Patents

Literature

34results about How to "Meeting power generation needs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

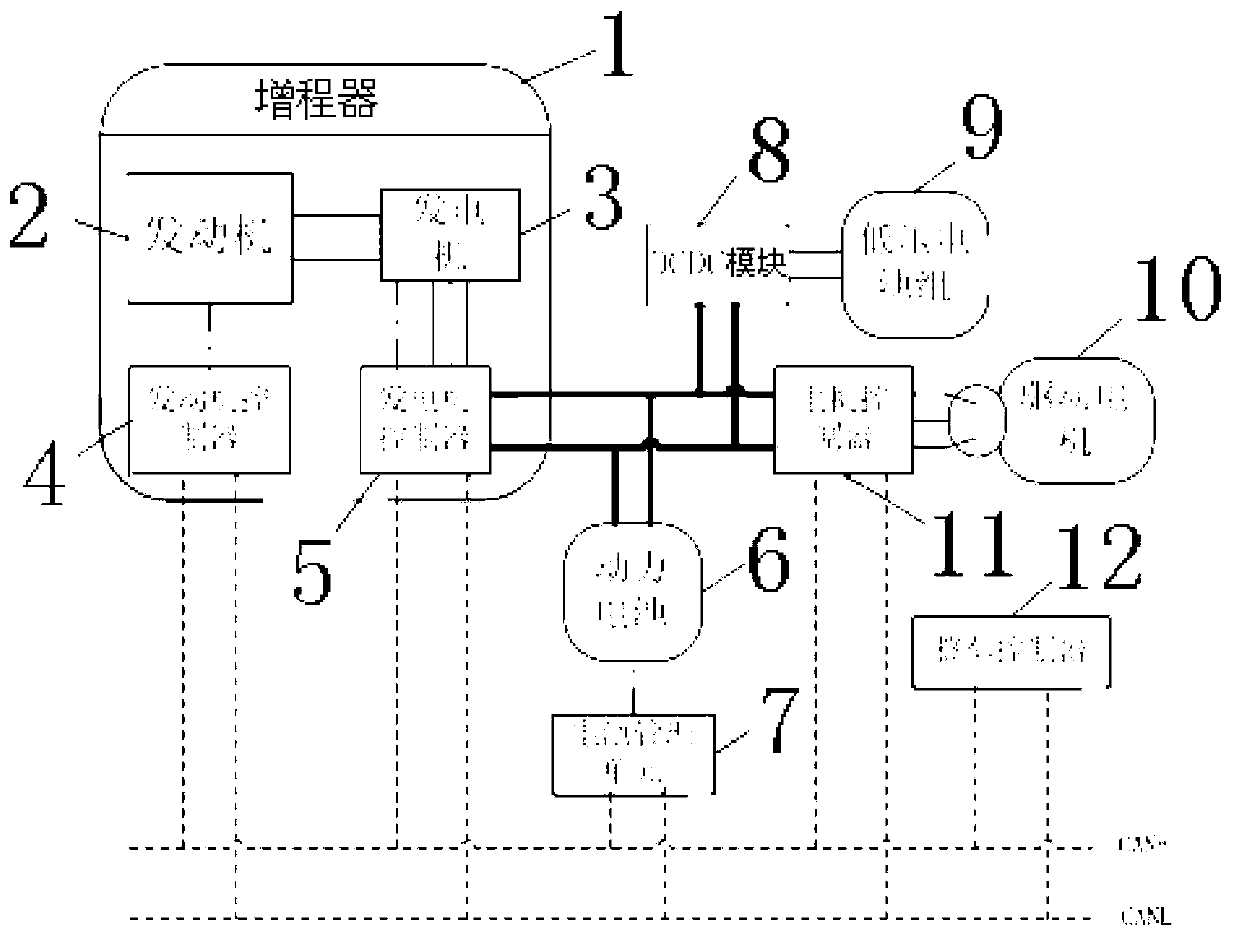

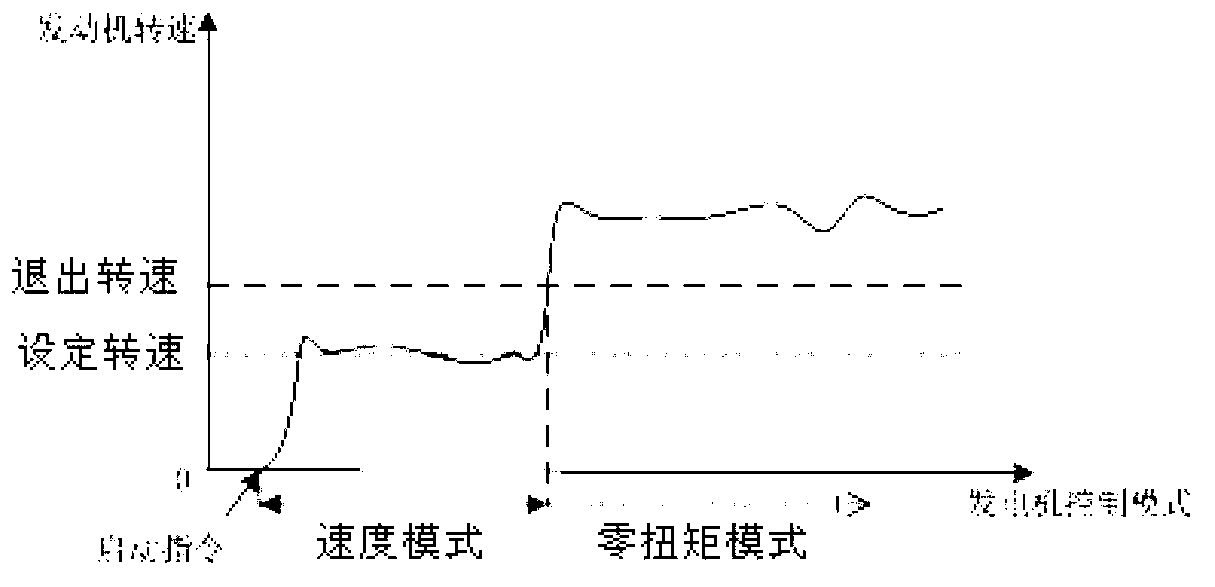

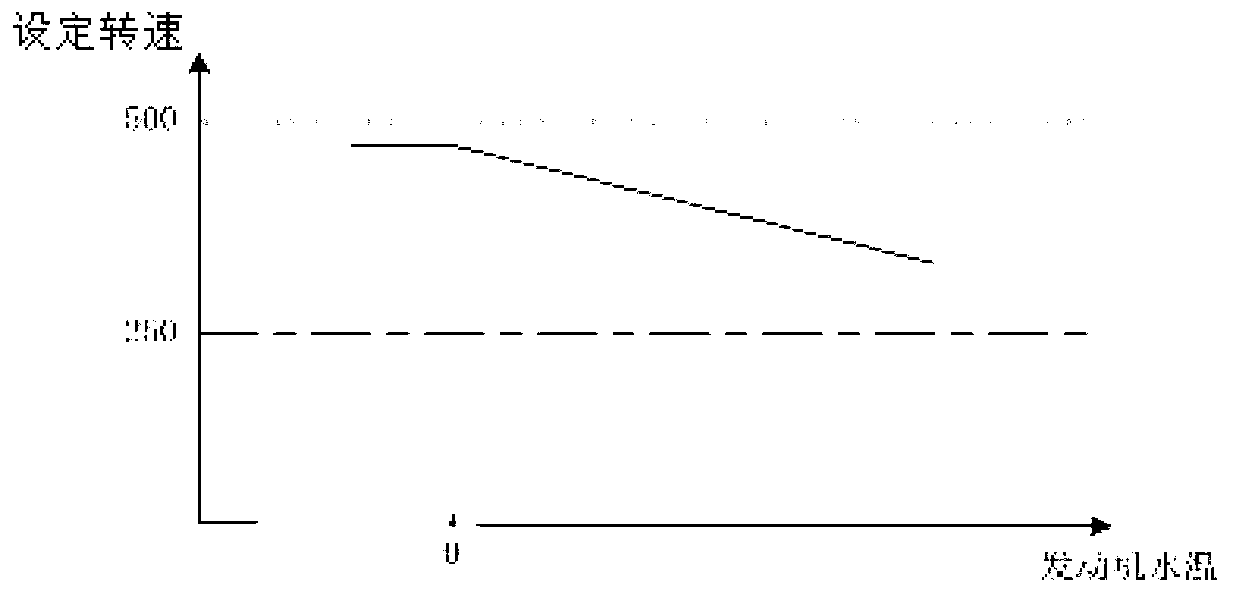

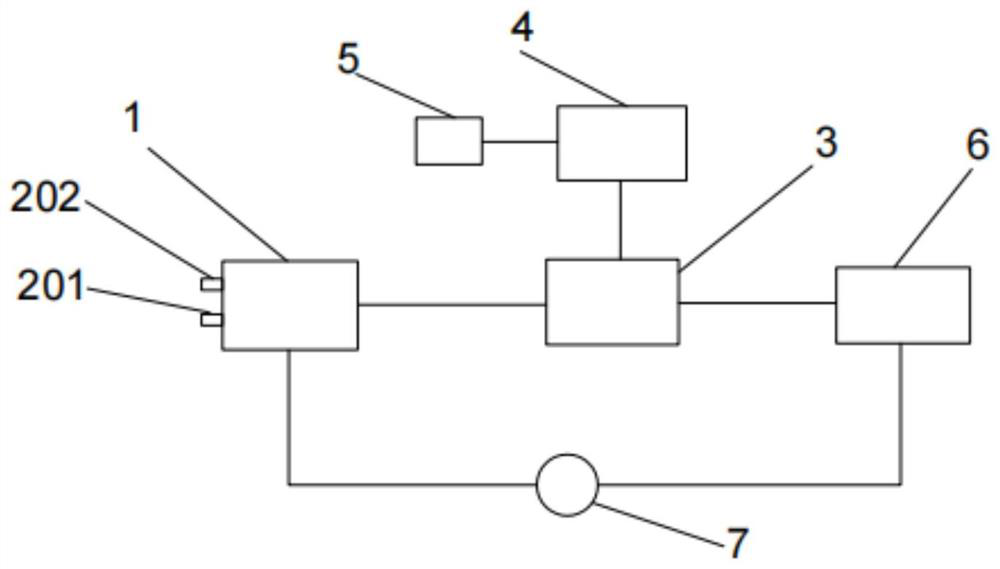

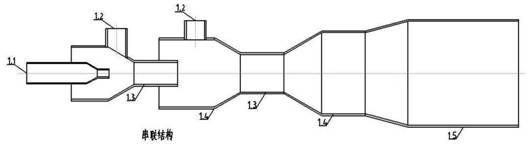

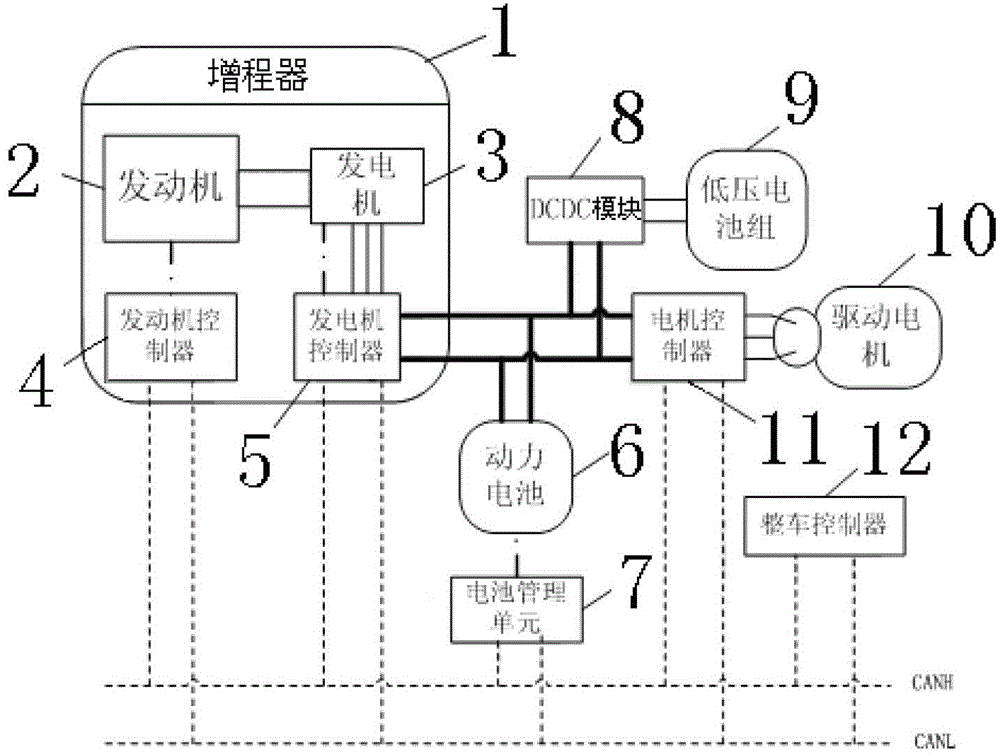

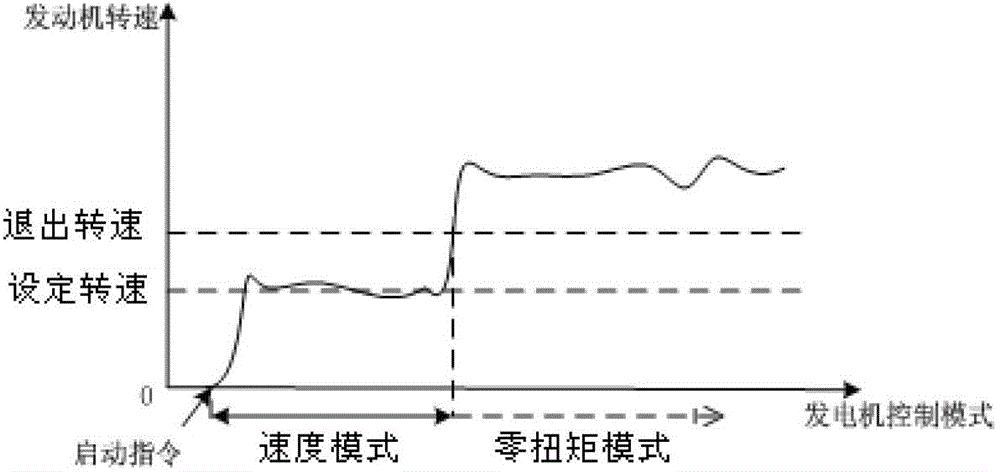

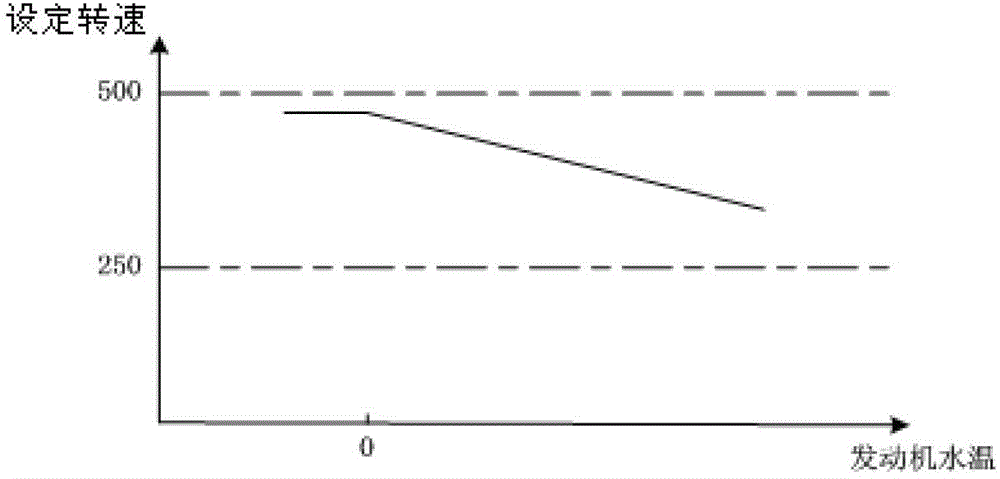

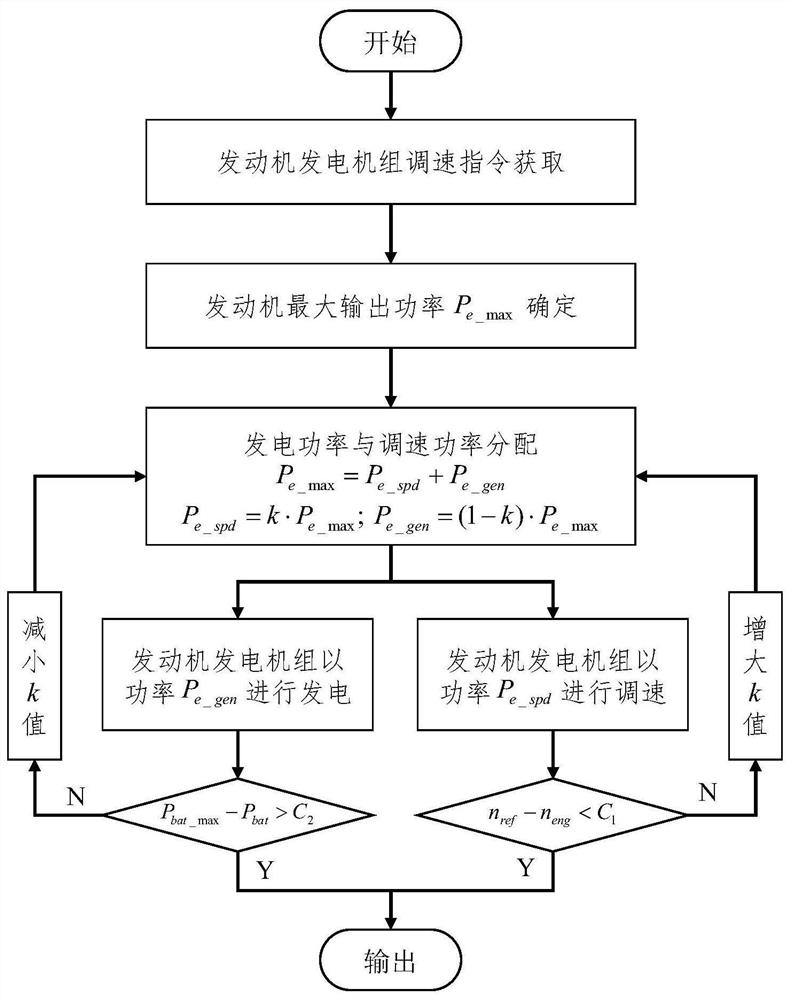

Implementation method for speed regulation of range extender of electric vehicle

ActiveCN102975625AMeeting power generation needsAchieve target speedPropulsion using engine-driven generatorsVehicular energy storageElectric machineDrive motor

The invention discloses an implementation method for speed regulation of a range extender of an electric vehicle. The range extender comprises an engine, an electric generator, a corresponding engine controller and a corresponding electric generator controller, the electric generator, a driving motor and a motive power battery share a direct current bus, and the engine controller and the electric generator controller are both connected with a whole vehicle controller. When the range extender receives a power request sent by the whole vehicle controller, the whole vehicle controller sends corresponding request torque to the engine controller, the engine controller controls the engine to output the request torque, the request torque sent by the whole vehicle controller to the engine controller serves as feedforward, and the electric generator controller controls and regulates torque of the electric generator. The range extender is enabled to work at a target rotation speed, control of the speed regulation of the range extender is achieved, requirements for whole vehicle electric generation are met, the torque of the engine and the torque of the electric generator are coordinated and controlled to achieve response to the target rotation speed, and the torque, electric current and output power of the electric generator have small fluctuation.

