Patents

Literature

118 results about "Manganese ferrite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mesoporous manganese ferrite fenton-like catalyst, preparation method therefor, and application thereof

InactiveUS20190240646A1Increase surface areaReduce mass transfer resistanceWater treatment compoundsWater contaminantsFenton reactionSludge

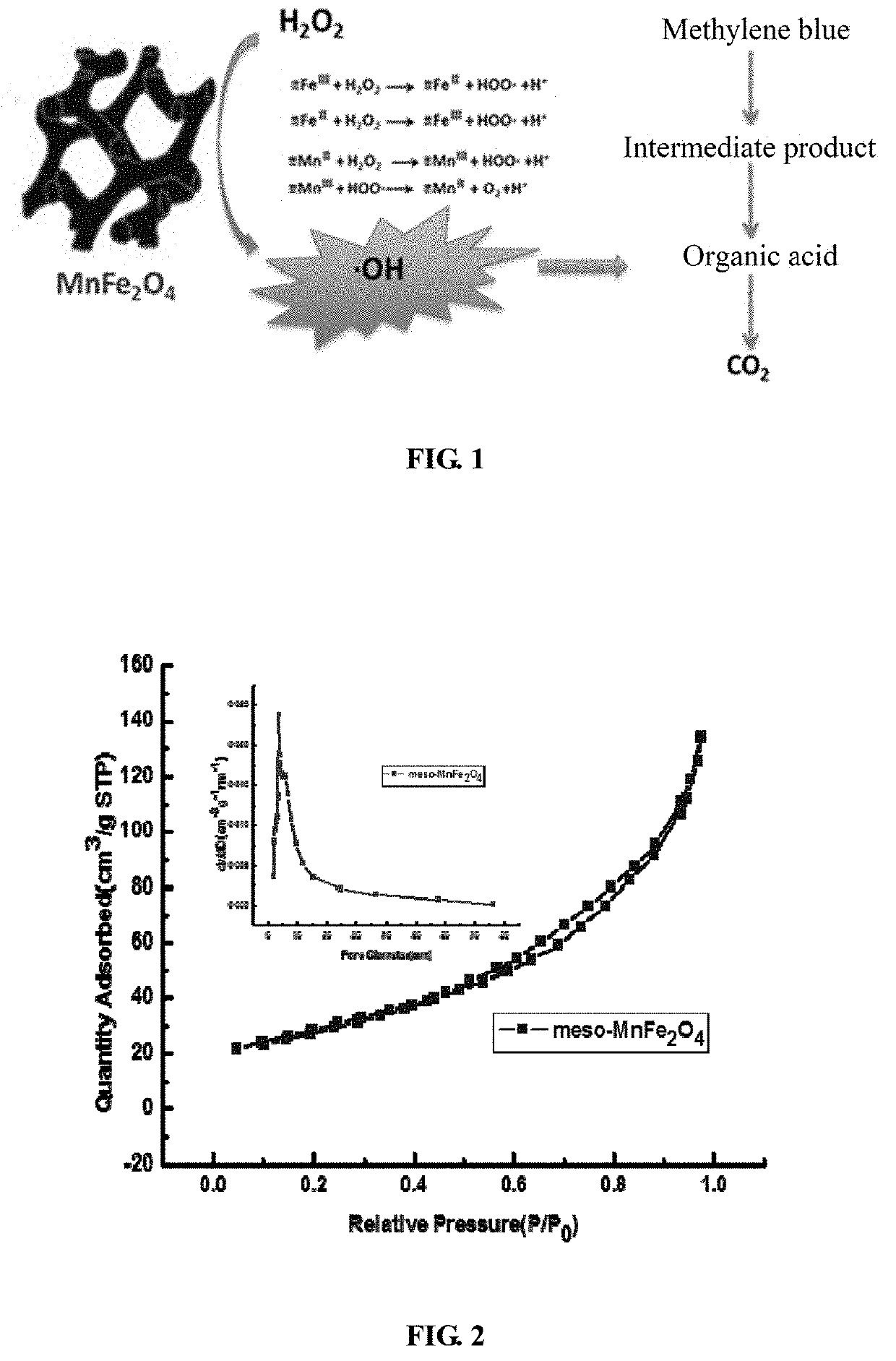

