Semi-coke powder and brown coal matched forming method

A lignite and semi-coke technology, which is applied in the field of semi-coke powder and lignite molding, can solve the problems of severe dust, lower coal calorific value, and high cost, and achieve the effects of simplifying the molding process, reducing molding costs, and low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

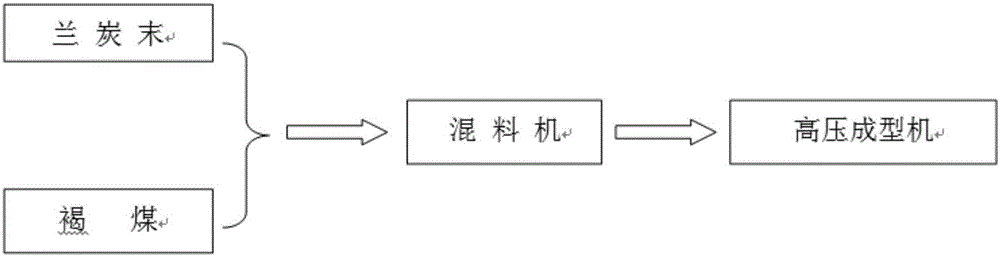

Method used

Image

Examples

Embodiment 1

[0023] Main features of semi-coke powder: particle size below 4mm, fixed carbon 65.8%;

[0024] Main features of lignite: particle size below 3mm, addition amount 30%, moisture content 15%;

[0025] Molding pressure of high pressure ball press: 20MPa;

[0026] Based on semi-coke powder, weigh 1000g of semi-coke powder and 300g of lignite, put the semi-coke powder and lignite into the EIRICH mixer, mix for 5 minutes, and put the mixture into the pre-pressing screw of the roller forming machine warehouse, and then molding; the resulting molded balls have a compressive strength of 213N / ball, a ball forming rate of 92%, and a calorific value of 5,400 kcal / kg.

Embodiment 2

[0028] Main characteristics of semi-coke powder: particle size below 4mm, fixed carbon 71.4%;

[0029] Main features of lignite: particle size below 3mm, additive amount 40%, moisture 15%;

[0030] Molding pressure of high pressure ball press: 20MPa;

[0031] Based on semi-coke powder, weigh 1000g of semi-coke powder and 400g of lignite, put the semi-coke powder and lignite into the EIRICH mixer, mix for 5 minutes, and put the mixture into the pre-pressing screw of the roller forming machine warehouse, and then carry out molding; the obtained molding ball has a compressive strength of 221N / ball, a ball forming rate of 94%, and a calorific value of the shaped ball reaches 5218 kcal / kg.

Embodiment 3

[0033] Main characteristics of semi-coke powder: particle size below 4mm, fixed carbon 75.1%;

[0034] Main features of lignite: particle size below 4mm, additive amount 20%, moisture 20%;

[0035] Forming pressure of high pressure ball press: 19MPa;

[0036] Based on semi-coke powder, weigh 1000g of semi-coke powder and 200g of lignite, put the semi-coke powder and lignite into the EIRICH mixer, mix for 3 minutes, and put the mixture into the double-roll forming machine for pre-pressing screw warehouse, and then molding; the obtained molding ball has a compressive strength of 199N / ball, a ball forming rate of 92%, and a calorific value of 5220 kcal / kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com