Owner:CHERY AUTOMOBILE CO LTD

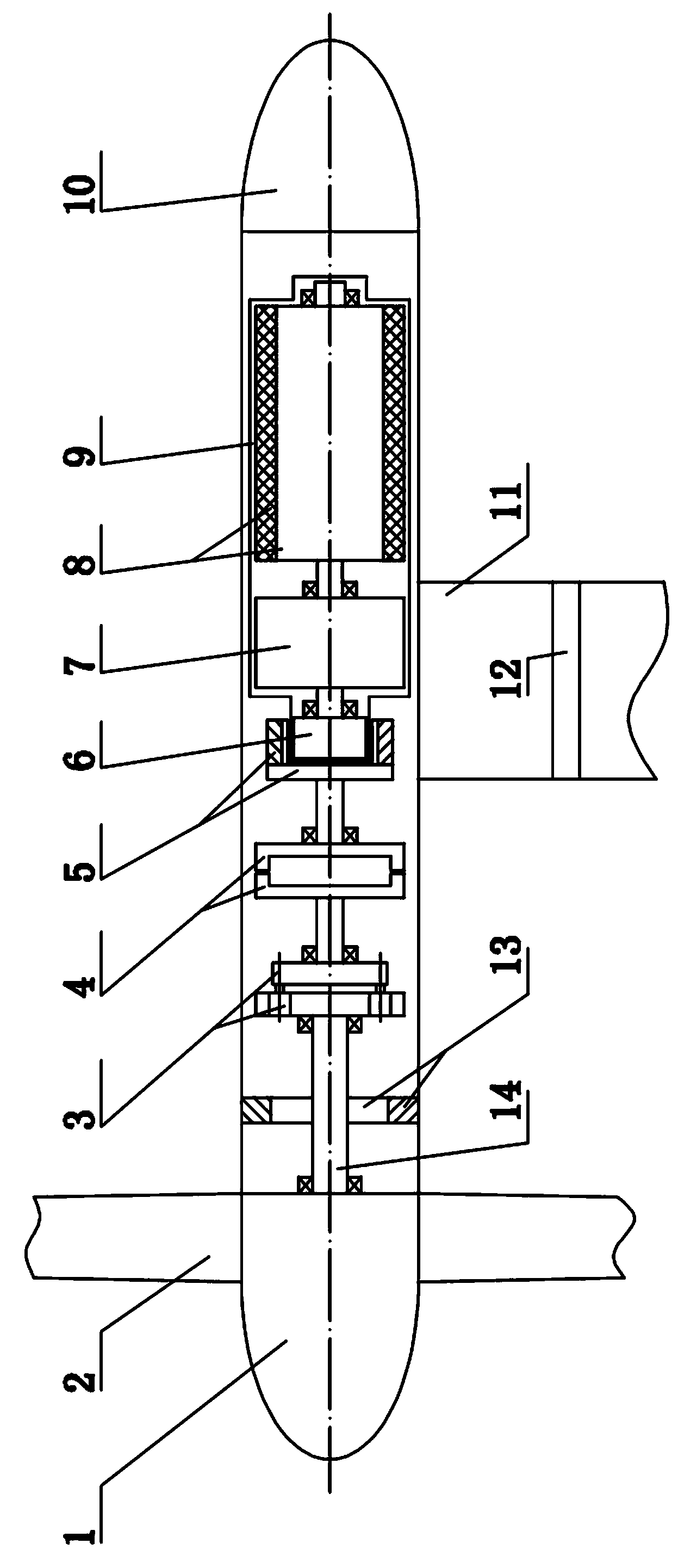

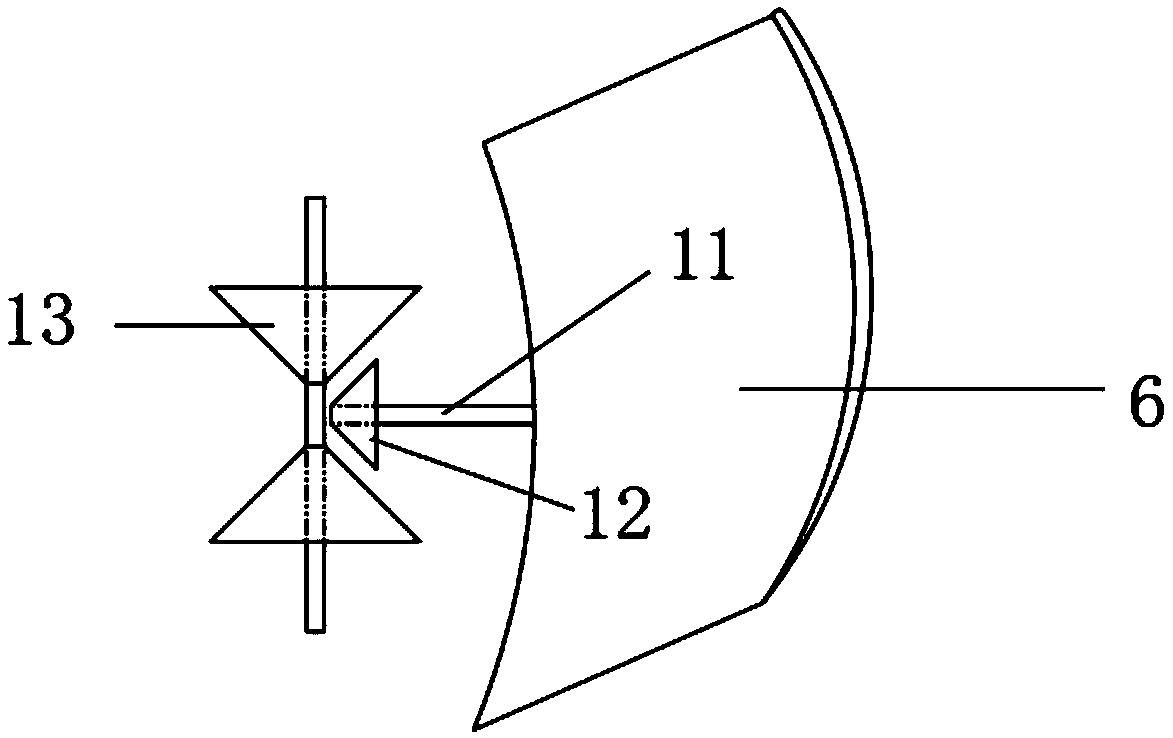

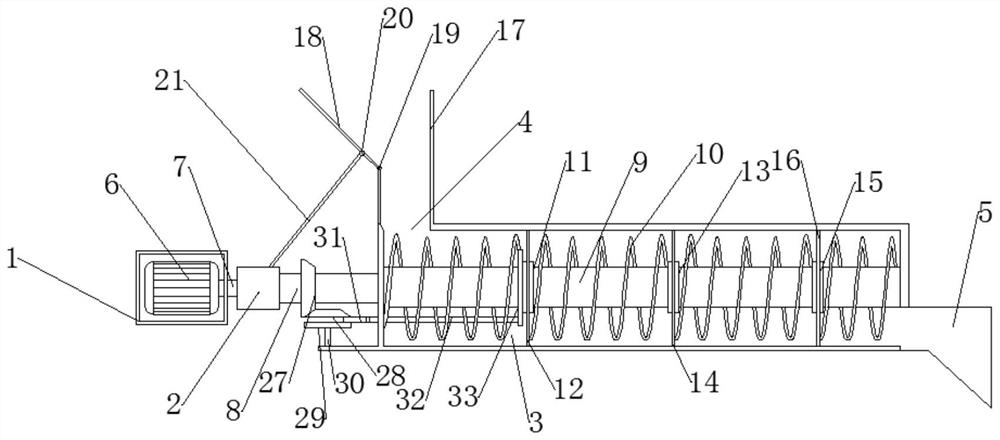

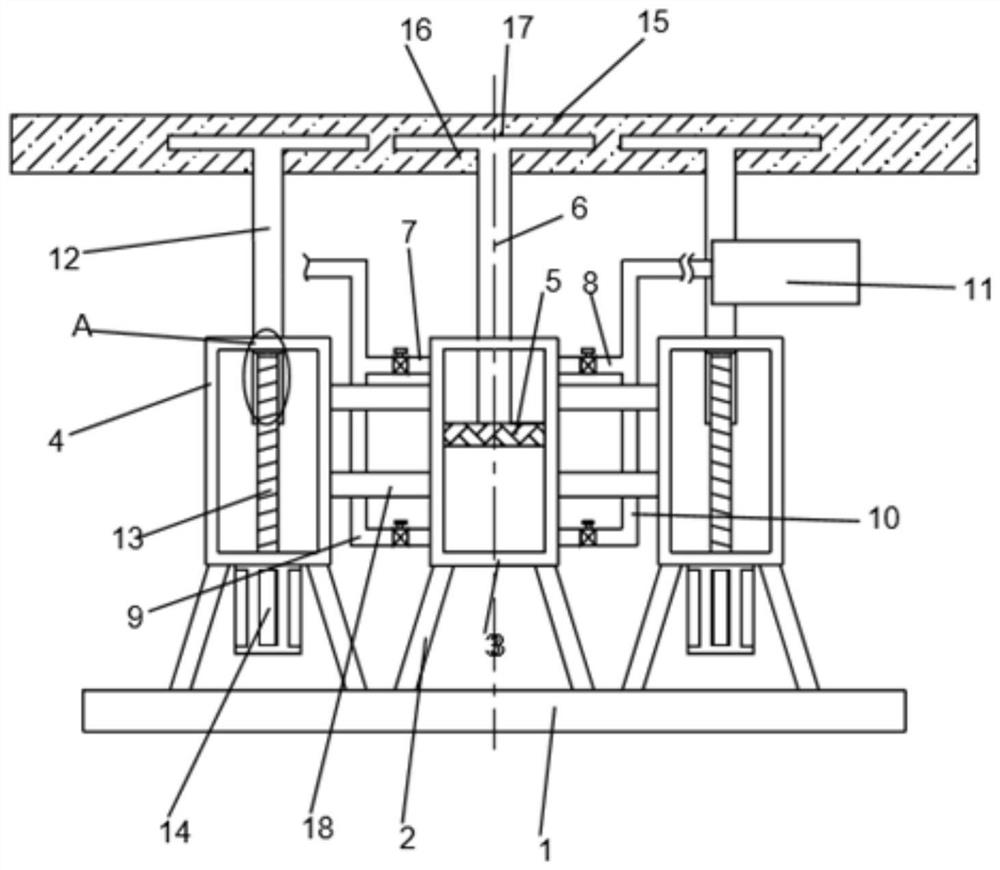

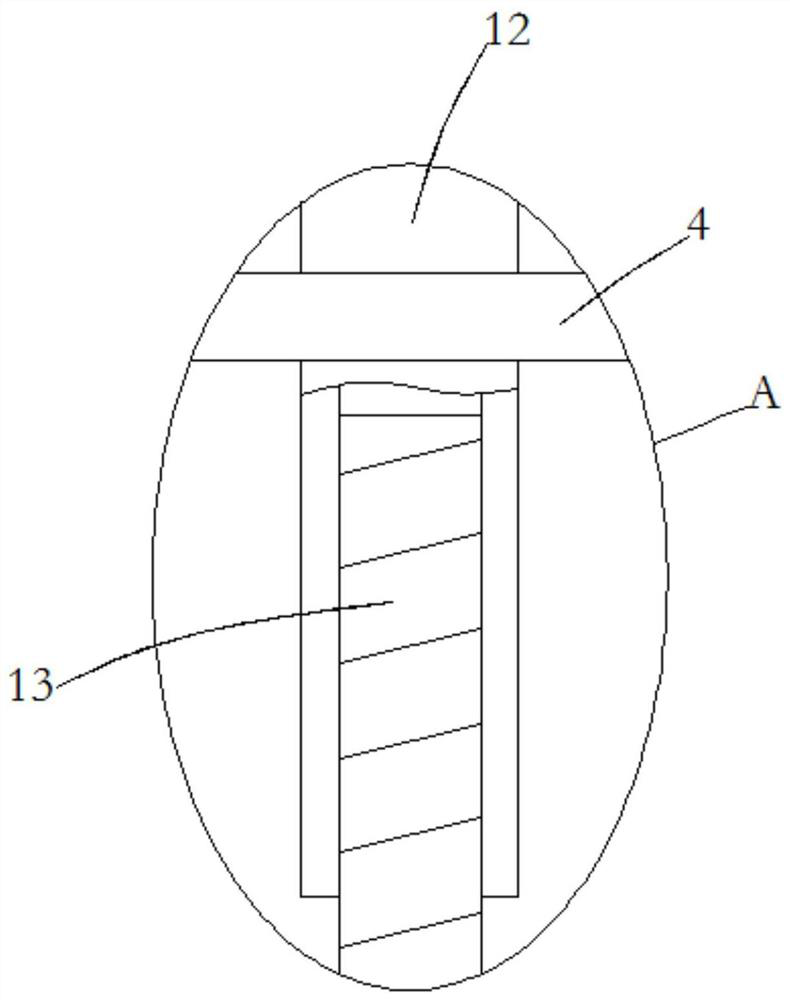

Horizontal shaft tide turbine power generation device storing energy by means of flywheel

InactiveCN103541854AMeeting power generation needsMachines/enginesEngine componentsFreewheelElectricity

A horizontal shaft tide turbine power generation device storing energy by means of a flywheel is characterized in that a turbine shaft is accelerated by means of a transmission, the flywheel is driven by an electromagnetic coupler to rotate, and the flywheel drives a generator to operate. When first starting is carried out, the flywheel needs to store energy, loads are disconnected by the generator at the moment, and the flywheel is continuously accelerated. When the flywheel reaches a designed rotating speed, the generator starts to generate electricity; when power of the turbine shaft is higher than power of the generator, the flywheel continues to store kinetic energy, and the rotating speed of the flywheel is increased; when the power of the turbine shaft is lower than the power of the generator, the flywheel releases the kinetic energy, and the rotating speed of the flywheel is decreased. When the tide speed is low, the turbine brakes and is disconnected with the flywheel, and the flywheel continues to drive the generator to operate by means of the stored kinetic energy. A turning device is adopted to maintain the obverse side of the turbine to always face towards a coming tide, and therefore the constant rotating direction of the turbine shaft is guaranteed. When a new tide circulation is started, the tide speed reaches to a starting speed, the flywheel can drive the turbine to be started through the electromagnetic coupler, and the problem that the turbine cannot be normally started is eliminated.

Owner:周军伟 +1

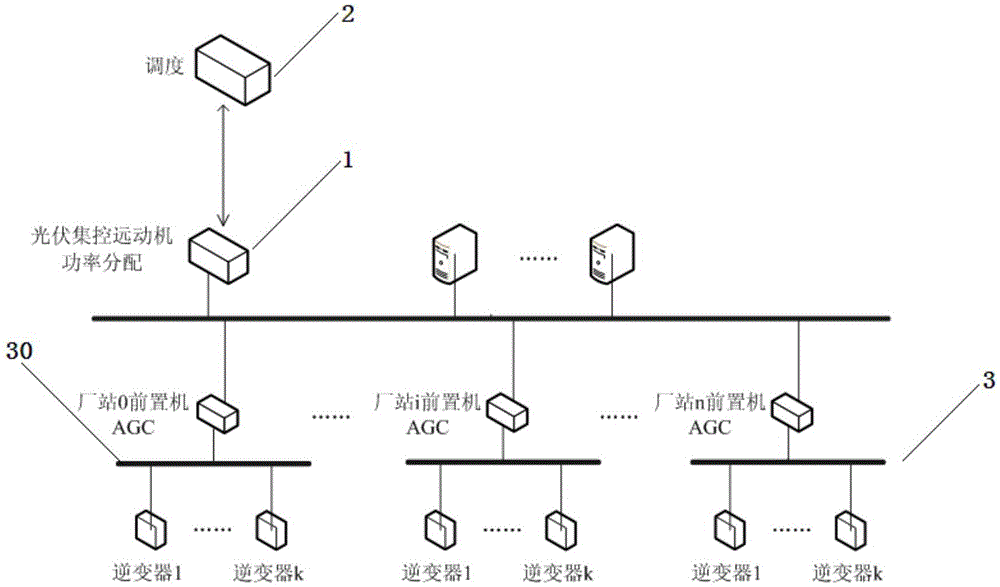

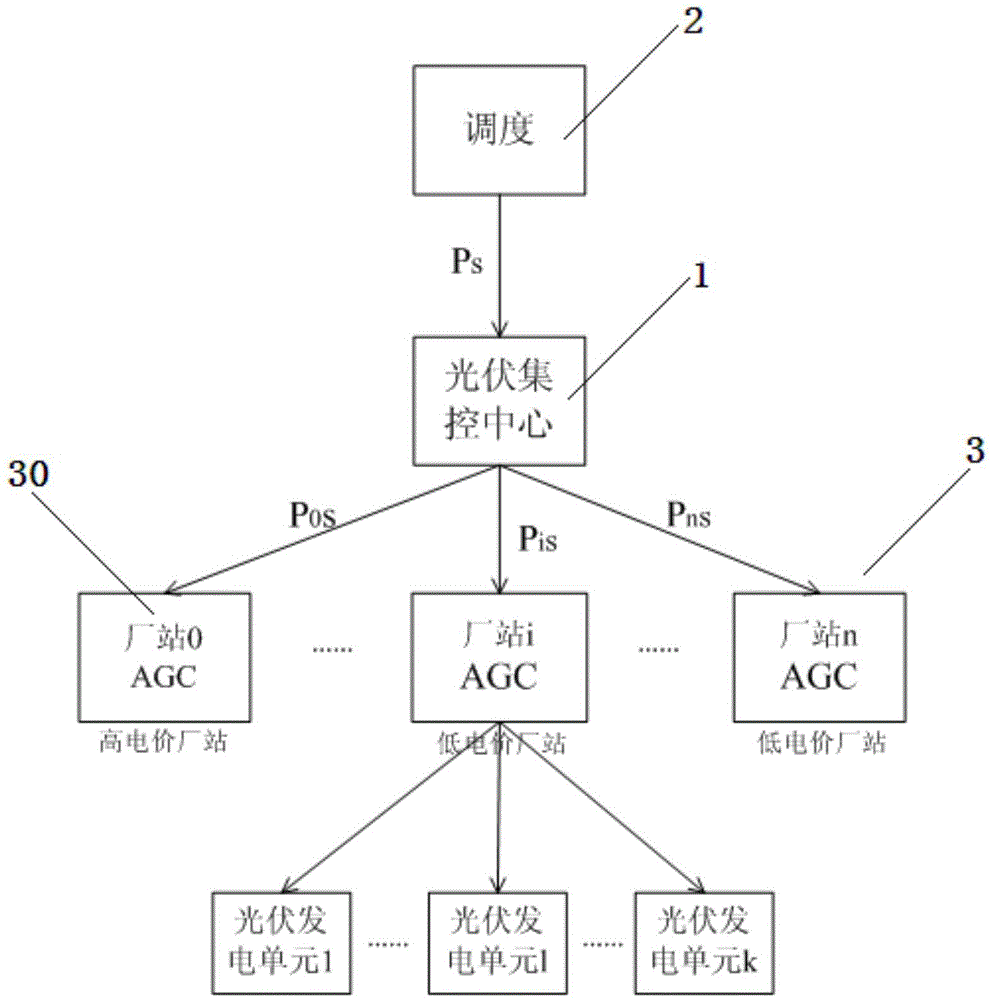

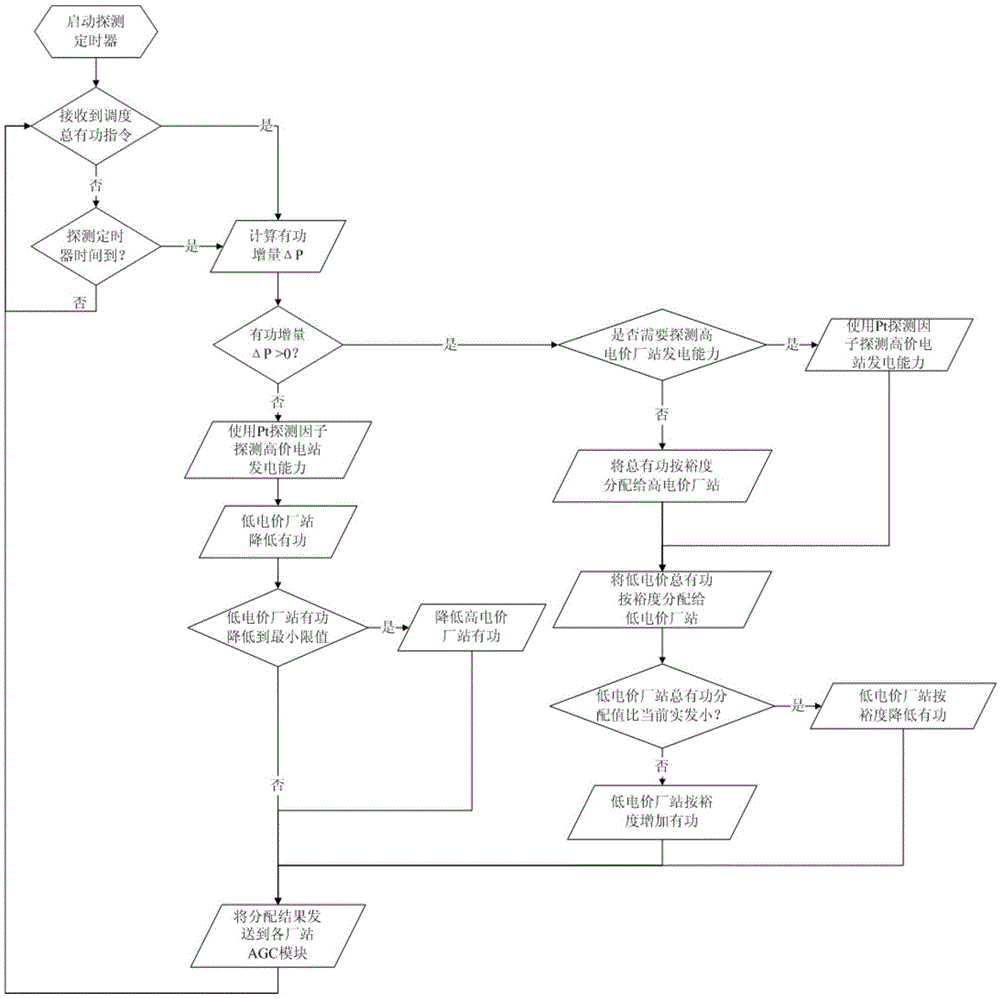

Active power distribution method for centralized control terminal of photovoltaic power station according to high electrovalence priority

ActiveCN105429186AMeeting power generation needsIncrease economic benefitsSingle network parallel feeding arrangementsPhotovoltaic energy generationDistribution methodEconomic benefits

The invention discloses an active power distribution method for a centralized control terminal of a photovoltaic power station according to high electrovalence priority. The method comprises the steps as follows: firstly, an active power distribution module of the centralized control terminal and a probe timer are arranged and run on a prime mover at the centralized control terminal of the photovoltaic power station; the active power distribution module of the centralized control terminal distributes total active power of the centralized control terminal on the basis of a high-electrovalence power station priority distribution principle according to the collected dispatching total active instruction and actually issued values of active power of power stations, and generates an active power distribution result of distributing the total active power of the centralized control terminal to the power stations in real time by a method of combining detection and distribution according to the margin; and finally, the active power distribution module of the centralized control terminal issues the active power distribution result to front-end processor AGC modules of the power stations for execution through a communication module on the prime mover. Maximization of total power generation benefits of different electrovalences of different power stations under the centralized control terminal of the photovoltaic power station is achieved; the power generation requirements of the power station with high electrovalence are met in priority; and the economic benefits are greatly improved.