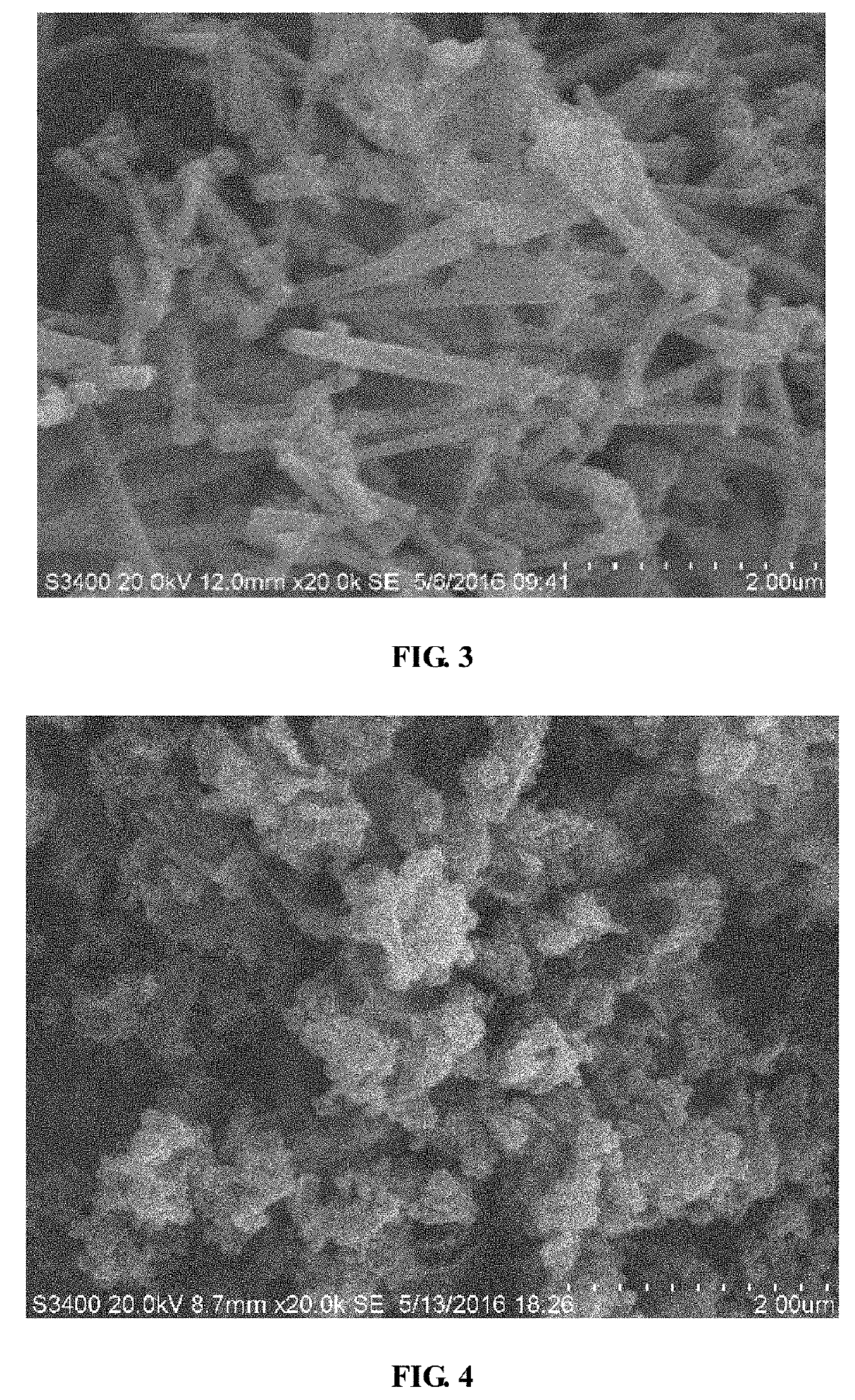

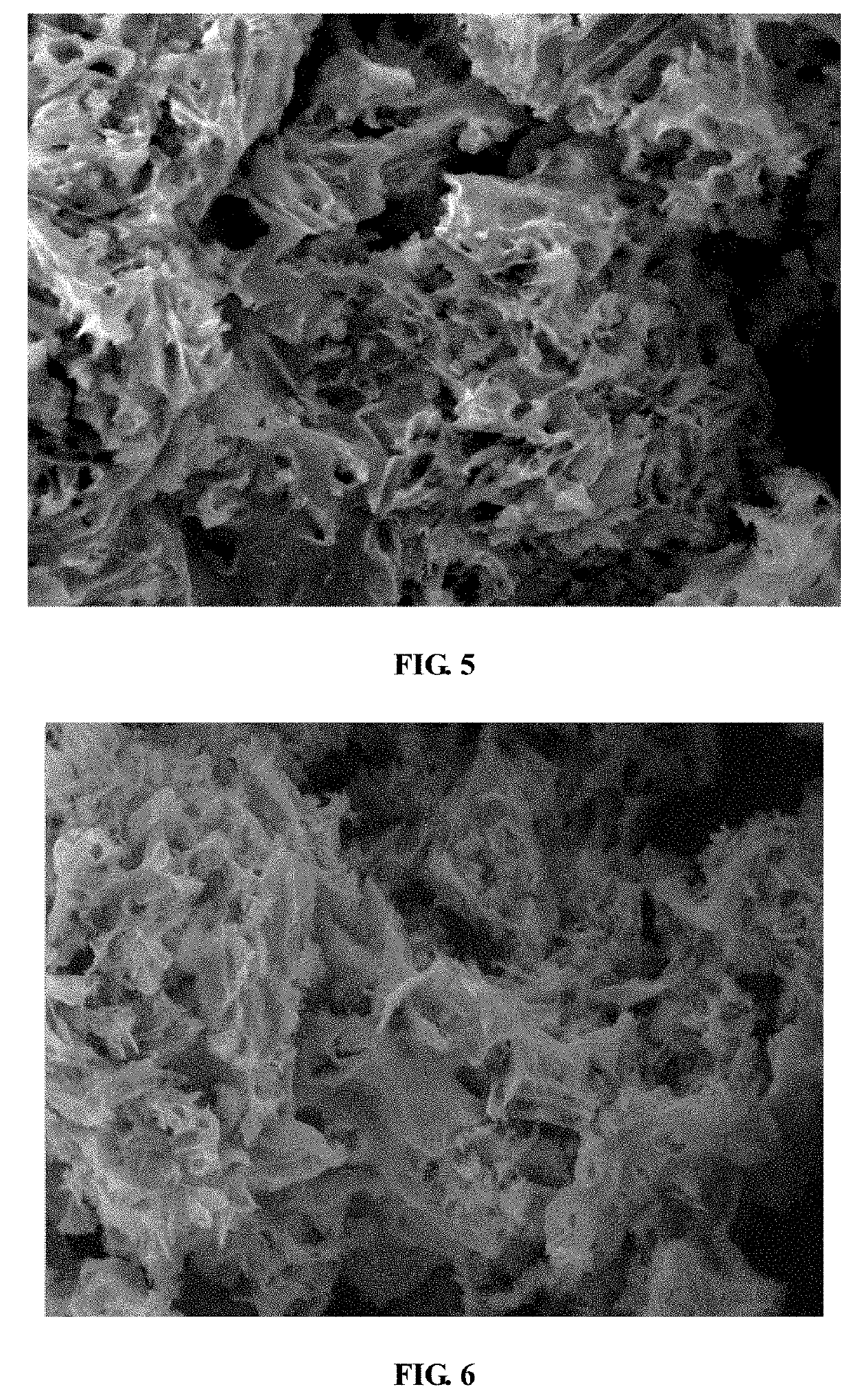

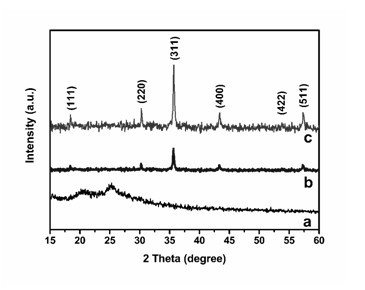

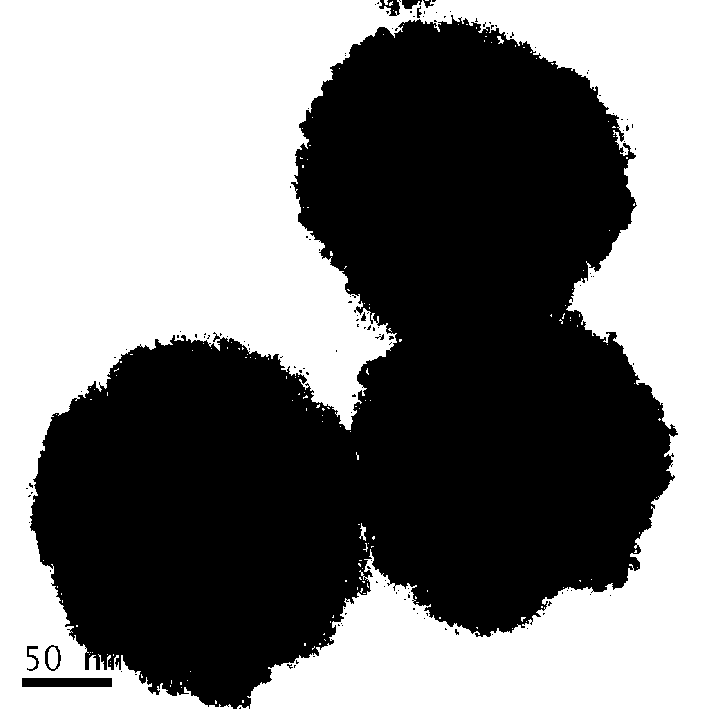

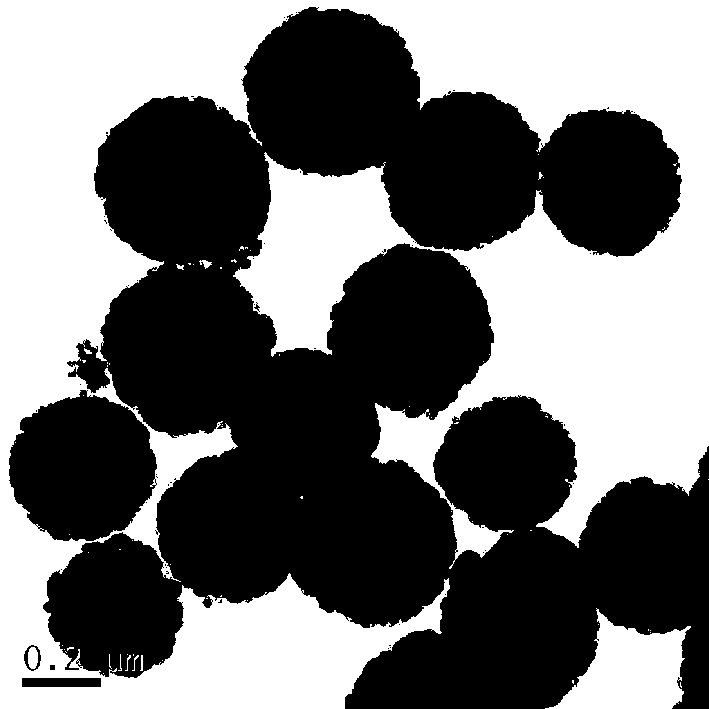

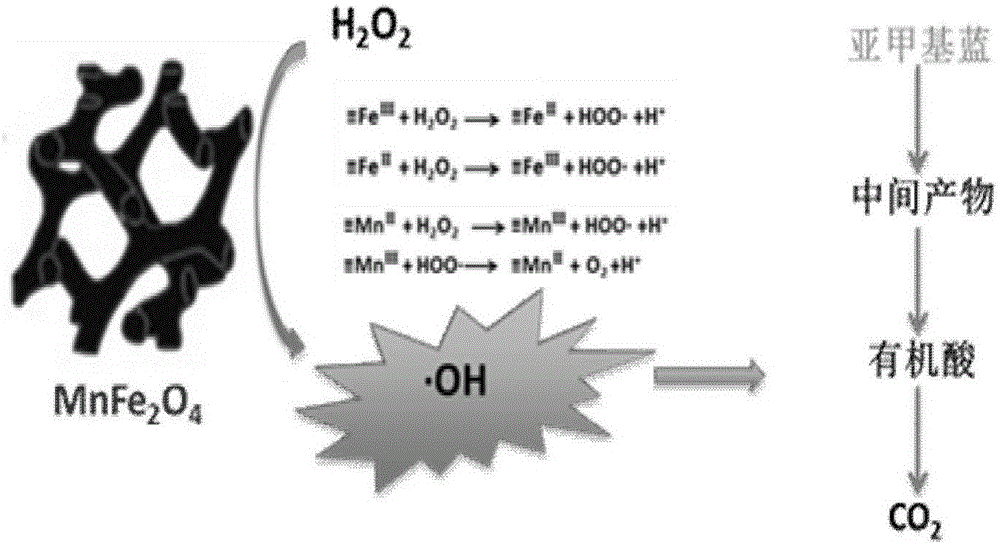

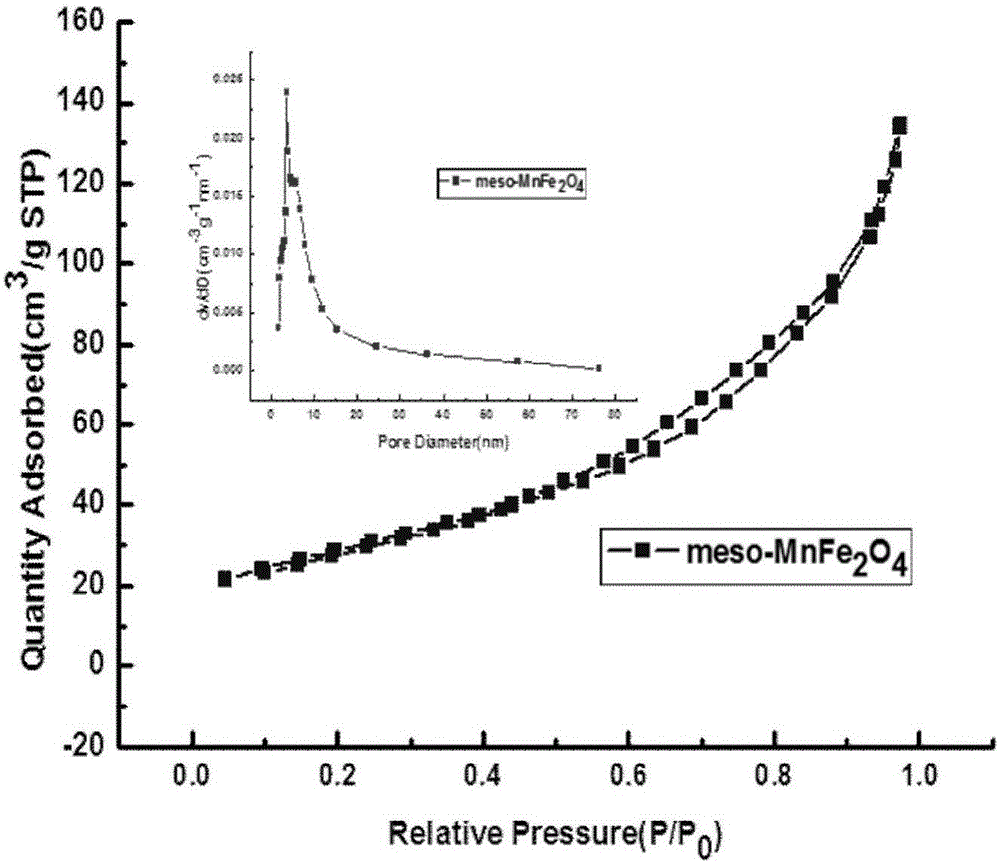

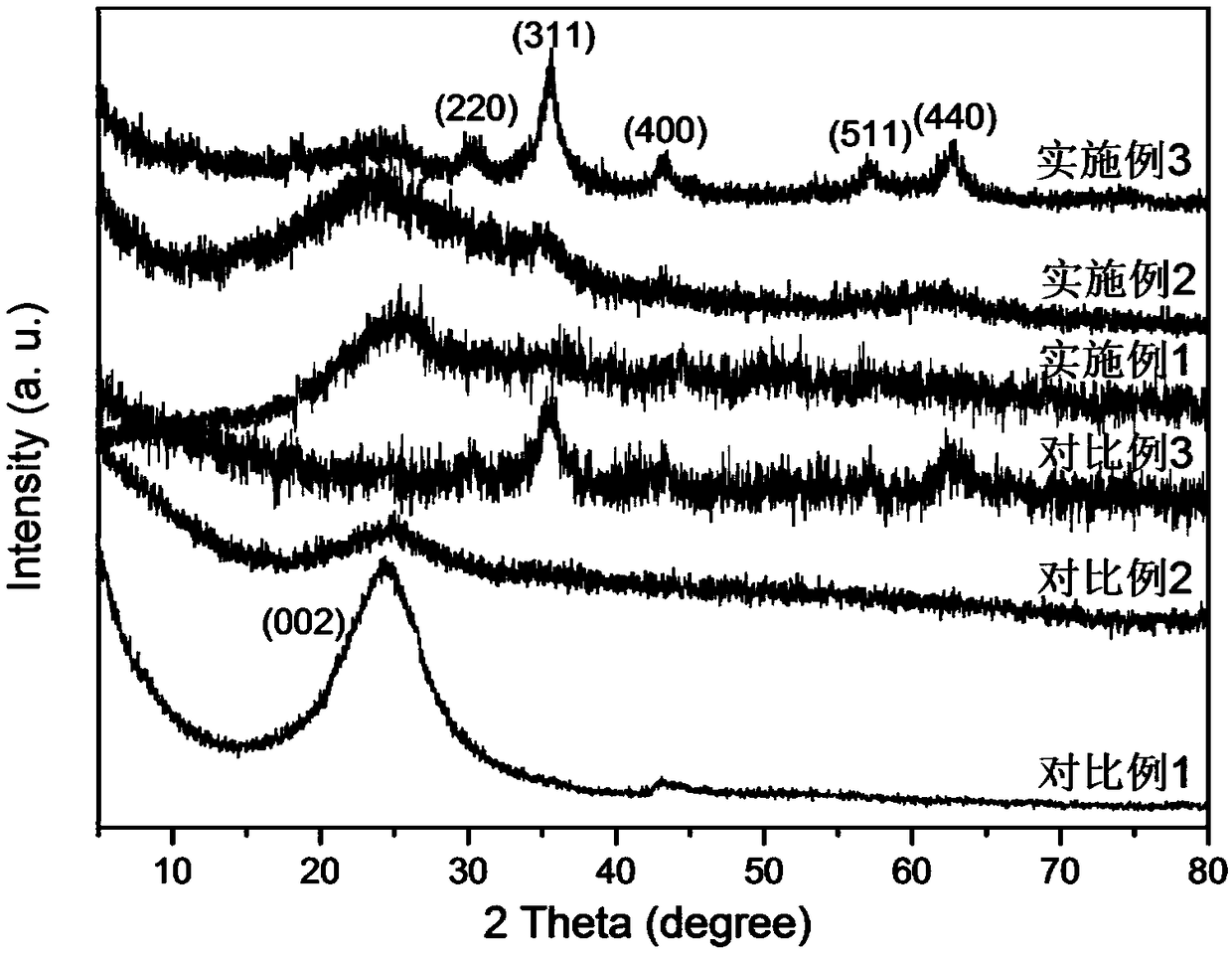

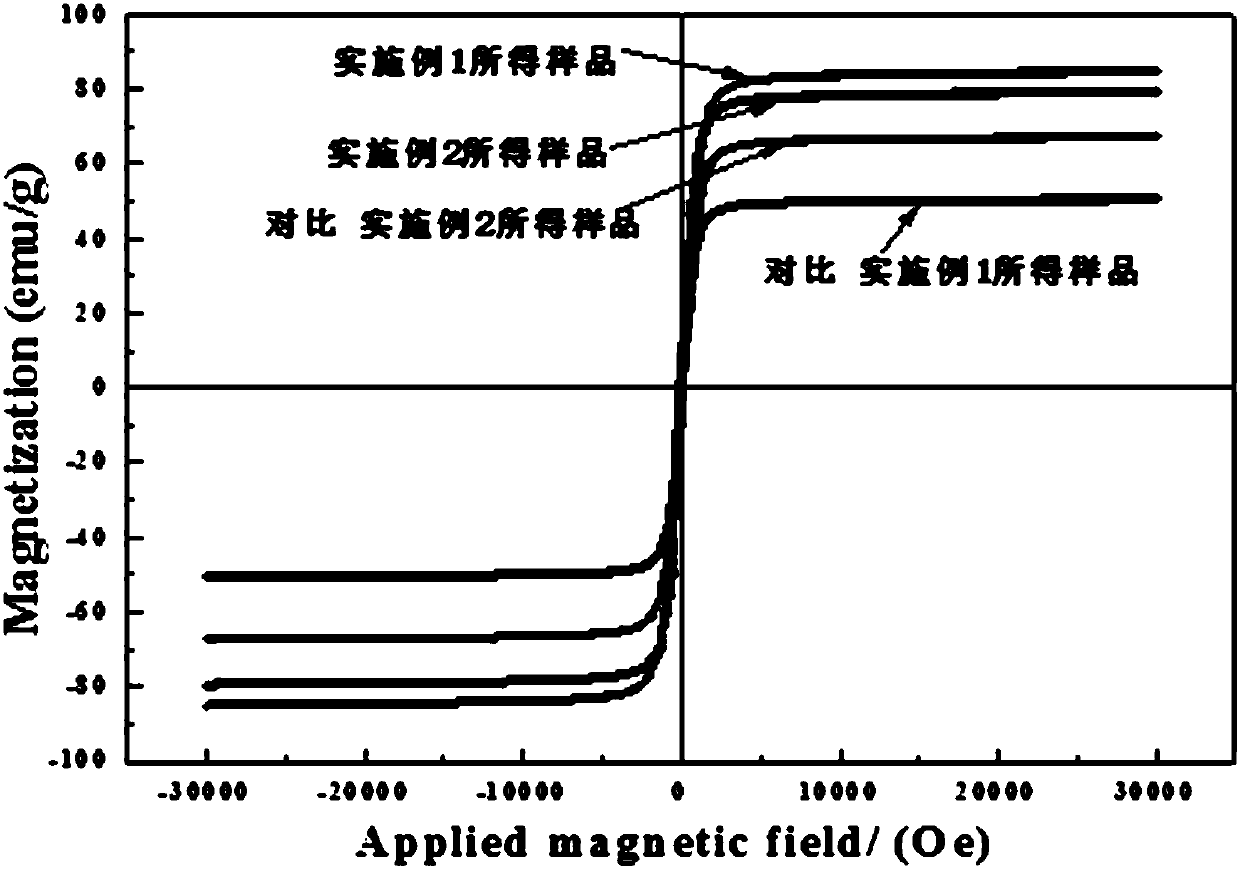

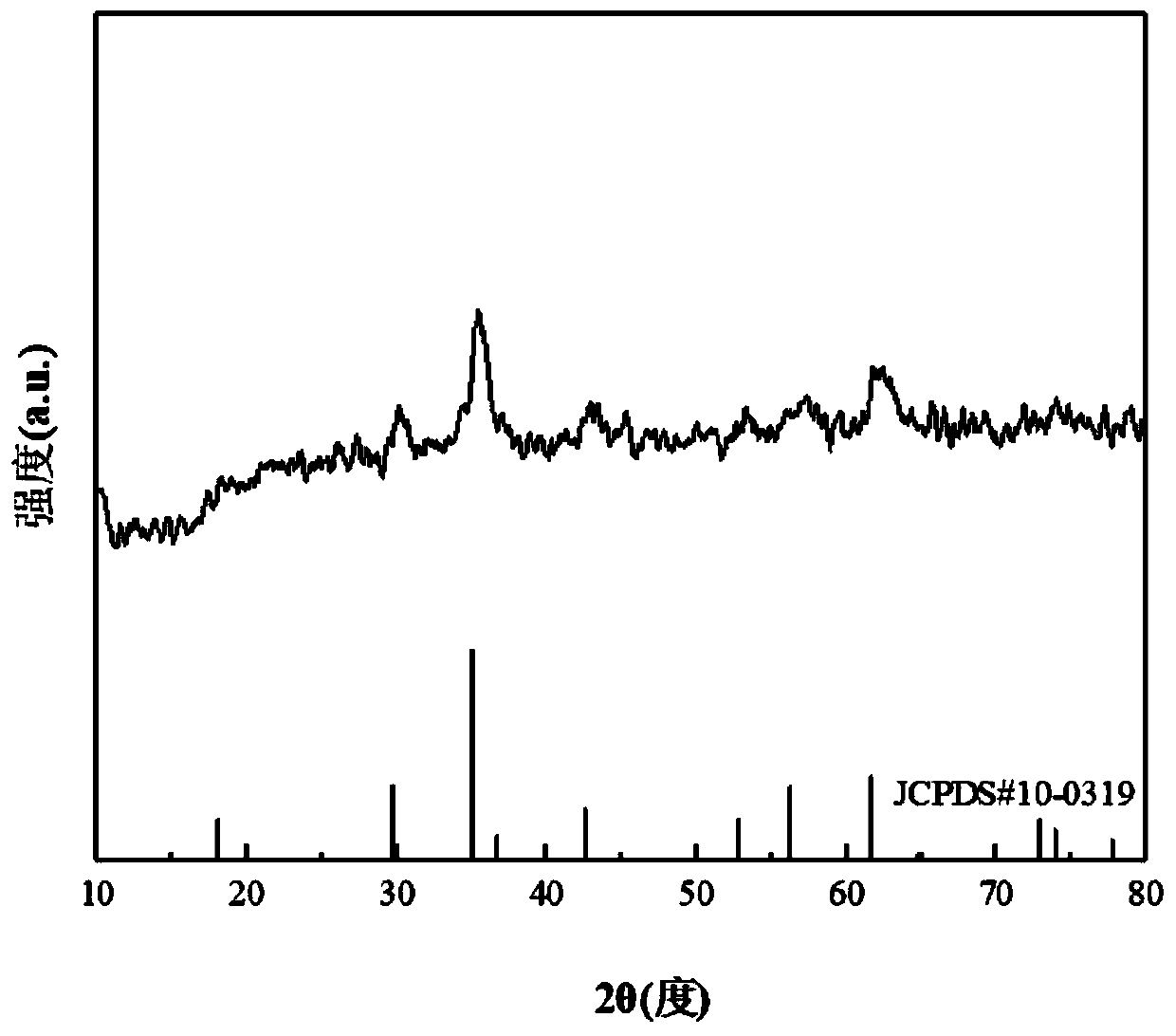

