Peony root processing device and method

A processing device and processing method technology, applied in the direction of pharmaceutical formula, plant raw materials, plant/algae/fungus/moss components, etc., to achieve the effect of improving cutting accuracy and realizing elastic adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

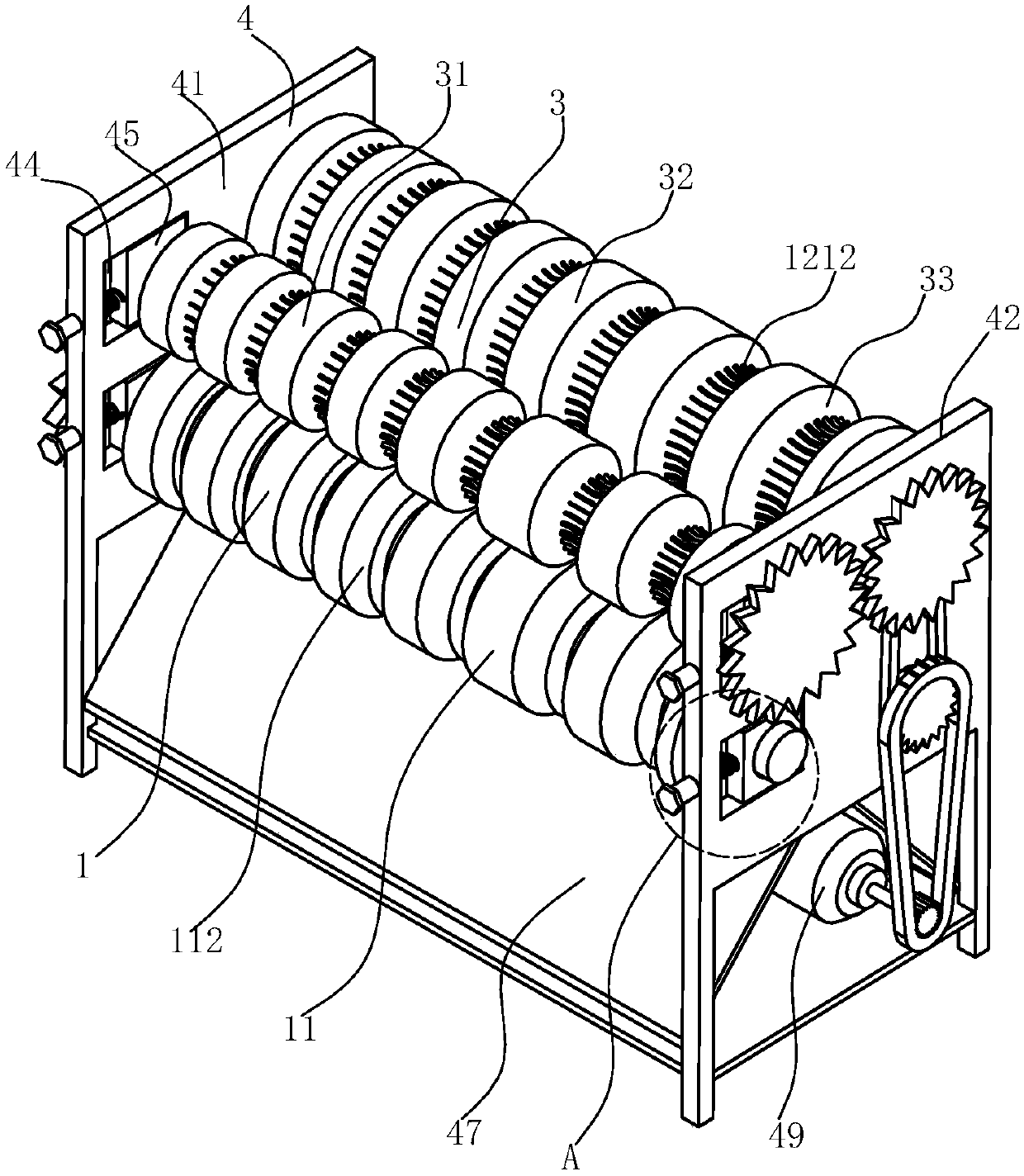

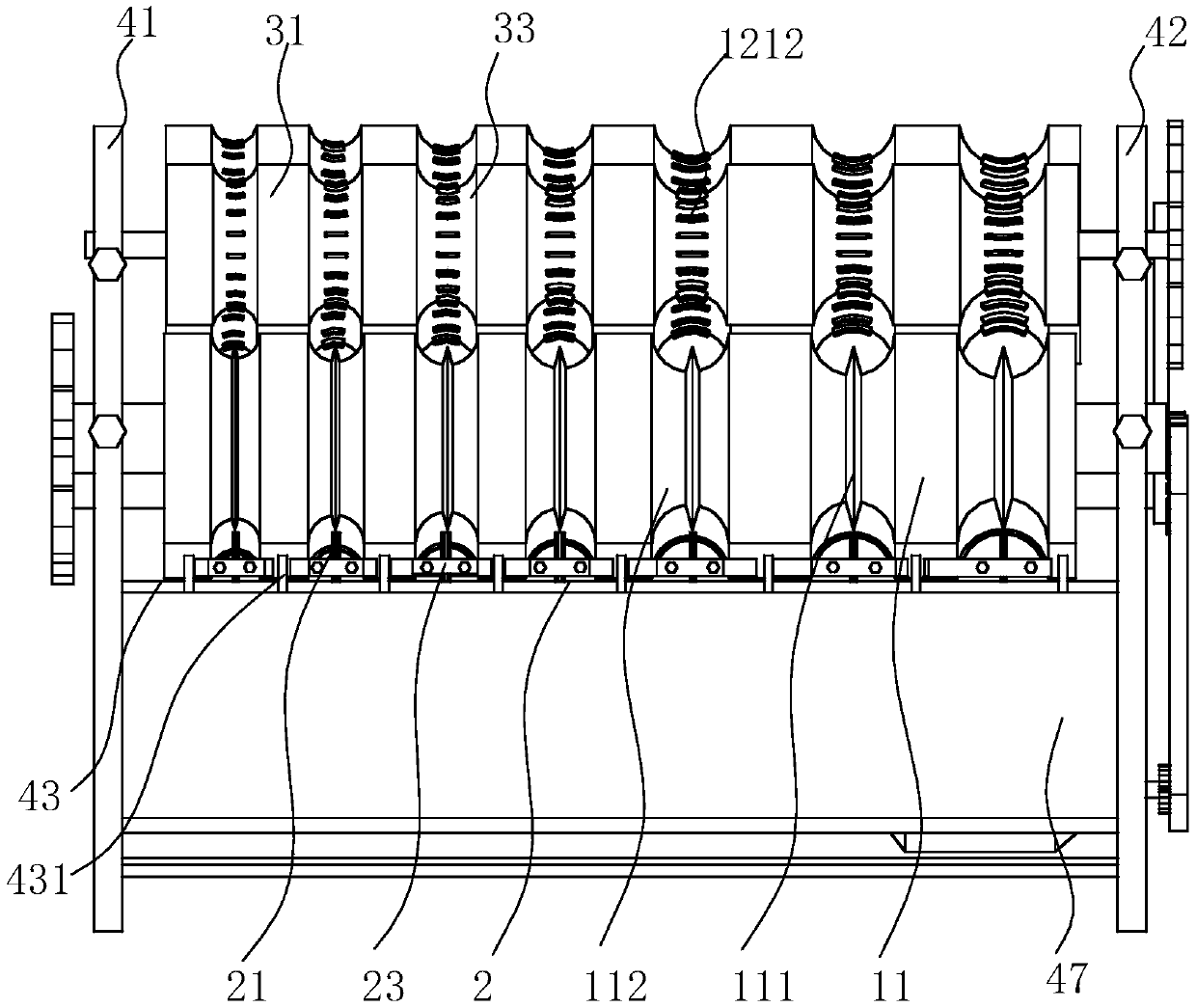

[0059] A peony root processing device comprises a main body frame 4, the main body frame includes a left side plate 41 and a right side plate 42, and a cutting tool for cutting the peony root epidermis along the length direction is installed between the left side plate 41 and the right side plate 42. Part 1 and the rejecting part 2 for picking out the peony root wood core; the cutting part 1 includes a cutting wheel 11 and a supporting wheel 12 used in conjunction with the cutting wheel 11; the two ends of the supporting wheel 12 are respectively installed on the left side plate 41 and the right side On the side plate 42, the support wheel 12 is provided with a first annular groove 121, and the inner wall of the first annular groove 121 is provided with an anti-skid pattern 1211 for better fixing and advancing peony roots; the two ends of the cutting wheel 11 are installed on the On the left side plate 41 and the right side plate 42, the cutting wheel 11 is provided with the se...

Embodiment 2

[0062] On the basis that the technical solution of Embodiment 1 remains basically unchanged, further, a pair of auxiliary wheels 3 are arranged above the cutting part 1, wherein the front auxiliary wheel 31 is located above the cutting wheel 11, and is located above the support wheel 12. The rear auxiliary wheel 32 is the rear auxiliary wheel 32, and the two ends of the front auxiliary wheel 31 and the rear auxiliary wheel 32 are respectively supported by the left side plate 41 and the right side plate 42; Three annular grooves 33, the third annular groove 33 on the front auxiliary wheel 31 and the third annular groove 33 on the rear auxiliary wheel 32 are matched one by one to form seven surrounding structures for clamping peony roots, the third annular groove 33 are also provided with anti-slip lines 1211, the anti-slip lines 1211 are transverse grooves 1212 arranged axially along the front auxiliary wheel 31 or rear auxiliary wheel 32, the resistance structure setting direct...

