Variable inductor

An inductor and variable technology, applied in the direction of continuously variable inductors/transformers, printed inductors, transformer/inductor components, etc. The problems of long path and small Q value can achieve the effect of facilitating large-scale industrial production, low processing cost and high working frequency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

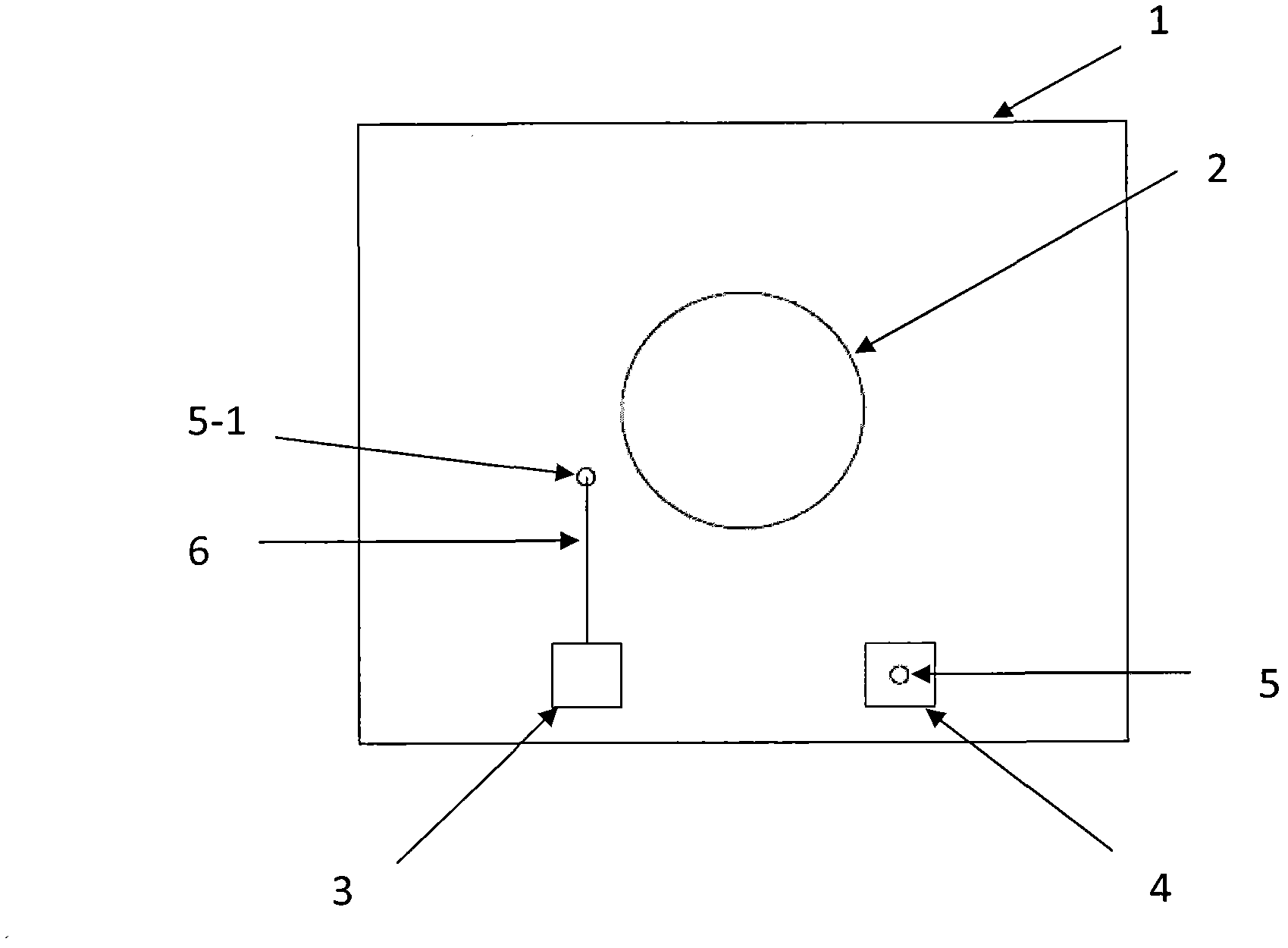

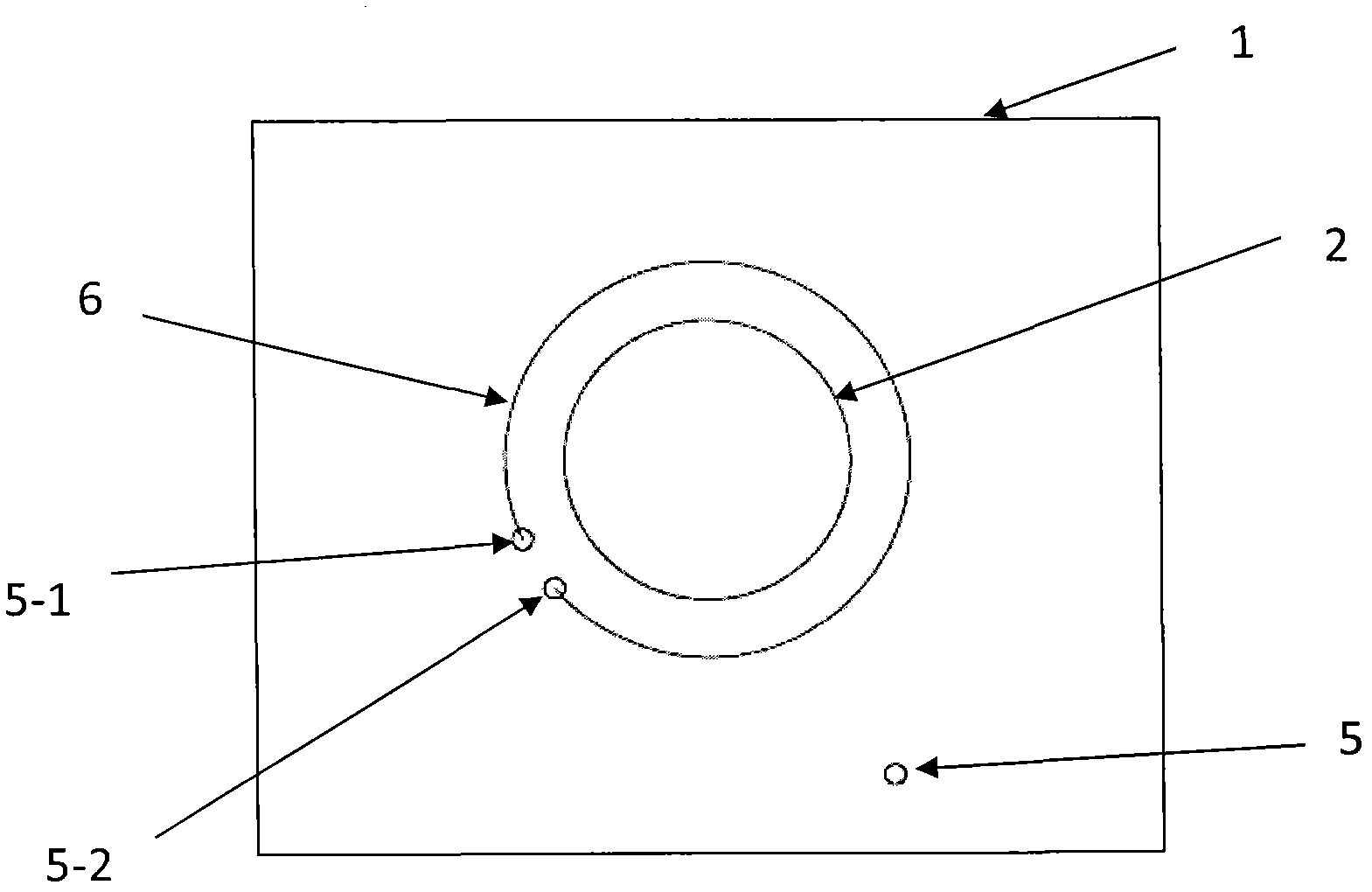

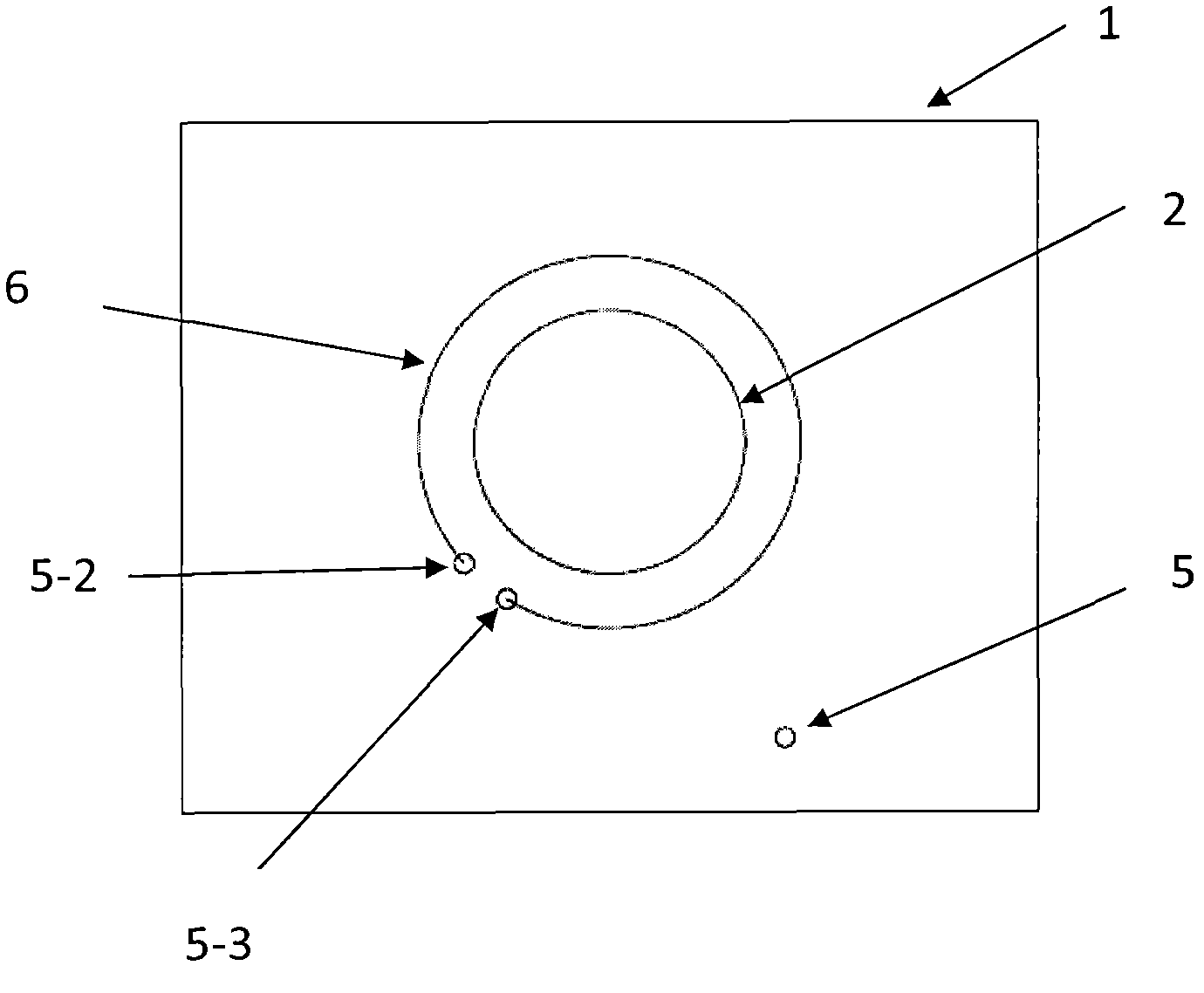

[0029] The variable inductor of the first embodiment of the present invention includes a substrate 1, an inductor 6 printed on the substrate, a pair of electrodes 3, 4, and a core 7 of the inductor 6. The substrate can be a one-layer or multi-layer PCB. The PCB in this embodiment is a 9-layer PCB board. The inductor 6 is a metal microstrip line (referred to as a metal wire) printed (or called printed) on the 9-layer PCB. Its shape is a coil. The width of the microstrip line made can determine the power and inductance of the inductor 6. There is a hole on the substrate 1. In this embodiment, a hole 2 is opened in the center of the substrate 1. The hole 2 can be a hole of other shapes such as a round hole, a square hole, or a triangular hole. This embodiment is a round hole, which is easy to process. The radius of the circular hole is smaller than the radius of the inductor 6 coil. The core 7 is also a cylinder. The core 7 can also be a square cylinder, a triangular cylinder, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com