Optical fiber splitter with good moisture resistance and use method thereof

A fiber optic splitter and moisture-proof technology, which is applied in the direction of instruments, optics, light guides, etc., can solve the problems of increasing internal device damage, affecting the effectiveness of fiber optic splitters, and insufficient sealing and moisture-proof performance inside the box. To achieve the effect of improving the sealing performance, improving the moisture-proof effect, and enhancing the moisture-proof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

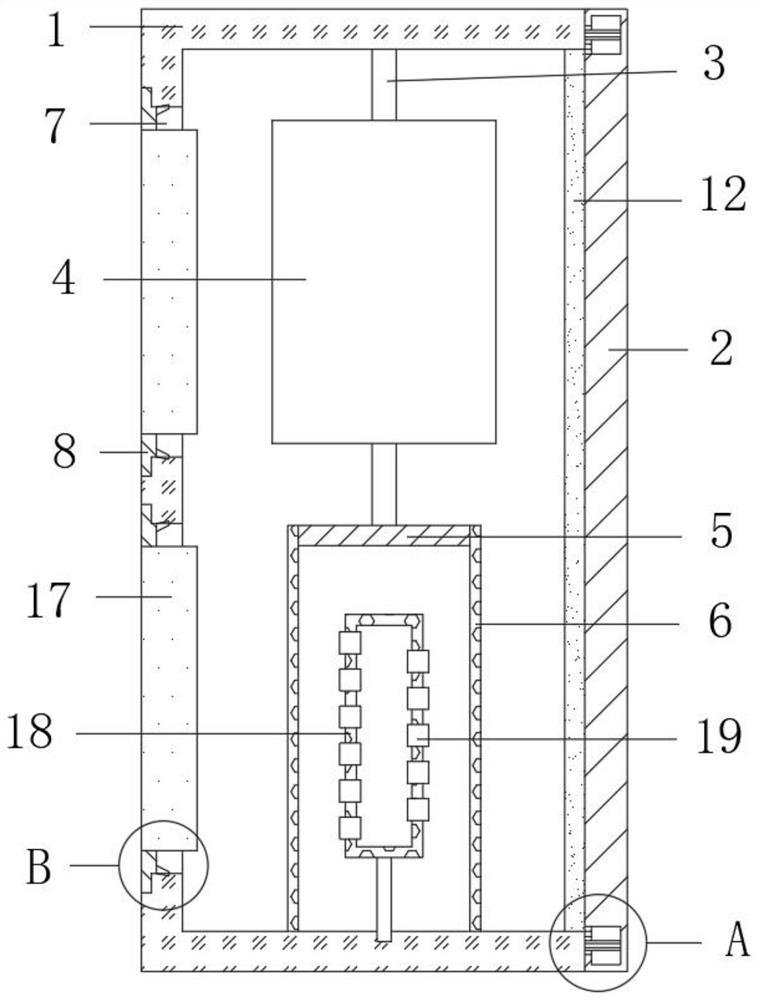

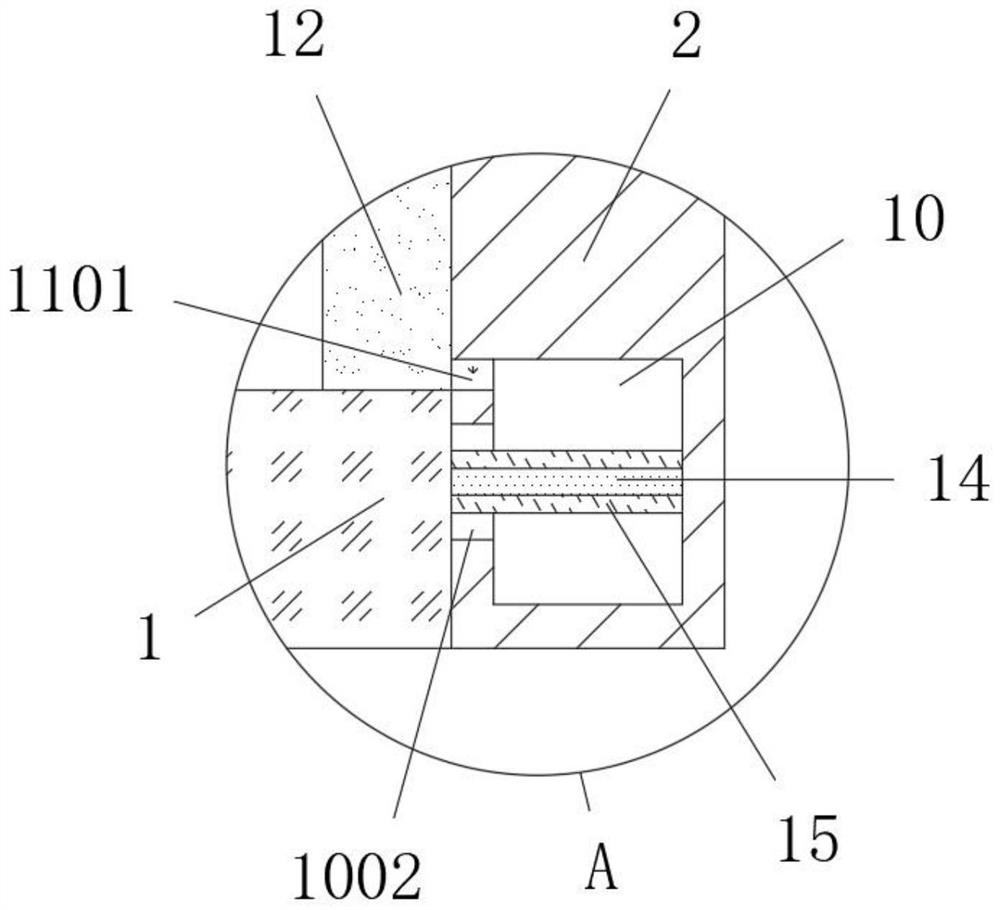

[0037] refer to Figure 1-2 and Figure 4-8 , a fiber optic splitter with good moisture resistance, comprising a splitter box 1, one end of the splitter box 1 is provided with a box door 2, and the middle position of the top inner wall of the splitter box 1 is fixed with a fixing frame 3, and fixed A plurality of shunt devices 4 are penetrated and fixed on the frame 3 , the bottom of the fixed frame 3 is provided with a cable rack 6 , and a connection cavity 10 is provided at the top and bottom of the box door 2 , and both sides of the inner wall of the connection cavity 10 Both are slidably connected with connectors 11, and the bottom ends of both sides of the inner wall of the connection chamber 10 near