Full-automatic stage seat lifting system

A lifting system, fully automatic technology, applied in the direction of lifting frame, lifting device, etc., can solve the problems of high investment cost, time-consuming and laborious, single function, etc., and achieve the effect of high safety performance, compact space structure and reasonable structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

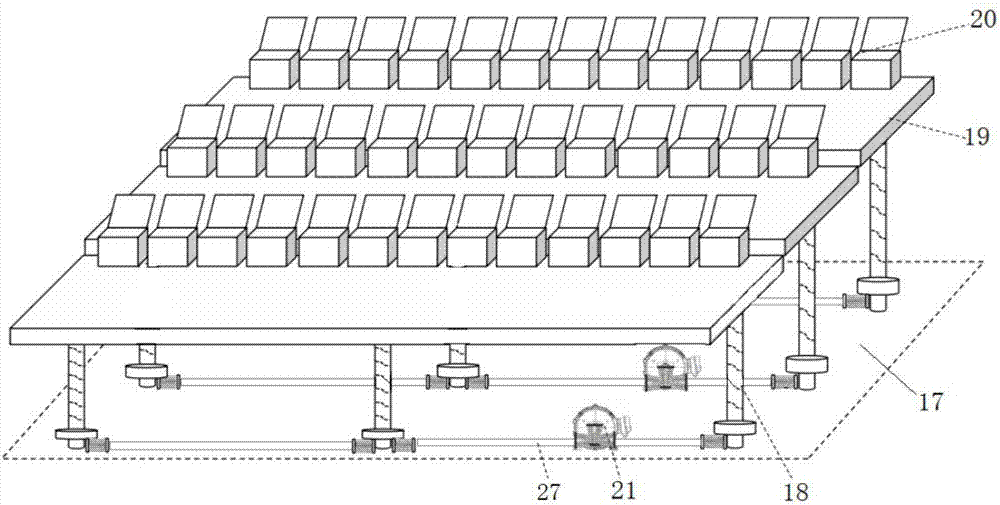

[0037] Such as Figure 1 to Figure 10 As shown, a fully automatic stage seat lifting system includes several lifting devices arranged side by side along the ground 17, a lifting platform 19 installed on the upper end of the corresponding lifting device, installed on the corresponding lifting platform 19 and can One or more sets of seats 22 arranged side by side are turned over to the seat mechanism 20 below the lifting platform 19 , and a controller for controlling the lifting device and the seat mechanism 20 is also included. The present invention lifts or lowers the corresponding lifting platform 19 through the lifting device, so that several lifting platforms 19 can be formed into a stepped distribution to meet the requirements of stage seat distribution; in addition, the seat mechanism 20 of the present invention can realize The seat 22 is hidden under the lifting platform 19, so that the lifting platform 19 can be combined into a large stage plane to meet the needs of sta...

Embodiment 2

[0047] Such as Figure 15 As shown, the lift platform 19 is a structure with a radian, and each lift platform 19 is distributed with three groups of seats 22 of B, C and D along the arc. At this time, the seat mechanism 20 includes three Rotate the motor 26, so that after the corresponding screw elevator lifts the lifting table 19, the three rotating motors 26 drive the corresponding three groups of seats 22 of B, C, and D to rotate to the bottom of the lifting table 19, and the seat can be completed. The collapse and hide of , the effect after collapse is as follows Figure 16 shown.