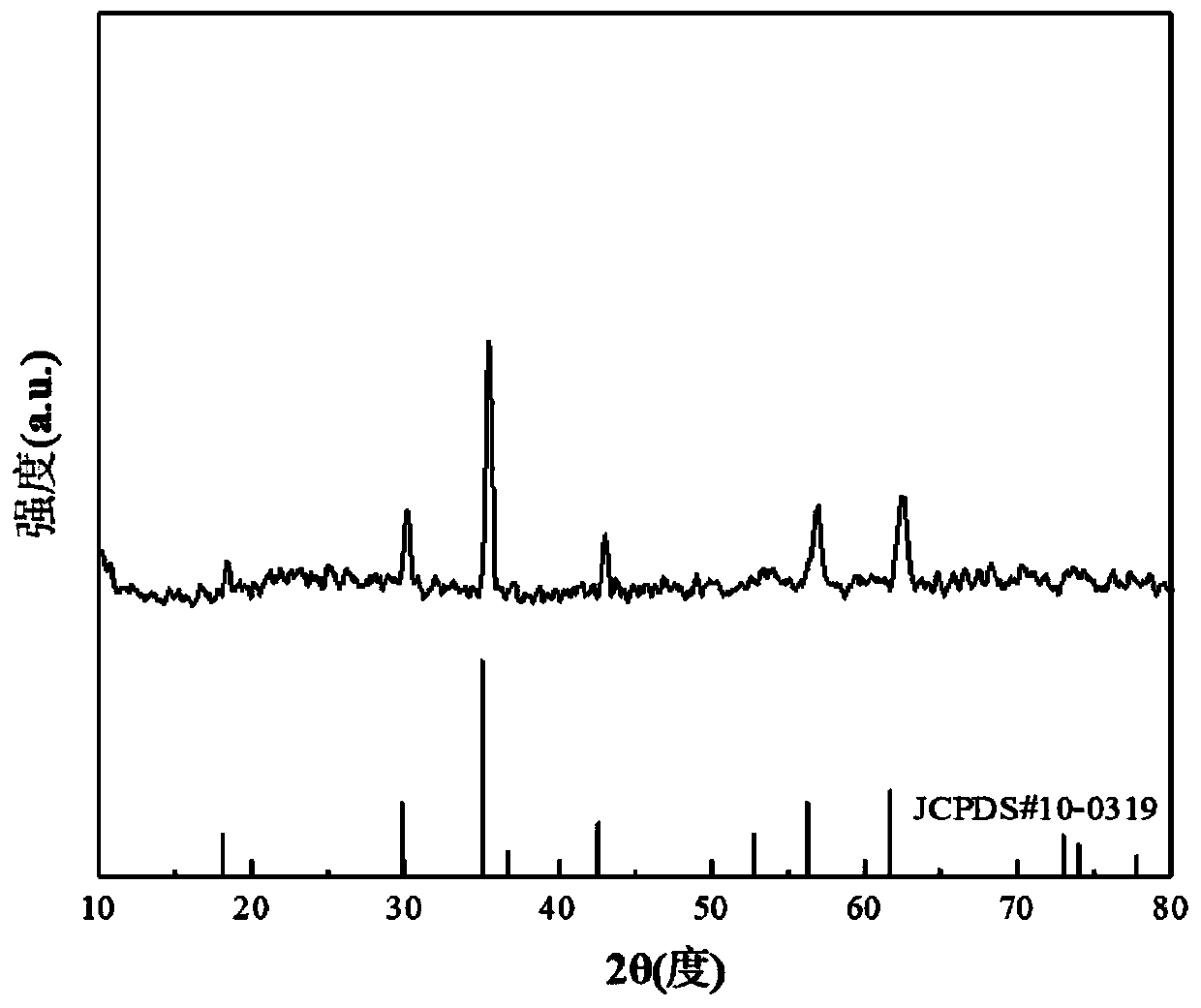

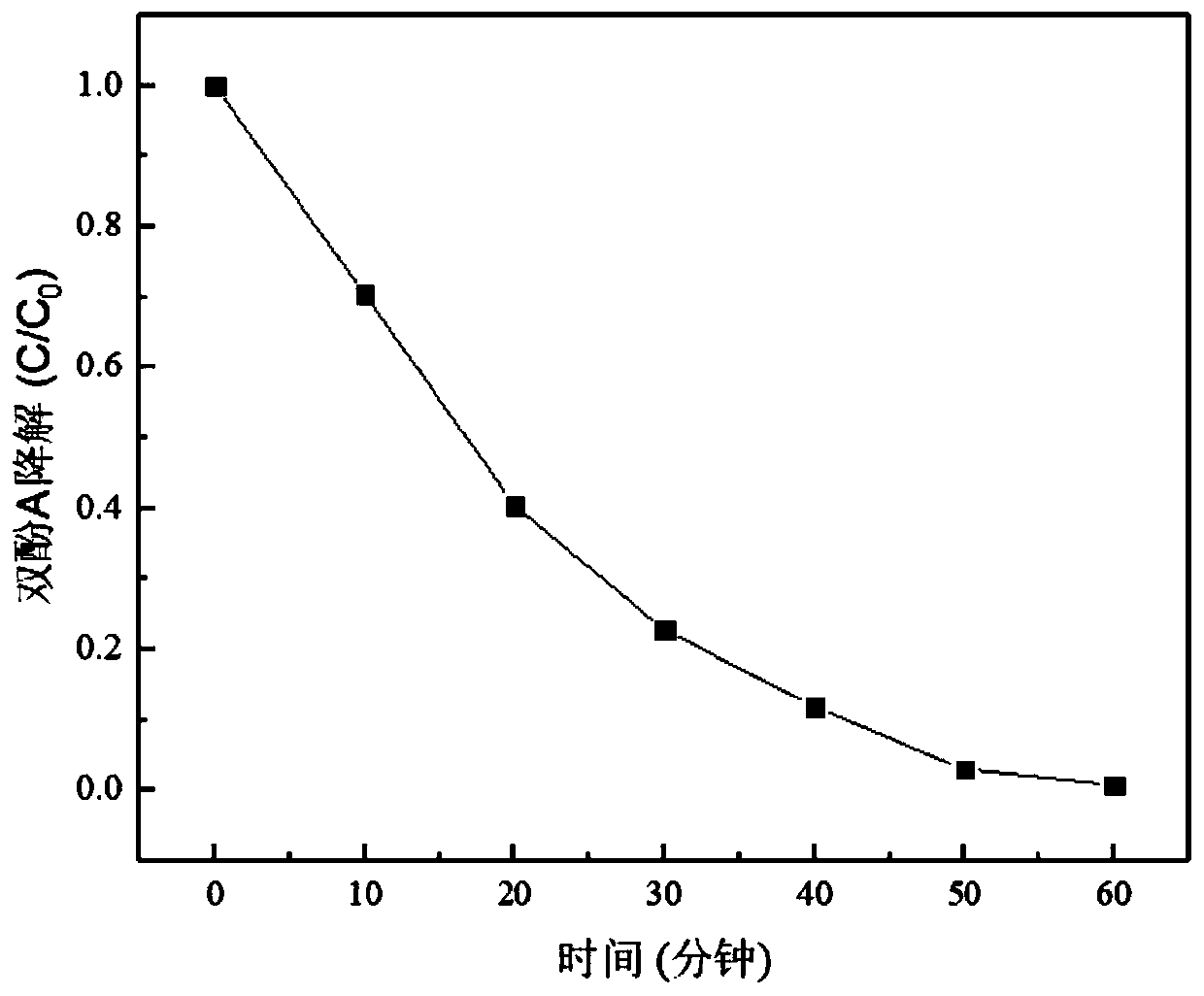

The present invention discloses a mesoporous manganese ferrite Fenton-like catalyst and preparation method and application thereof and pertains to the field of preparation of Fenton-like catalysts. The present invention uses KIT-6 as a hard template agent to synthesize mesoporous manganese ferrite catalyst. The prepared mesoporous manganese ferrite and hydrogen peroxide constitute a Fenton-like system oxidation wastewater treatment system to carry out efficient removal and mineralization of organic pollutants in wastewater. The preparation method of the present invention is simple and efficient. The prepared Fenton-like catalyst has a mesoporous structure and a relatively large specific surface area. It can provide more adsorption sites and catalytic site and efficiently degrade pollutants in a wide pH range (acidic, neutral and even alkaline) and solves the problem that conventional Fenton reaction occurs only under an acidic condition and a large amount of iron sludge is generated during reaction, causing secondary pollution. Further, the catalyst can be used cyclically and easily separated from the water solution and recovered after use.

