Helical airflow type wet method flue gas desulfurization process and spraying tower thereof

A technology of wet flue gas desulfurization and spiral air flow, which is applied in the direction of separation methods, chemical instruments and methods, and separation of dispersed particles, which can solve the problems of complex supporting structure of the outlet flue, increased pressure loss of flue gas flow, and unfavorable equipment safe operation and other issues, to achieve the effect of increasing the effective contact area, increasing the gas flow rate, and reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

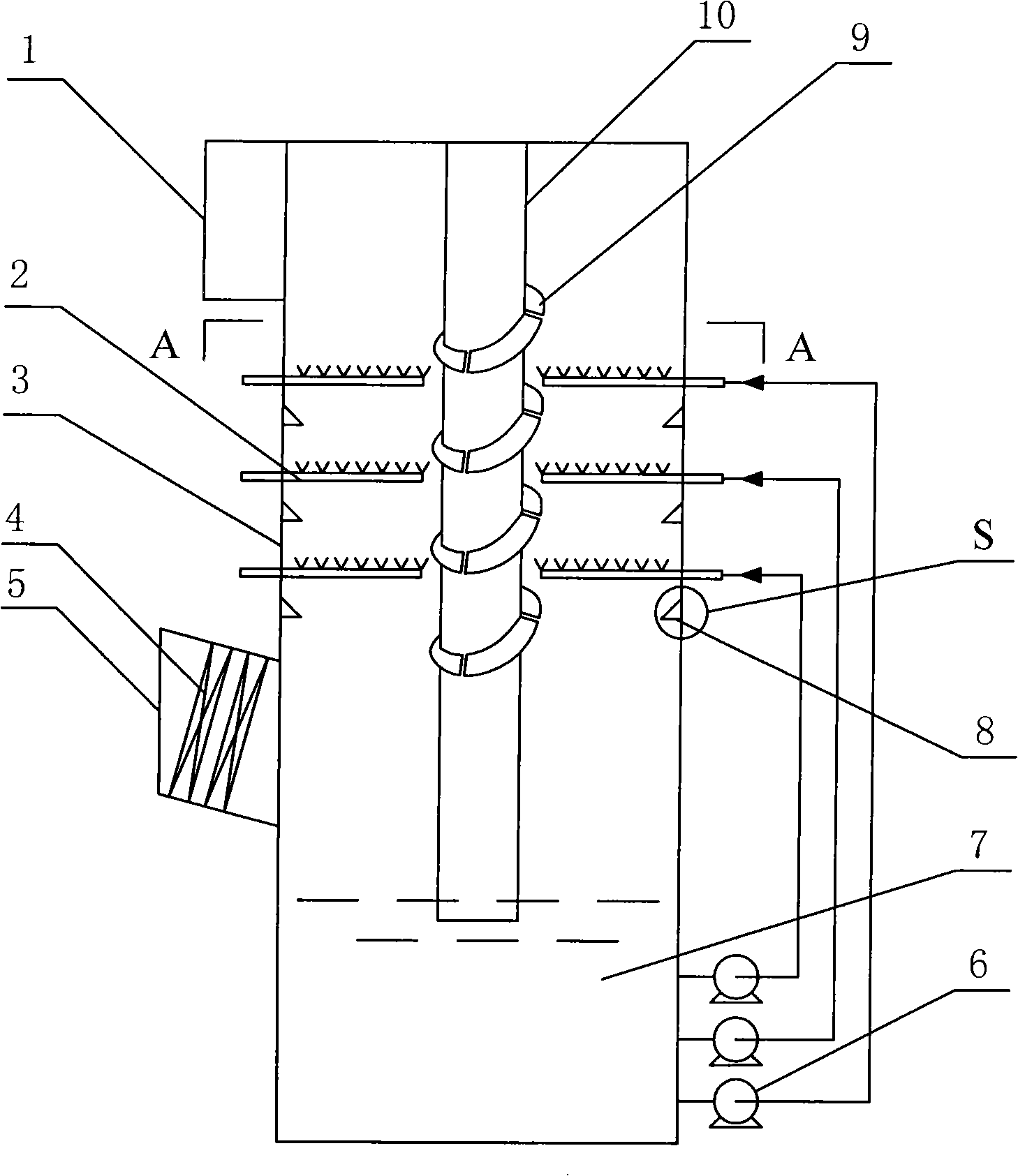

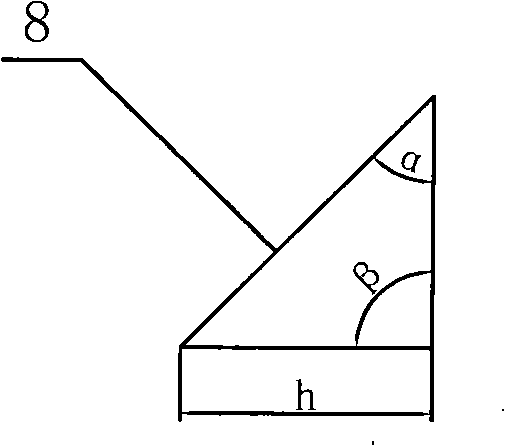

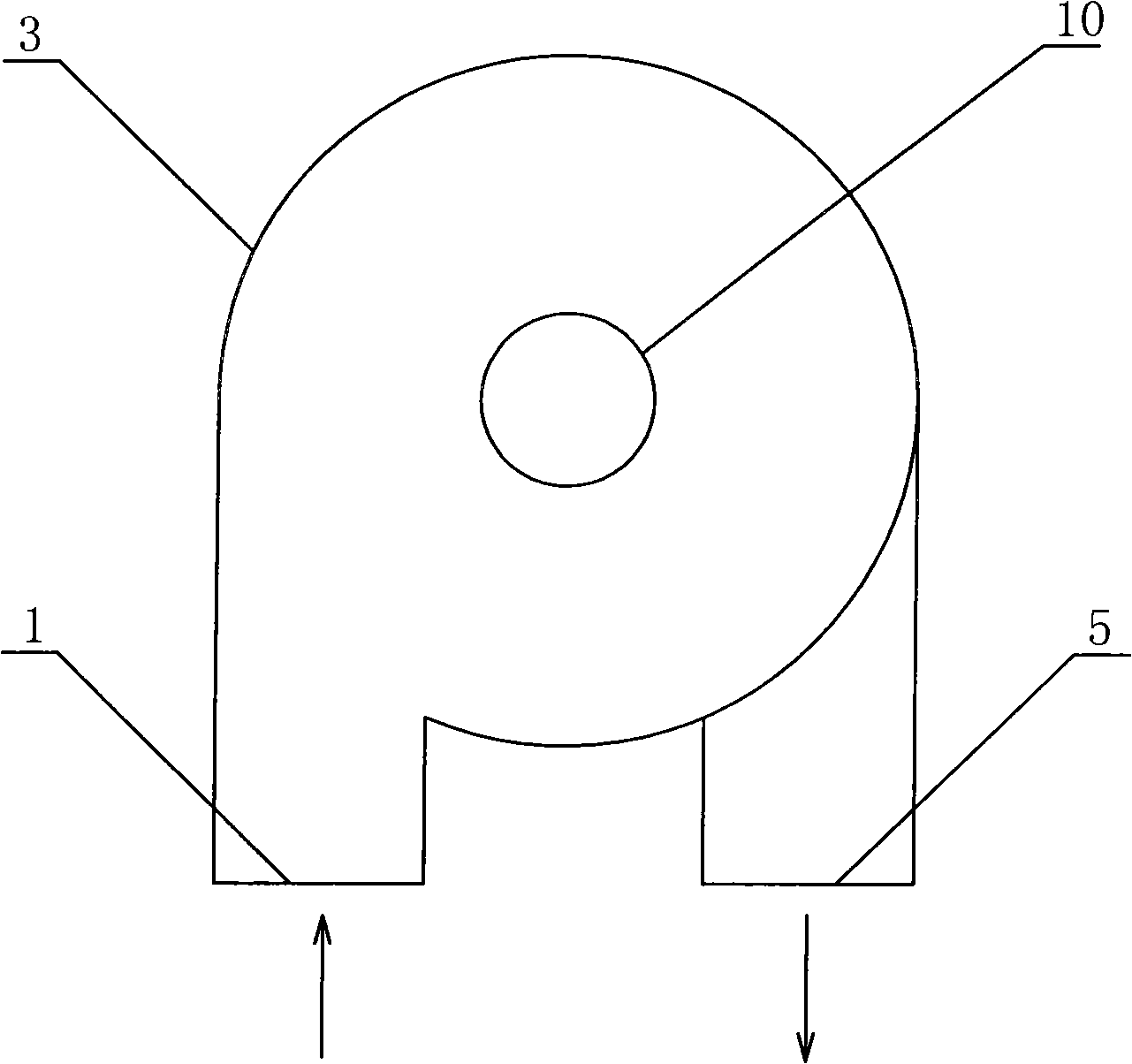

[0022] The spiral flow type wet flue gas desulfurization spray tower shown in the figure has a spray tower cylinder 3, and the upper and lower parts of the spray tower cylinder 3 are respectively provided with flue gas inlet channels 1 in a tangential arrangement. And flue gas outlet channel 5. Inside the spray tower cylinder body 3, three layers of absorbent slurry spraying devices 2 are arranged in parallel between the flue gas inlet channel 1 and the flue gas outlet channel 5, and the three layers of absorbent slurry spraying devices 2 pass through the corresponding slurry The circulation pump 6 is connected with the slurry pool 7 at the bottom of the spray tower cylinder body 3 . The center of the spray tower cylinder 3 is provided with a central cylinder 10 that passes through the three-layer absorbent slurry spray device 2 from top to bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com