Owner:NARI NANJING CONTROL SYST

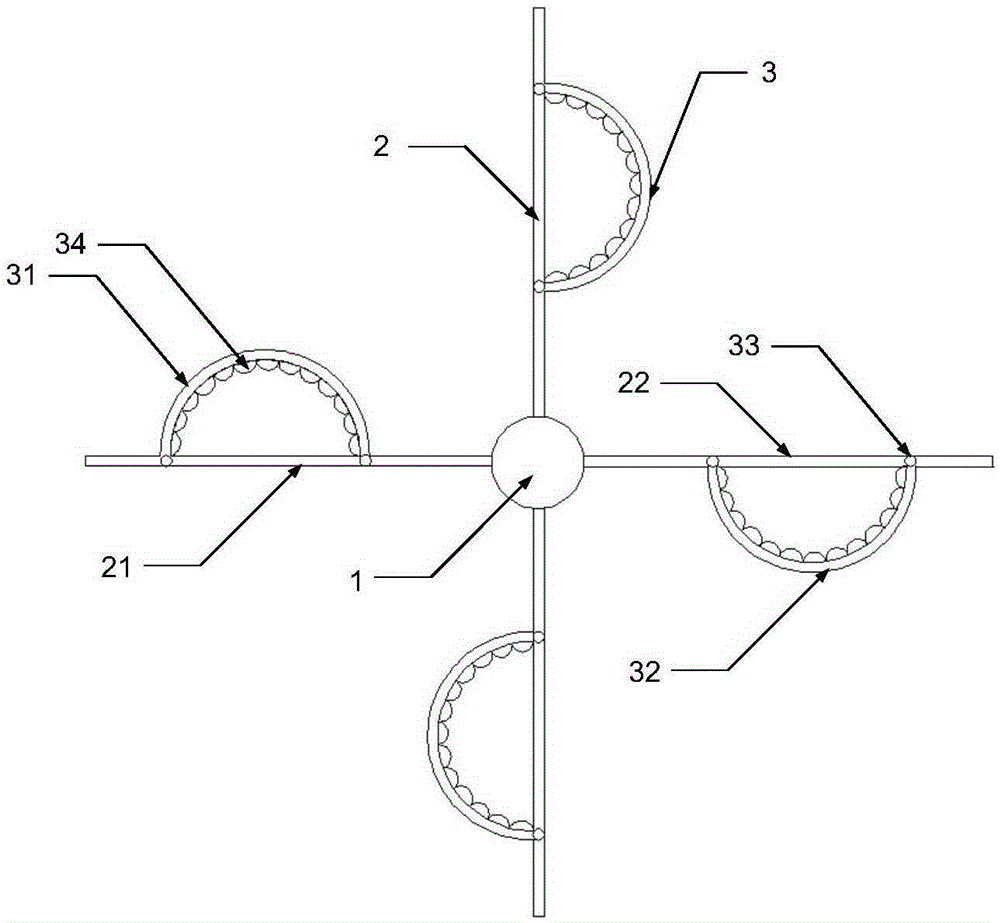

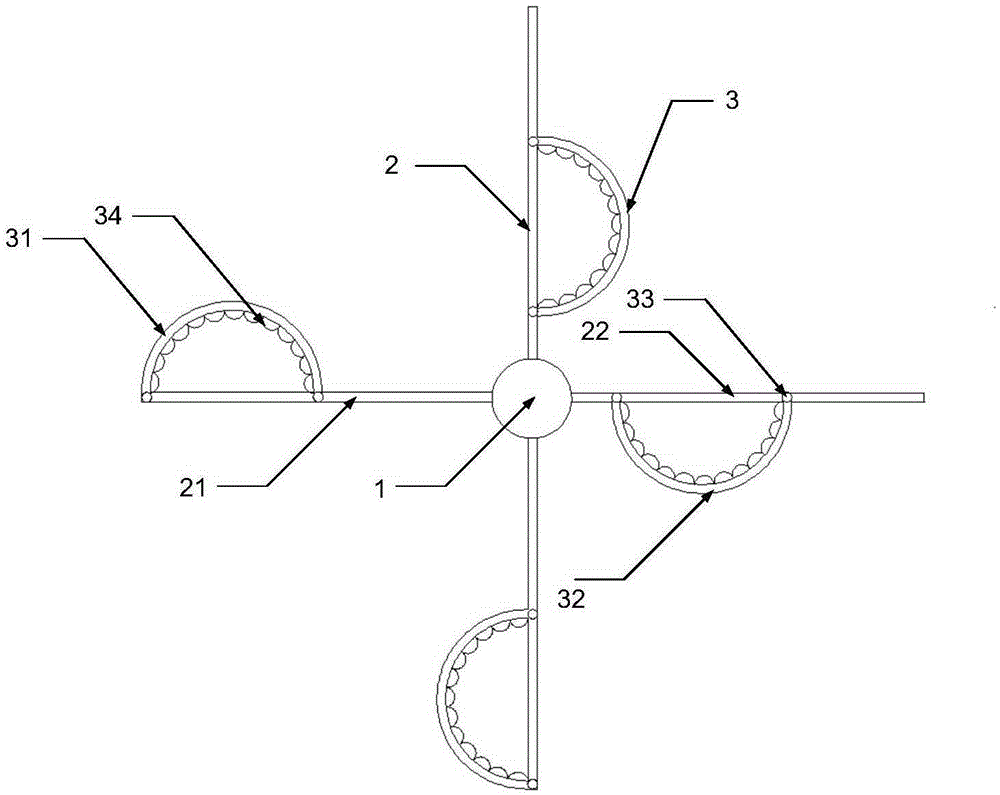

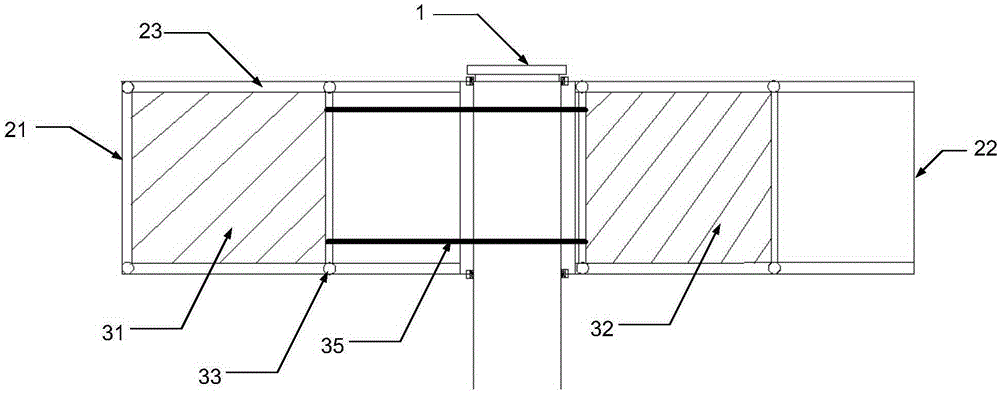

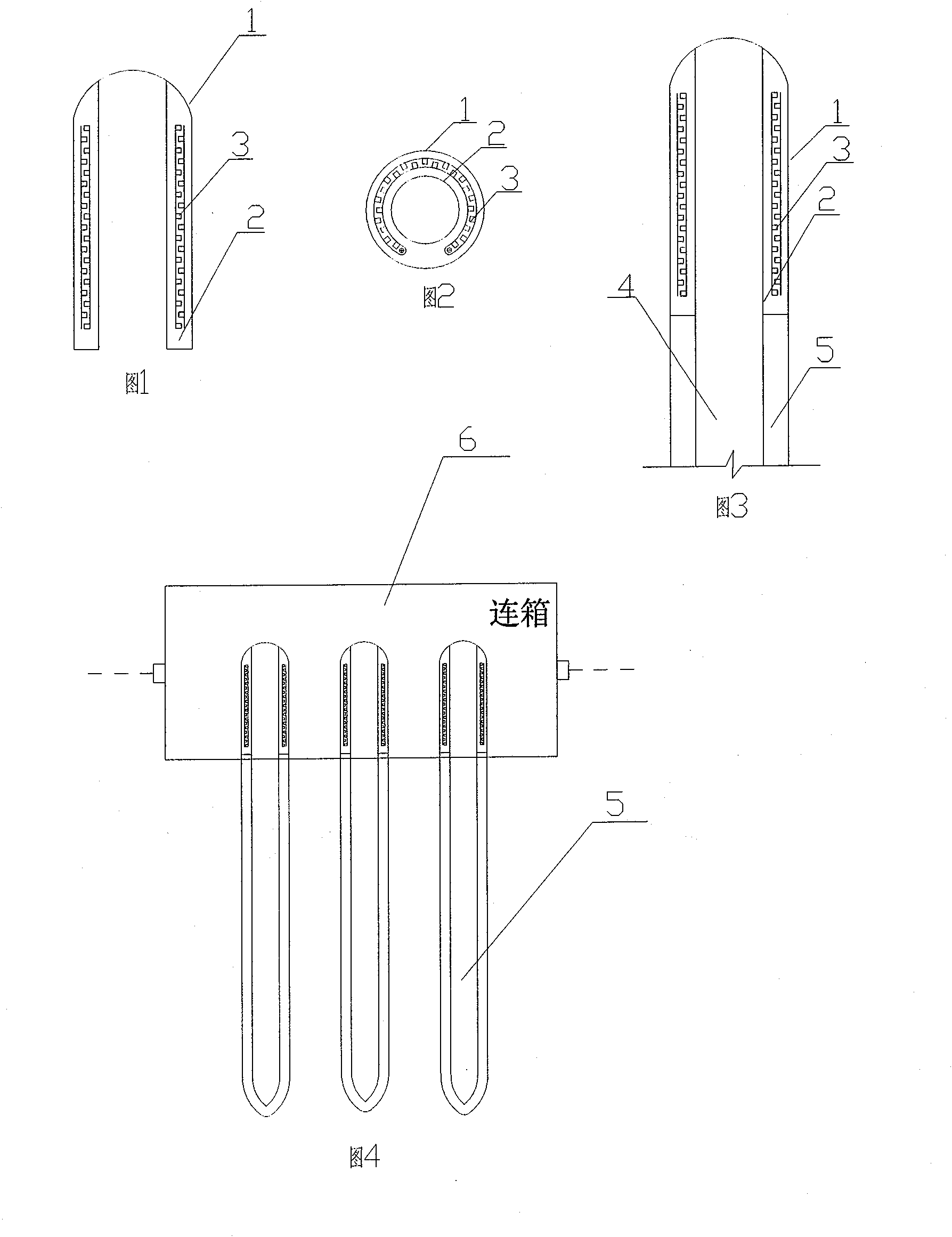

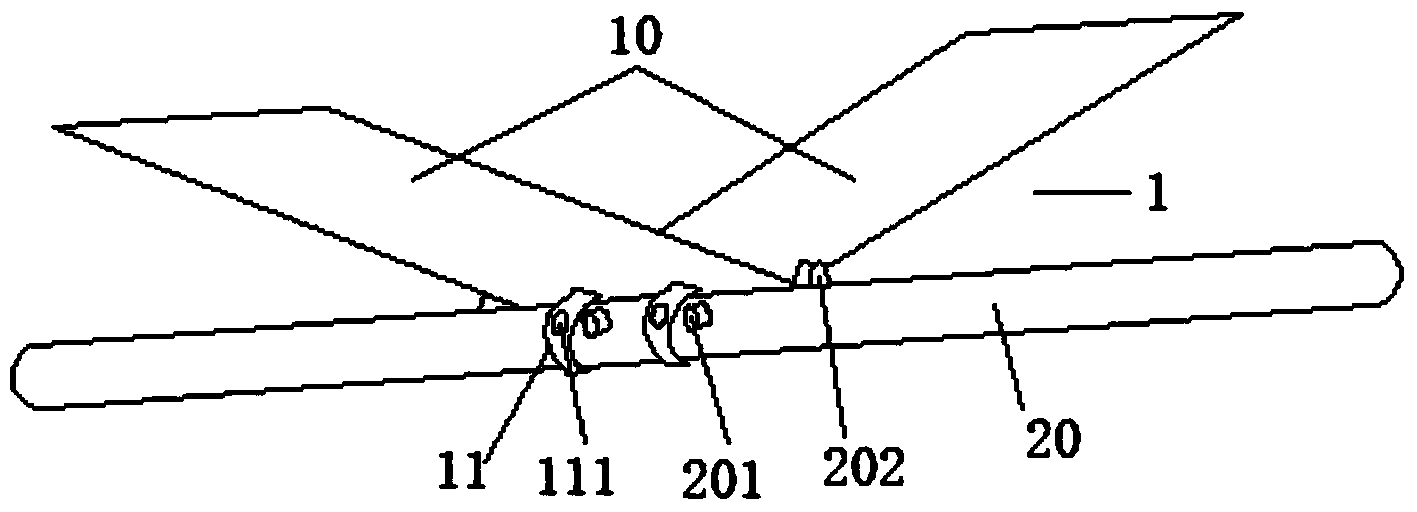

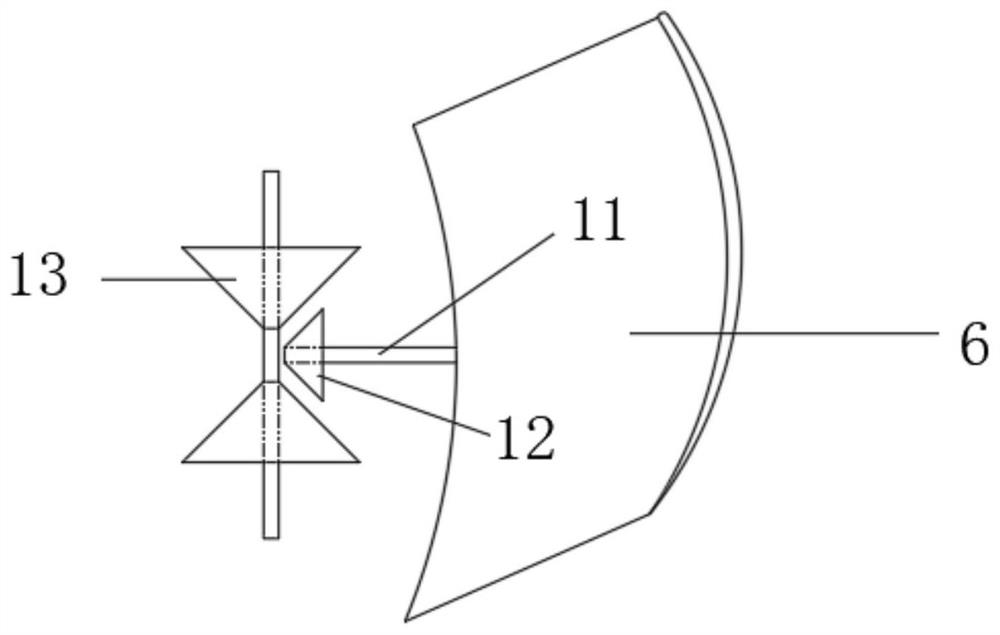

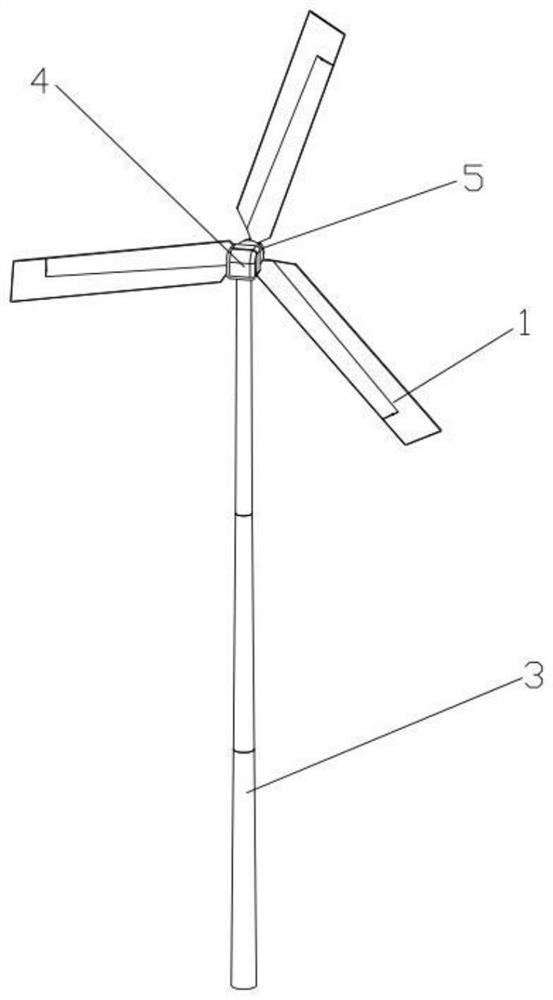

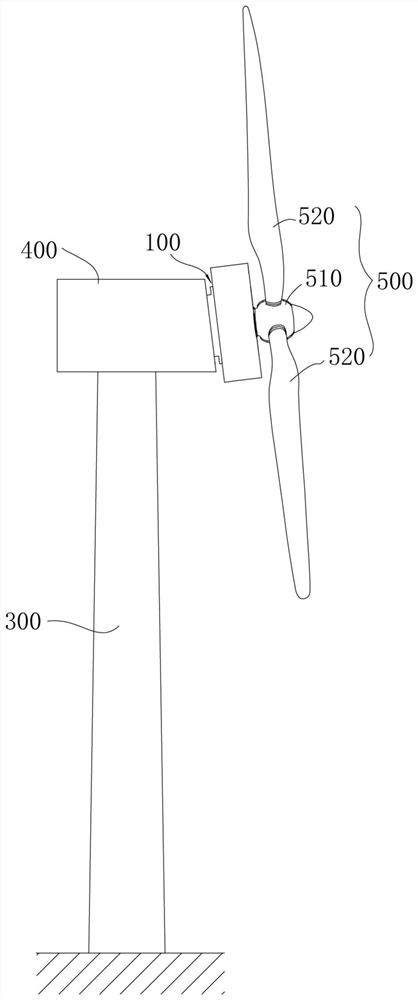

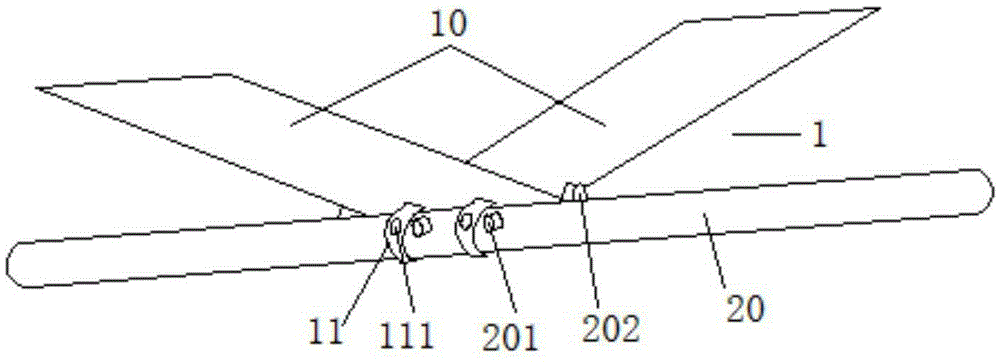

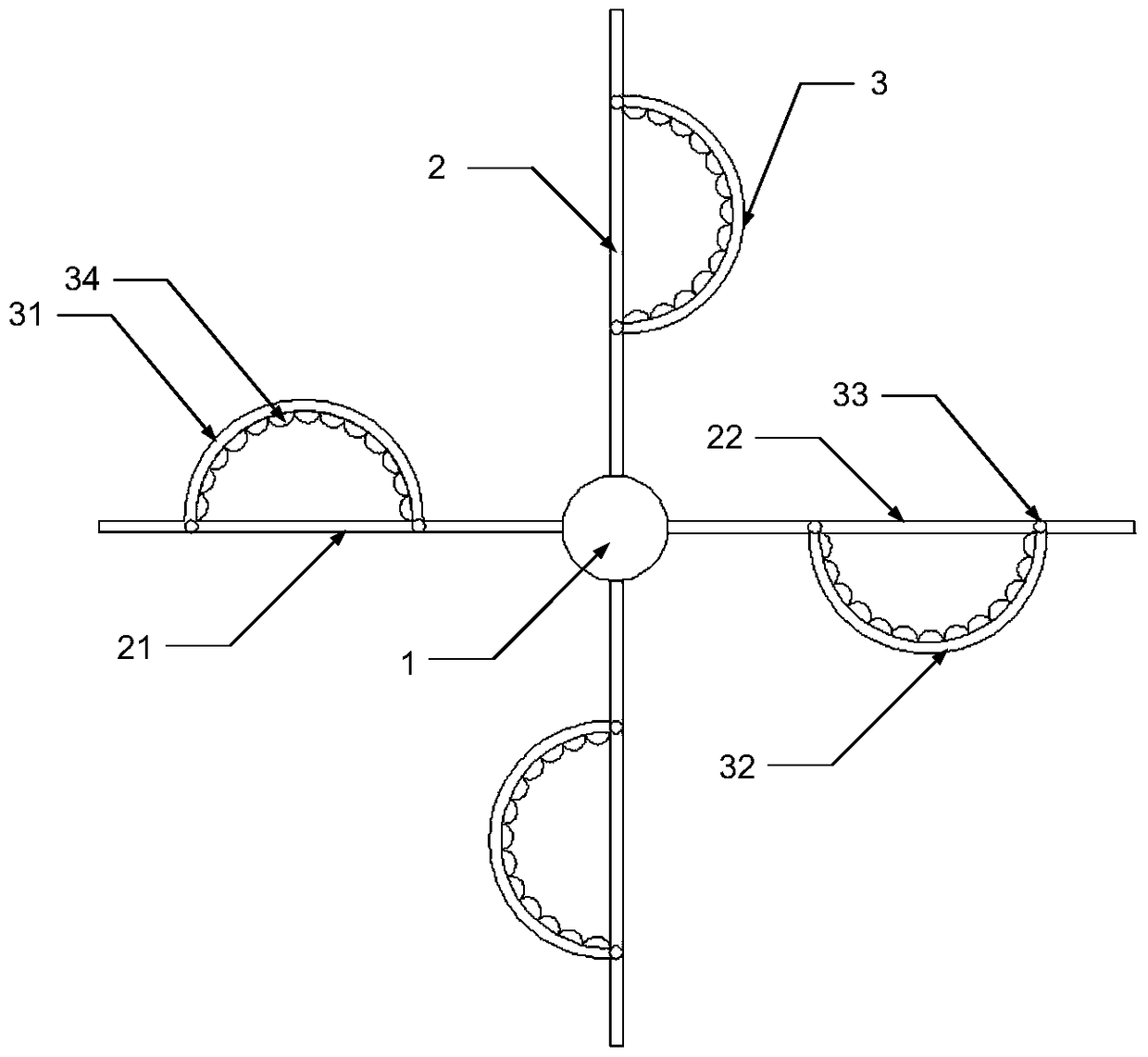

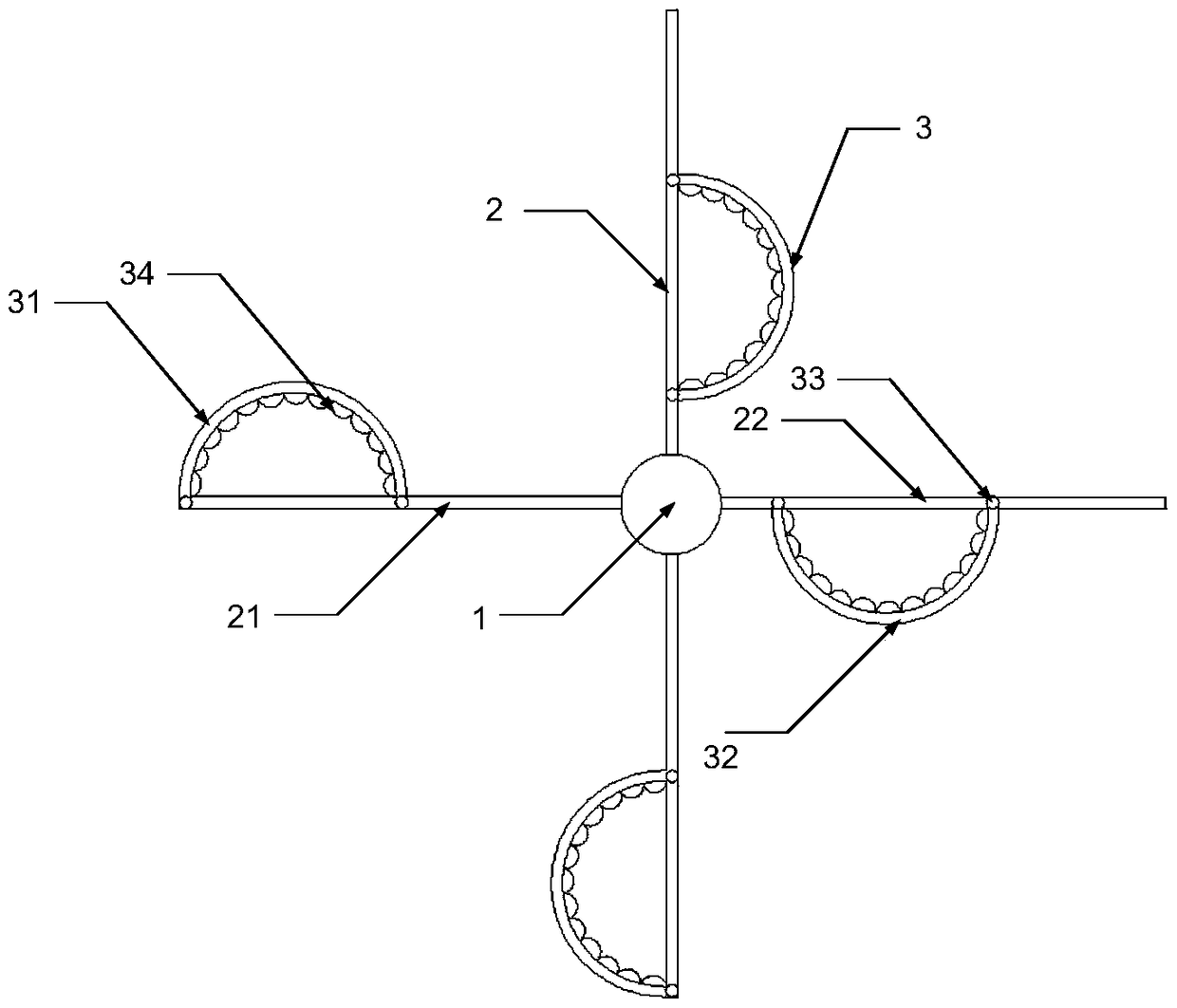

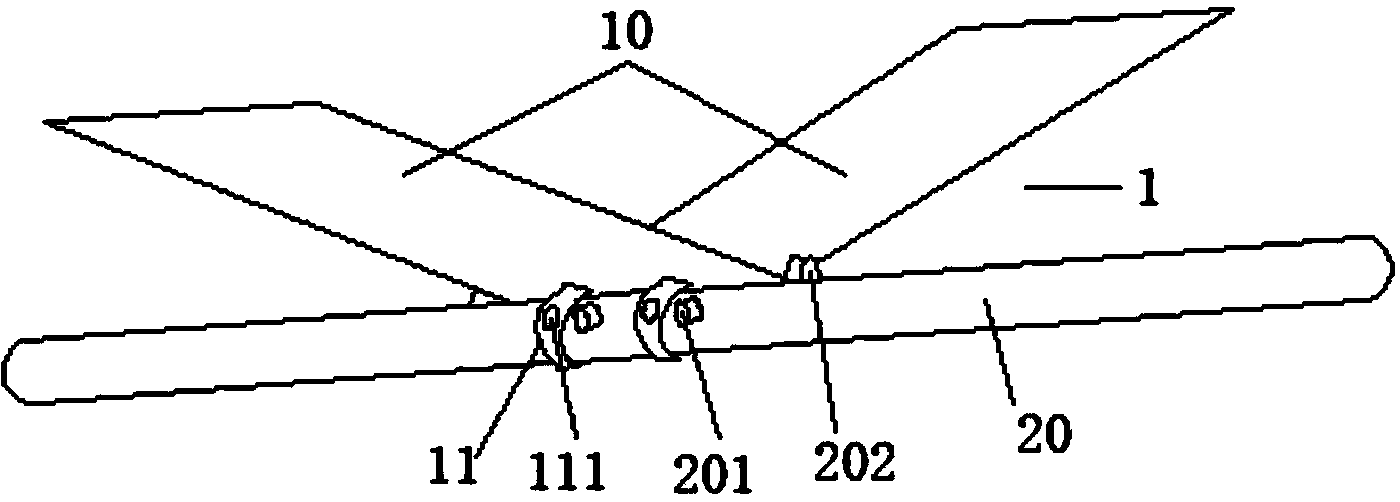

Wind turbine impeller

ActiveCN105298742AImprove wind energy utilizationIncrease motivationMachines/enginesRenewable energy generationImpellerTurbine

The invention provides a wind turbine impeller used for solving the problems that an existing wind turbine impeller is low in wind sweeping capacity, not enough in power and the like. The impeller comprises a spindle, n sets of impeller frames, n sets of blades and a bearing pedestal, wherein n is a positive integer which is not smaller than 1; each set of impeller frames comprises a first impeller frame and a second impeller frame; the spindle 1 serves as the symmetry axis of each first impeller frame and the corresponding second impeller frame, and each first impeller frame and the corresponding second impeller frame are fixedly mounted on the spindle in a mirror symmetry mode; each set of blades comprises a first blade and a second blade; each first blade is movably mounted on the corresponding first impeller frame, and each second blade is movably mounted on the corresponding second impeller frame; each first blade and the corresponding second blade are connected into a whole through connecting components and move synchronously; the spindle 1 is perpendicularly mounted on the bearing pedestal. The wind turbine impeller has the characteristics that the wind sweeping capacity is enhanced, the structure is simple, the electricity generation power range is wide, the application range is wide, and the like.