Owner:NANJING UNIV

Fire resistant black iron oxide pigment and preparation method thereof

ActiveCN101314678AImprove acid resistanceGood alkali resistanceInorganic pigment treatmentFerric oxidesEngineering plasticManganese oxide

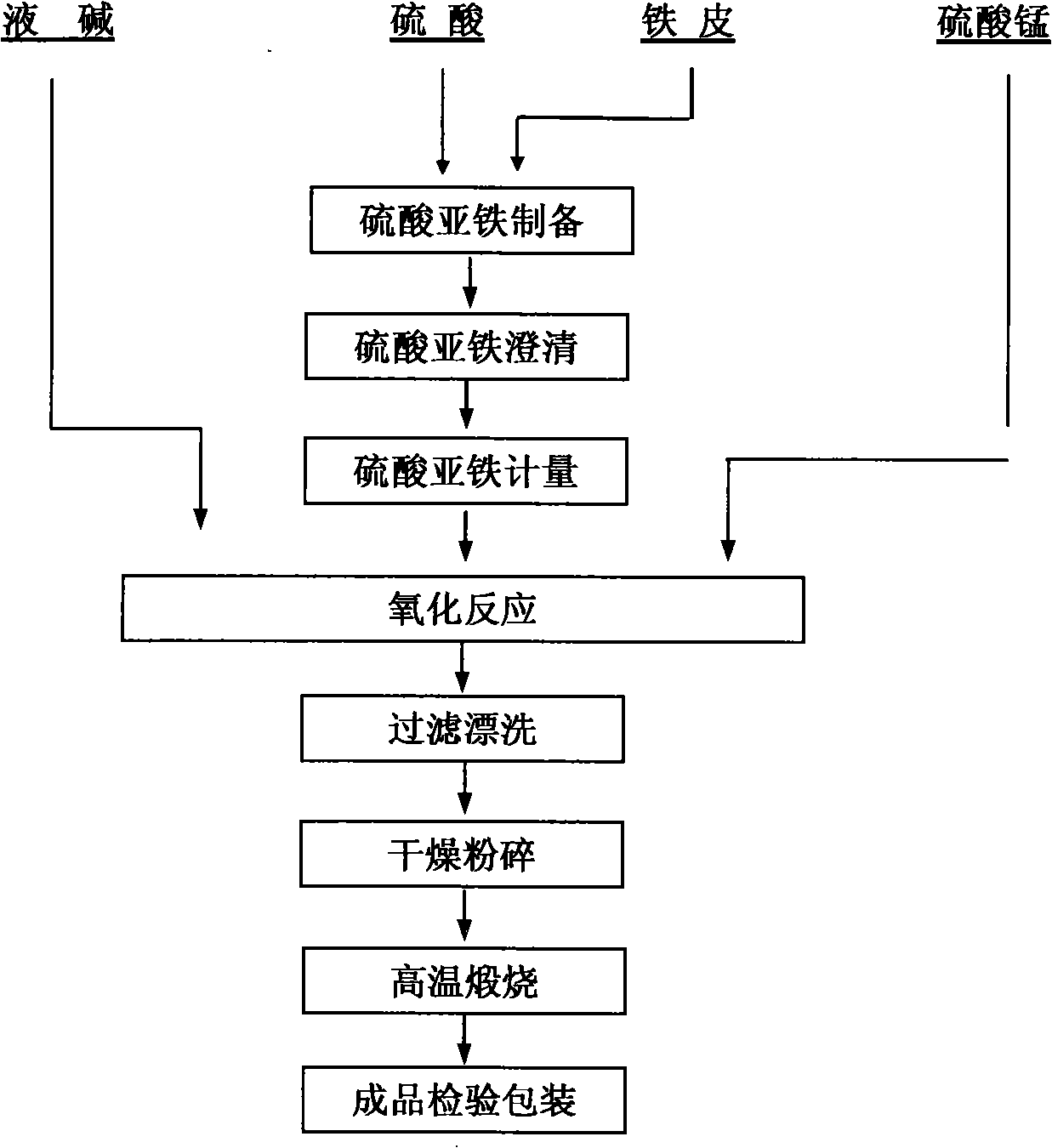

The invention relates to an inorganic iron oxide black pigment, in particular to a heat-resistant iron oxide black pigment (manganese ferrite black) and the preparation method thereof. The heat-resistant iron oxide black pigment comprises manganese ferrite black prepared from ferroferric oxide and manganese oxide by high-temperature lattice reaction, wherein the molar ratio of iron element to manganese pigment in the pigment is 1.5:1 to 5:1. The heat-resistant iron oxide black pigment has high heat resistance up to 700 DEG C or above, and can be widely used for ceramic, engineering plastic, color sand, etc., for products manufactured at high temperature, and for coloring agent for products. Meanwhile, the inorganic iron oxide black pigment has the advantages of high acid resistance, high alkali resistance and high light absorbability.

