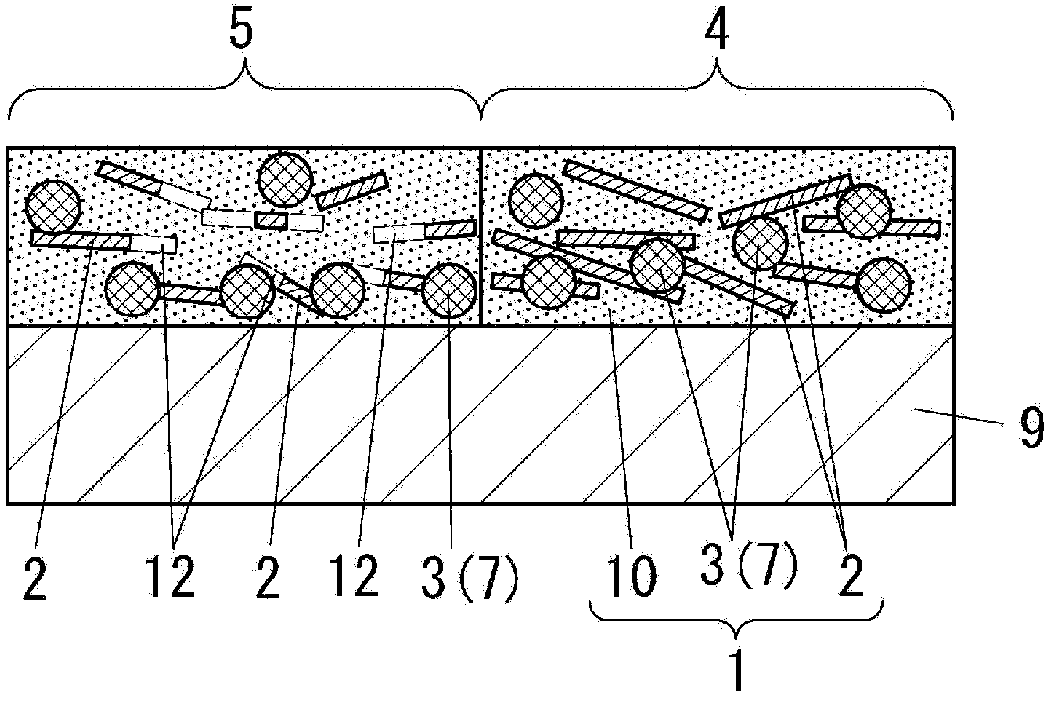

Embodiment 1

[0094] The transparent substrate 9 used was a non-alkali glass plate ("No. 1737", refractive index at a wavelength of 500 nm: 1.50 to 1.53, available from Corning Inc.). The transparent conductive material A was applied on the surface of the transparent substrate by spin coating and heated under the conditions of 100° C. and 5 minutes for drying and hardening to give a transparent conductive film having a film thickness of 100 nm. After that, in order to form the insulating region, there will be 0.5J / cm 2 The light of the average energy density is emitted to the left half of the transparent conductive film by means of a UV-YAG laser. Thus, a substrate with a transparent conductive film having a conductive region in the right half of the transparent conductive film and an insulating region in the left half thereof was prepared.

Embodiment 2

[0096] A transparent conductive film having a film thickness of 100 nm was prepared in a similar manner to Example 1 except that transparent conductive material A was replaced with transparent conductive material B. After that, an insulating region was formed similarly to Example 1 to give a substrate with a transparent conductive film having a conductive region in the right half of the transparent conductive film and an insulating region in the left half thereof.

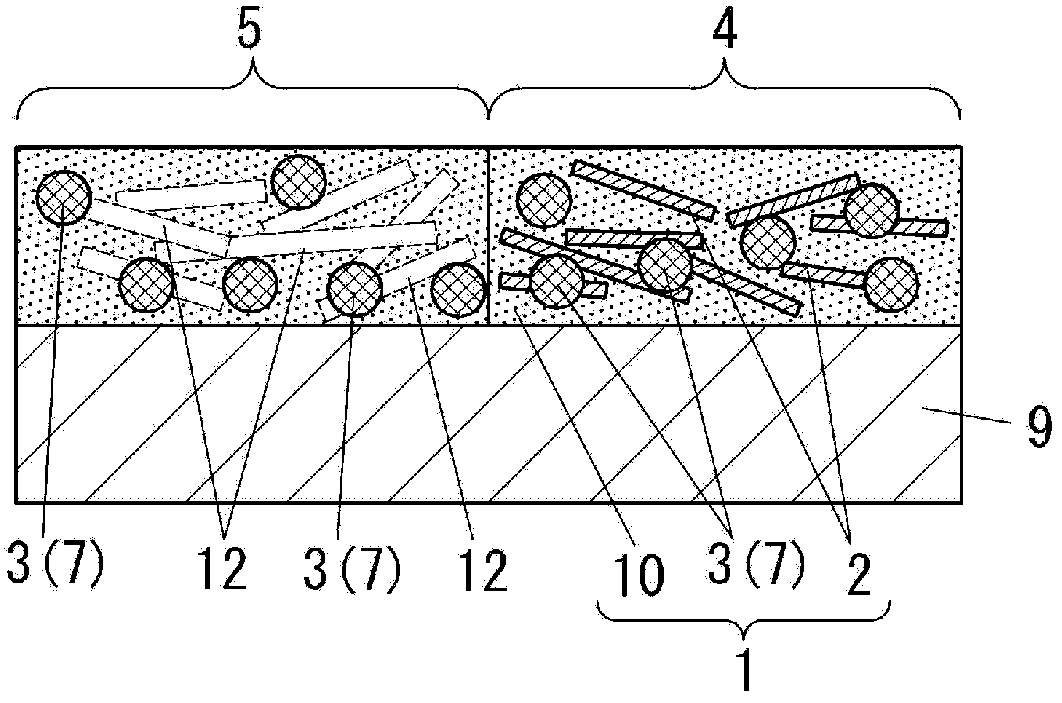

Embodiment 3

[0098] A transparent conductive film having a film thickness of 100 nm was prepared in a similar manner to Example 1 except that transparent conductive material A was replaced with transparent conductive material C. After that, an insulating region was formed similarly to Example 1 to give a substrate with a transparent conductive film having a conductive region in the right half of the transparent conductive film and an insulating region in the left half thereof.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com