Wind energy machine

A technology for wind turbines and blades, which is applied to wind turbines, motors, and wind turbines at right angles to the wind direction, etc., can solve problems such as reducing the effect of wind turbine mechanisms, and achieve the effects of improving power generation efficiency and reducing resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

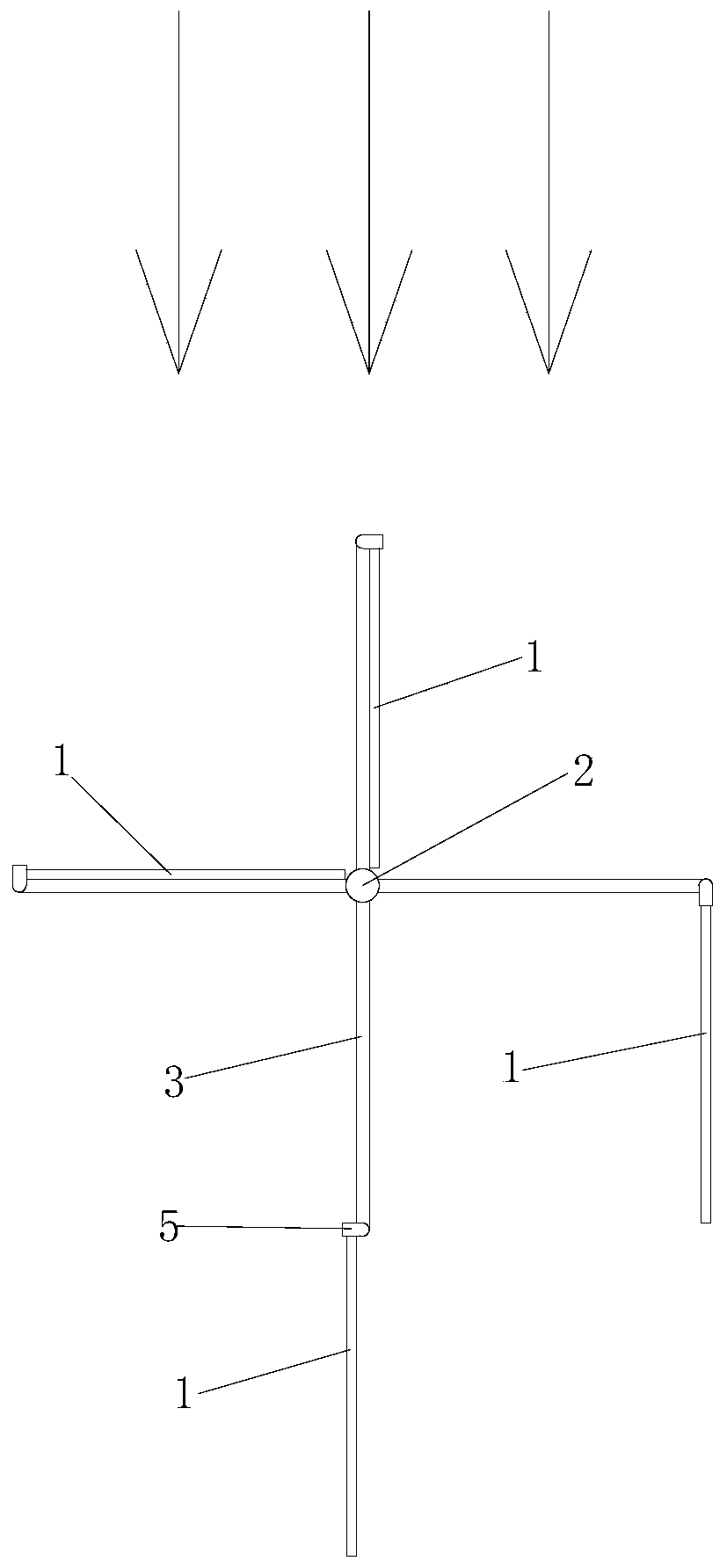

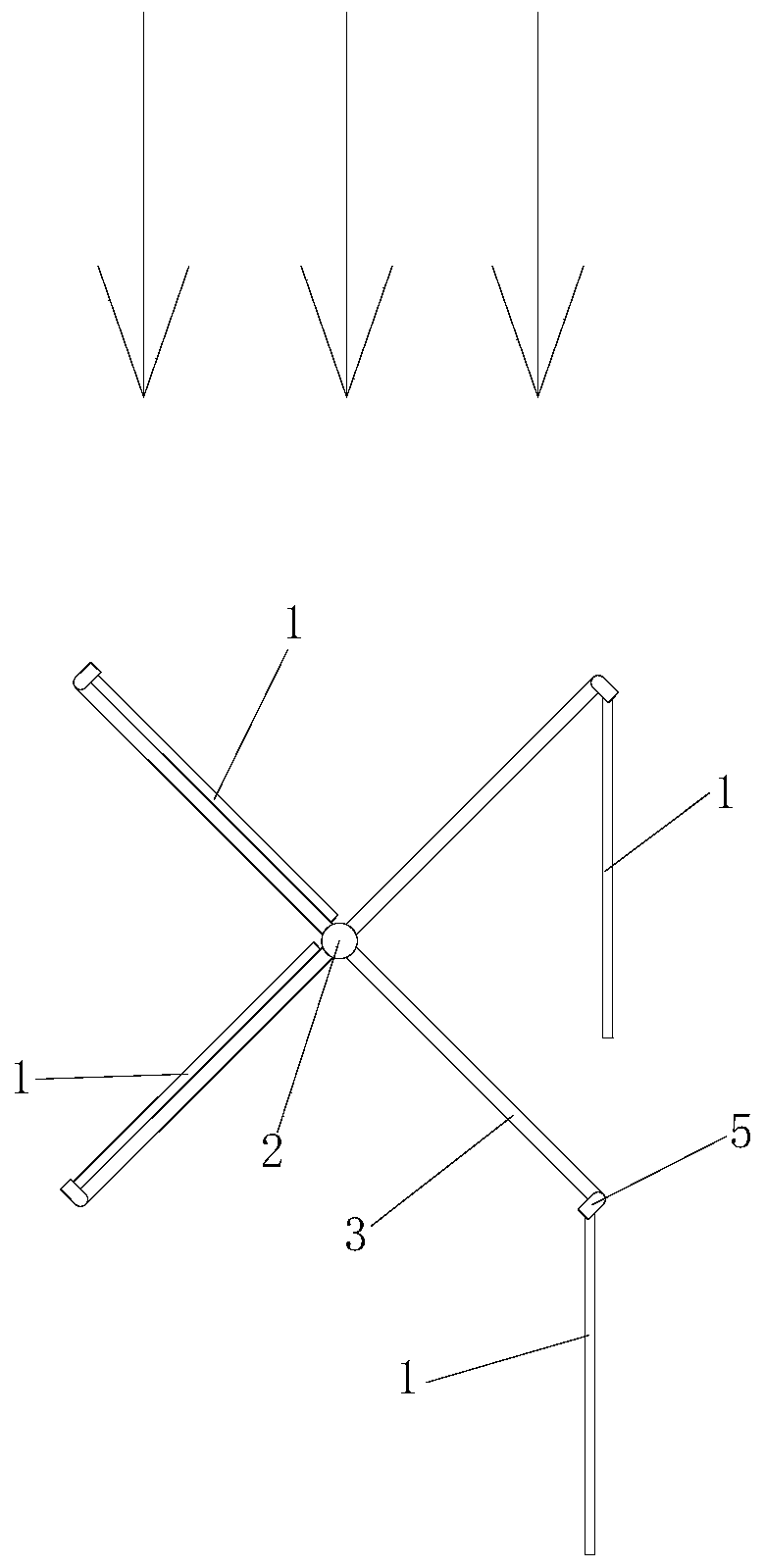

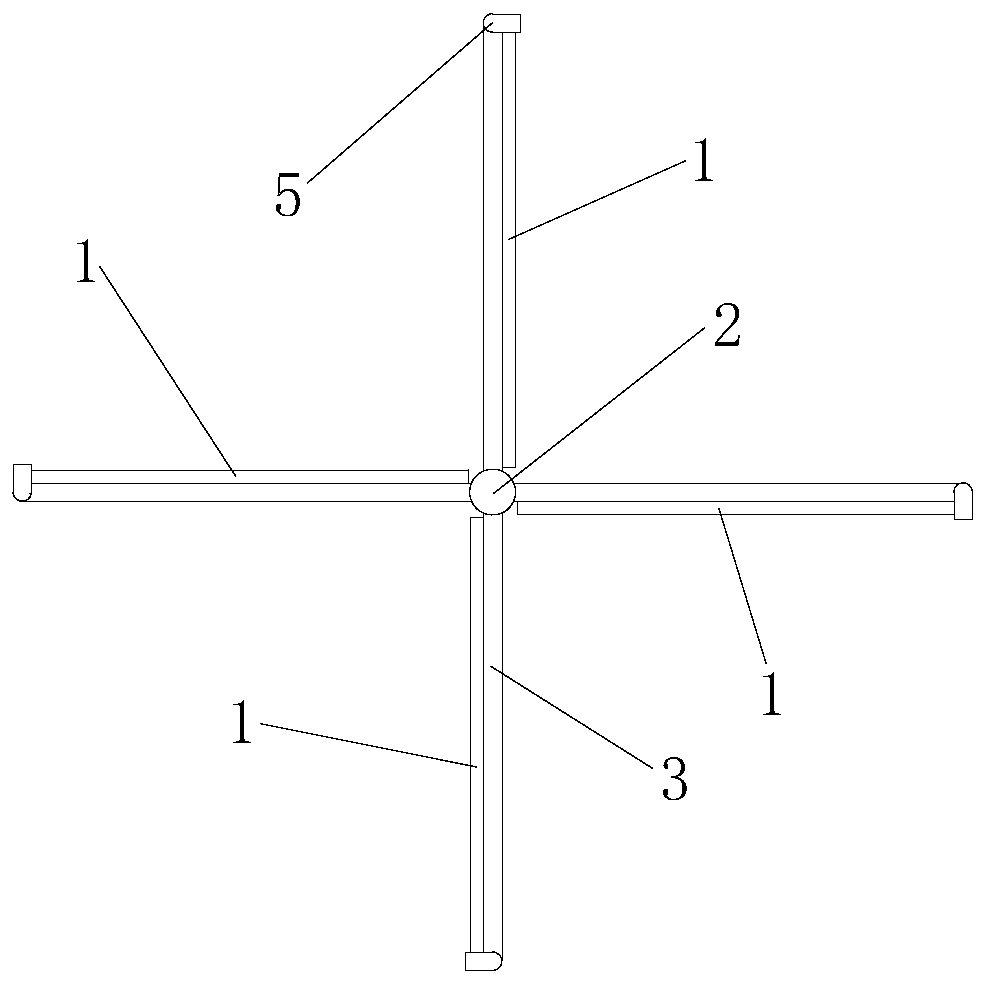

[0031] Such as Figure 1-4 as shown, figure 1 and figure 2 The arrow in the figure is the wind direction. This embodiment provides a wind energy machine, which includes a fan blade 1 and a central shaft 2. The upper end of the central shaft 2 is vertically connected with two support rod groups. The two support rod groups are perpendicular to each other and up and down. Staggered arrangement; each support rod group includes two support rods 3, and the two support rods 3 in each support rod group are symmetrically arranged with the central axis 2 as the central axis, which is