the end of the splitter box 1 are provided with horizontally placed limiting grooves 1001, and the positions corresponding to the outer walls of the connectors 11 and the limiting grooves 1001 are fixed. The limit block 1101 slidingly connected with the limit groove 1001, th...

Embodiment 2

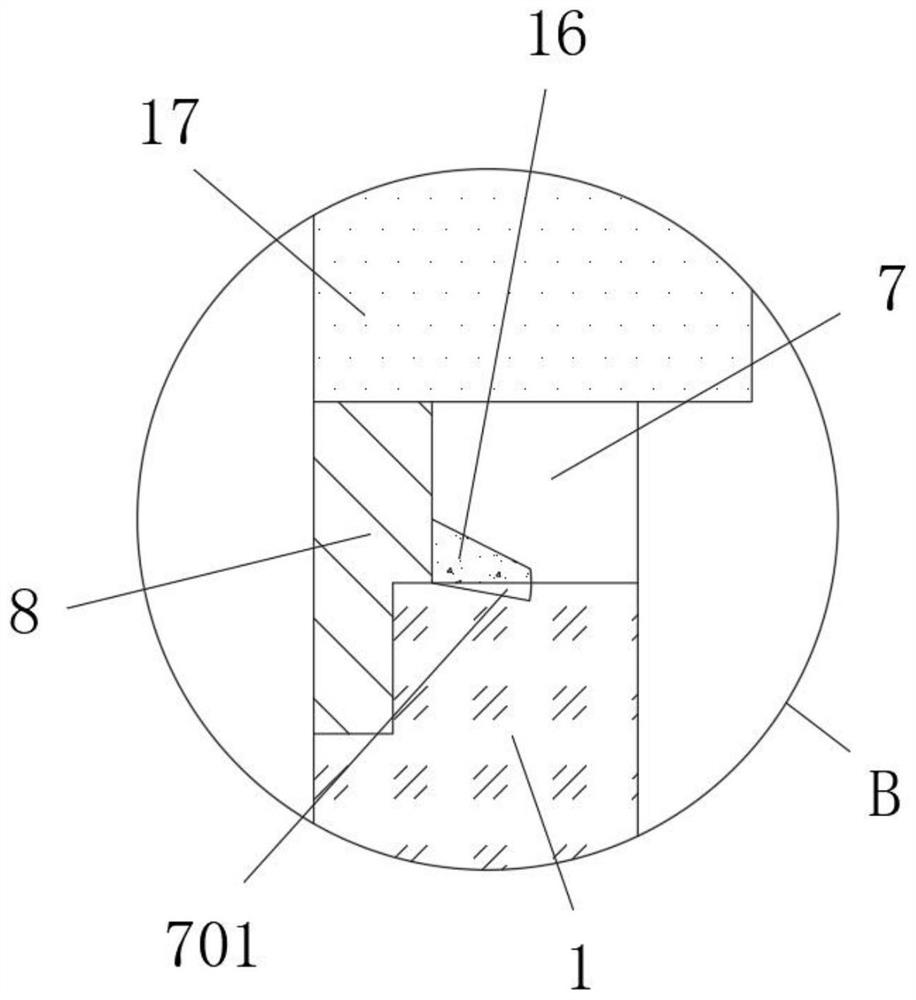

[0049] Embodiment 2 includes all structure and method parts of embodiment 1, with reference to Figure 1-10 , a fiber optic splitter with good moisture resistance, also includes, the top and bottom of the end of the splitter box 1 far away from the box door 2 are provided with a penetrating maintenance slot 7, and the maintenance slot 7 is far away from the side of the box door 2 One end is detachably connected to a cover plate 8, and the outer wall of one end of the cover plate 8 penetrates and fixes heat sinks 17 equidistantly distributed in the horizontal direction;

[0050] Filler 16 is fixed on the top and bottom of the inner wall of the cover plate 8 close to the maintenance tank 7, and the outer wall of the filler 16 away from the heat sink 17 is set to a horizontal plane, and the outer wall of the end of the filler 16 close to the heat sink 17 is set to be arched. The arc surface structure, the filler 16 is made of rubber material, the top and bottom inner walls of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com