Lifting robot car

A technology of robots and screw lifts, which is applied in lifting frames, lifting devices, etc., can solve problems such as troublesome maintenance, large space volume, and many maintenance times, and achieve the effect of solving space size, small space size, and high safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

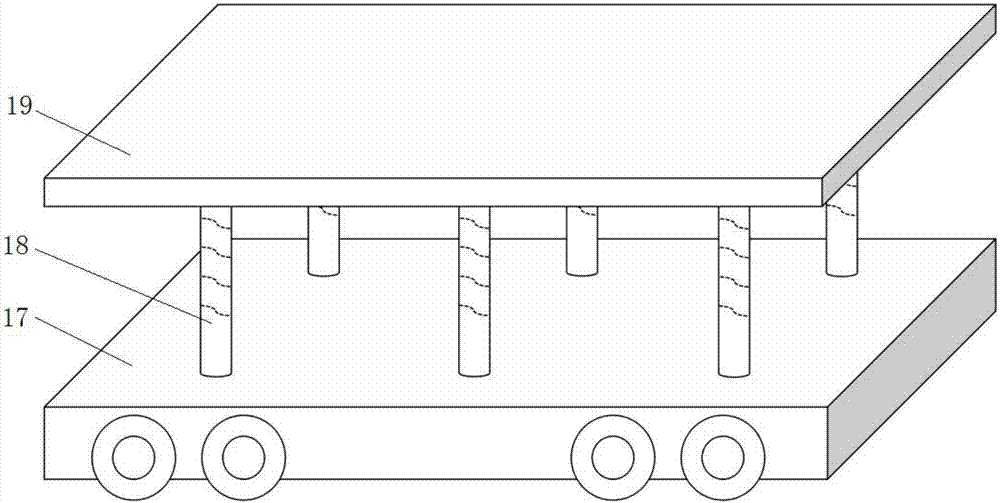

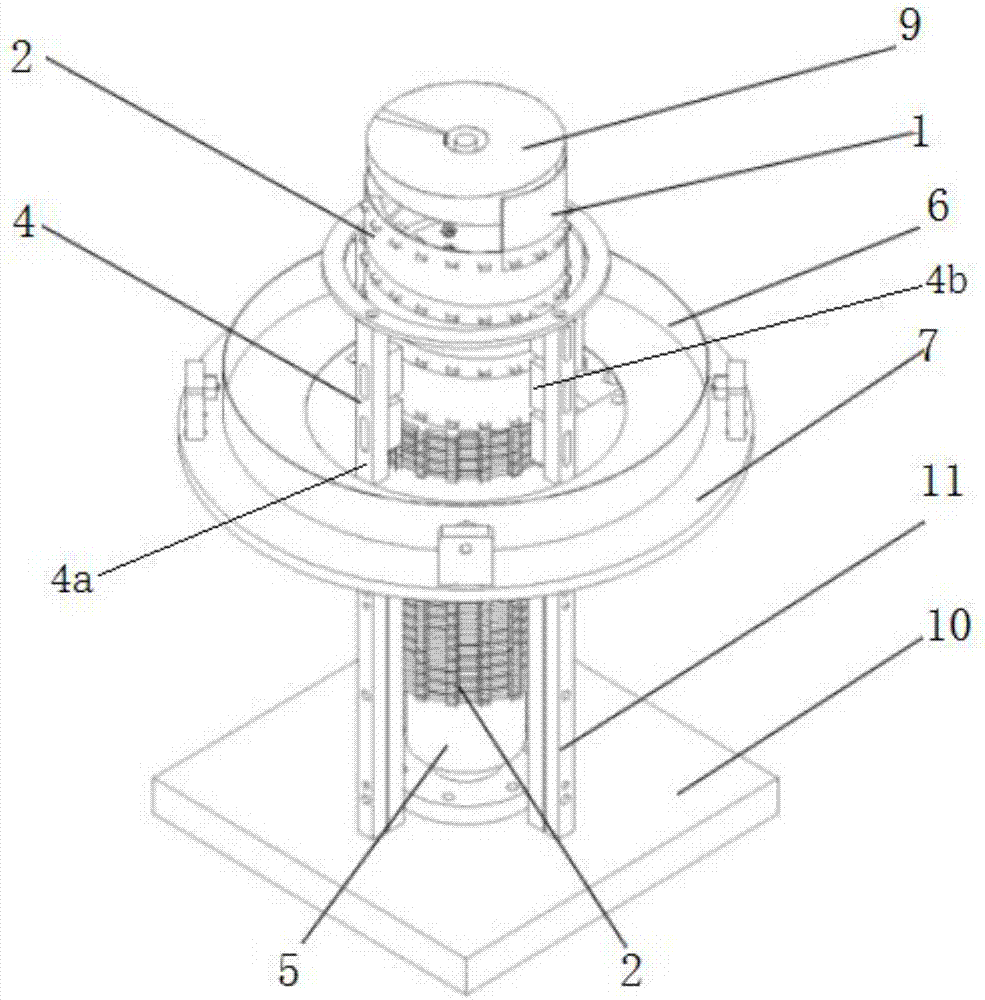

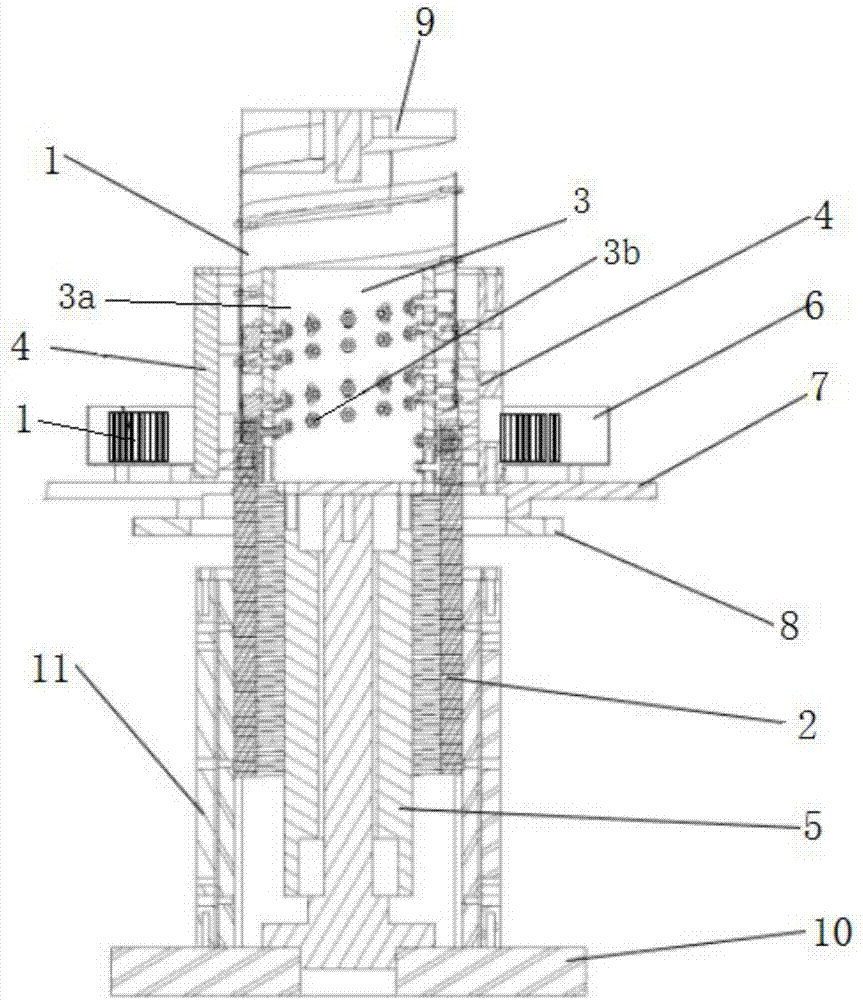

[0037] Such as Figure 1 to Figure 8 As shown, a lifting robot trolley includes a dolly 17 with wheels, several lifting devices arranged side by side along the upper end of the dolly 17, a loading platform 19 installed on a lifting device or a plurality of lifting devices, for controlling The controller of the lifting motion of the lifting device. After the goods loaded on the stage 19 are transported to the specified position by the trolley 17, the controller is activated to control the lifting device, thereby lifting the stage 19 to a specified height, so as to meet the production and processing requirements.

[0038] The lifting device is embedded in the trolley 17. When it needs to be lifted, the lifting device will protrude from the trolley 17 to lift the loading platform 19. The advantage of this design is to save space, and after the lifting device is used to shrink, it will be greatly reduced. the overall size.

[0039] The trolley 17 is an AGV or OMV trolley, and th...

Embodiment 2

[0047] see Figure 13 , that is, the number of screw jacks is 1, which constitutes a single lifting structure.

Embodiment 3

[0049] see Figure 14 and Figure 15 , that is, the number of screw lifters is 2, and the number of loading platforms 19 is also 2, forming a double-lifting structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com