Upper-section sliding device for mechanical valve

A sliding device and mechanical technology, which is applied to non-mechanical actuated valves, valve devices, mechanical equipment, etc., can solve problems such as high sealing requirements, liquid leakage, and delayed response speed of valve lift changes. Fast response, simple structure, reasonable design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

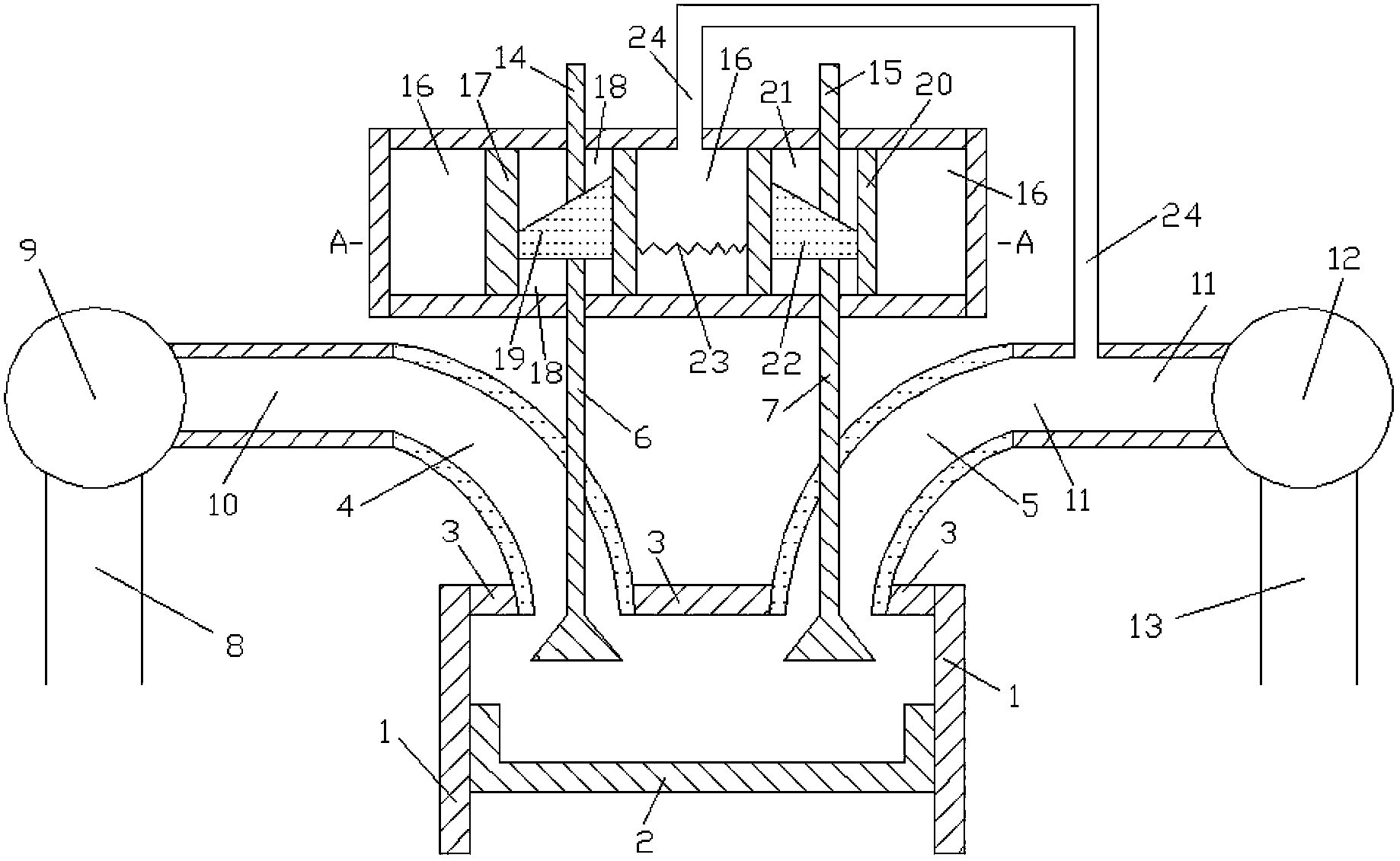

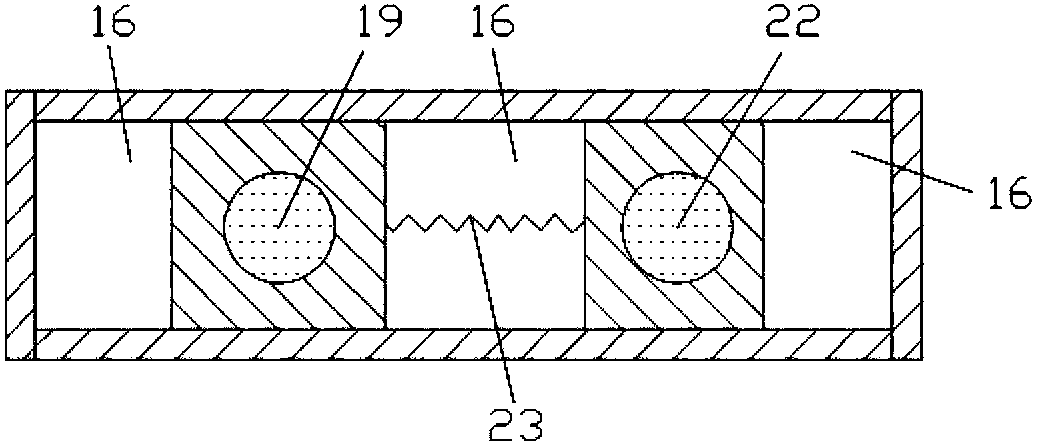

[0013] Such as figure 1 and figure 2 Shown, the present invention comprises: comprise cylinder 1, piston 2, cylinder head 3, intake channel 4, exhaust channel 5, intake valve lower section 6, exhaust valve lower section 7, compressor intake pipe 8, compressor 9, Engine intake pipe 10, engine exhaust pipe 11, turbine 12, turbine outlet pipe 13, intake valve upper section 14, exhaust valve upper section 15, volume chamber 16, first moving body 17, first through pipe 18, first moving Block 19, second moving body 20, second through pipe 21, second moving block 22, spring 23 and connecting pipe 24, the piston 2 is installed in the space surrounded by the cylinder 1 and is in sealing contact with the inner wall of the cylinder 1, The air outlet of air intake passage 4 and the air inlet of exhaust passage 5 are all connected with cylinder head 3, and the air inlet and outlet of compressor 9 are respectively connected with the air outlet of compressor air intake pipe 8 and the air i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com