equivalent to four support rods 3 at 90° The distance is evenly distributed around the central axis 2, and the stability of the central axis 2 can also be guaranteed when the support rod 3 drives the central axis 2 to rotate; the ends of the four support rods 3 away from the central axis 2 are all movably connected with a wind turbine. leaves 1, and the four fan blades 1 are all arranged on the same side...

Embodiment 2

[0034] This embodiment is a further improvement made on the basis of Embodiment 1. The specific differences between this embodiment and Embodiment 1 are:

[0035] What needs to be further explained in this embodiment is that the end of each support rod 3 away from the central axis 2 is vertically connected with a vertical rod 4. At this time, the vertical rod 4 is parallel to the central axis 2, and each fan blade 1 is flexibly connected to the On the corresponding vertical rod 4, the fan blade 1 is movably connected to the vertical rod 4, so that the connection points of the fan blade 1 can be increased, so that the connection between the fan blade 1 and the vertical rod 4 is easier than the connection between the fan blade 1 and the support rod 3. Stable, to ensure the stable rotation of the fan blade 1 and the subsequent continuous work.

Embodiment 3

[0037] This embodiment is a further improvement made on the basis of Embodiment 2. The specific differences between this embodiment and Embodiment 2 are:

[0038] What needs to be further explained in this embodiment is that each support rod 3 is vertically connected to the middle part of the corresponding vertical rod 4, so that the stability of the vertical rod 4 can be maintained, thereby ensuring the stress stability of the fan blade 1. During the rotation of the blade, it is natural to ensure the stability of the support rod 3 when it is subjected to the reverse force of the blade 1 to a greater extent, thereby ensuring the stable rotation of the central axis, making the generated mechanical energy more stable, and the conversion of mechanical energy into electrical energy is naturally easier. more efficient.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com