Owner:中科众瑞(哈尔滨)清洁能源股份有限公司 +1

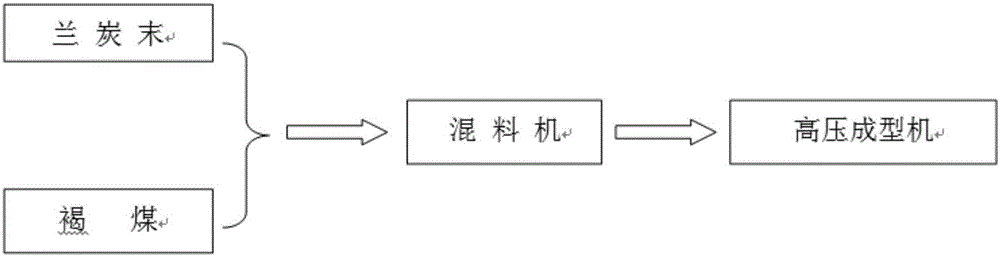

Semi-coke powder and brown coal matched forming method

The invention discloses a semi-coke powder and brown coal matched forming method for the first time. The method includes steps: (1) drying brown coal; (2) respectively screening the dried brown coal and semi-coke powder; (3) mixing the screened semi-coke powder and brown coal to obtain a mixed material; (4) subjecting the mixed material to forming to obtain formed balls. By direct forming after proportional mixing of the semi-coke powder and the brown coal, compressive strength of the formed balls reaches 199-237N per ball, and the ball forming rate reaches 92-94%. The method has advantages that addition of adhesives is avoided, forming cost is reduced, technical simplicity is achieved, and comprehensive utilization of the semi-coke powder and the brown coal resources is realized.

Owner:SHENWU TECH GRP CO LTD

Electric energy chip generating device

InactiveCN101610052AMeeting power generation needsHeating temperature increasedGenerators/motorsElectricityEngineering

The invention relates to an electric energy chip generating device, in particular to an electric energy chip generating device for generating electricity by electric energy chips. The electric energy chip generating device of the invention comprises a superconductive heat pipe and an electric energy chip generating head, wherein, the electric energy chip generating head is sheathed with the pipe end of the vacuum superconductive heat pipe; the electric energy chip generating head comprises an outer casing, an inner casing and an electric energy chip, and the arc-shaped electric energy chip is located in a vacuum cavity formed by sealing up the outer casing and the inner casing. The invention has the advantages of simple and novel structure and good generating effect; and the invention can make full use of various heat sources, such as solar heat sources, industrial heat sources, domestic heat sources and the like, to realize the thermoelectric generation by reducing the temperature of the electric energy chips and heat up the water at the same time, thereby ensuring the wide applicable range.

Owner:李泽明

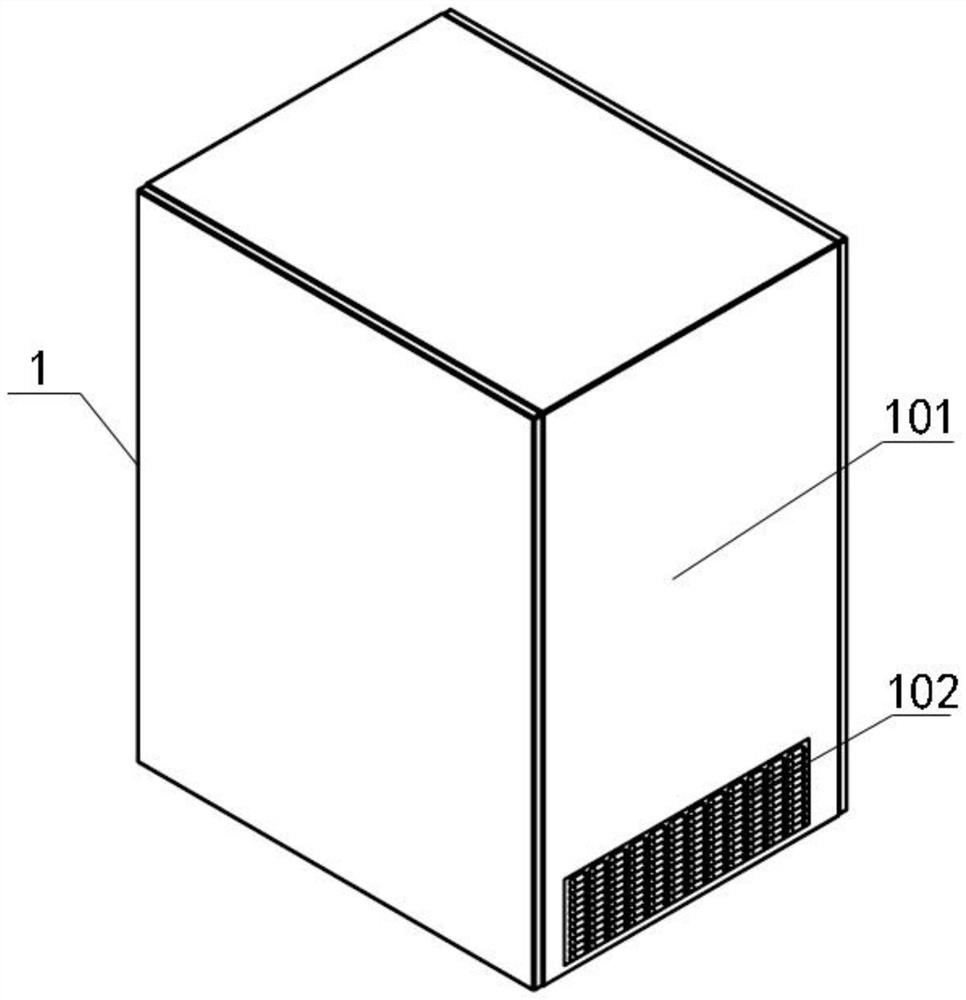

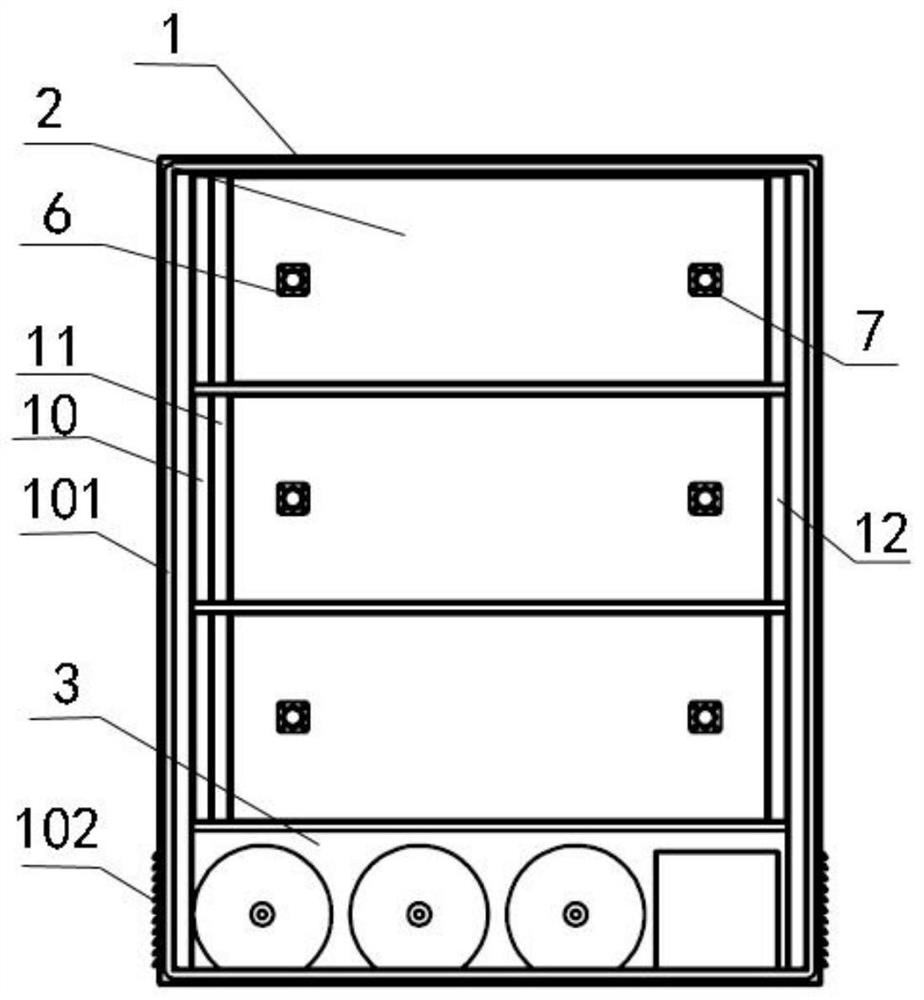

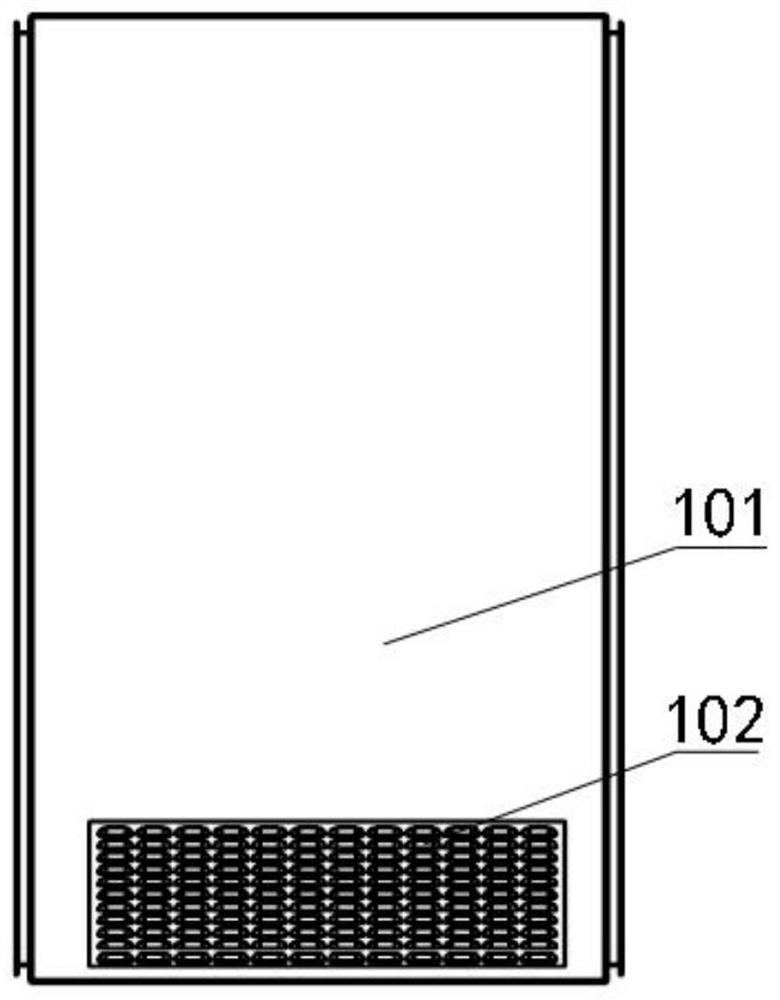

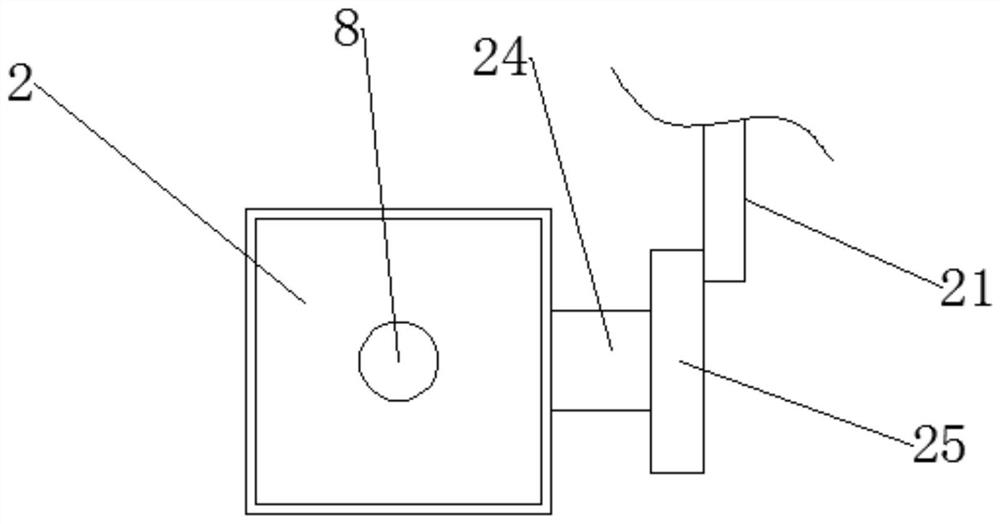

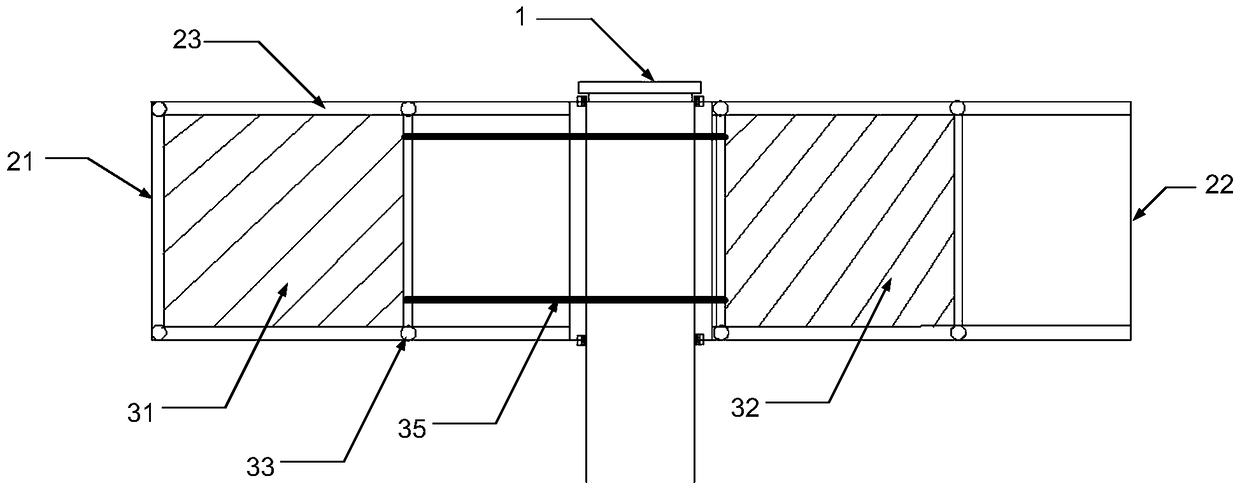

Air cooling fuel cell power generation device

PendingCN112786940ASimple structureOptimize layoutFuel cell heat exchangeReactant parameters controlElectrical batteryEngineering

The invention discloses an air cooling fuel cell power generation device, and belongs to the technical field of fuel cells. According to the device, ventilation holes are formed in the two sides of a box body, at least one battery stack is arranged in the box body and communicates with the ventilation holes in the two sides, a filtering module, a heating module and a heat dissipation module are arranged between the battery stack and the ventilation holes, and a hydrogen inlet and a hydrogen outlet are formed in one side of the battery stack; the other side of the battery stack is provided with a connector, the connector is electrically connected with the DC / DC converter, the hydrogen supply and circulation system is arranged in the box body and communicated with the hydrogen inlet and the hydrogen outlet, and the controller is arranged in the box body and electrically connected with the heating module, the heat dissipation module and the DC / DC converter. The air cooling fuel cell power generation device is simple in structure, and can be modularly arranged according to actual conditions so as to meet power generation requirements of different scenes.

Owner:SHANGHAI ELECTRICGROUP CORP

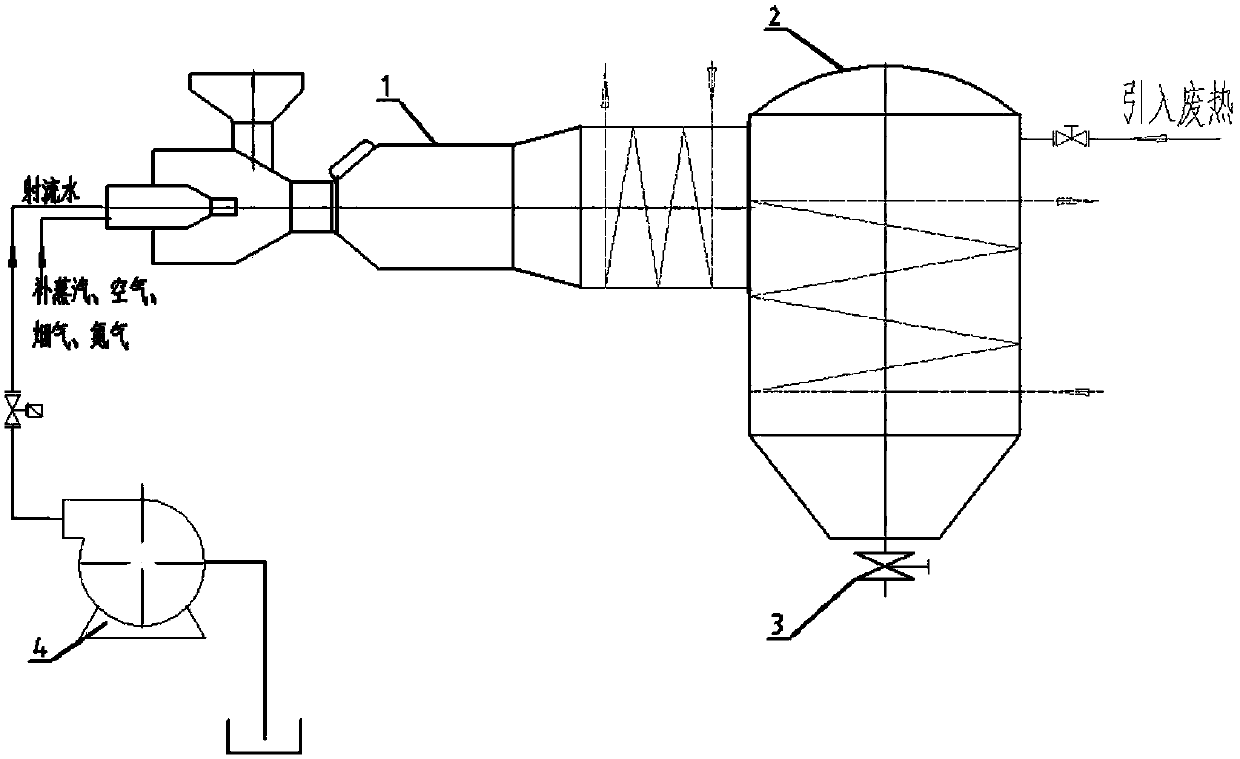

Replaceable multi-heat-source waste heat generator set

ActiveCN113586193AReduce input flowMeeting power generation needsSteam engine plantsEngineeringElectromagnetic valve

The invention relates to a replaceable multi-heat-source waste heat generator set, and relates to the technical field of generators. The replaceable multi-heat-source waste heat generator set comprises an evaporator used for evaporating an input heat source and transmitting high-temperature and high-pressure gas formed after the evaporation to an expansion machine, the evaporator is provided with a first input port and a second input port, the first input port is used for inputting a flue gas heat source into the evaporator, the second input port is used for inputting a hot water heat source into the evaporator so as to ensure multi-heat-source input, each input port is provided with an electromagnetic valve so as to accurately control heat source input, the expansion machine is used for conducting adiabatic expansion on input gas and transmitting internal energy generated by acting of the gas into a power generator, the power generator is used for converting the input internal energy into electric energy, the power generator is connected to a controller, and the controller is used for controlling the waste heat power generation process. According to the replaceable multi-heat-source waste heat generator set, the power generation efficiency is effectively improved by accurately controlling the input state of the heat source.

