Continuous changeable air inlet tumbling flow control mechanism of engine and engine

A control mechanism and engine technology, applied in engine control, combustion engine, machine/engine, etc., can solve the problem of variable tumble flow not working, and achieve the effect of improving airflow movement and better tumble flow effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

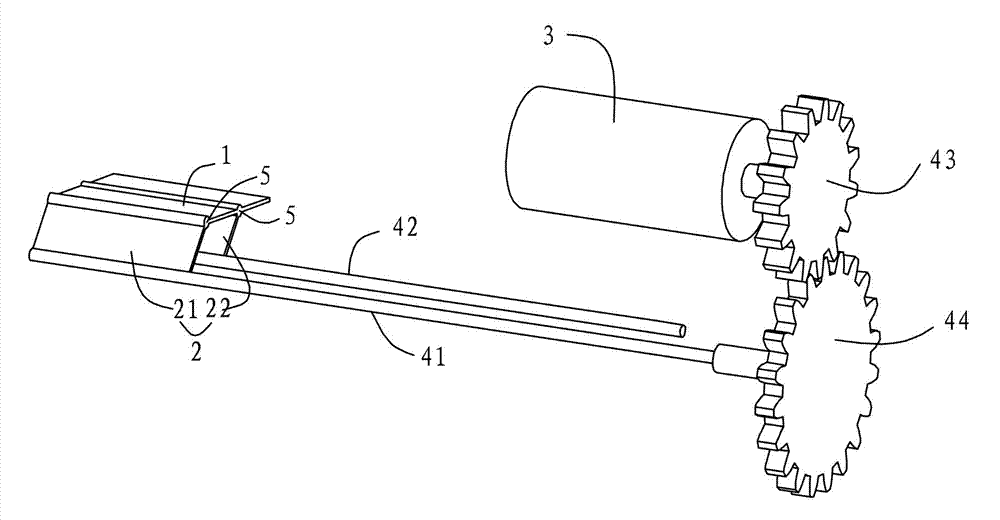

[0023] This embodiment relates to a continuously variable intake tumble control mechanism for an engine, which is arranged in the intake pipe of the engine, and is composed of figure 1 As shown, it includes a top plate 1 arranged horizontally in the state shown in the figure, a support blocking device 2 connected to the bottom of the top plate 1 , and a power transmission mechanism connected between the support blocking device 2 and the power output device 3 . The power is transmitted to the support and blocking device 2 through the power transmission mechanism, so that the support and blocking device 2 drives the top plate to have a vertical displacement while keeping the top plate 1 in a horizontal state. In this embodiment, the power output device 3 adopts a servo motor.

[0024] Wherein, the support blocking device 2 comprises a first side plate 21 and a second side plate 22 of the same size that are arranged in parallel and connected below the top plate 1, and the first s...

Embodiment 2

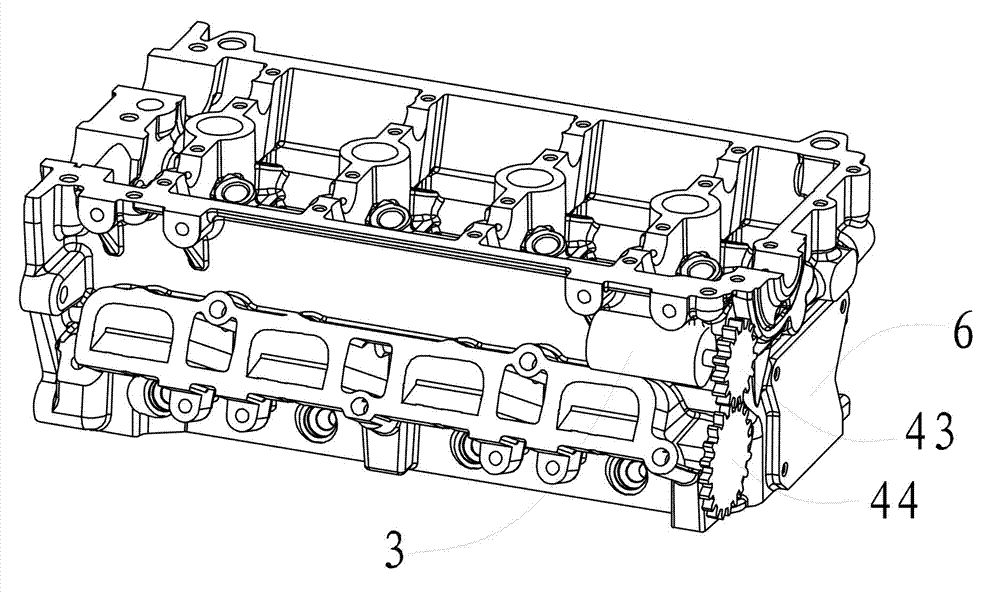

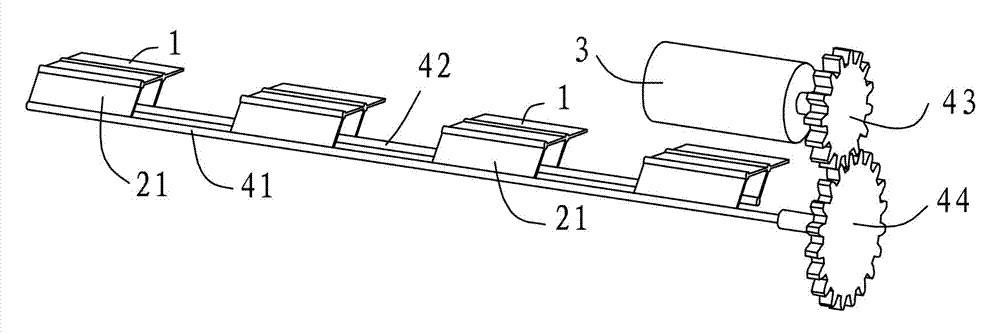

[0029] This embodiment relates to an engine, which is an application of the continuously variable intake tumble control mechanism of the engine involved in the first embodiment. Depend on figure 2 combine image 3 As shown, the engine of this embodiment has four intake ducts, each of which is provided with the continuously variable intake tumble flow control mechanism of the engine involved in the first embodiment. Depend on image 3 As shown, the continuously variable intake tumble control mechanism of the engine is basically the same as the first embodiment, the difference is that four sets of supporting and blocking devices 2 are used to cooperate with the top plate 1, and one rotating shaft 41, one Root driven shaft 42, a power output device 3 and a speed reduction structure.

[0030] Depend on figure 2 As shown, the power take-off device 3 is fixedly arranged on the main body 6 of the engine, and the rotating shaft 41 connected with the driven gear 44 penetrates fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com