Bottle cap slideway

A technology of bottle caps and slides, which is applied in the direction of threaded bottle caps, etc., can solve the problems of difficult adjustment, troublesome adjustment operation, complicated processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

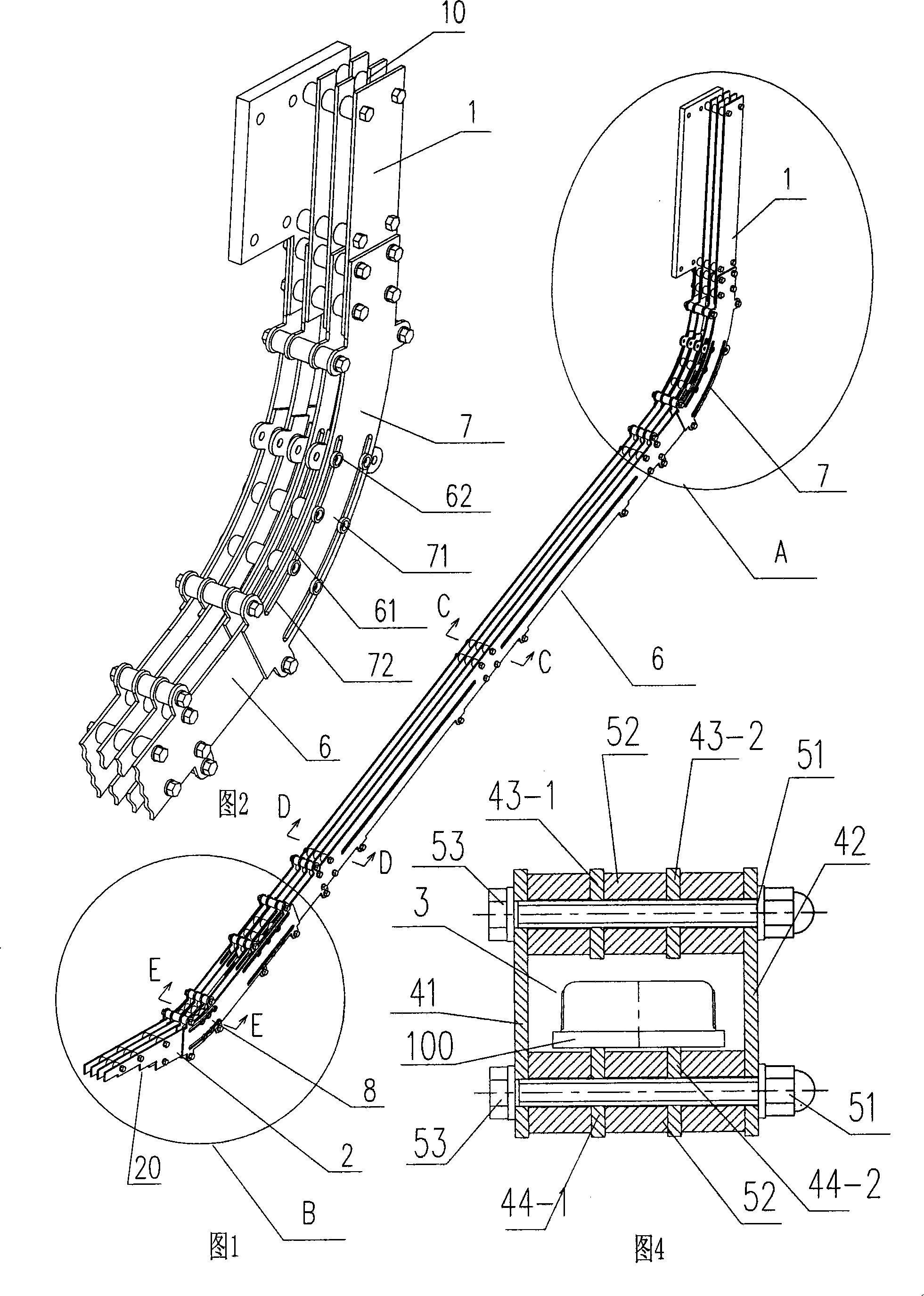

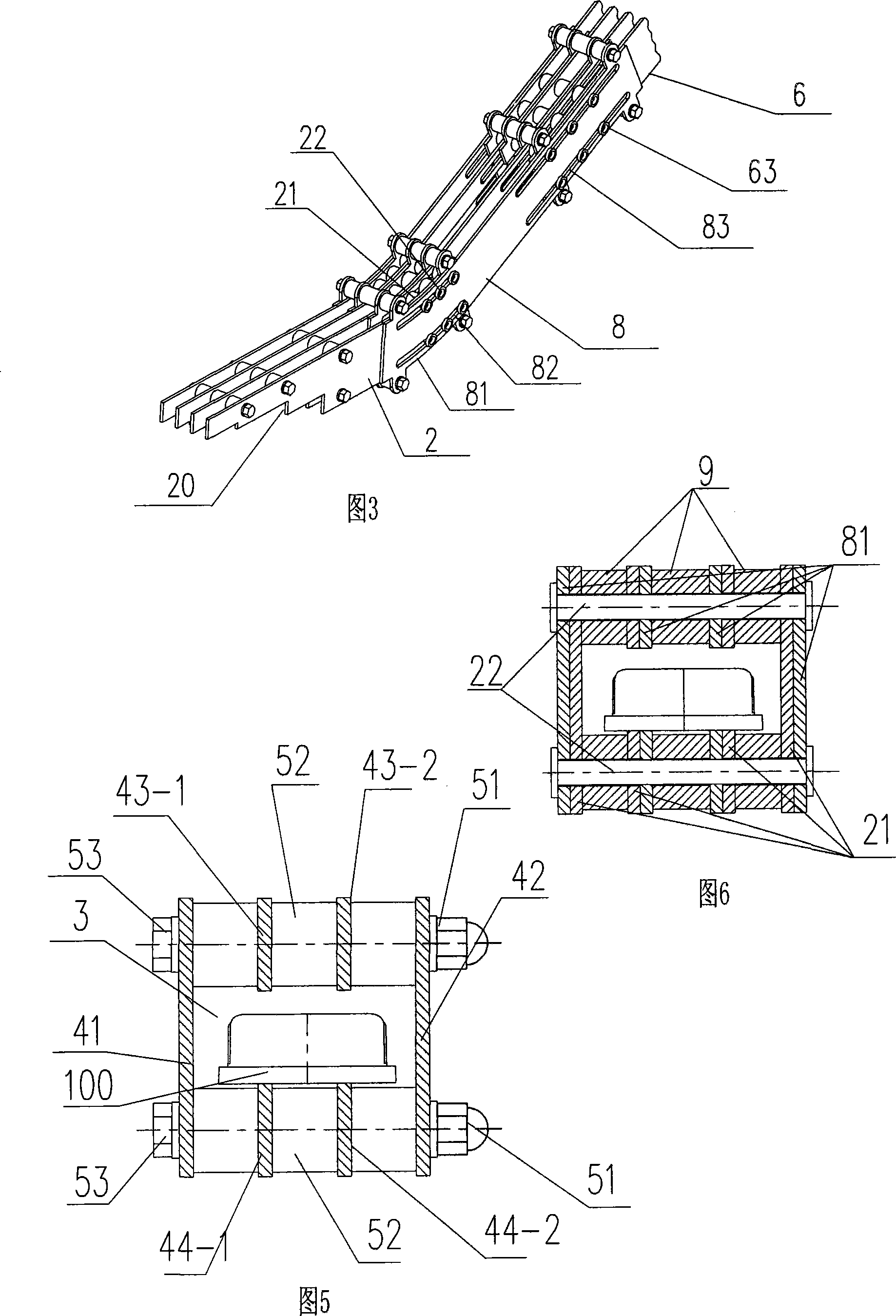

[0010] Refer to attached picture. The present invention is formed by connecting the upper connecting track section 1, the lower connecting track section 2, and several intermediate track sections. The connection includes a linear telescopic connection and an arc surface sliding connection; The sheet material is connected, the upper connecting track section has a bottle cap inlet 10, and the lower connecting track section has a bottle cap outlet 20. The upper connecting track section 1 can be connected with the cap sorter, and the lower connecting track section 2 can be connected with the cap screwing machine.

[0011] The bottle cap channel 3 in the slideway of the present invention is surrounded by sheet materials, and the sheet material can be cut from thin steel plates, so that the connection and composition of the bottle cap slideway is simple, and there is no need to use milling, and then segmented bending, Complex processes such as welding and forming. In the drawings,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com