A heat exchange method suitable for short well spacing in dry hot rock

A technology of hot dry rock and heat exchange medium, which is applied in the field of thermal energy utilization of dry hot rock, can solve the problems of large surface wellhead area, unfavorable large-scale mining power generation, and high difficulty of drilling costs, so as to solve operating costs and save operations Time and money, the effect of reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

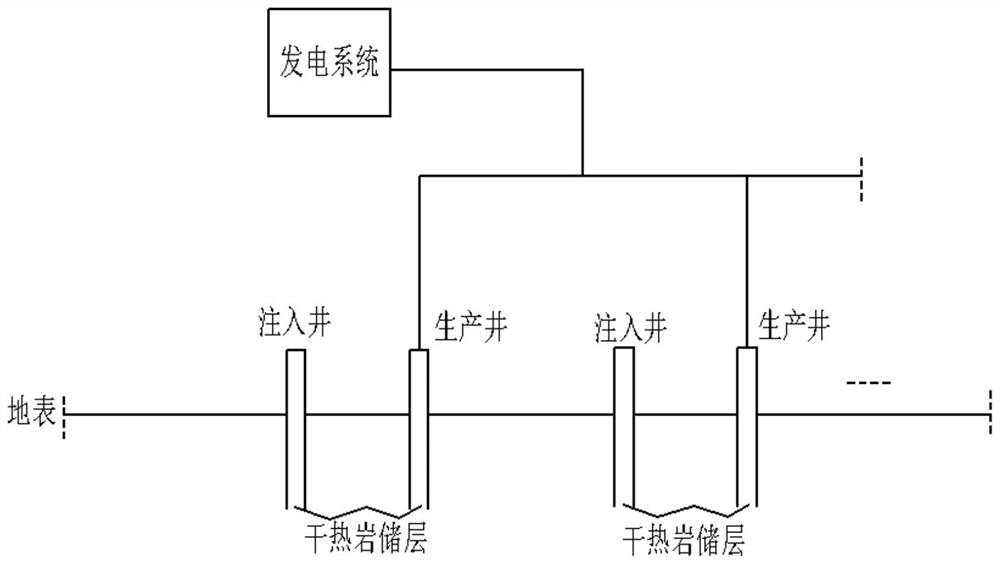

[0027] In the prior art, the heat exchange principle adopted is generally: inject low-temperature and high-pressure fluid into the well from the injection well, the low-temperature and high-pressure fluid enters into the high-temperature thermal reservoir along the wellbore, and then the low-temperature and high-pressure fluid flows along the high-temperature thermal reservoir Fractures move and fill until they reach the bottom of the production well; during the process of moving the low-temperature and high-pressure fluid from the production well to the bottom of the production well, since all the moving routes are high-temperature heat storage layers, the low-temperature and high-pressure The fluid is continuously heated during the moving process, and the fluid heated to high temperature enters the power generation system through the wellbore of the production well to achieve the purpose of power generation; when the low-temperature and high-pressure fluid moves in the high-te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com