Embodiment 3

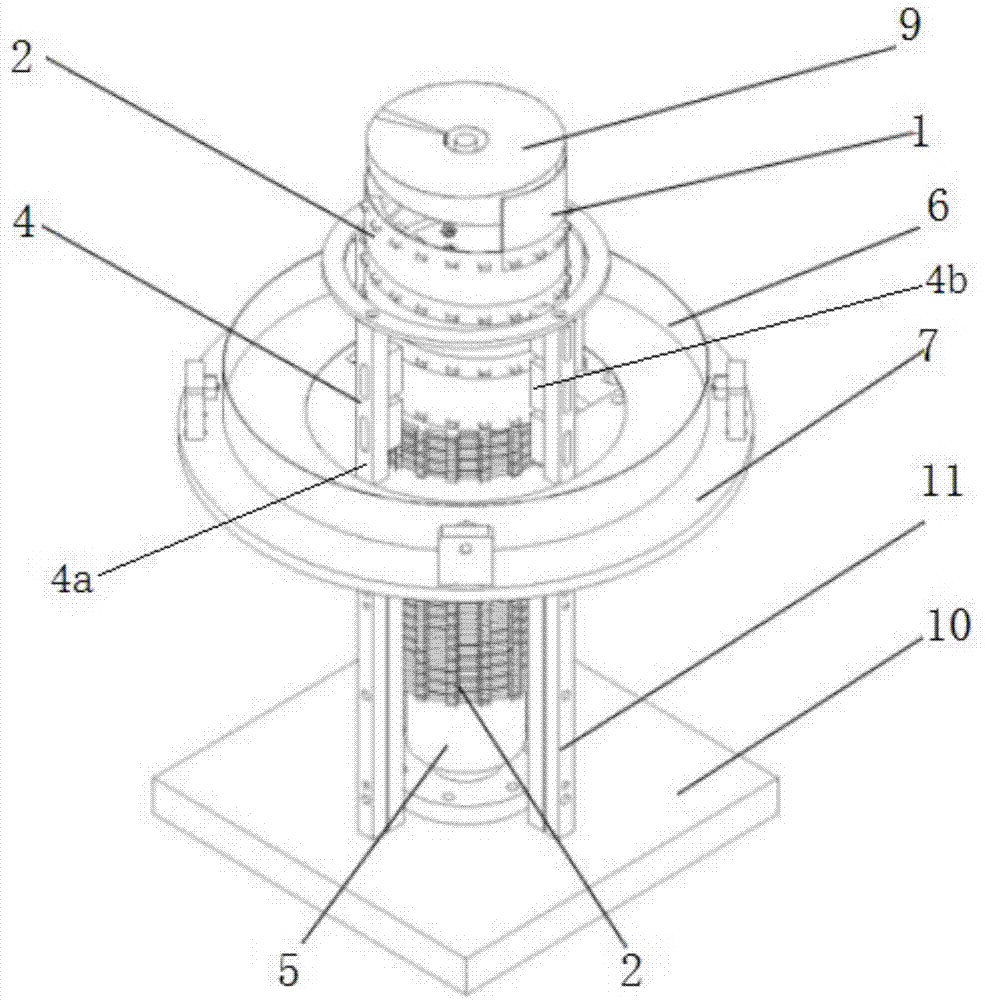

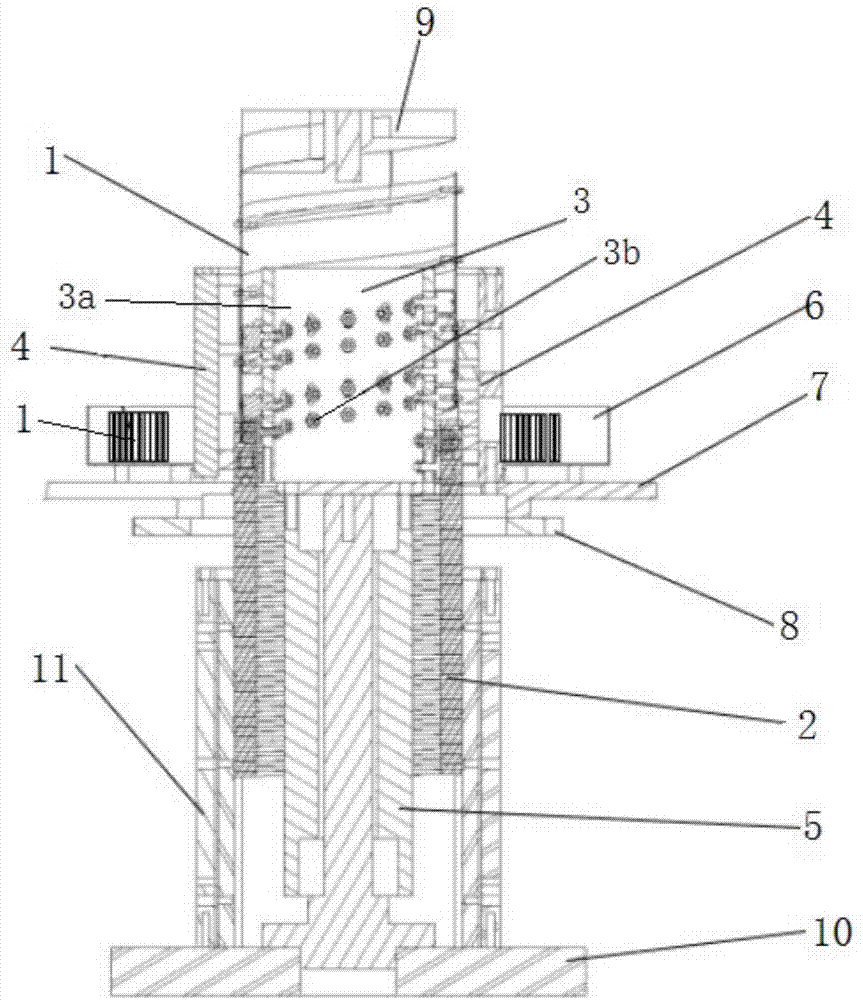

[0050]The screw jack 18 includes a fixed base, a platform that rotates around the fixed base, a storage box 6 installed on the platform, a spring flat belt 1 stored in the storage box 6, and a spring flat belt 1 that is installed in the fixed base and is flat with the spring. The belt 1 cooperates with the toothed spring bar 2 forming the spiral cylinder, and the belt track lifting mechanism installed on the platform is used to bind the toothed spring bar 2 to lift or shrink. 3. It is used to make the spring flat belt 1 and the toothed spring bar 2 snapping track guides 4 . The lifting motor 21 drives the platform to rotate, and then drives the belt track lifting mechanism 3 to rotate, and the belt track lifting mechanism 3 makes the toothed spring bar 2 rise and fall under the guidance of the belt track lifting mechanism 3, and synchronously pulls the spring flat belt 1 spiral Climbing, under the pushing effect of the rail guide frame 4, the spring flat belt 1 and the toothed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com