Owner:重庆国贵赛车科技股份有限公司

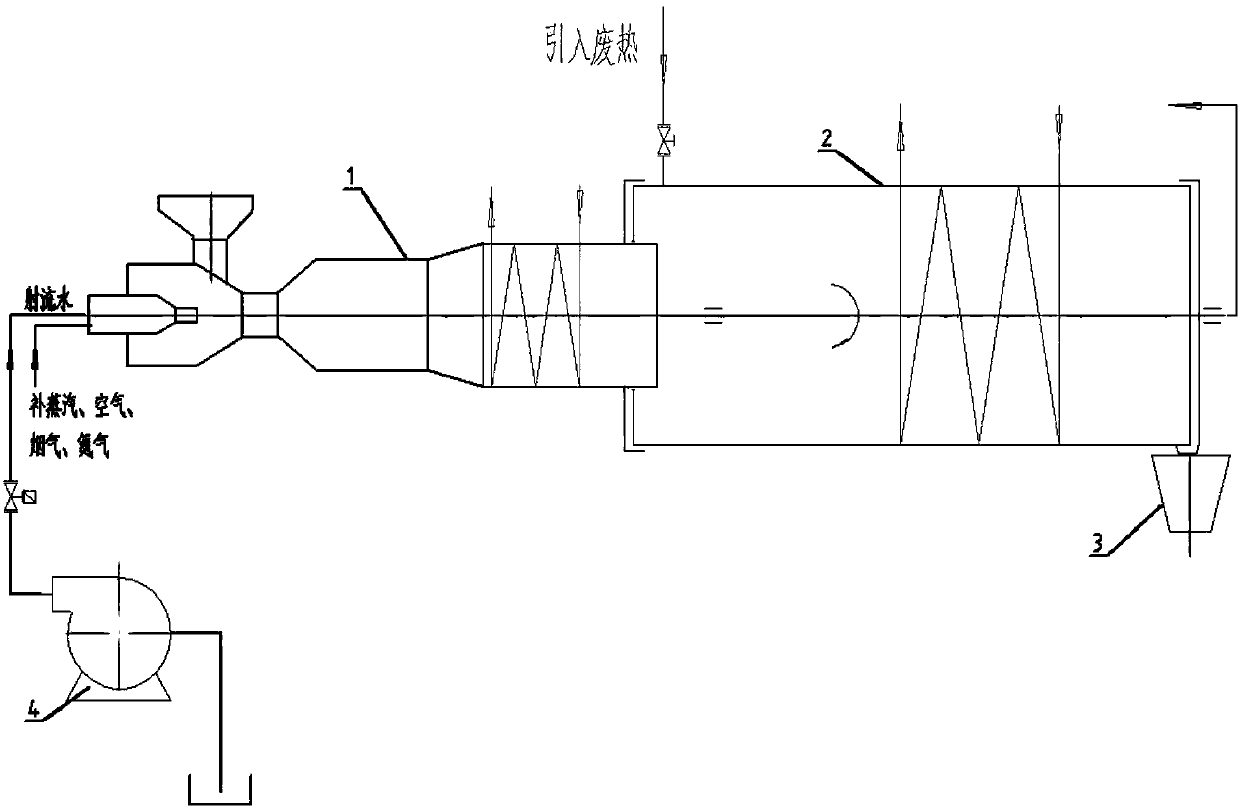

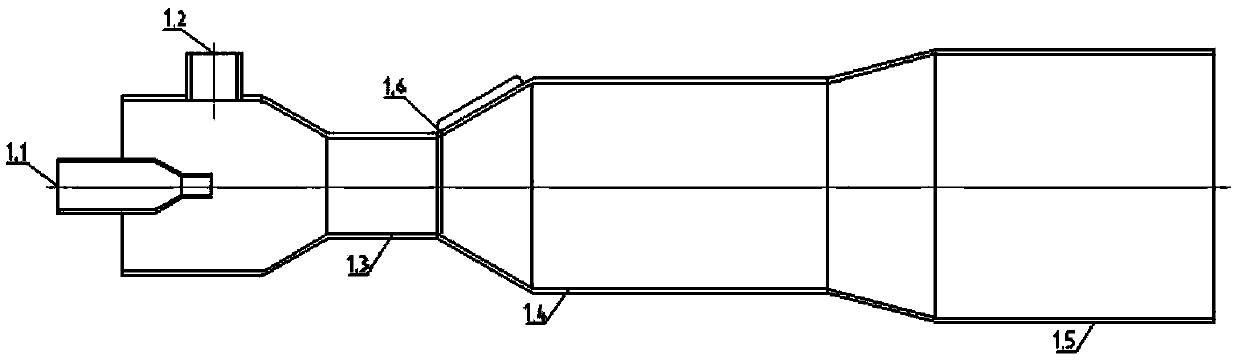

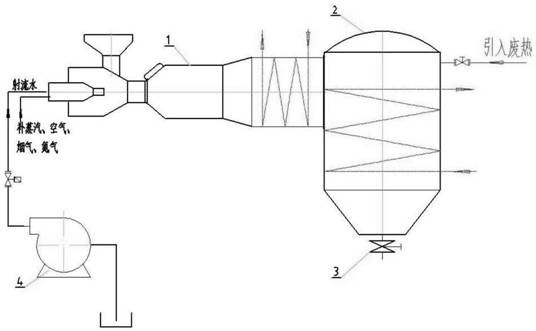

Jet steam process slag granulation and heat utilization method

ActiveCN108060280ASimple processImprove thermal efficiencyRecycling and recovery technologiesProcess efficiency improvementMetallurgical slagHigh pressure water

The invention provides a new metallurgical slag granulation and heat utilization method and an apparatus thereof. A jet device which is commonly used in the market is used in a metallurgical slag treatment process, the principles of the jet device and a steam explosion tank are combined with the principle of a steam process slag treatment process, the jet process of the jet device is used to carryout metallurgical slag granulation, high-pressure jetted water is used to realize the sealing of the mouth of the jet device in order to form a semi-closed space composed of a mixing chamber and a primary heat exchange chamber, steam explosion process energy in a semi-closed container is used to carry out slag granulation and heat exchange, the slag is cooled mainly relying on the vaporization ofwater and the overheating process of steam, and superheated steam output is directly generated to carry out heat utilization. The new jet steam process slag granulation and heat utilization method utilizes water quenching and high-pressure water kinetic energy to crush the slag and utilizes the steam explosion process energy to granulate the slag, and the steam explosion energy formed in the closed space is used to achieve high-pressure rapid heat exchange. The one apparatus can realize the heat exchange process while achieving slag granulation, and the generated slag and steam output undergoheat exchange in a boiler to form clean steam or high-temperature hot water which can be used. The method is carried out in the closed container, the steam explosion energy is utilized, and the slagis cooled by using the steam process water vaporization and steam overheating process, so the method has the advantages of water saving, energy saving, environmental protection and high heat utilization efficiency, and the apparatus meets the heat exchange process while realizing slag treatment, and has practical application values.

Owner:姜学仕 +1

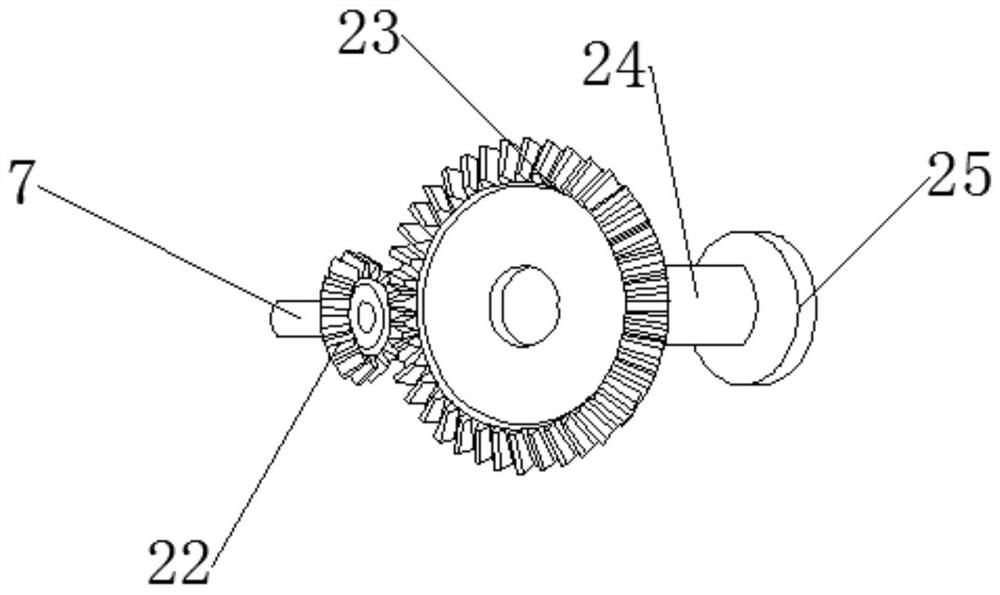

Vertical axial flow pump

ActiveCN109209899AIncrease powerFlexible angle adjustmentPump componentsHydro energy generationAxial-flow pumpImpeller

The invention discloses a vertical axial flow pump comprising an elbow-shaped water inlet channel, a siphon type water outlet channel, a pump shaft, an impeller and a generator set, the generator setcomprises a generator body, and the elbow-shaped water inlet channel is communicated with the siphon-type water outlet channel, one end of the pump shaft extends into the elbow-shaped water inlet channel and is in transmission connection with the hub of the impeller, and the other end extends out of the elbow-shaped water inlet channel and is in transmission connection with the main shaft of the generator body, the vertical axial flow pump further comprises a blade angle adjusting device; the blade angle adjusting device comprises a large gear having the gear shaft relatively fixed and connected to the hub, and a pinion meshed with the large gear, the small gears and the blades of the impeller are arranged in a one-to-one correspondence mode, and are fixedly connected with the corresponding blades. According to the invention, the impeller drives the pump shaft to rotate through the water flow impacting on the impeller, so that the main shaft of the generator body is driven to carry outreverse power generation, the angle of the blades is adjusted through meshing of the large gear and the pinion, and the precision of the blade adjusting angle is improved.

Owner:HOHAI UNIV

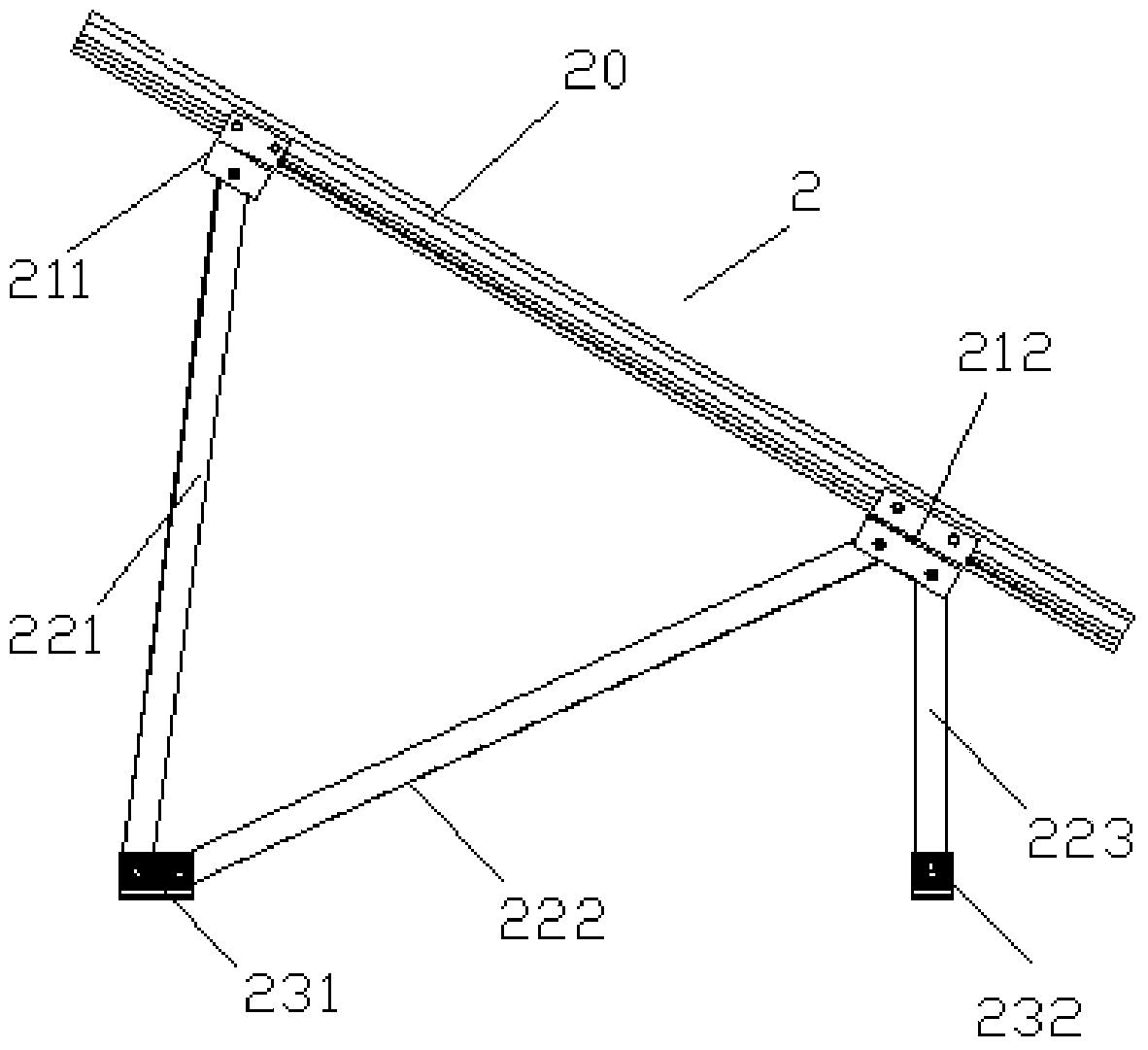

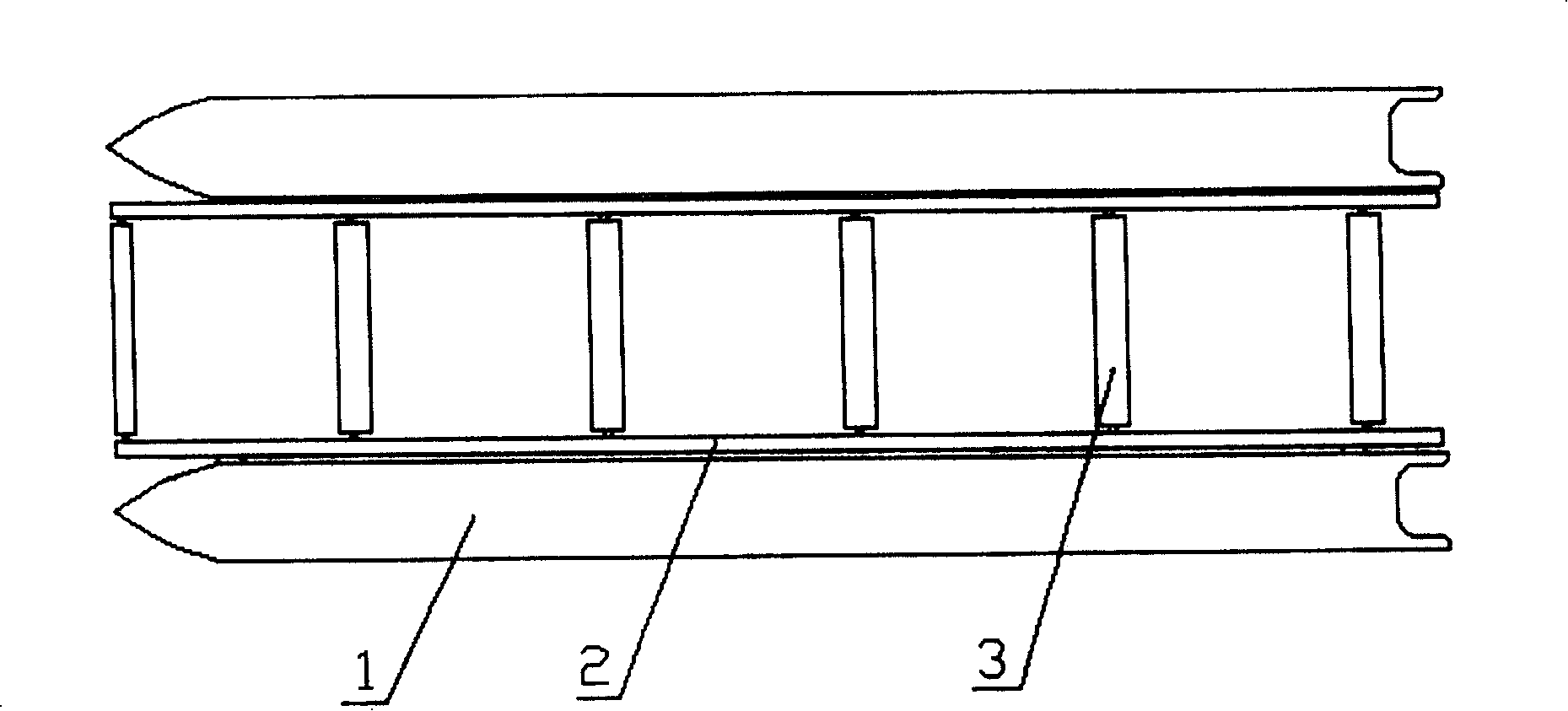

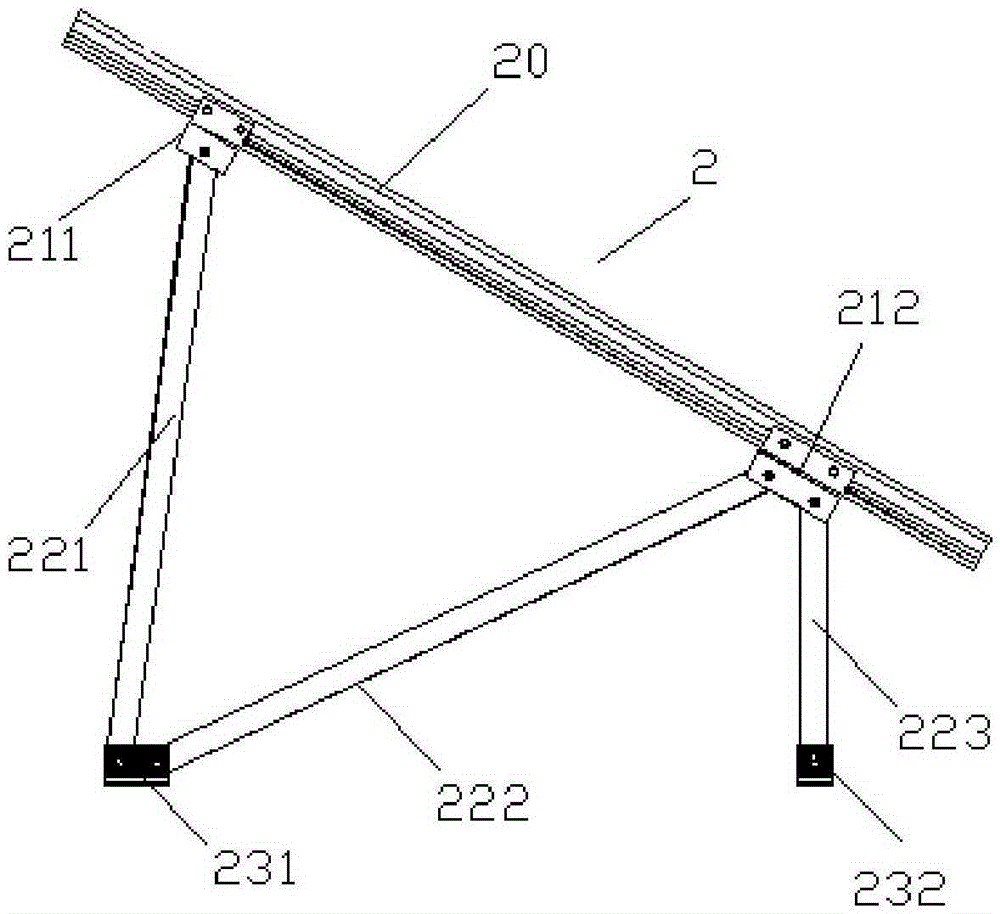

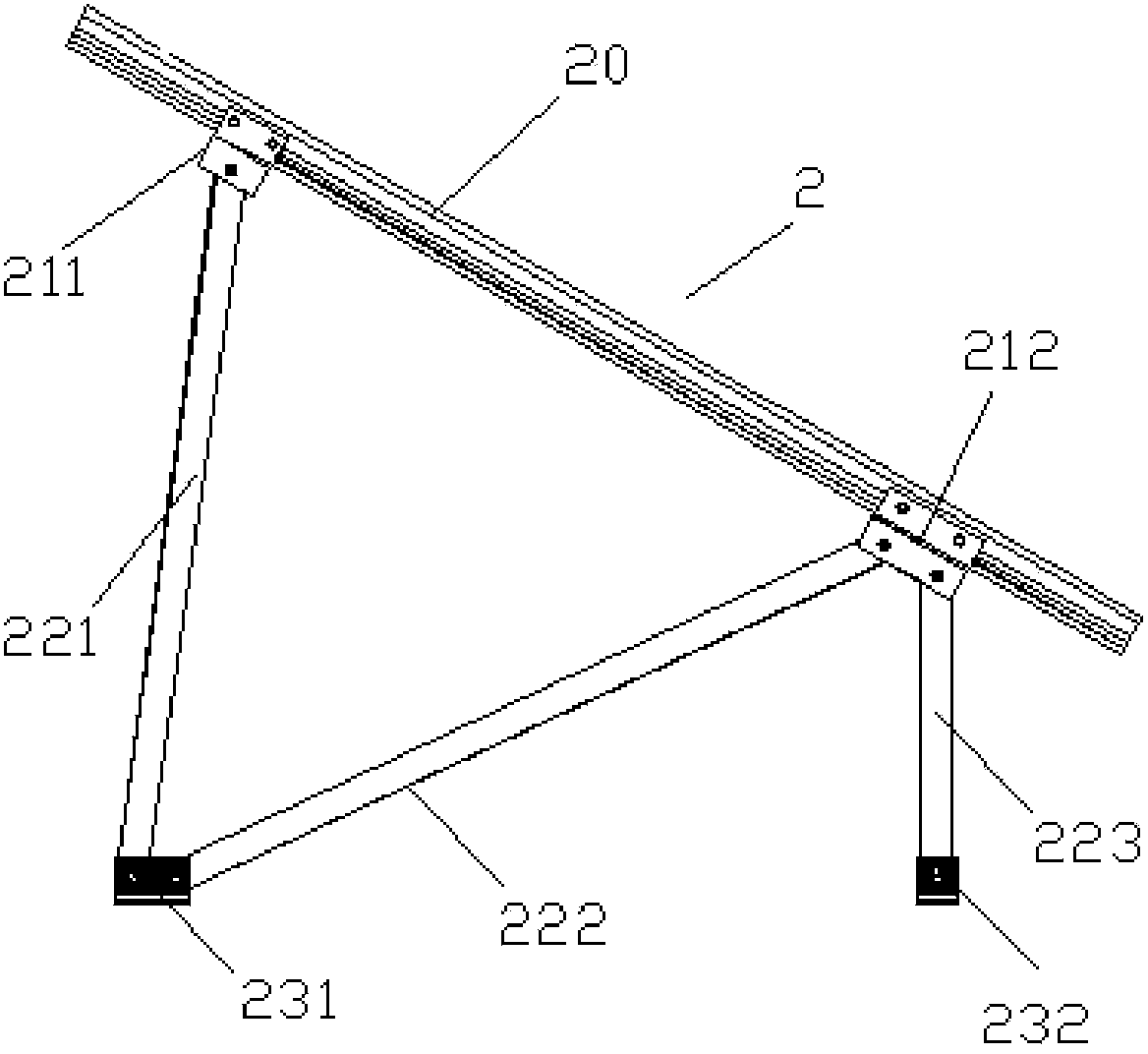

Conveniently-disassembled solar power generation device

InactiveCN104113276AEasy to separateEasy to fixPhotovoltaic supportsPV power plantsSolar powerFastener

The invention discloses a conveniently-disassembled solar power generation device. The conveniently-disassembled solar power generation device comprises a base, a support rack and a solar module. The solar module is mounted on the support rack, and the support rack is mounted on the base; the solar module comprises two rectangular solar panels, and one width sides of the two solar panels are spliced and hinged into a whole through hinges; the support rack comprises a mounting rod, two connecting seats, three support legs and two support feet; the solar module is fixed onto the mounting rod through clamping fasteners. By means of the technical scheme above, the conveniently-disassembled solar power generation device is convenient to assemble and facilitates post-disassembly storage and transportation, thereby meeting the requirements on solar power generation on moving occasions.

