Yellow phosphorus tail gas deep purification system and deep purification method

A technology for deep purification of yellow phosphorus tail gas, applied in chemical instruments and methods, separation methods, air quality improvement, etc., can solve problems such as poor utilization of CO resources, rapid boiler corrosion, high cost of tail gas resource utilization, and achieve CO resource utilization High utilization rate, low P2O5 content, and low cost of tail gas resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

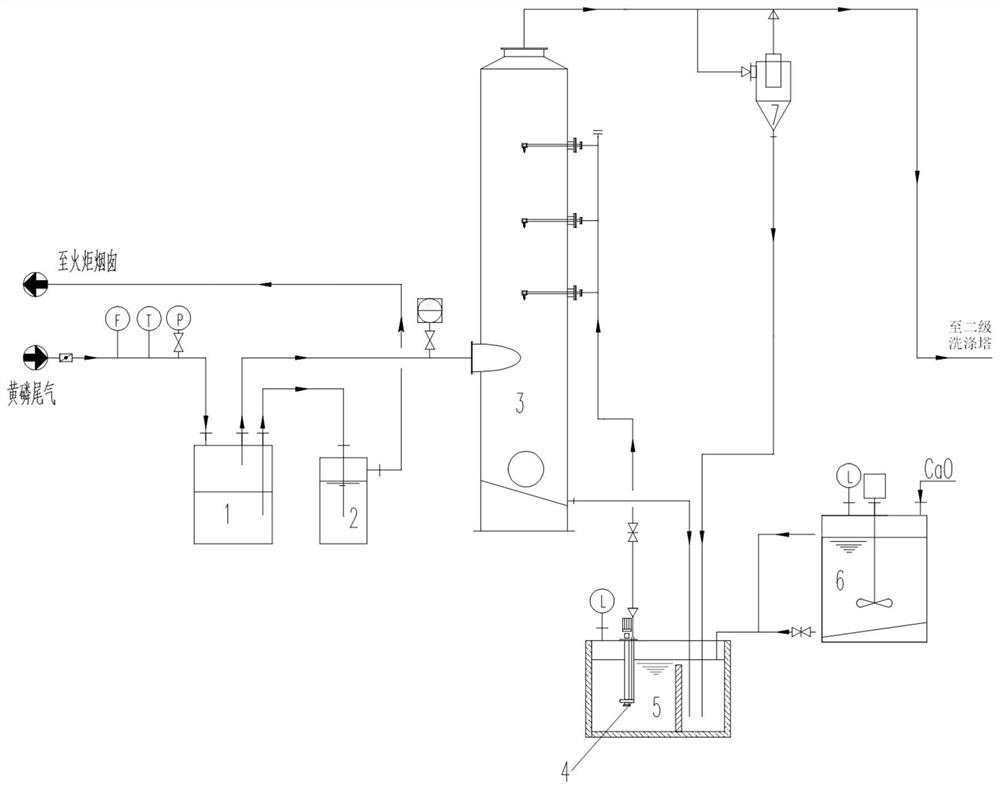

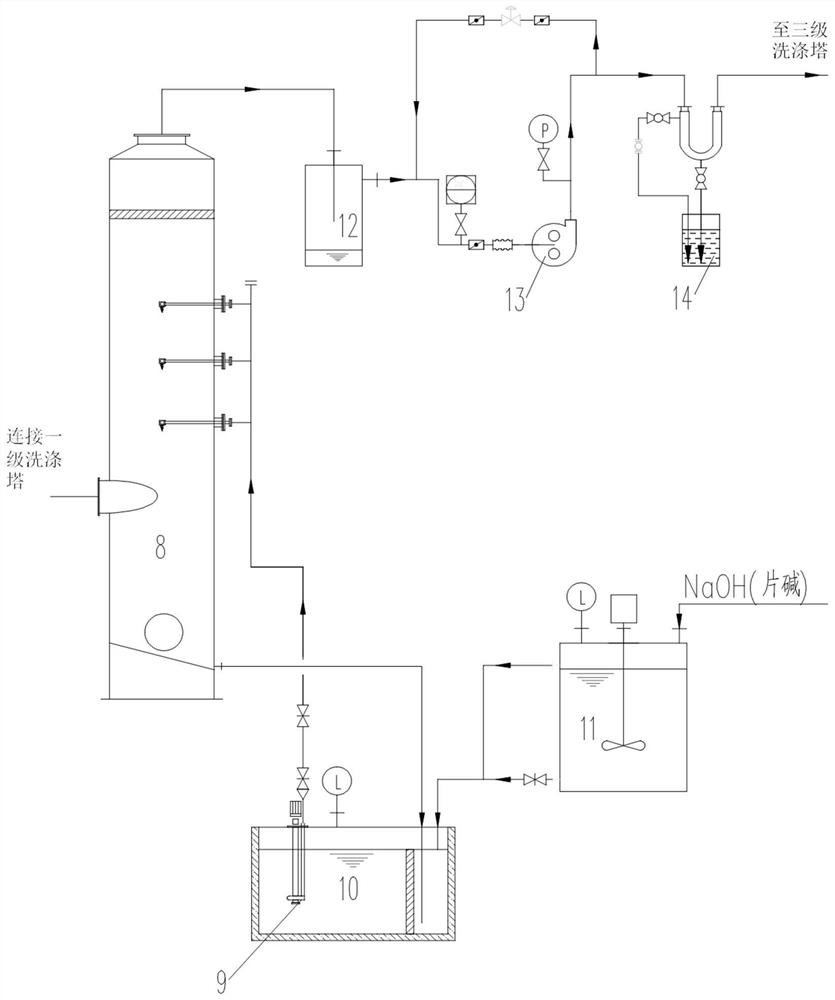

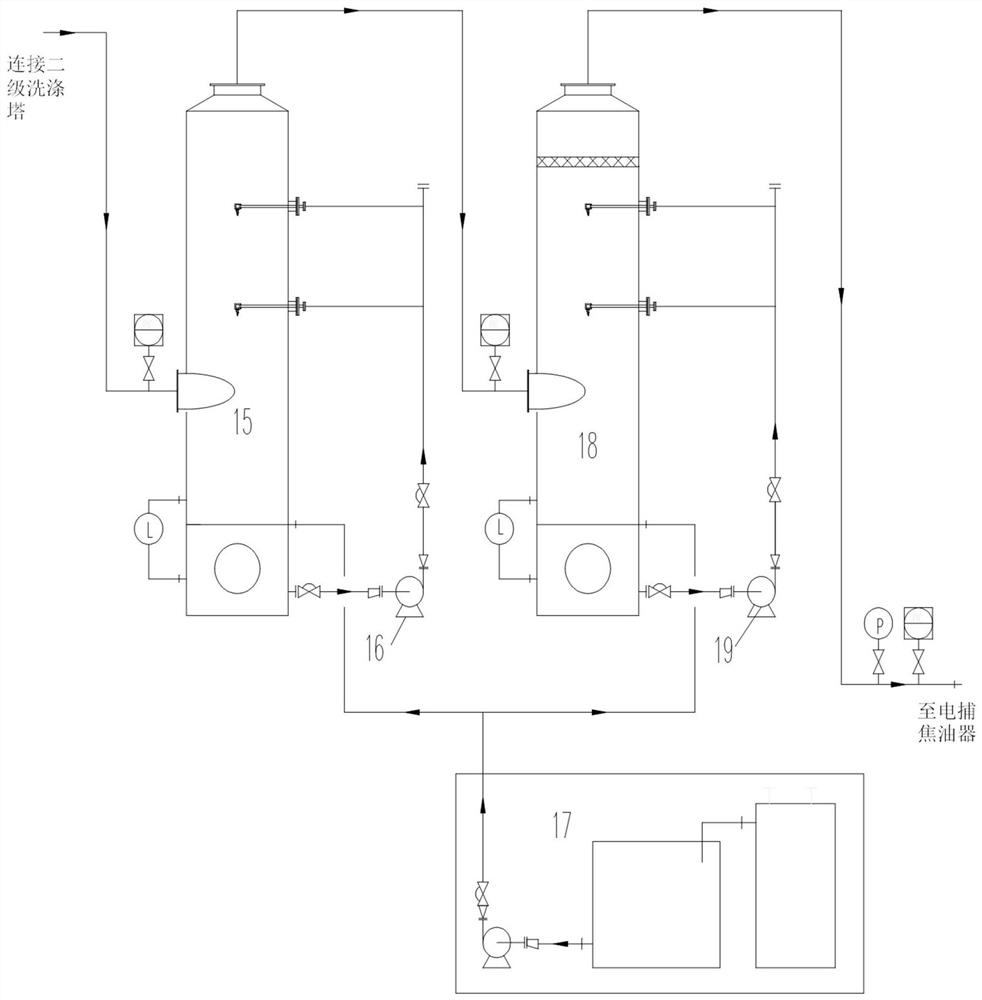

[0066] of the present invention Figure 1-Figure 4 It is a diagram of each part of the system of the present invention, and combining all the parts together is a schematic diagram of the overall structure of the system of the present invention.

[0067] like Figure 1-4 As shown in the figure, a deep purification system for yellow phosphorus tail gas, the system includes a first-stage washing tower 3, a cyclone demister 7, a second-stage washing tower 8, a third-stage washing tower 15, a fourth-stage washing tower 18, and an electric tar catcher. 20 and activated carbon adsorption tower 21;

[0068] The air inlet of the primary washing tower 3 is connected to the yellow phosphorus tail gas, the air outlet of the primary washing tower 3 is connected to the air inlet of the cyclone demister 7, and the air outlet of the cyclone demister 7 is connected to the air inlet of the secondary washing tower 8 The liquid outlet of the first-level washing tower 3 is connected to the liqui...

Embodiment 2

[0082] Adopt the yellow phosphorus tail gas deep purification method of the yellow phosphorus tail gas deep purification system of embodiment 1, described method comprises the steps:

[0083] 1) The yellow phosphorus tail gas enters the primary washing tower through the primary tail gas water seal. When the system fails, the passage from the primary tail gas water seal to the primary washing tower is closed, and the yellow phosphorus tail gas is released to the flare chimney through the secondary tail gas water seal;

[0084] 2) The yellow phosphorus tail gas is sprayed and washed by the first-level washing tower, the second-level washing tower, the third-level washing tower and the fourth-level washing tower, and enters the electric tar catcher. NaOH solution is used for washing, and the third-stage washing tower and the fourth-stage washing tower are washed with oxidant solution for wet oxidative dephosphorization;

[0085] 3) The tar in the yellow phosphorus tail gas is rem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com