Emulsified liquid for processing organic waste gas, device for processing organic waste gas and method for processing organic waste gas

A technology of organic waste gas and emulsion, which is applied in the field of emulsion, can solve the problems of complex treatment process, unsatisfactory treatment efficiency, and high operation and operation costs, and achieve the effects of reducing dust pollution emissions, improving recycling rate, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

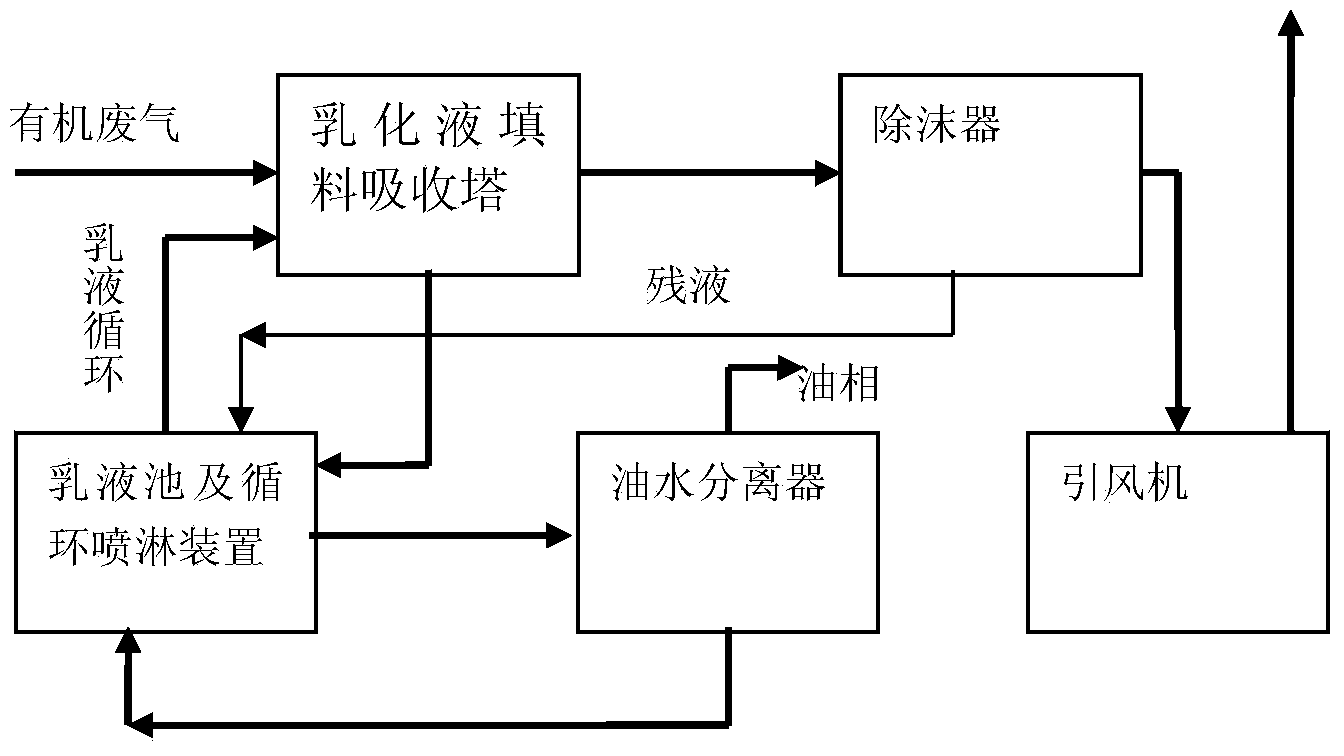

[0036] Such as figure 1 The device for treating organic waste gas with emulsion for treating organic waste gas shown includes an emulsion filled absorption tower, a circulation spray device, an oil-water separator, a demister and an induced draft fan, and the emulsion filled absorption tower is sequentially connected with a circulation spray The device is connected with the oil-water separator; the emulsion packed absorption tower is also connected with the demister and the induced draft fan in turn; the emulsion filled absorption tower, the demister and the circulating spray device are connected in sequence to form a circulation loop; the emulsion filled absorption tower and the The circulating spray device forms a circulating loop; the circulating spraying device and the oil-water separator form a circulating loop.

[0037] The method for treating organic waste gas with the above-mentioned device comprises the following steps in sequence:

[0038] A. After being first absor...

Embodiment 2

[0046] It is basically the same as Example 1, except that the mass concentration of the emulsion used is 4%, and the emulsion contains polyoxyethylene sorbitan fatty acid ester, sorbitan with a mass ratio of 4:2:1 Fatty acid esters and sodium polyoxyethylene lauryl ether sulfate.

[0047] Into the device, the concentration of 800mg / m 3 Butyl acetate gas, control the gas-liquid ratio (Nm 3 / m 3 ) is 6000 for 24 hours;

[0048] The discharge of butyl acetate after treatment by the above device is about 20mg / m 3 (Using gas chromatography to measure GB / T16069-1995 (national testing standard) detection), in line with the "Comprehensive Emission Standard of Air Pollutants" (GB16297-1996), the highest removal rate of butyl acetate is 97.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com