Owner:广东德日光伏科技有限公司

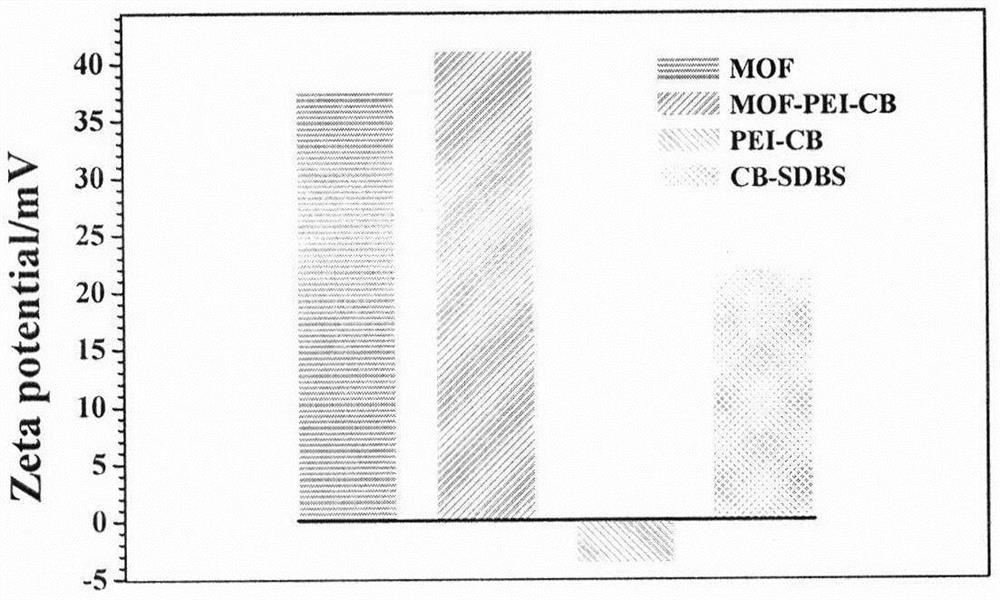

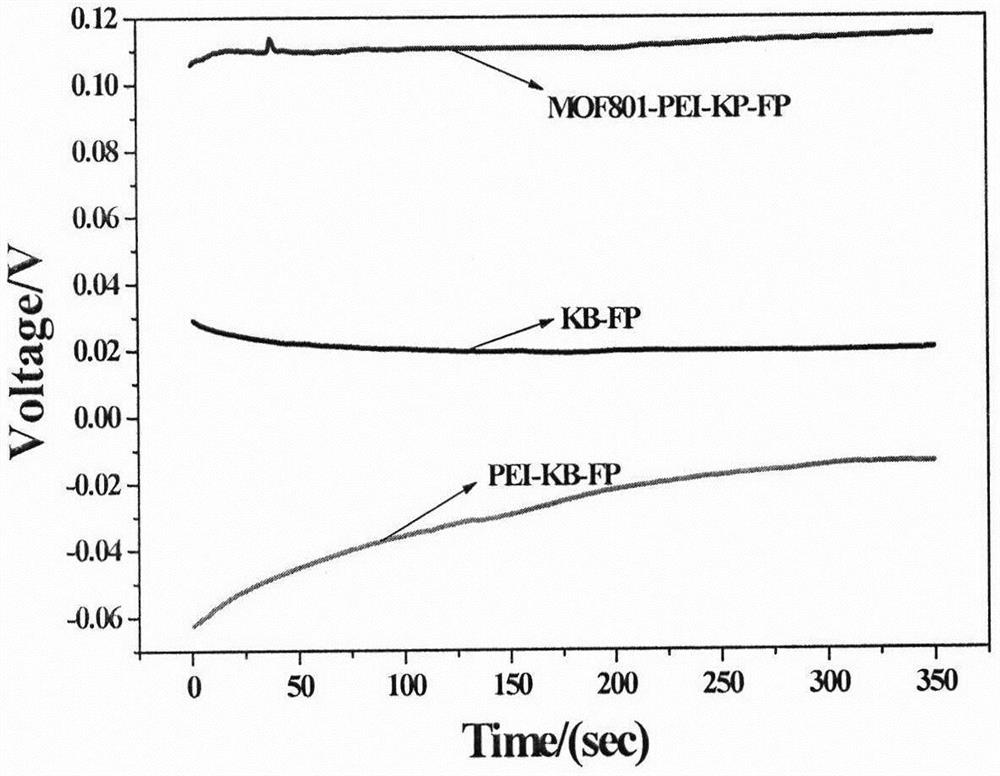

Evaporation-induced battery based on carbon material surface function modification

PendingCN113437404AImprove electricity production efficiencyMeeting power generation needsElectrical apparatusChemical physicsElectrical battery

The invention discloses an evaporation-induced battery based on carbon material surface functional modification. Counterions entering a pore channel are changed by modifying the Zeta potential of a qualitative filter paper capillary channel, and then output voltage and current are changed. According to the invention, the MOF material with high Zeta potential and the PEI are used for modifying the surface potential of the carbon material for the first time to form the novel evaporation-induced battery with the surface function modified by the carbon material, so that a new research thought is provided for modification of the evaporation-induced power generation battery in the future.

Owner:TIANJIN UNIV

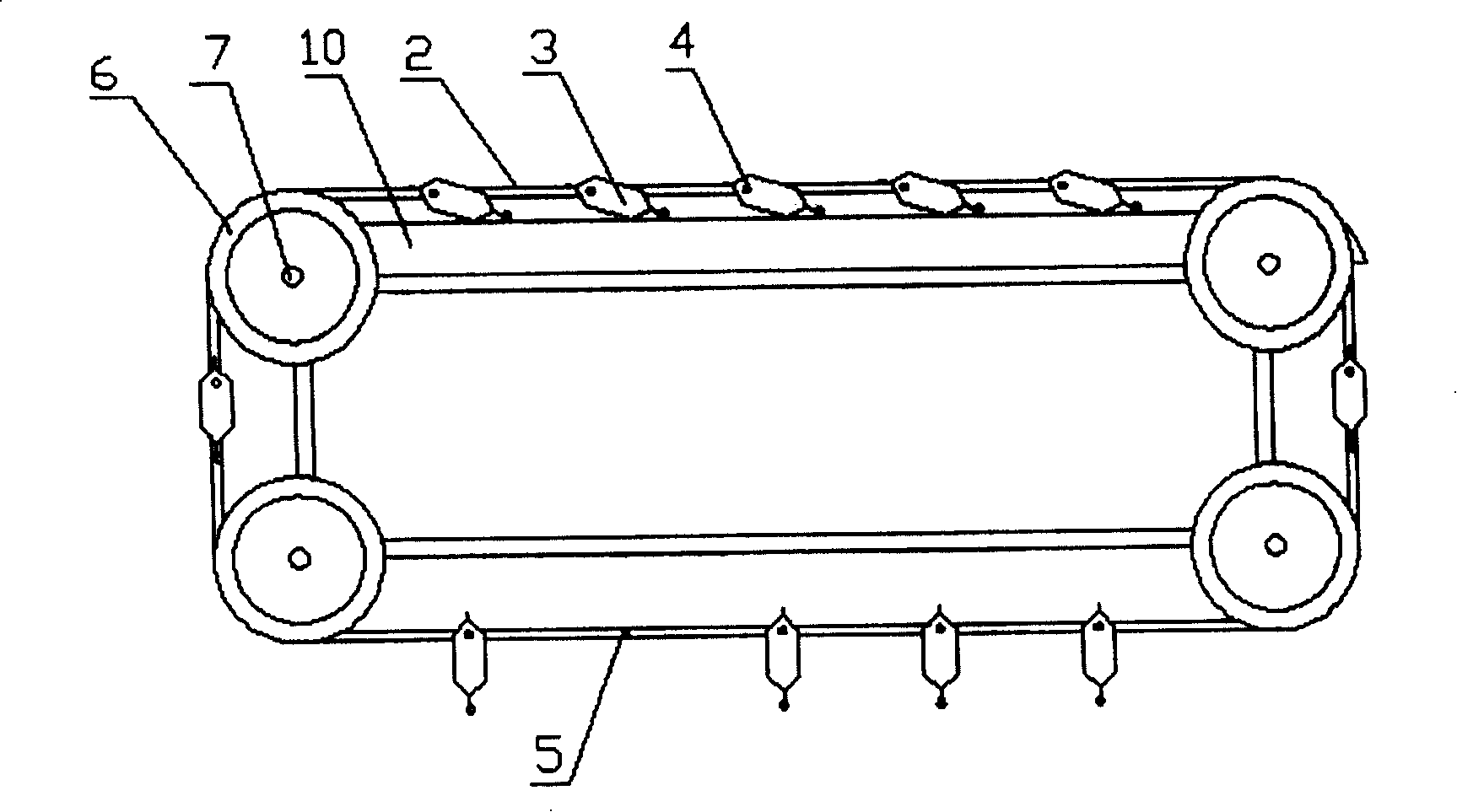

Rotary pontoon type soft-drive sea-wave hydraulic power generation unit

InactiveCN100410529CCreate pollutionLow costMachines/enginesEngine componentsVertical projectionTransmission belt

The invention discloses a rotational pontoon soft transmission sea-wave hydraulic generator, which comprises large pontoons at two sides which are connected by steel support. The invention is characterized in that: the opposite side of each large pontoon is symmetry mounted with at least two transmission wheels; the transmission wheels at the same side are sheathed by transmission belt; the rotational pontoon is mounted on the transmission belt; said pontoon is a chamber whose positive projection is larger than the vertical projection, while its top has an exhaust port and a sealed air room, and its positive upper half part has opening, and its side surfaces are symmetry mounted with mounting axles, and its bottom has weight distributions; the upper part of large pontoon is mounted with track, while it will contact the track when the rotational pontoon moves to the upper half part of pontoon, and the rotational pontoon will rotate around the axle, to make its opening downward; the generator axle via transmission axle is connected to at least one transmission wheel axle. The invention has lower cost, simple production and environment friend property.

Owner:周建国

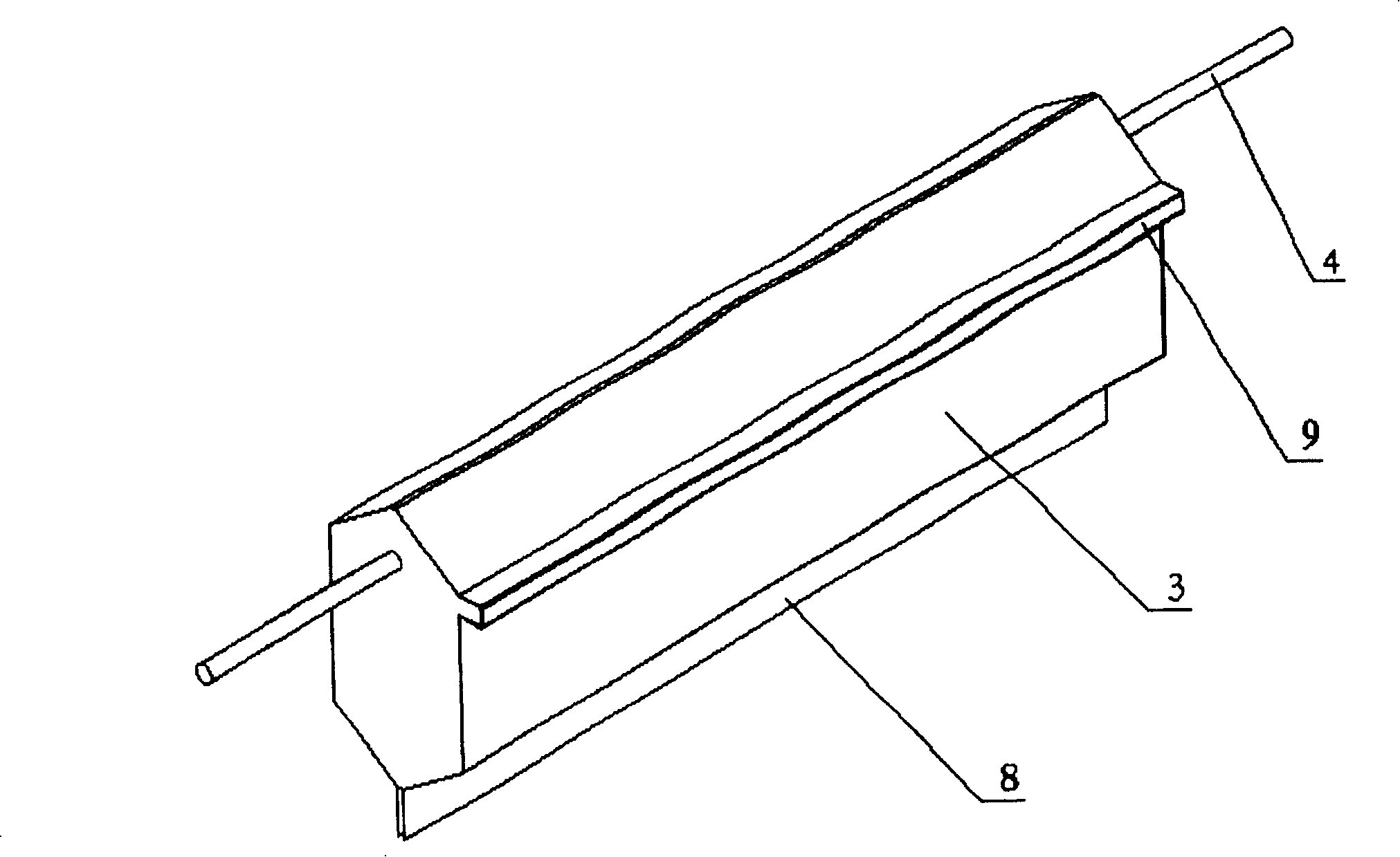

A feeder for biomass power generation

The invention discloses a feeding device for biomass power generation, comprising a pulverizing box, a pulverizing shaft is arranged in the pulverizing box, a pulverizing blade is arranged on the pulverizing shaft, a feeding port is fixed on the top of the pulverizing box, and the pulverizing box is far from the feeding port There is a discharge port on one side, and the crushing shaft runs through the crushing box and is fixedly connected to the second transmission shaft. The side of the second transmission shaft far from the crushing box is provided with a conversion device, and the other side of the conversion device is provided with a power box, and a motor is arranged in the power box. There is a first drive shaft on the motor, a third bevel gear on the second drive shaft, a rotating shaft on the side of the crushing box close to the second drive shaft, a turntable on the top of the rotating shaft, a hinged rod on the turntable, and the hinged rod The top is provided with a fourth bevel gear, which meshes with the third bevel gear, and a push rod is arranged on the hinge rod.

Owner:潍坊泓晟新能源股份有限公司

A vertical axial flow pump

ActiveCN109209899BIncrease powerFlexible angle adjustmentPump componentsHydro energy generationAxial-flow pumpSiphon

The invention discloses a vertical axial flow pump, comprising: an elbow-shaped water inlet channel, a siphon-type water outlet channel, a pump shaft, an impeller and a generator assembly, the generator assembly includes a generator body, an elbow-shaped water inlet channel and a siphon-type outlet The water outlet channel is connected, one end of the pump shaft extends into the elbow-shaped water inlet channel and is connected with the hub of the impeller, and the other end extends beyond the elbow-shaped water inlet channel to connect with the main shaft of the generator body. Vertical axial flow pump It also includes a blade angle adjustment device, the blade angle adjustment device includes: a gear shaft that is relatively fixedly connected to the hub and a pinion that meshes with the gear, and the pinion is set in one-to-one correspondence with the blades of the impeller, And it is fixedly connected with the corresponding blade. The invention drives the pump shaft to rotate through the impact of the water flow on the impeller, thereby driving the main shaft of the generator body to perform reverse power generation. The angle of the blade is adjusted through the meshing of the large gear and the small gear, which improves the efficiency of the blade adjustment angle. precision.

Owner:HOHAI UNIV

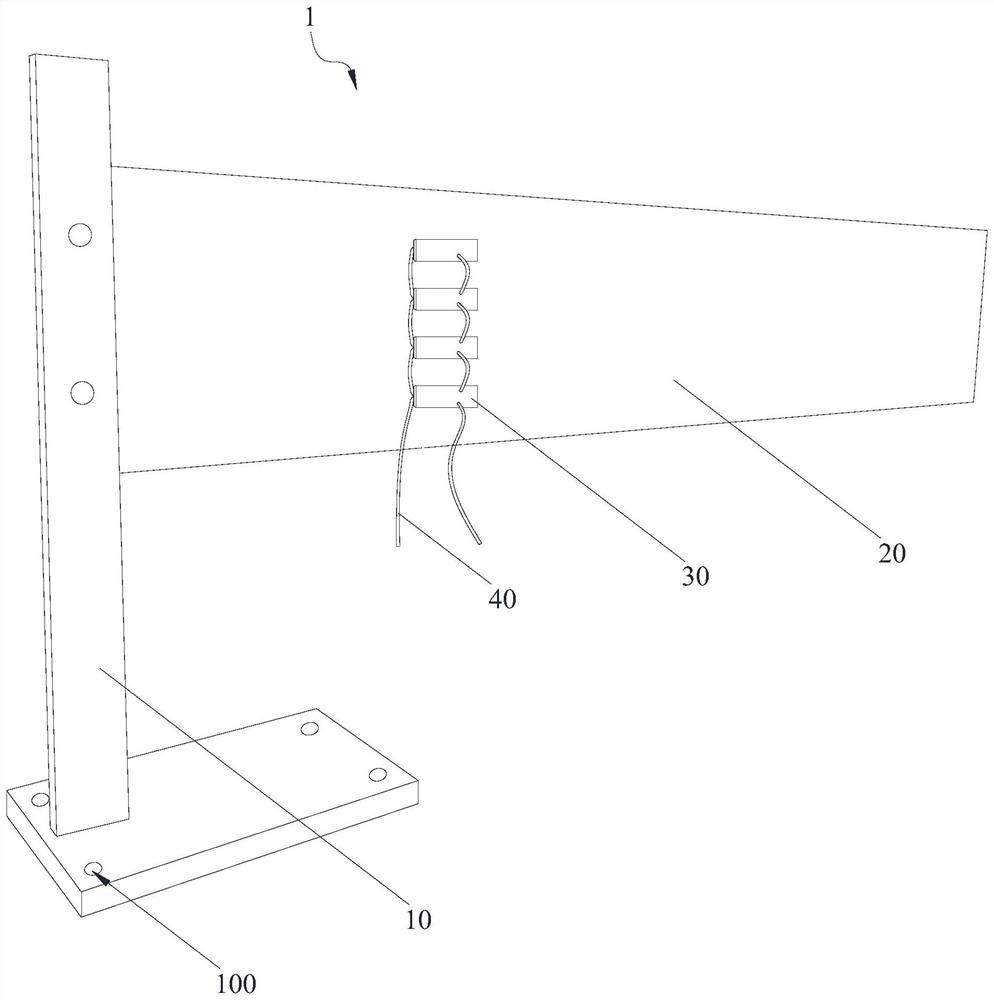

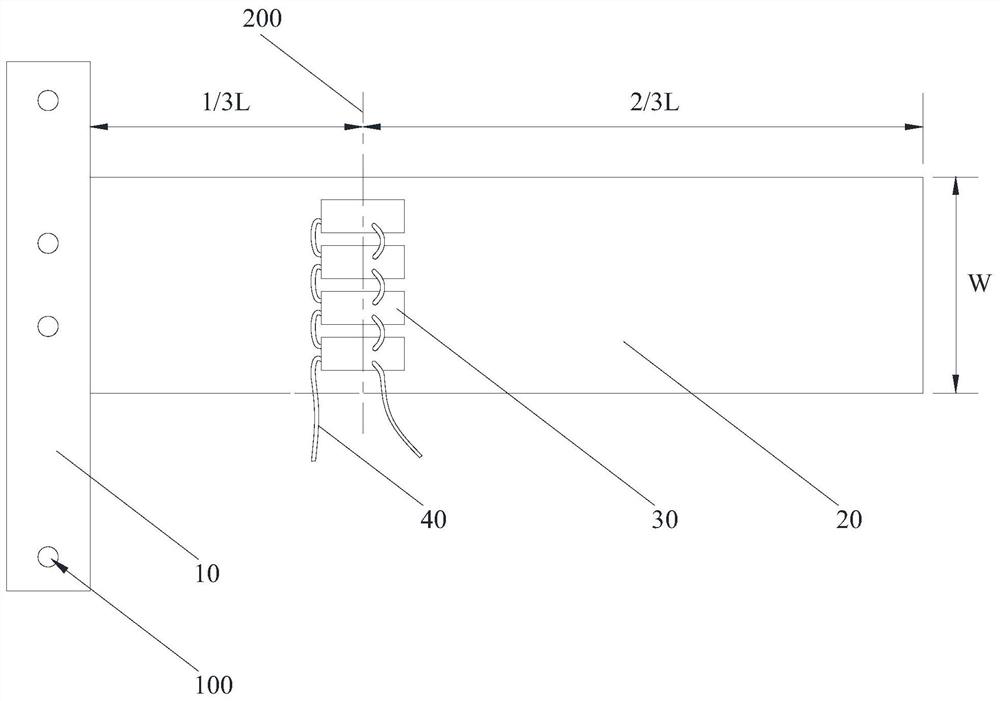

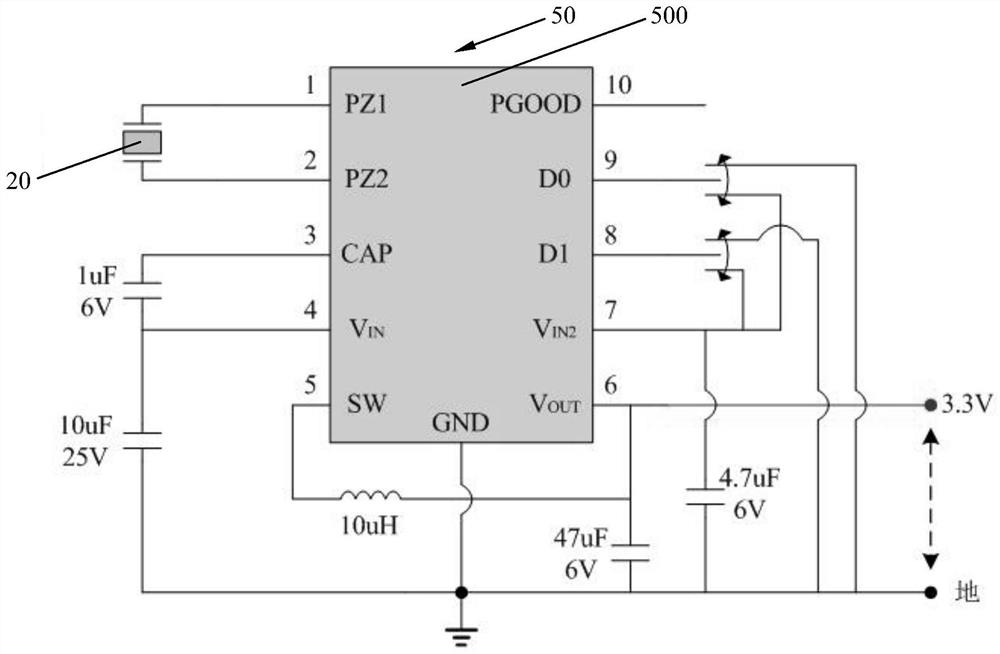

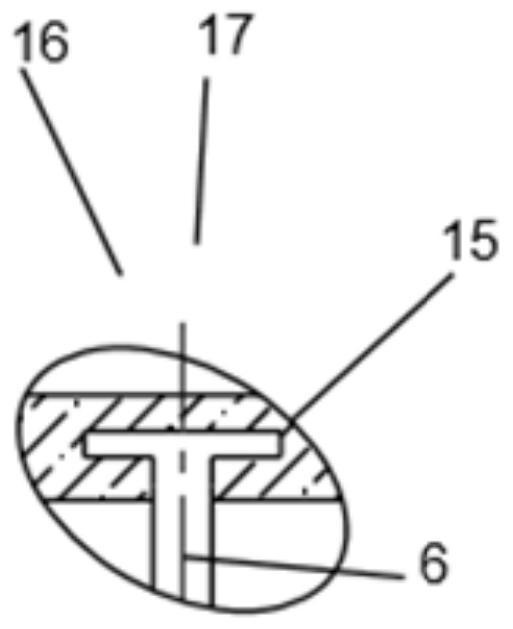

Cantilever type self-generating device and manufacturing method thereof

ActiveCN110311589BReduce design difficultyMeeting power generation needsPiezoelectric/electrostriction/magnetostriction machinesLead zirconate titanateElastic substrate

The invention provides a cantilever self-generating device, which includes a base for connecting with external devices, an elastic substrate and a plurality of piezoelectric sheets, one end of the elastic substrate is fixed on the base, and the other end of the elastic substrate is a free end , the area of the piezoelectric sheet is smaller than the area of the elastic substrate, and the elastic substrate has a strained part where the stress is concentrated, and a plurality of piezoelectric sheets are fixed on the strained part and arranged at intervals along the axis of the strained part; in addition, the present invention also provides a A method for manufacturing a cantilever type self-generating device. In the present invention, a plurality of piezoelectric sheets with smaller areas are fixed on the strained part of the elastic substrate, and the vibration energy of the elastic substrate is converted into electric energy through the piezoelectric effect of the plurality of piezoelectric sheets, so as to meet the requirements of larger power generation. Power generation needs, thus solving the technical problem that large-area lead zirconate titanate piezoelectric ceramic sheets need to be assembled for high-power piezoelectric power generation devices, reducing the design difficulty of cantilever self-generating devices, and expanding the scope of application of cantilever self-generating devices.