Embodiment 3

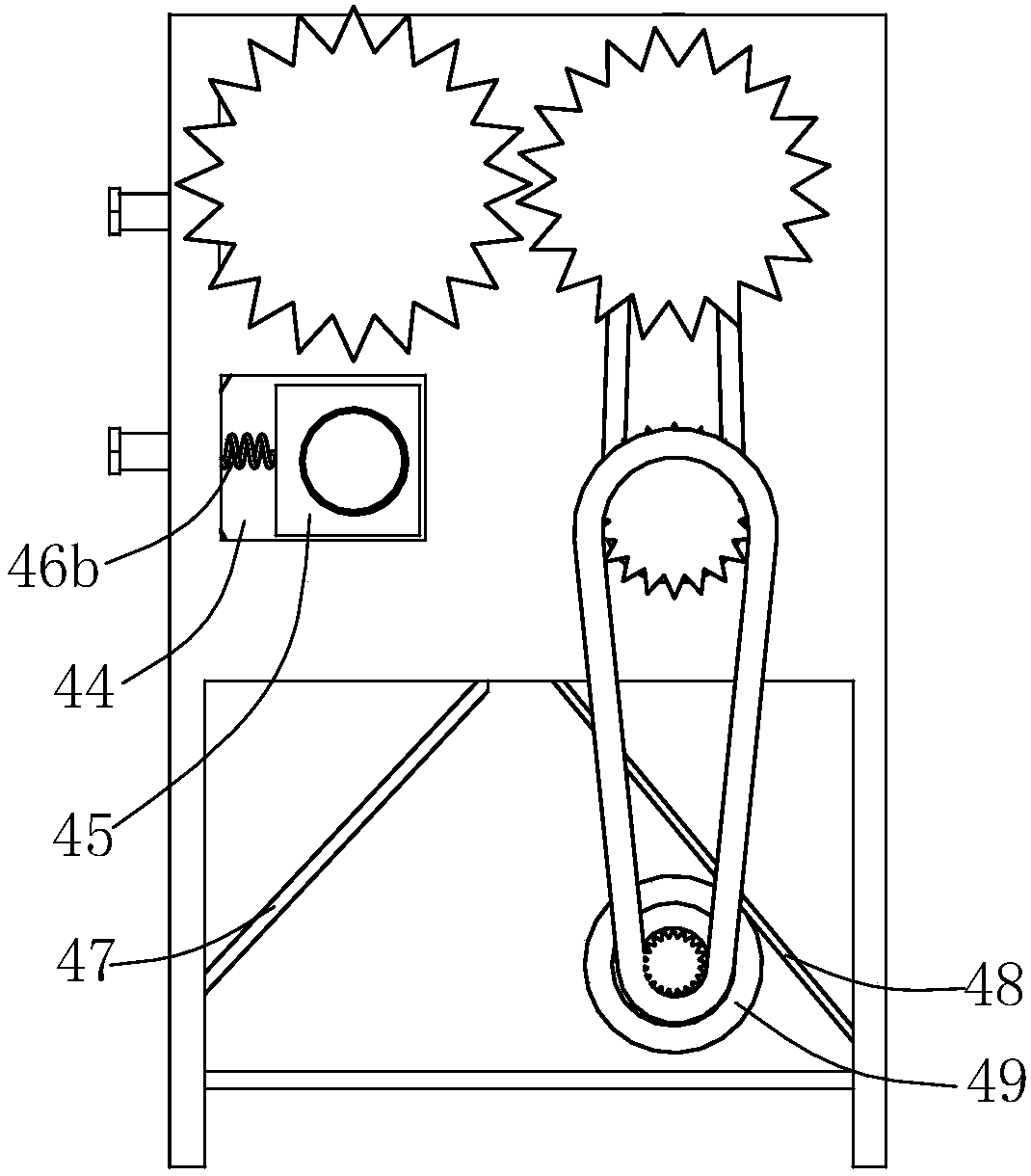

[0064] On the basis that the technical scheme of embodiment 1 or 2 remains basically unchanged, further, a rectangular through hole 44 is provided on the left side plate 41 and the right side plate 42, the left side plate 41, the right side plate 42 Rectangular through-holes 44 are positioned at the lower side of corresponding side plate respectively; Said rectangular through-hole 44 inner sidewalls are all provided with slideway, and corresponding slideway is equipped with a clamping block 45 respectively in said slideway, and clamping block 45 is arranged with the help of this slideway. The limiting effect is to avoid protruding from the rectangular through hole 44, and the clamping block 45 can slide back and forth along the corresponding slideway. On the block 45; a round through hole 46 is arranged between the rectangular through hole 44 and the front end of the corresponding left side plate 41 or right side plate 42, and a screw rod is respectively installed in the said r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com