Chromium ore pellet pre-reduction direct-supply submerged arc furnace system and pre-reduction direct-supply method

A submerged arc furnace and pellet technology, applied in the field of metal smelting, can solve problems such as environmental pollution and high energy consumption of the system, and achieve the effects of reducing dust pollution, large processing capacity, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

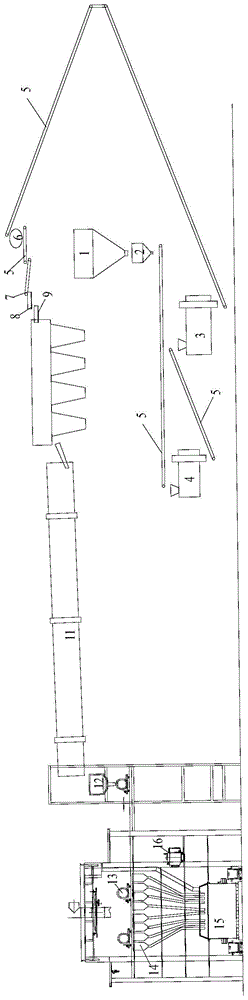

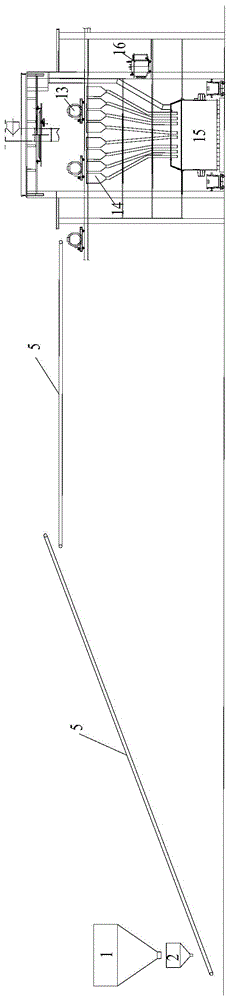

[0048] see figure 2 . The system of pre-reduction of chrome ore pellets and direct supply to the submerged arc furnace is abbreviated as GQYZ technology according to the pinyin. It includes a Φ6m disc pelletizer 6 set at a height of 50m from the ground, which is connected to a grate machine 10, a 4×60m pre-reduction rotary kiln 11,

[0049] The feeding port of the disc pelletizer 6 is connected with a batching unit through a B650 belt 5 . The discharge port of the pelletizing machine is connected to the feed port of the grate machine 11 through the swing head belt 7, the large ball round roller screen 8, and the roller screen distributor 9 in sequence, and the discharge port of the chain grate machine is connected to the pre-reduction rotary The feed port of the kiln; the discharge port of the pre-reduction rotary kiln is connected to the submerged arc furnace;

[0050] The pelletizer, chain grate, and pre-reduction rotary kiln are supported by reinforced concrete structur...

Embodiment 2

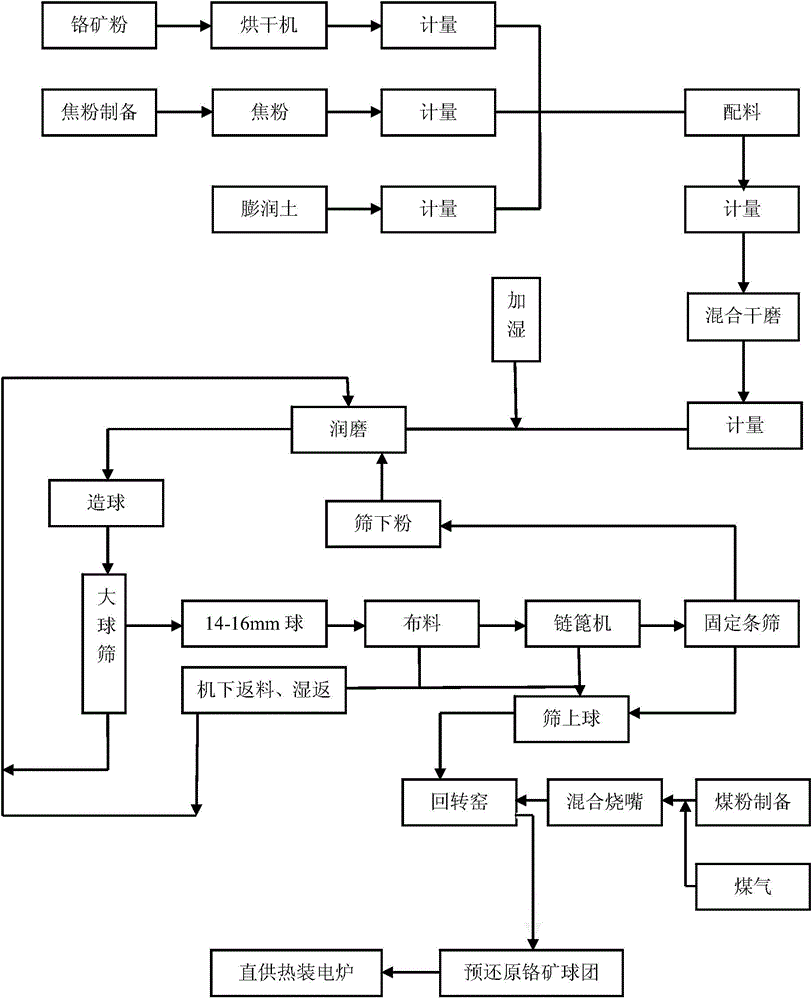

[0055] Use the direct supply system of embodiment 1, technological process such as figure 1 . The annual consumption of bentonite is 0.3 million tons (dry). The low calorific value of coke powder used for pelletizing is 7200-7400Kcal / kg. The pulverized coal used in the rotary kiln has a low calorific value of 5800-6000Kcal / kg.

[0056] Pre-reduction pellet process:

[0057] (1) Raw materials, fuels and adhesives accept:

[0058] Chromium concentrate powder is transported by car to the raw material yard for stockpiling; the binder is bentonite, also known as bentonite, which is sent to the bentonite mine tank by manual unpacking.

[0059] Coke powder (used for pellet batching) and coal powder (coal powder used for rotary kiln roasting) are directly sent to the coal shed by car, loaded by a loader, and sent to the raw coal bunker (shared) in the powder plant building through a bucket elevator .

[0060] (2) Drying of chrome concentrate powder

[0061] Since the chrome con...

Embodiment 3

[0077] Use the direct supply system of embodiment 1, raw material is with embodiment 2.

[0078] Pre-reduction pellet technology differs from Example 2:

[0079] (3) Ingredients

[0080] According to the resource situation, the batching room adopts a single-row setting for the feed tank, and the batching tank is designed to store chrome concentrate powder, binder, and coke powder respectively. 2 o 3 Content up to 10-14%, SiO 2 Content up to 4-5%, Cr 2 o 3 Content up to 40-45%, TFe content up to 20-25%, for batching. The batched mixture is sent to a dry ball mill for grinding.

[0081] (4) Humidification and grinding process

[0082] In order to ensure that the batch material and water are fully mixed, improve and stabilize the quality of the pellets, and stabilize the roasting process, a humidification and moistening process is selected. Through humidification, control moisture 5-6%.

[0083] (5) Ball making

[0084] The pelletizing room is equipped with a mixing bin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com