Automatic argon-blowing butt-joint device

A docking device and automatic technology, applied in casting melt containers, manufacturing tools, metal processing equipment, etc., can solve problems such as air leakage and molten steel backflow, and achieve the effect of improving sealing, reducing labor intensity and facilitating docking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

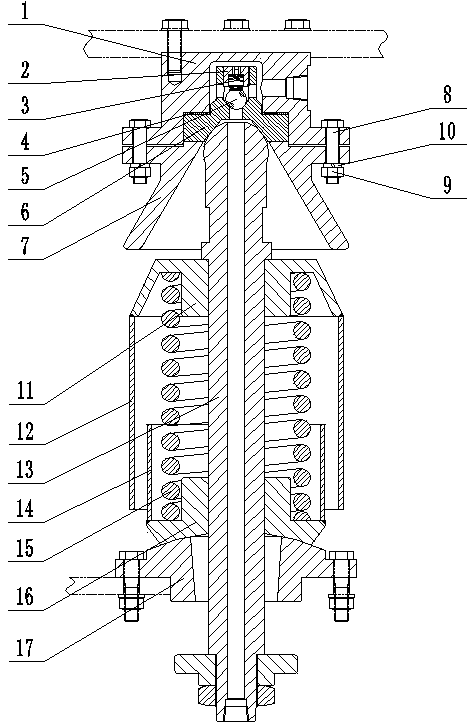

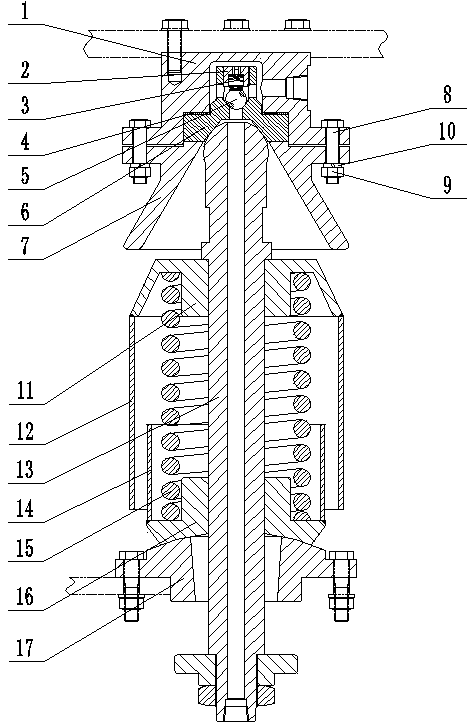

[0014] Embodiment 1, as shown in the figure: an automatic argon blowing docking device, including a male head and a female head, the male head and the female head are snapped together, the female head is fixed on the outer wall of the ladle, and the The male head is fixed on the base 17, the female head includes a joint 1, the joint 1 is provided with a cavity, and the cavity in the joint 1 is connected to the through port provided on the side wall of the joint 1 In general, the outer wall of the joint 1 at the top of the cavity is provided with an adjusting screw plug 2, and the adjusting screw plug 2 passes through the joint 1 and is closely combined with the adjusting spring 3 in the cavity, and the adjustment spring 3 is provided below There is a steel ball 5, a copper sleeve 6 is provided under the steel ball 5, and an air hole is provided in the middle of the copper sleeve 6, and the copper sleeve 6 is embedded in the joint 1, and the copper sleeve 6 and the A gasket 4 i...

Embodiment 2

[0015] Embodiment 2, an automatic argon blowing docking device, a spring washer 10 is provided between the fixing nut 9 and the conical flange 7 . The air holes, cavities and passage ports are in communication. The lower part of the copper sleeve 6 is provided with a hemispherical groove, and the hemispherical groove is closely combined with the top of the argon gas tube 13, and the top of the argon gas tube 13 is a spherical end. The sealing gasket 4 is an asbestos rubber plate. Through the cooperation between the spherical end on the top of the argon tube 13 and the hemispherical groove on the lower part of the copper sleeve 6, good sealing performance is achieved, and the position error compensation range caused by inclination is large, and it is easy to connect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com