Owner:SHENZHEN INSTITUTE OF INFORMATION TECHNOLOGY

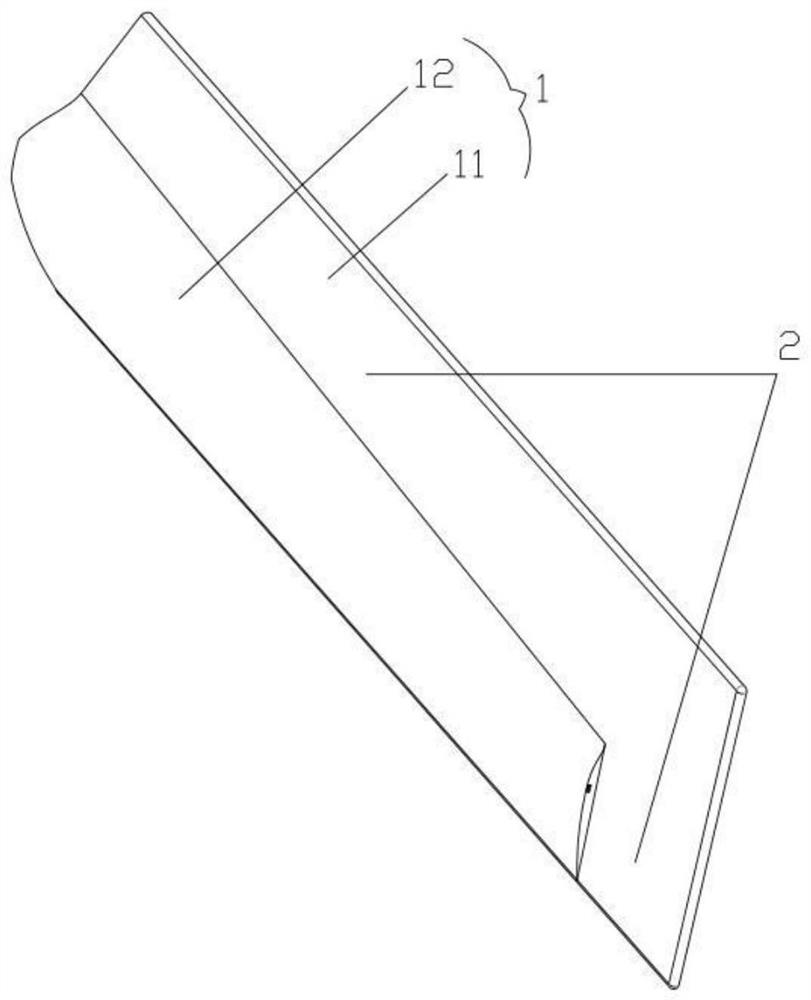

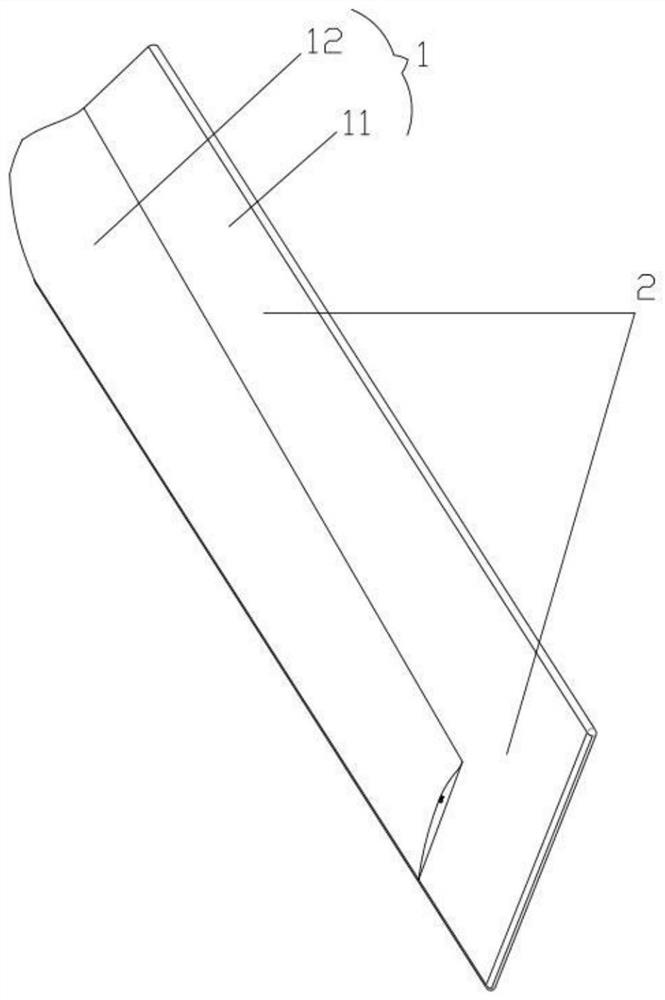

Medium-sized wind power generation blade and application thereof

PendingCN114458529AHigh strengthExtended service lifeFinal product manufactureWind motor combinationsPhysicsMechanical engineering

The medium-sized wind power generation blade comprises a blade body, and a flat plate structure is arranged on the rear edge of the blade body; the invention further discloses a wind power system comprising the medium-sized wind power generation blade. According to the wind power generation device, wind energy can be utilized to the maximum extent, and the wind power generation device is high in strength, not prone to being damaged by wind power and long in service life.

Owner:张跃

Jet steam slag granulation and heat utilization method

ActiveCN108060280BSimple processImprove thermal efficiencyRecycling and recovery technologiesProcess efficiency improvementMetallurgical slagHigh pressure water

The invention provides a new metallurgical slag granulation and heat utilization method and an apparatus thereof. A jet device which is commonly used in the market is used in a metallurgical slag treatment process, the principles of the jet device and a steam explosion tank are combined with the principle of a steam process slag treatment process, the jet process of the jet device is used to carryout metallurgical slag granulation, high-pressure jetted water is used to realize the sealing of the mouth of the jet device in order to form a semi-closed space composed of a mixing chamber and a primary heat exchange chamber, steam explosion process energy in a semi-closed container is used to carry out slag granulation and heat exchange, the slag is cooled mainly relying on the vaporization ofwater and the overheating process of steam, and superheated steam output is directly generated to carry out heat utilization. The new jet steam process slag granulation and heat utilization method utilizes water quenching and high-pressure water kinetic energy to crush the slag and utilizes the steam explosion process energy to granulate the slag, and the steam explosion energy formed in the closed space is used to achieve high-pressure rapid heat exchange. The one apparatus can realize the heat exchange process while achieving slag granulation, and the generated slag and steam output undergoheat exchange in a boiler to form clean steam or high-temperature hot water which can be used. The method is carried out in the closed container, the steam explosion energy is utilized, and the slagis cooled by using the steam process water vaporization and steam overheating process, so the method has the advantages of water saving, energy saving, environmental protection and high heat utilization efficiency, and the apparatus meets the heat exchange process while realizing slag treatment, and has practical application values.

Owner:姜学仕 +1

A method for realizing speed regulation of electric vehicle range extender

ActiveCN102975625BMeeting power generation needsAchieve target speedPropulsion using engine-driven generatorsVehicular energy storageElectric machineEngineering

The invention discloses an implementation method for speed regulation of a range extender of an electric vehicle. The range extender comprises an engine, an electric generator, a corresponding engine controller and a corresponding electric generator controller, the electric generator, a driving motor and a motive power battery share a direct current bus, and the engine controller and the electric generator controller are both connected with a whole vehicle controller. When the range extender receives a power request sent by the whole vehicle controller, the whole vehicle controller sends corresponding request torque to the engine controller, the engine controller controls the engine to output the request torque, the request torque sent by the whole vehicle controller to the engine controller serves as feedforward, and the electric generator controller controls and regulates torque of the electric generator. The range extender is enabled to work at a target rotation speed, control of the speed regulation of the range extender is achieved, requirements for whole vehicle electric generation are met, the torque of the engine and the torque of the electric generator are coordinated and controlled to achieve response to the target rotation speed, and the torque, electric current and output power of the electric generator have small fluctuation.

Owner:CHERY AUTOMOBILE CO LTD

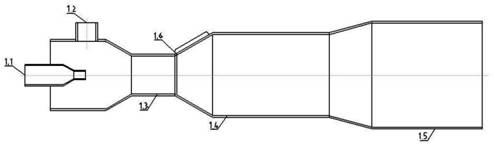

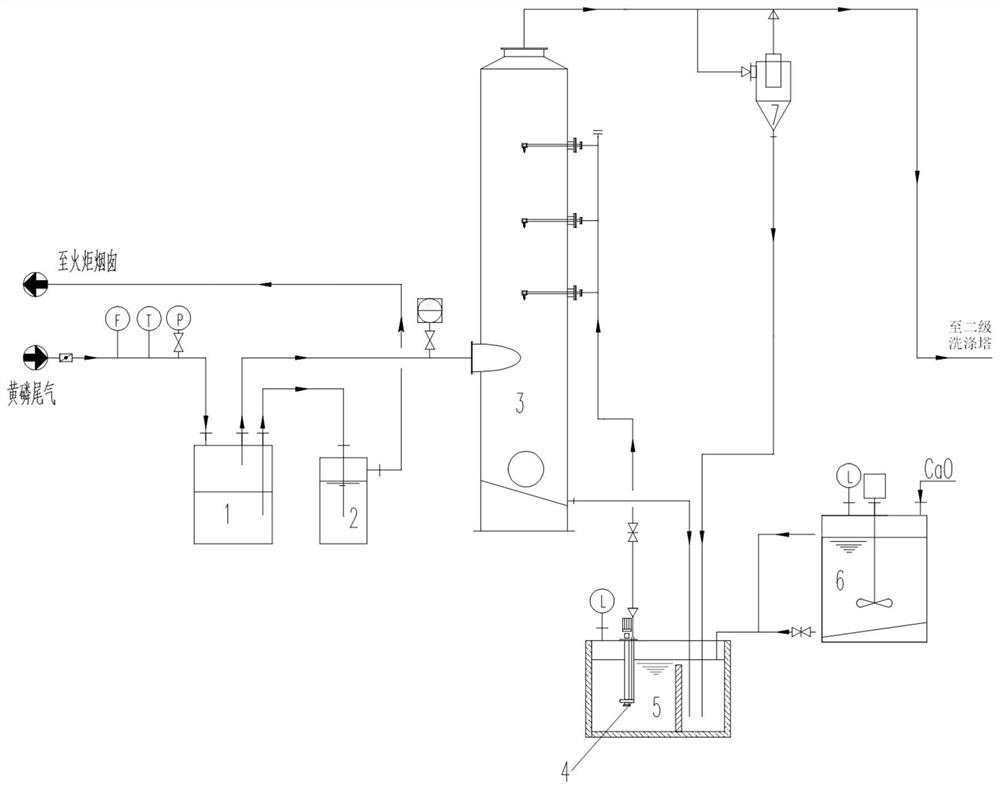

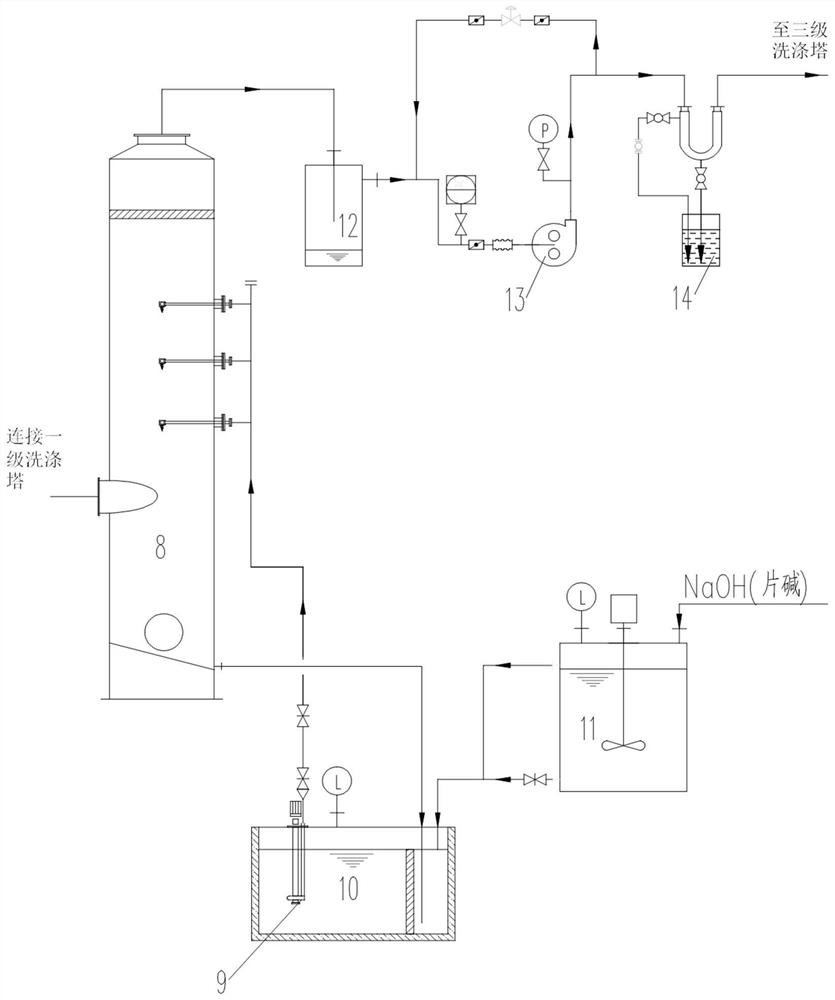

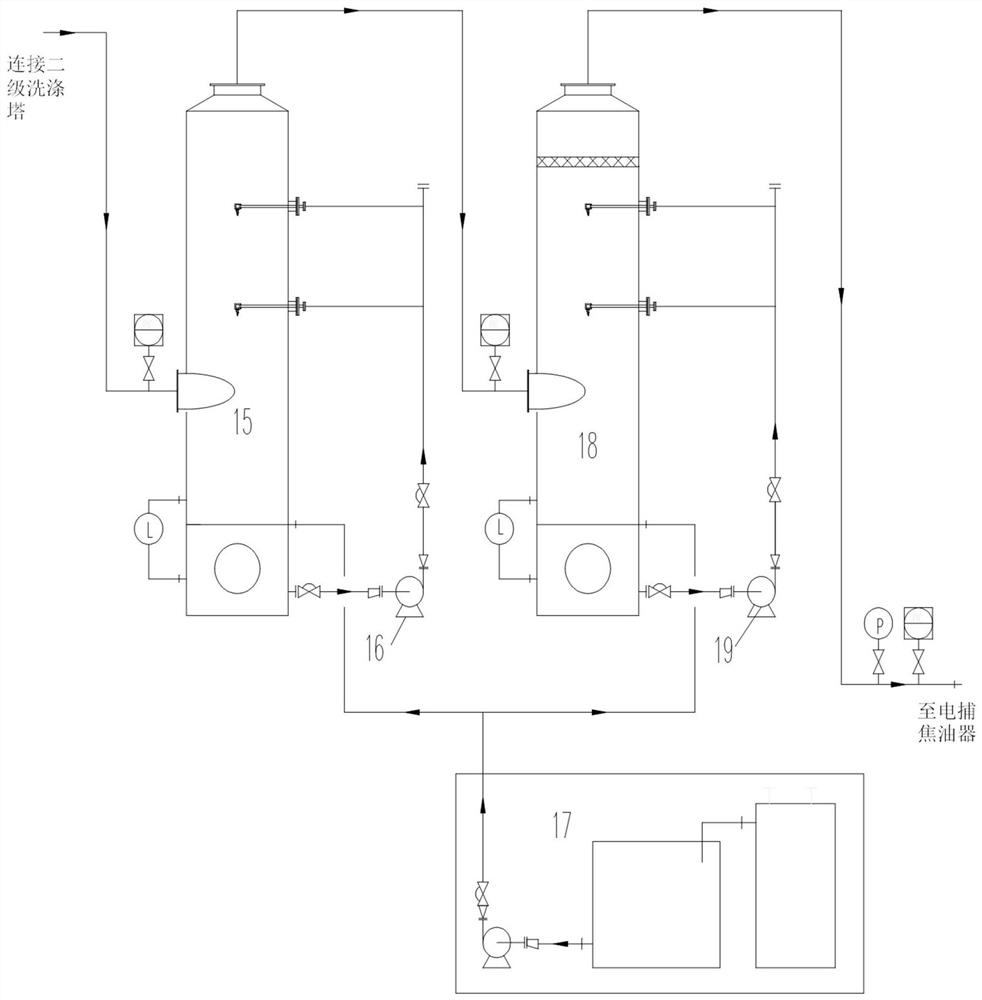

Yellow phosphorus tail gas deep purification system and deep purification method

PendingCN114713011AHigh CO resource utilizationLow P2O5 contentCombination devicesMagnetic separationDemisterExhaust gas

The invention belongs to the field of yellow phosphorus tail gas resource utilization, and particularly relates to a deep purification system and a deep purification method for yellow phosphorus tail gas. The deep purification system comprises a first-stage washing tower, a cyclone demister, a second-stage washing tower, a third-stage washing tower, a fourth-stage washing tower, an electrical tar precipitator and an activated carbon adsorption tower, and the first-stage washing tower, the cyclone demister, the second-stage washing tower, the third-stage washing tower, the fourth-stage washing tower, the electrical tar precipitator and the activated carbon adsorption tower are connected in series. According to the invention, a series of problems of poor CO resource utilization rate, fast boiler corrosion, high P2O5 content in the purified tail gas, high tail gas resource utilization cost and the like in the existing yellow phosphorus tail gas purification treatment and power generation process are solved.

Owner:CECEP INDAL ENERGY CONSERVATION

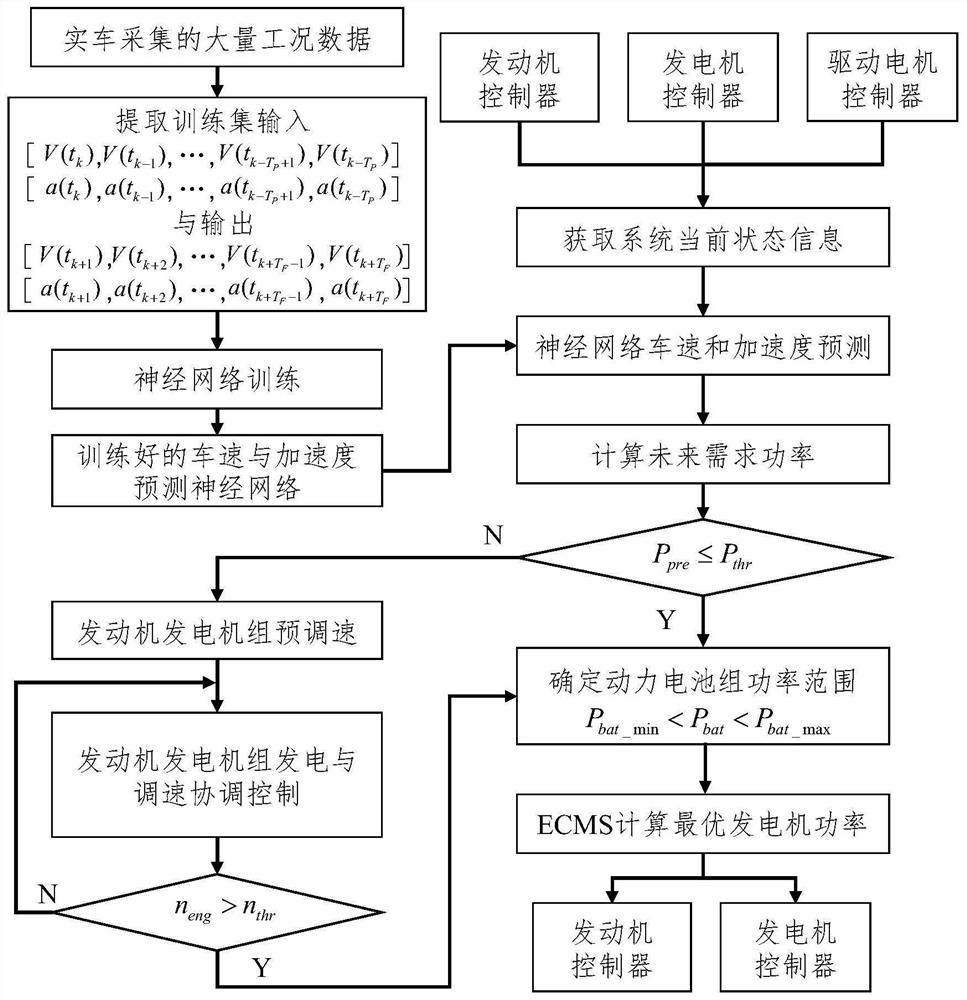

Power reserve prediction control method for tandem electromechanical composite transmission system

ActiveCN113212414AIncrease power reserveSolve the slow speedHybrid vehiclesControl devicesPower batteryFlameout

The invention provides a power reserve prediction control method for a tandem electromechanical composite transmission system. The method comprises the following steps: employing the historical data of vehicle driving as a training set, and training a neural network for predicting the vehicle speed and acceleration; according to the vehicle state data sampled at the current moment and the previous moment, applying the trained neural network to predict the vehicle speed and the acceleration within 2-3 seconds in the future, and further calculating the required power of the vehicle in the future time domain; when it is predicted that the current rotating speed of the generator cannot meet the future required power, pre-speed-regulation control is conducted on the engine generator set at the current moment, the rotating speed of the engine generator set is increased in advance, and the power reserve of the engine generator set is increased so as to meet the power generation power requirement at the future moment. The problems of slow speed regulation of the engine and over-discharge of the power battery pack during high-power demand are solved, the power generation demand is met during speed regulation, and rotating speed oscillation or flameout of the engine during speed regulation of the engine is prevented.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

