Evaporation-induced battery based on carbon material surface function modification

A technology of evaporation induction and carbon materials, applied in the direction of electrical components, etc., can solve problems such as energy loss, and achieve the effects of improving electricity production efficiency, simple and easy-to-obtain raw materials, and simple preparation processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

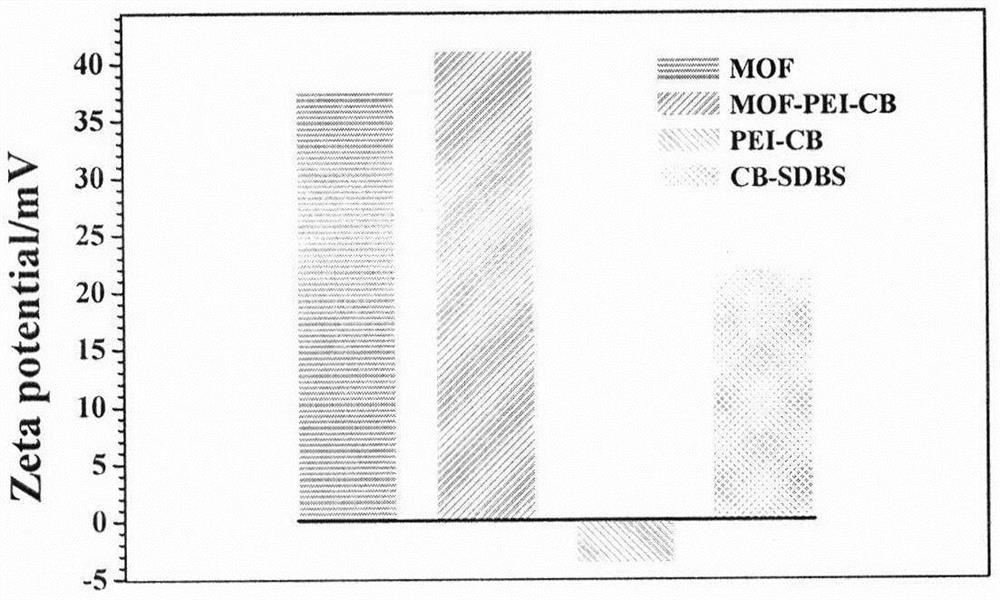

[0029] The preparation of embodiment 1 MOF801, concrete steps are as follows:

[0030] (1) 2.03g (17.5mmol) fumaric acid and 5.6g (17.5mmol) ZrOCl 2 ·8H 2 O was dissolved in a mixed solvent of DMF and formic acid (70 L and 24.5 mL, respectively). Then the mixture was placed in a polytetrafluoroethylene-lined autoclave and heated at 130°C for 6h.

[0031] (2) The product was collected through a microporous membrane (45 μm pore size) vacuum filtration device, washed three times with 60 mL of DMF, three times with 40 mL of methanol, and dried in air.

[0032] (3) The above MOF samples were placed in a 15kPa vacuum oven and dried at 150°C for 24h.

Embodiment 2

[0033] Example 2 PEI-KB-FP electricity production voltage and PEI concentration experiment, the specific steps are as follows:

[0034] First prepare PEI aqueous solutions with concentrations of 0.4wt%, 0.2wt%, 0.1wt%, 0.05wt%, 0.025wt%, after ultrasonication for 30min, place the CB-SDBS-treated qualitative filter papers in the above solution respectively, and hydrothermally treat them at 70°C Take it out after 2 hours, and then dry it in a blast oven at 80°C for 30 minutes. Put the dried different PEI-modified PEI-KB-FP in a beaker filled with 0.5mol / L NaCl aqueous solution, where the wet end of PEI-KB-FP was connected to the reference electrode of the electrochemical workstation, and the dry end of PEI-KB-FP was Connect the terminal to the working electrode of the electrochemical workstation, and then adjust the specific parameters of the electrochemical workstation, measure and record the electricity production voltage value of PEI-KB-FP at 1000s, we found that PEI-KB-FP tr...

Embodiment 3

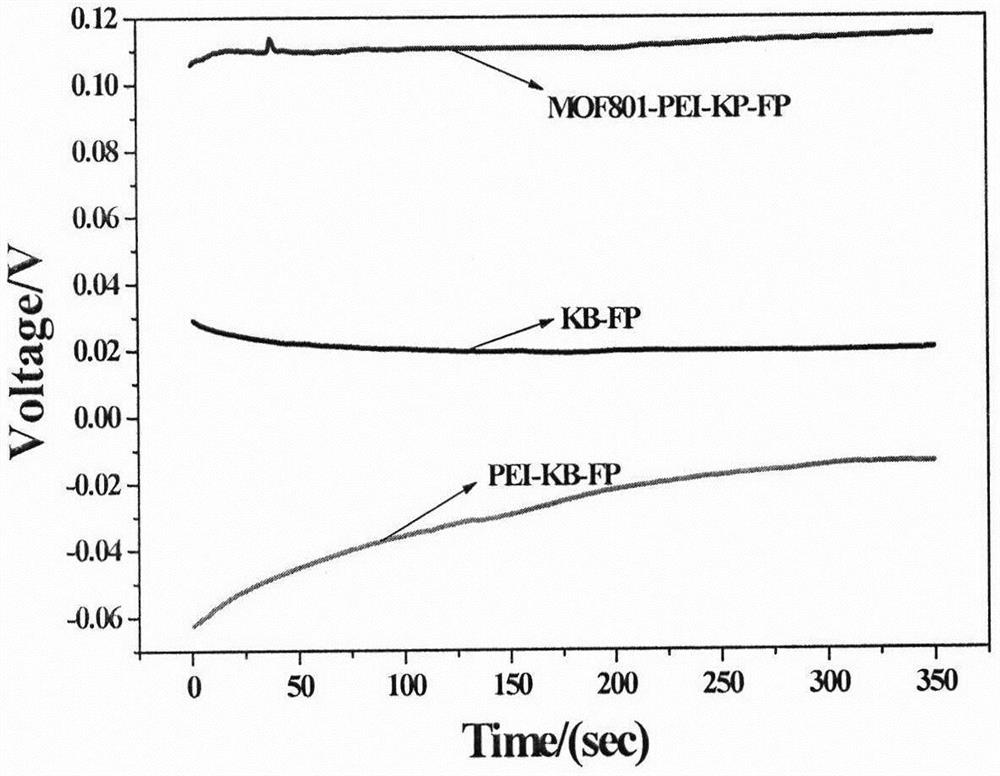

[0035] Example 3 Voltage comparison experiment of KB-FP, PEI-KB-FP, MOF801-PEI-KB-FP, the specific steps are as follows:

[0036] First prepare KB-FP, PEI-KB-FP, MOF801-PEI-KB-FP power generation modules, and connect the stems of KB-FP, PEI-KB-FP, and MOF801-PEI-KB-FP with a multi-channel electrochemical workstation terminal and wet terminal, the connection method is the same as in Example 2, three different power generation modules are immersed in 0.6mol / L NaCl aqueous solution at the same time, and the multi-channel workstation is used to record the power production of the battery, and record KB-FP, PEI -KB-FP, MOF801-PEI-KB-FP's power generation voltage value at 1000s, figure 2 The voltage comparison of KB-FP, PEI-KB-FP, MOF801-PEI-KB-FP is shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com