Horizontal shaft tide turbine power generation device storing energy by means of flywheel

A flywheel energy storage and tidal current technology, applied in the directions of hydropower generation, ocean energy power generation, tidal flow/damless hydropower, etc., can solve the problems of hindering tidal current turbine power generation, friction loss, and difficulty in providing power output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] specific implementation plan

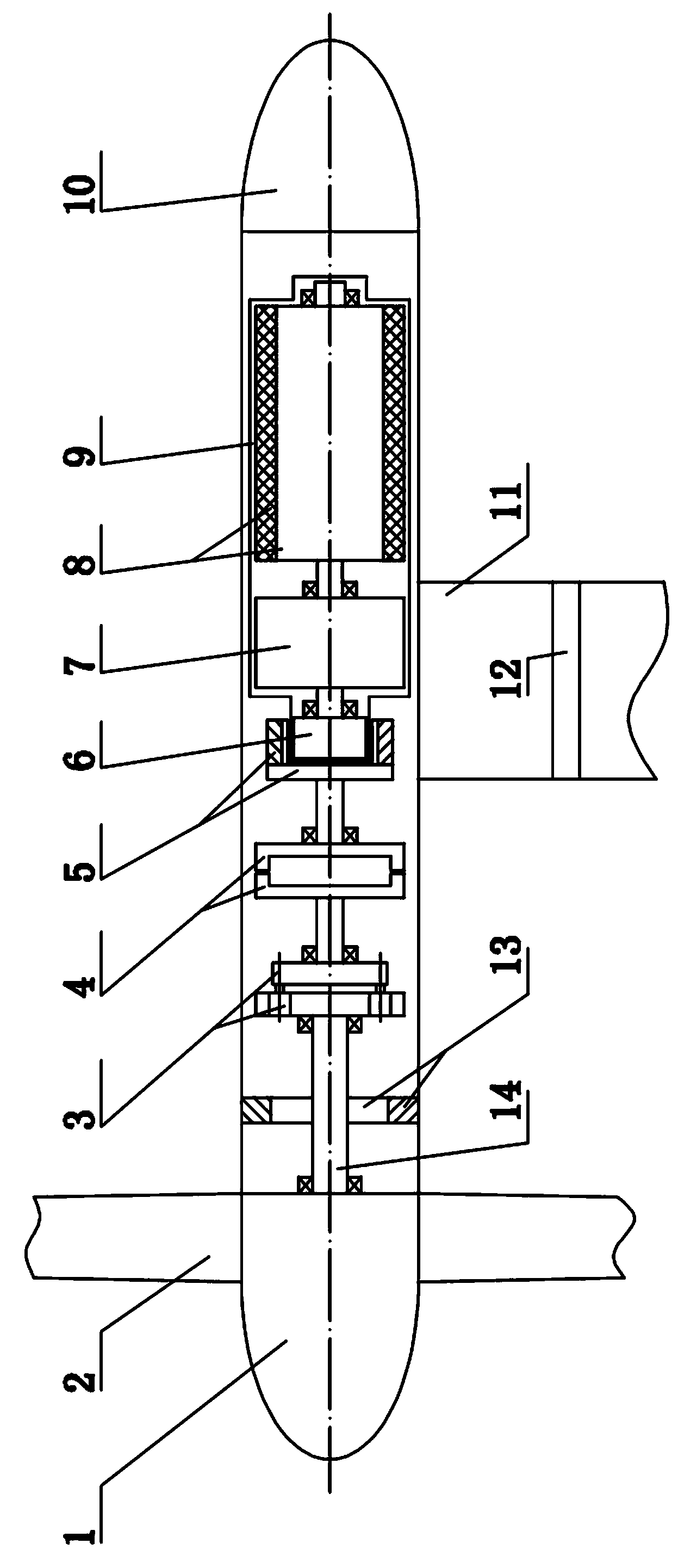

[0010] like figure 1 As shown, the turbine 2 of the power generating device is sequentially connected with the brake 13, the gearbox 3, the clutch 4, the outer rotor 5 of the electromagnetic coupler, the inner rotor 6 of the electromagnetic coupler, the flywheel 7 and the generator 8. The turbine is used to convert tidal current energy into shaft power, the brake is used for braking when the turbine stops, the gearbox outputs the low speed of the turbine shaft to a high speed, and the clutch is used for the power of the turbine shaft and When the electromagnetic coupler is turned on and off, the outer rotor and inner rotor of the electromagnetic coupler transmit torque through electromagnetic force. The inner rotor, flywheel and generator of the electromagnetic coupler are placed in the sealed cabin 9, and the sealed cabin is evacuated.

[0011] The design output power of the power generation device is P2=100 kW; the highest tidal curren...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com