Stacked gear structure with side clearance removal through elasticity

A technology for installing gears and backlash, which is applied to belts/chains/gears, hoisting devices, components with teeth, etc., can solve the problems of increased thermal stress due to tooth thickness, strong friction and wear, and difficulty for the machine to work normally. The effect of improving tooth surface lubrication, relieving internal stress and reducing operating noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

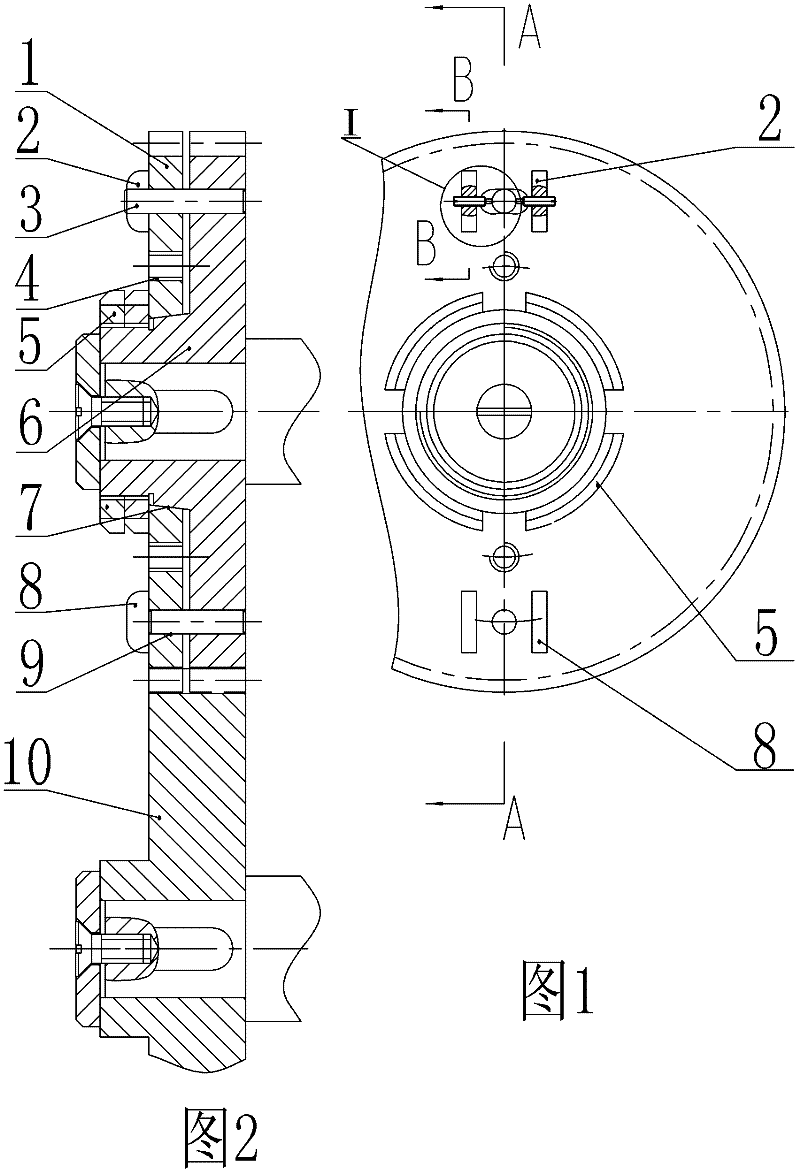

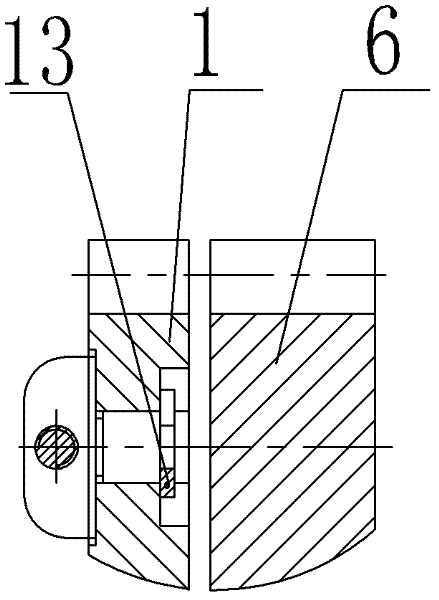

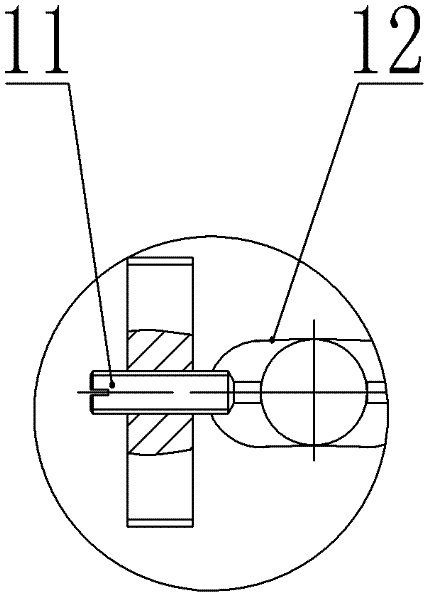

[0025] The schematic diagram of the structure of stacked gears with elastic backlash removal in the present invention is as follows: Figure 1-Figure 5 As shown, it includes a main gear 6 and a backlash removal gear 1. The main gear 6 is provided with a conical surface 7. The backlash removal gear 1 is connected to the main gear through a tapered hole matched with the conical surface 7. 6 Self-locking connection, the conical angle of the conical surface on the main gear is preferably 1-3 degrees. The outer thread of the upper conical surface of the main gear is connected with the backlash removal gear compression nut 5, and the main gear 6 and the backlash removal gear 1 are respectively provided with a positioning device for forming the zero point of the main gear and the backlash removal gear in the circumferential direction. Pin hole 9, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com