Fly ash glass bead-ferrite compound microwave absorbing material and preparation method thereof

A composite wave-absorbing material and glass microsphere technology, applied in the field of wave-absorbing materials, can solve problems such as narrow wave-absorbing frequency band, uneven distribution of wave-absorbing agent, and high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

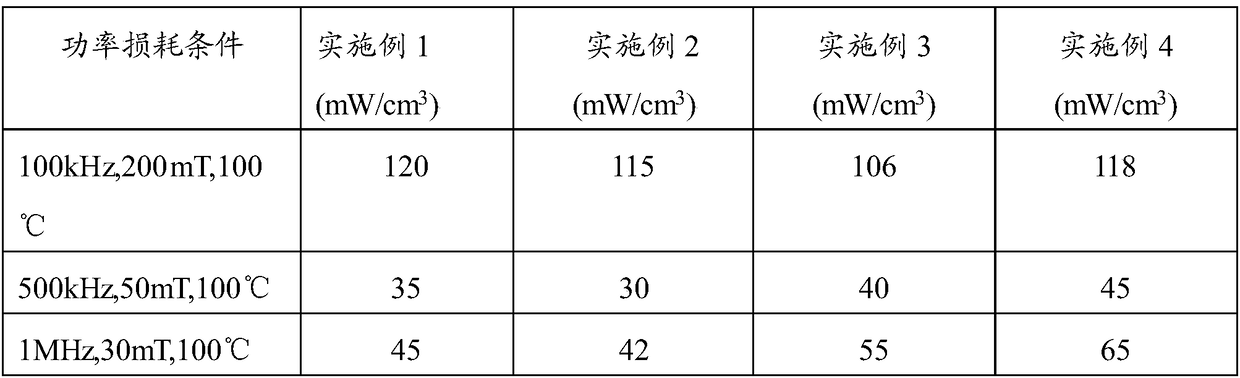

Examples

preparation example Construction

[0025] The present invention provides a preparation method of the composite wave-absorbing material described in the above technical solution, comprising the following steps:

[0026] mixing the sol raw material with ferric nitrate and glycine to obtain a precursor solution; the sol raw material is selected from one or more of barium nitrate, manganese nitrate, cobalt nitrate and nickel nitrate;

[0027] Adjust the pH value of the precursor solution to 6.8-7.2, add fly ash glass beads, stir at 85-95°C to obtain a wet gel; after drying, obtain a dry gel;

[0028] The dry gel is sintered at 800-900° C. to obtain a composite wave-absorbing material of fly ash glass microspheres and ferrite.

[0029]In the invention, the sol raw material is mixed with iron nitrate and glycine to obtain a precursor solution; the sol raw material is selected from one or more of barium nitrate, manganese nitrate, cobalt nitrate and nickel nitrate. Alcohols are also added when the sol raw material is...

Embodiment 1

[0035] (1) Preparation of sol solution

[0036] Weigh ferric nitrate, barium nitrate and aminoacetic acid respectively according to the stoichiometric ratio, add distilled water to dissolve, and obtain barium ferrite BaFe 12 o 19 A precursor solution, wherein the molar ratio of aminoacetic acid to metal ions is 2.5:1, and an appropriate amount of ethylene glycol is added simultaneously;

[0037] (2) Coating with absorbing agent

[0038] First drop ammonia water to adjust the pH value of the precursor solution to 7, then add fly ash glass beads according to the mass ratio of fly ash glass beads to ferrite is 1:1, and keep stirring to make the sol solution evenly coated on Fly ash glass bead surface.

[0039] (3) Gelation

[0040] The coated mixed sol solution was placed in a water bath at 90°C and stirred until the liquid became a viscous colloid, and the prepared sol was dried at 120°C to obtain a xerogel.

[0041] (4) Sintering

[0042] Put the gel in a muffle furnace a...

Embodiment 2

[0045] (1) Preparation of sol solution

[0046] Weigh ferric nitrate, barium nitrate, cobalt nitrate and aminoacetic acid respectively according to the stoichiometric ratio, add distilled water to dissolve, and form barium cobalt ferrite BaCo x Fe 12-x o 19 (x=0.8) precursor solution, wherein glycine and metal ion molar ratio is 2.5:1, adds appropriate amount of polyethylene glycol simultaneously;

[0047] (2) Coating with absorbing agent

[0048] First drop ammonia water to adjust the pH value of the precursor solution to 7, then add fly ash glass beads according to the mass ratio of fly ash glass beads to ferrite of 1.5:1, and keep stirring to make the sol solution evenly coated on the Fly ash glass bead surface.

[0049] (3) Gelation

[0050] The coated mixed sol solution was placed in a water bath at 90°C and stirred until the liquid became a viscous colloid, and the prepared sol was dried at 120°C to obtain a xerogel.

[0051] (4) Sintering

[0052] Put the gel in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com