Jet steam slag granulation and heat utilization method

A steam and granulation technology, which is applied in the direction of recycling technology and process efficiency improvement, and can solve the problems of high energy consumption, complex equipment, and inability to realize heat utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

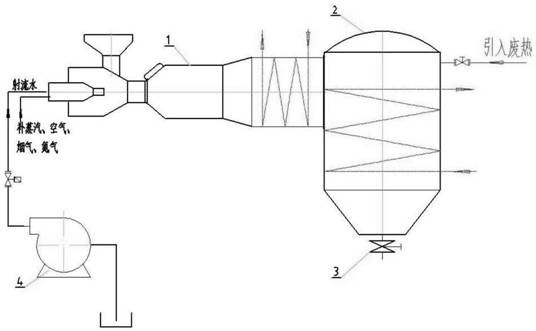

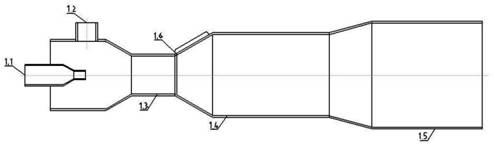

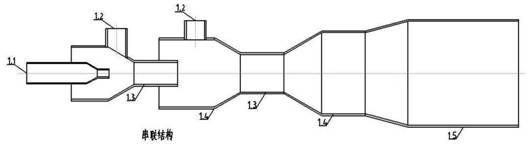

[0056] like figure 1 , figure 2 As shown, it is mainly composed of ejector device 1, secondary heat exchange device 2, slag output device 3, water pump 4 and other parts. The jet device is mainly composed of jet port 1.1, ejector port 1.2, throat pipe 1.3, mixing chamber 1.4, primary heat exchange chamber 1.5 and check valve 1.6.

[0057] Process overview:

[0058] The working process is as follows: when working, the liquid slag enters the ejector device from the injection port, water, steam or air enters the ejector device from the ejection port, and the water, steam or air is ejected from the nozzle at a high flow rate under high pressure, so that A certain negative pressure is formed in the surrounding space, and the liquid slag is brought into the high-speed fluid water from the ejection port. The two fluids are mixed and exchanged energy in the throat pipe. The slag undergoes water quenching and granulation, and steam is generated to form a steam explosion process. Si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com