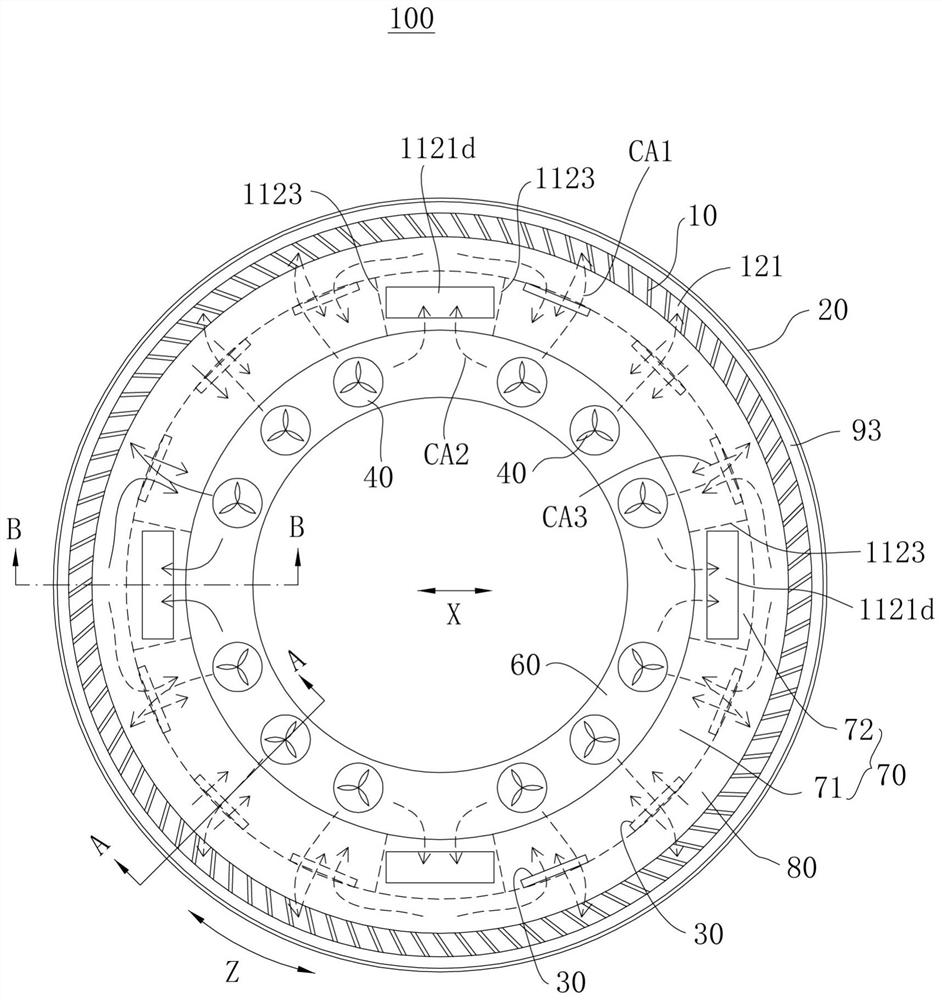

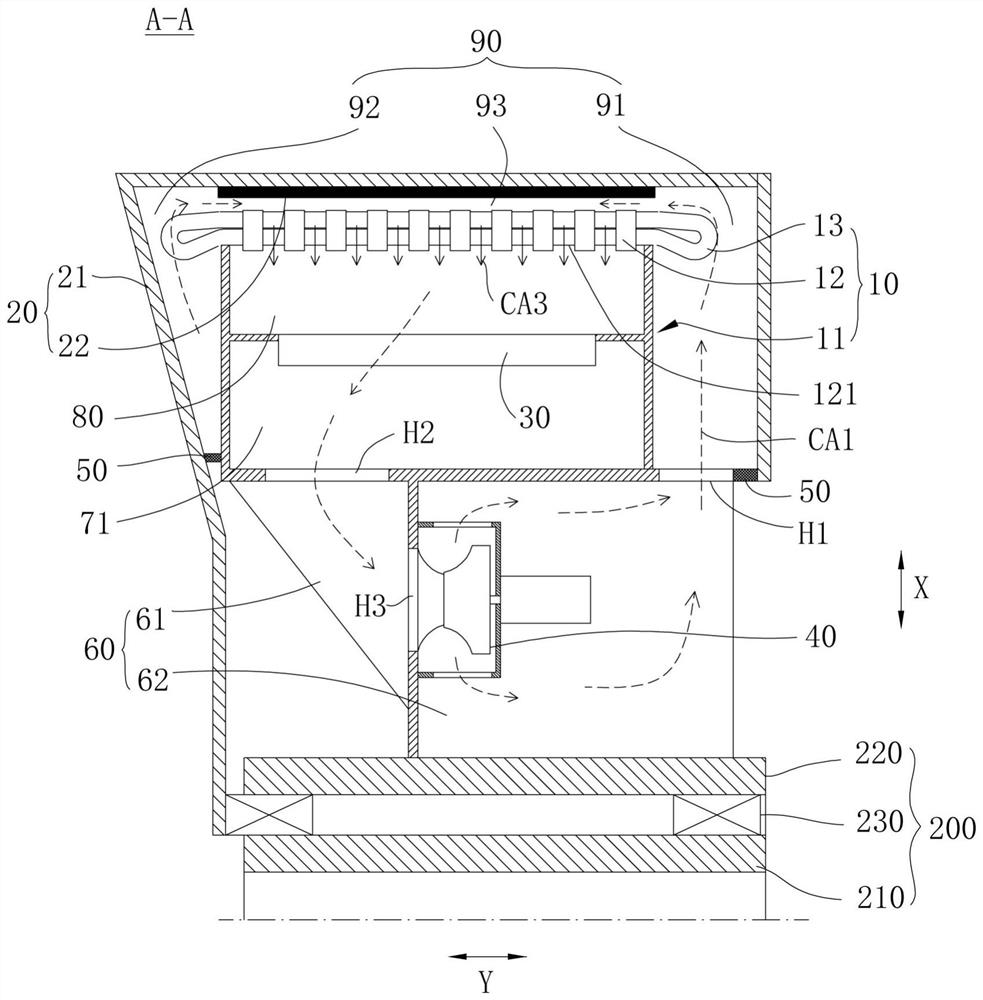

Generator and wind generating set

PendingCN114665662ACompact structureSmall footprintWind motor combinationsMachines/enginesPhysicsStator

The generator comprises a stator, the stator comprises a stator support and a stator iron core which are sequentially arranged in the radial direction of the stator, a radial air channel is formed in the stator iron core, and the stator support is used for being connected with a shafting structure and forming an inner cavity; the inner cavity comprises a first cavity, a second cavity and a third cavity which are sequentially arranged in the radial direction, and the third cavity communicates with the radial air channel. The rotor is arranged around the shafting structure, a circulating chamber is formed between the rotor and the stator, and the circulating chamber is communicated with the first chamber and the radial air duct; the heat exchanger is arranged in at least one of the second cavity and the third cavity and communicates with the second cavity and the third cavity; and the fan is arranged in the first cavity so as to drive airflow to circularly flow in the first cavity, the circulating cavity, the third cavity, the heat exchanger and the second cavity. According to the generator and the wind generating set provided by the embodiment of the invention, the generator integrates a cooling function and is compact in structure, small in occupied space and high in integration degree.

Owner:XINJIANG GOLDWIND SCI & TECH

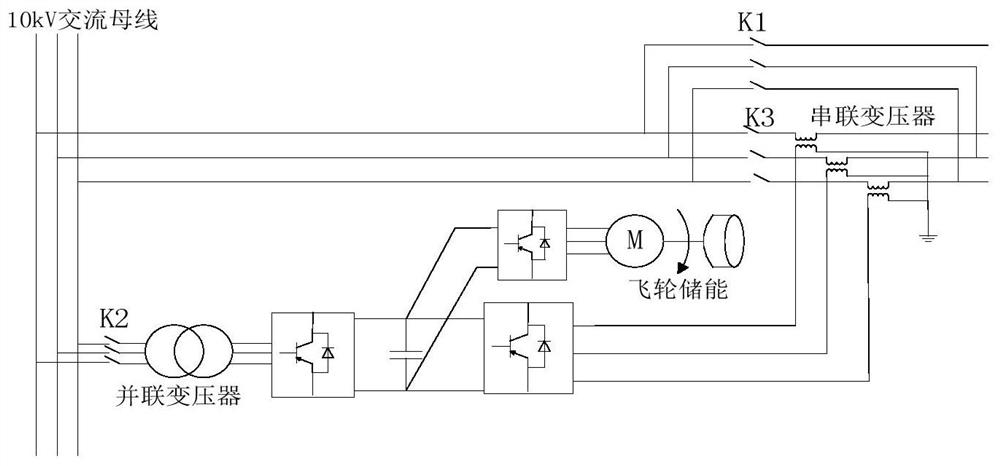

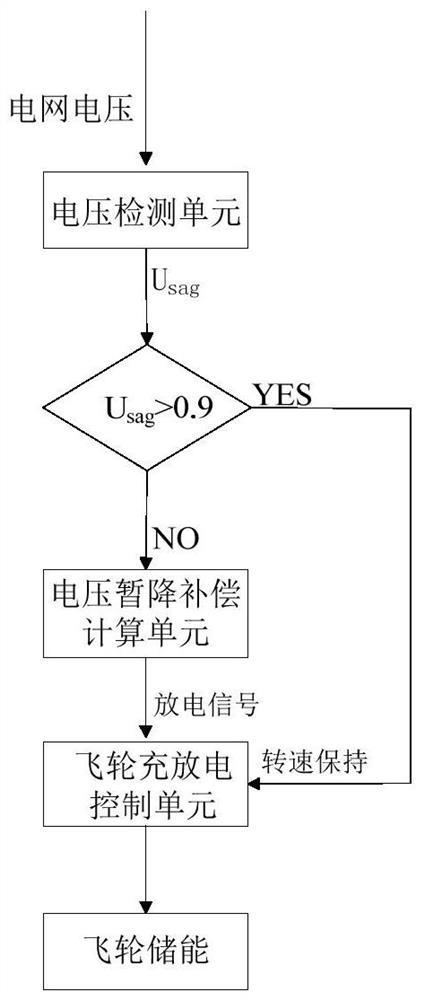

Flywheel energy storage voltage sag system for power distribution network and use method thereof

PendingCN113452046ATroubleshoot voltage sagsAvoid influenceAc network load balancingPower oscillations reduction/preventionFlywheel energy storageTransformer

The invention provides a flywheel energy storage voltage sag system for a power distribution network, which relates to the technical field of flywheel energy storage of a transformer substation. The flywheel energy storage voltage sag system for the power distribution network comprises a voltage sag detection unit, a voltage sag compensation calculation unit and a flywheel charging and discharging control unit. The invention further discloses a use method of the flywheel energy storage voltage sag system for the power distribution network. The method comprises steps that S1, when flywheel energy storage undertakes a frequency modulation task, k2 is in a closed state, the flywheel energy storage is connected to a 10kV alternating current bus of a transformer substation through a parallel transformer; S2, k1 is in a closed state, k3 is disconnected, and a series transformer does not work, and aiming at the problem that the utilization rate of the DVR is not high, flywheel energy storage is fully utilized, and the flywheel energy storage is used for solving the problem of voltage sag of the power distribution network while cooperating with new energy power generation, so that the influence of the voltage sag of the power distribution network on sensitive users can be solved, and the fee paid by additionally installing a DVR can be avoided.

Owner:STATE GRID SHANDONG ELECTRIC POWER

A kind of solar power generation device assembly method

InactiveCN104113272BEasy to separateEasy to fixPhotovoltaic supportsPhotovoltaic energy generationEngineeringSolar power

The invention discloses a solar power generation device assembling method. When using, a pedestal is arranged firstly, and a support frame is unfolded secondly; an insert head on a first supporting leg of the support frame is inserted in a socket of the pedestal and fixed through bolts, and meanwhile, a connecting seat is fixed with a mounting rod through bolts, and a solar module is unfolded finally; when two solar plates are unfolded, two clamp pieces are closed, and pin holes in the clamp pieces face to pins in the mounting rod. Because the two solar plates of the solar module are large and heavy, by means of the lever effect of the weight of the solar module, after the solar module is unfolded, the two clamp pieces tightly hold the mounting rod, and at the moment, pins are clamped in the pin holes, and the solar module would not fall off even if there is no other fixing device. By means of the solar power generation device assembling method, the disassembling is facilitated, the storage and transportation are facilitated after the disassembling, and the solar power generation requirements are satisfied under a mobile situation.

Owner:广东德日光伏科技有限公司

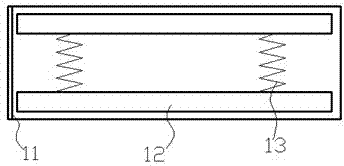

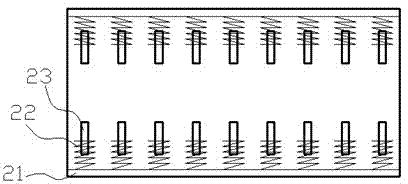

Wind-vibration-powered vehicle-mounted purifier

InactiveCN104753304AEfficient use ofCompact structureDynamo-electric machinesElectricityMagnetic poles

The invention relates to a wind-vibration-powered vehicle-mounted purifier. The wind-vibration-powered vehicle-mounted purifier comprises a wind vibration cavity, a generating cavity and a purifier body; by observing from the front end of a vehicle body to the back, iron magnetic strips in parallel to the inner walls are symmetrically mounted on the left and right inner walls of the wind vibration cavity; a pressing spring of which the axis is vertical to the iron magnetic strips is fixed between the two iron magnetic strips; the iron magnetic strips can translate only along the axis of the pressing spring by reciprocating; collector plates coupled to a rectifier are fixed on the left and right inner walls of the generating cavity; magnetic inductive coils are electrically symmetrically connected at intervals to the two collector plates; two rows of strip-shaped magnets directly facing the iron magnetic strips in positions are arranged at intervals in the generating cavity; one magnetic pole of each strip-shaped magnet extends into each magnetic inductive coil. The vehicle-mounted purifier is small in size, and simple in appearance; electricity energy can be independently generated, and the operation is convenient; meanwhile, the air can be efficiently purified.

Owner:胡振华

Tidal current energy power generation device

PendingCN112412688AImprove conversion efficiencyImprove structural stabilityMachines/enginesEngine componentsEngineeringExhaust pipe

The invention relates to the technical field of tidal current power generation, and discloses a tidal current energy power generation device. The tidal current energy power generation device comprisesa bottom plate fixed to a water bed, the upper end of the bottom plate is fixedly connected with a pneumatic power generation shell located in the middle and two mechanical power generation shells located on the two sides through a plurality of supporting legs, and a piston is arranged in the pneumatic power generation shell. The upper end of the piston is fixedly connected with a piston rod, theupper end of the piston rod penetrates through the upper end of the pneumatic power generation shell through a sealing guide bearing, and the side wall of the upper end of the pneumatic power generation shell symmetrically and fixedly communicates with a first air inlet pipe and a first air outlet pipe. The side wall of the lower end of the pneumatic power generation shell symmetrically and fixedly communicates with a second air inlet pipe and a second air outlet pipe, and the first air outlet pipe and the second air outlet pipe communicate with a steam turbine. The tidal current energy powergeneration device can effectively utilize tidal current fluctuation for efficient power generation, multiple power generation modes are achieved, and different power generation requirements can be met.

Owner:SHANGHAI MARITIME UNIVERSITY

A wind turbine impeller

ActiveCN105298742BImprove wind energy utilizationIncrease motivationRenewable energy generationMachines/enginesImpellerMirror image

The invention provides a wind turbine impeller, which is used to solve the problems of low wind-sweeping ability and insufficient power of the wind turbine impeller. The impeller includes a main shaft, n sets of impeller frames, n sets of blades and bearing housings, wherein n is a positive integer not less than 1; each set of impeller frames includes a first impeller frame and a second impeller frame; the first The impeller frame and the second impeller frame take the main shaft 1 as the axis of symmetry, and are fixedly mounted on the main shaft in mirror image symmetry; the blades include first blades and second blades; the first blades are movably installed on the first impeller frame, and the second The two blades are movably installed on the second impeller frame; the first blade and the second blade are connected as a whole through connecting parts and move synchronously; the main shaft 1 is vertically installed on the bearing seat. The invention has the characteristics of enhanced wind-sweeping ability, simple structure, large generating power range, wide application range and the like.

Owner:中科众瑞(哈尔滨)清洁能源股份有限公司 +1

Solar power generation device assembling method

InactiveCN104113272AEasy to separateEasy to fixPhotovoltaic supportsPhotovoltaic energy generationSolar powerSolar module

The invention discloses a solar power generation device assembling method. When using, a pedestal is arranged firstly, and a support frame is unfolded secondly; an insert head on a first supporting leg of the support frame is inserted in a socket of the pedestal and fixed through bolts, and meanwhile, a connecting seat is fixed with a mounting rod through bolts, and a solar module is unfolded finally; when two solar plates are unfolded, two clamp pieces are closed, and pin holes in the clamp pieces face to pins in the mounting rod. Because the two solar plates of the solar module are large and heavy, by means of the lever effect of the weight of the solar module, after the solar module is unfolded, the two clamp pieces tightly hold the mounting rod, and at the moment, pins are clamped in the pin holes, and the solar module would not fall off even if there is no other fixing device. By means of the solar power generation device assembling method, the disassembling is facilitated, the storage and transportation are facilitated after the disassembling, and the solar power generation requirements are satisfied under a mobile situation.

Owner:广东德日光伏科技有限公司

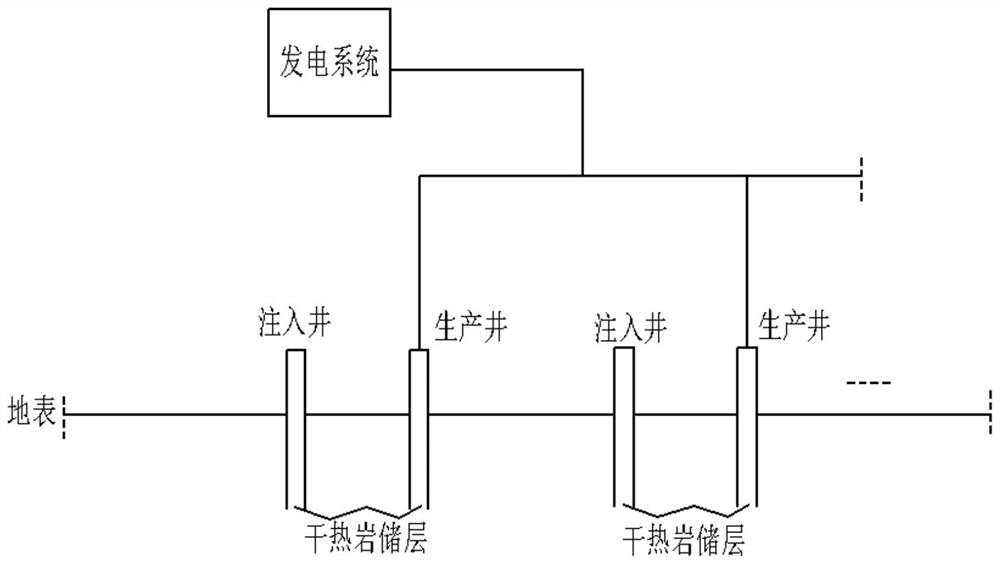

A heat exchange method suitable for short well spacing in dry hot rock

ActiveCN111561304BWell spacing shortenedSave work timeGeothermal energy generationFluid removalFracturing fluidDry heat

A method for heat exchange with short well spacing of hot dry rock, comprising the following steps: injecting fracturing fluid into the hot dry rock reservoir from an injection well, and waiting for the high pressure fracturing fluid to extrude the dry hot rock reservoir to a larger size. After the main fracture, a temporary plugging agent is added, which will block the main fracture and extrude more fractures in other directions. The width of the bottom hole crack, and then calculate the time required for heat exchange, and calculate the required quantity and size of the temporary plugging agent based on the data; The heat exchange medium cannot flow, and the heat exchange medium stays in the high-temperature rock formation and is heated until it reaches the design temperature. After the temporary plugging material dissolves, the high-pressure fluid enters the power generation system to complete the power generation operation. While shortening the well spacing, the invention also improves the power generation efficiency, reduces the production cost, and avoids land occupation and waste.

Owner:EXPLORATION TECH RES INST OF CHINESE ACADEMY OF GEOLOGICAL SCI

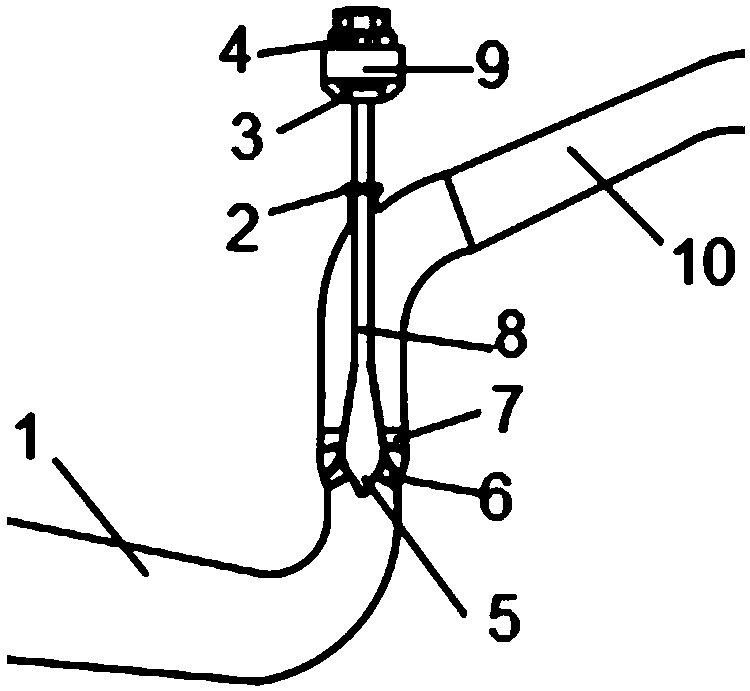

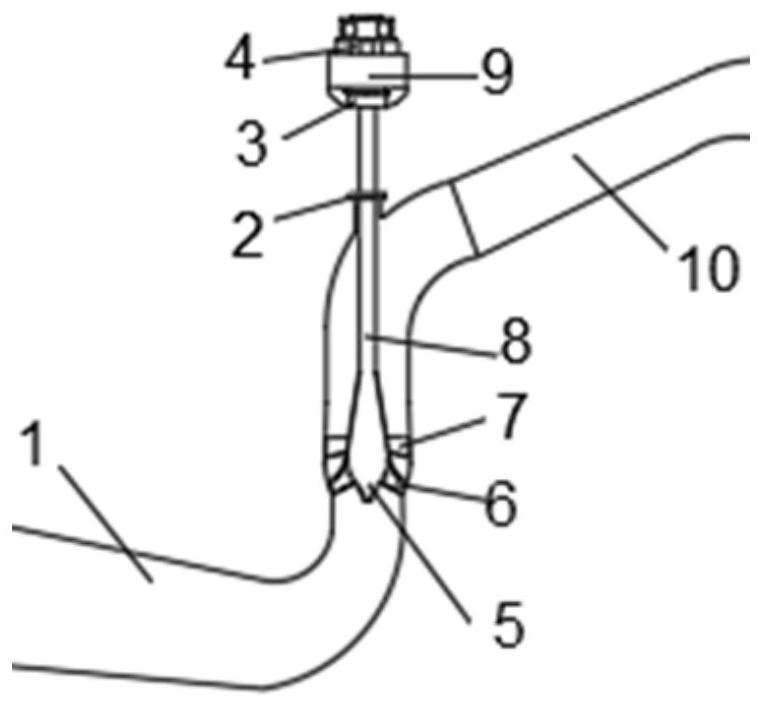

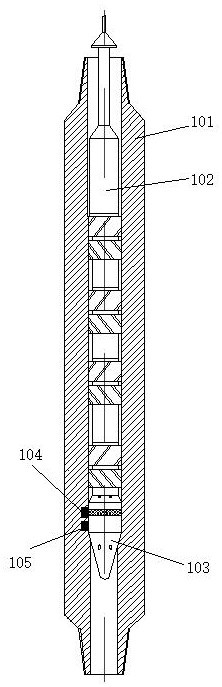

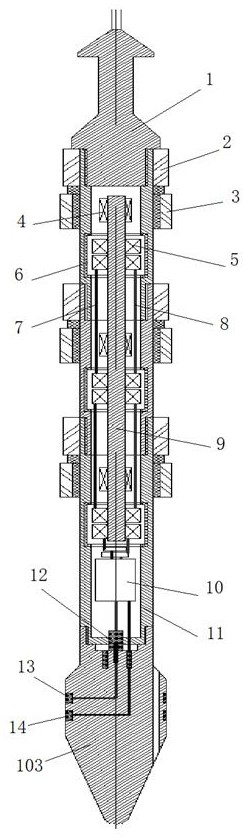

A throwing-and-fishing downhole power generation device and method for water injection wells

ActiveCN109681163BEnsure long-term normal workMeet pass requirementsBatteries circuit arrangementsFluid removalEngineeringWater well

The invention discloses a throwing-and-fishing type downhole power generation device and method for water injection wells, wherein the device includes a hollow positioning sub-joint and a throwing-and-fishing type generator set, the throwing-and-fishing type generator set is arranged in the inner cavity of the hollow positioning sub-joint, and the hollow The inner wall of the positioning nipple is provided with a nipple positive joint and a nipple negative joint. The lower end of the throwing type generator set is connected to the positioning joint. The outer wall of the positioning joint is positioned on the positioning step set on the inner wall of the hollow positioning joint. The positioning joint Set up the positioning wet positive terminal and the positioning wet negative terminal. The positioning wet positive terminal and the positioning wet negative terminal are connected with the positive and negative terminals of the throwing and fishing generator set on the one hand, and on the other hand with the short joint positive joint and short joint negative joint. corresponding connection. The invention can provide long-term and stable power energy for downhole intelligent water injection tools. The long-term normal operation of the downhole intelligent water injection device is guaranteed.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com