Owner:ZHEJIANG HUAYUAN PIGMENT CO LTD

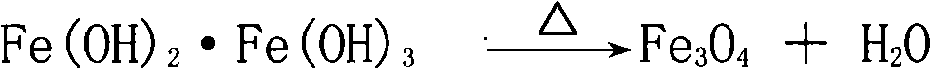

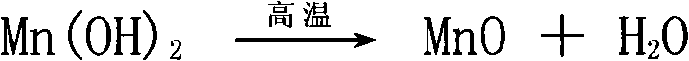

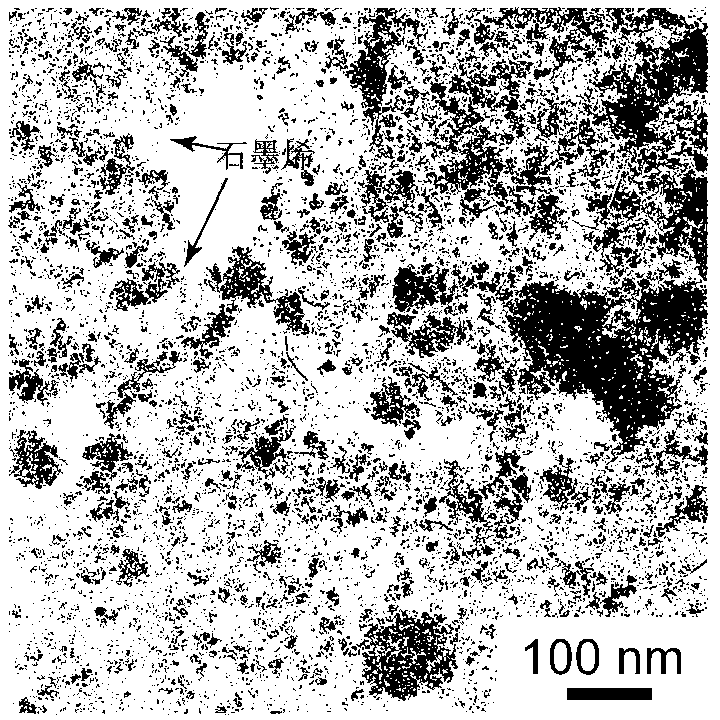

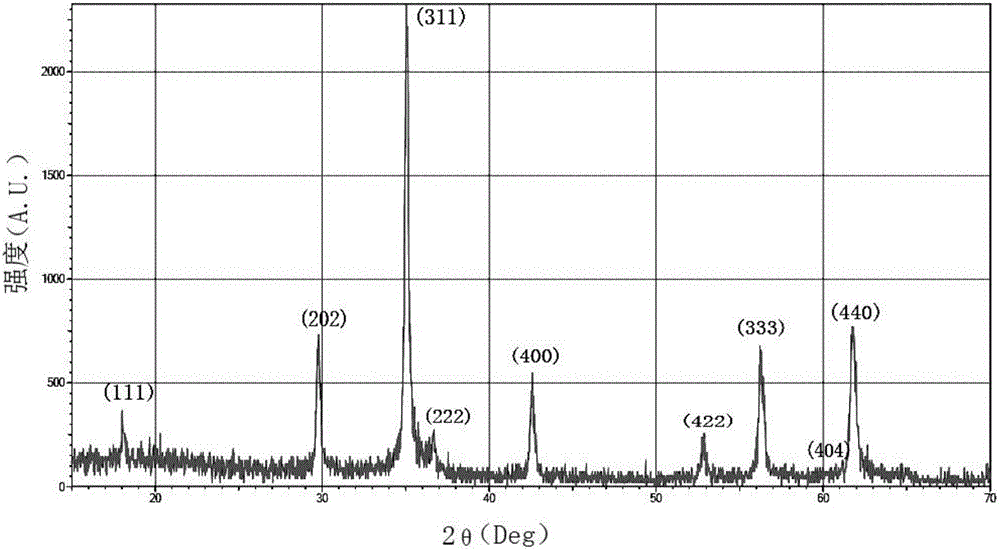

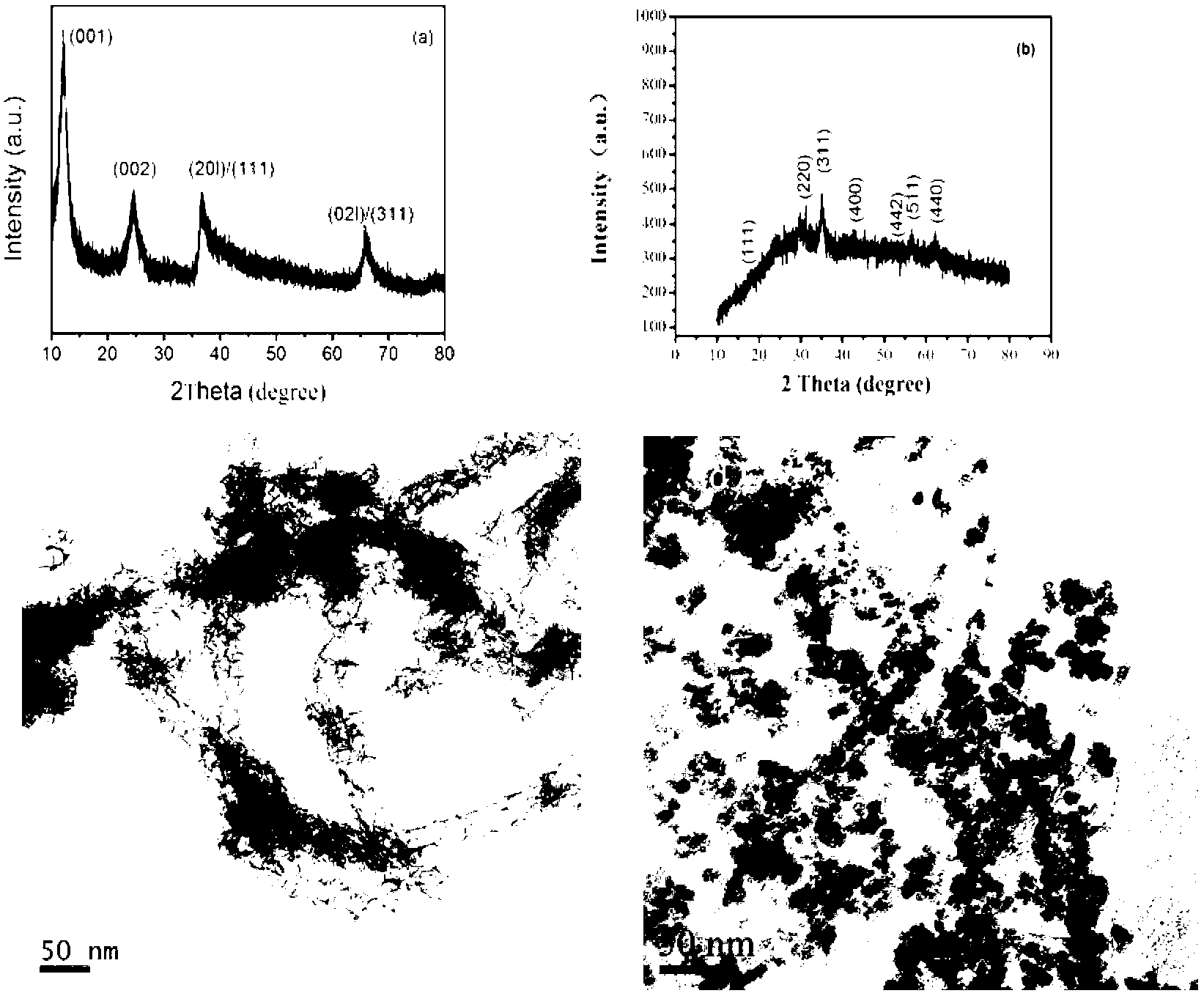

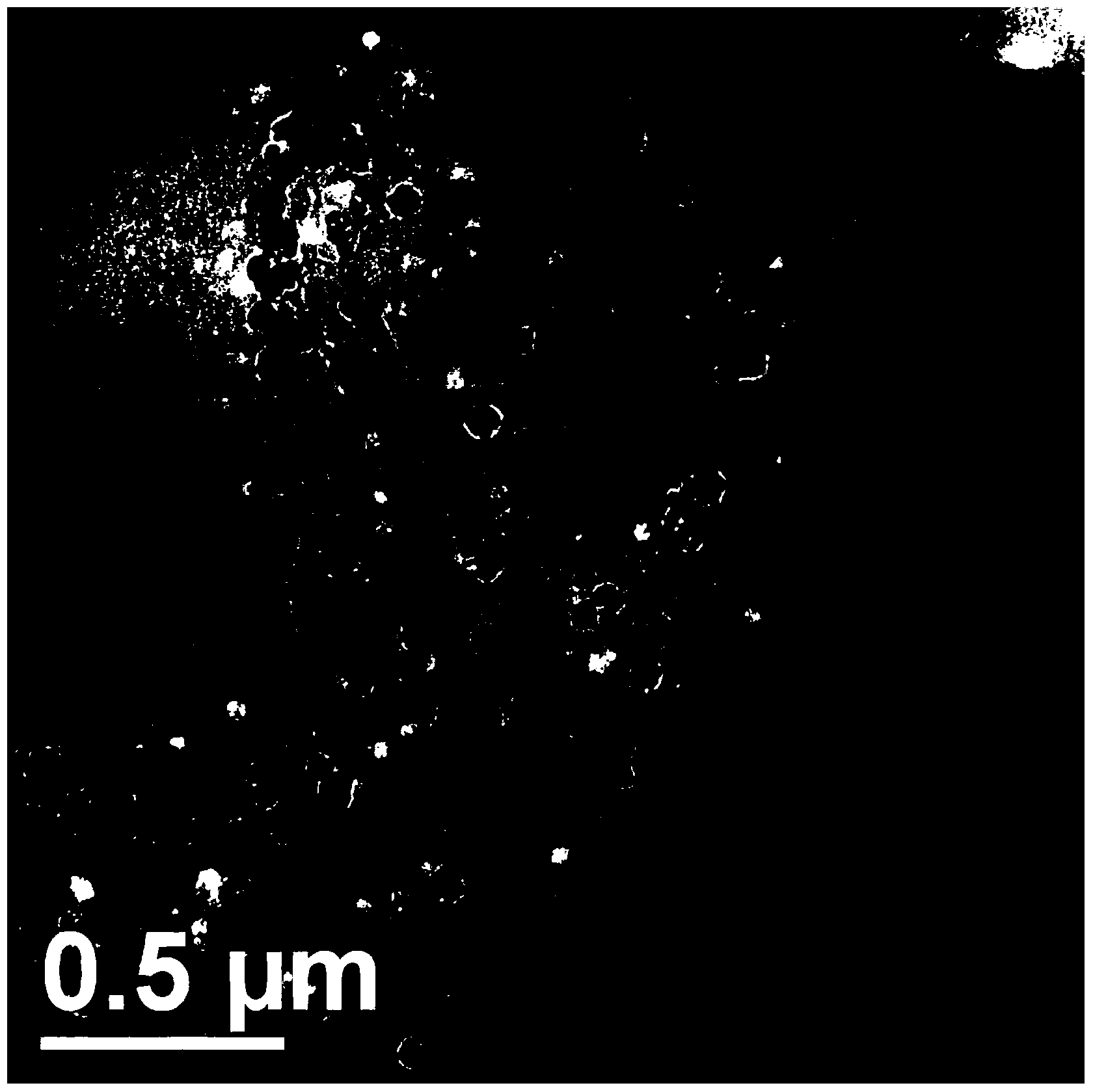

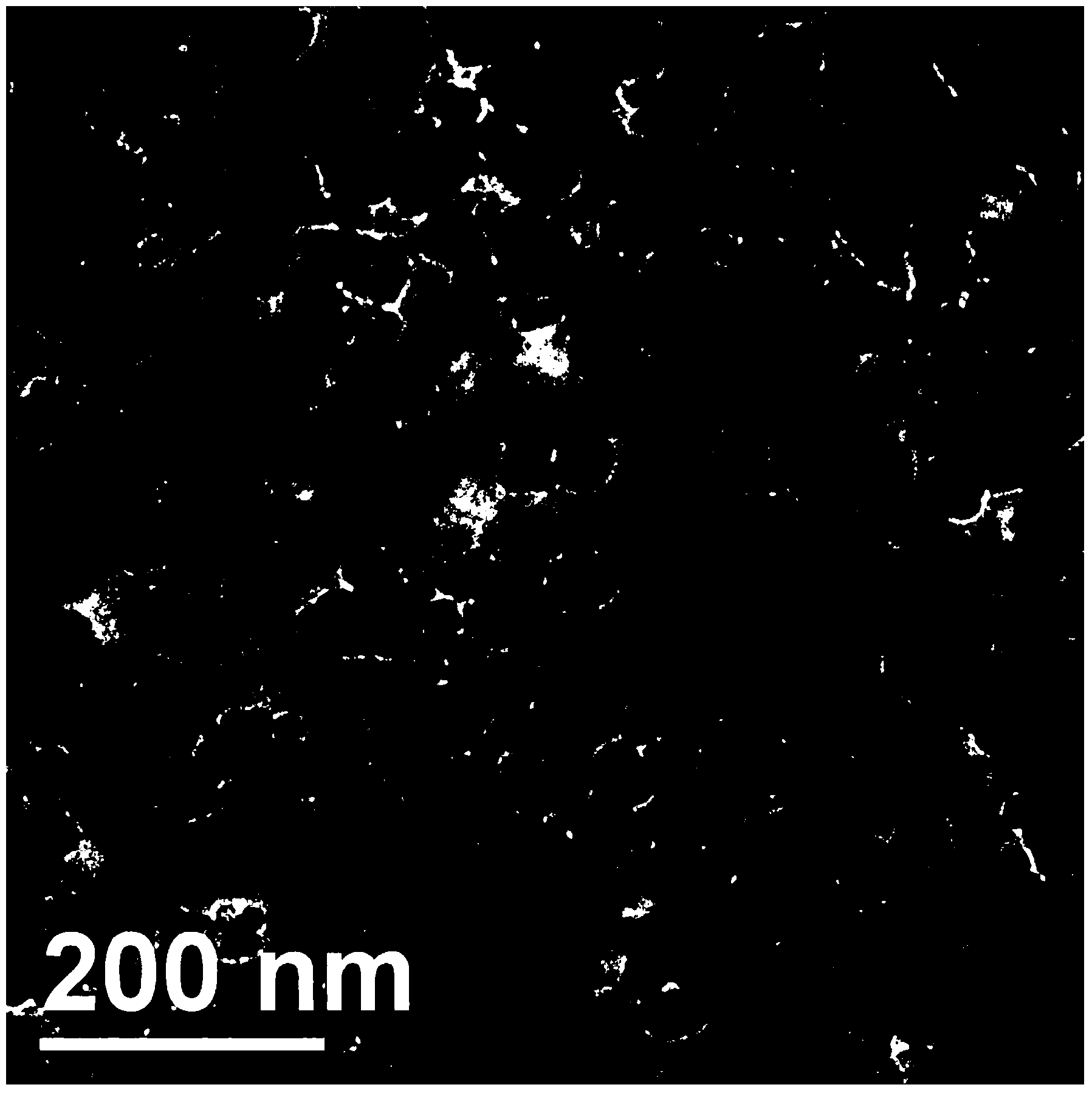

Preparation method of manganese ferrite nanoparticle-graphene compound

InactiveCN103341346AAvoid separabilityAvoid operabilityOther chemical processesMagnetic/electric field screeningEnvironmental resistanceCvd graphene

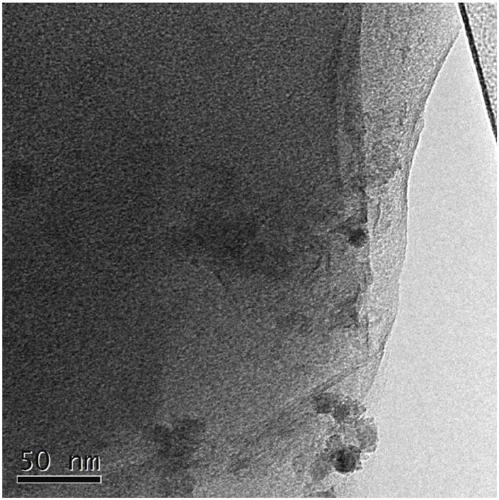

The invention provides a preparation method of a manganese ferrite nanoparticle (MnFe2O4)-graphene compound. The preparation method comprises the following steps of: obtaining a mixed solution of manganese ions and oxidized graphene in the process of preparing the oxidized graphene by using a potassium permanganate graphite oxidizing method; adding enough H2O2 in the mixed solution, and reducing the manganese element into divalent manganese ions; adding tervalent ferric salt and divalent manganese salt, uniformly stirring the mixture, then, adding an alkaline solution in the mixed solution, adjusting the pH value of the solution to 8-13, then, heating the mixed solution to 70-99 DEG C, adding a reducing agent, and stirring for 0.5-24h to obtain a suspension liquid; and magnetically separating the suspension liquid and drying to obtain the manganese ferrite nanoparticle-graphene compound. According to the preparation method of the manganese ferrite nanoparticle-graphene compound, potassium permanganate used when the oxidized graphene is prepared can be sufficiently utilized so that the potassium permanganate can be converted into a nanomaterial containing manganese ferrites; and the preparation method has the characteristics of simplicity, environment friendliness, low cost and the like.

Owner:JIANGSU PROVINCIAL ACAD OF ENVIRONMENTAL SCI +1

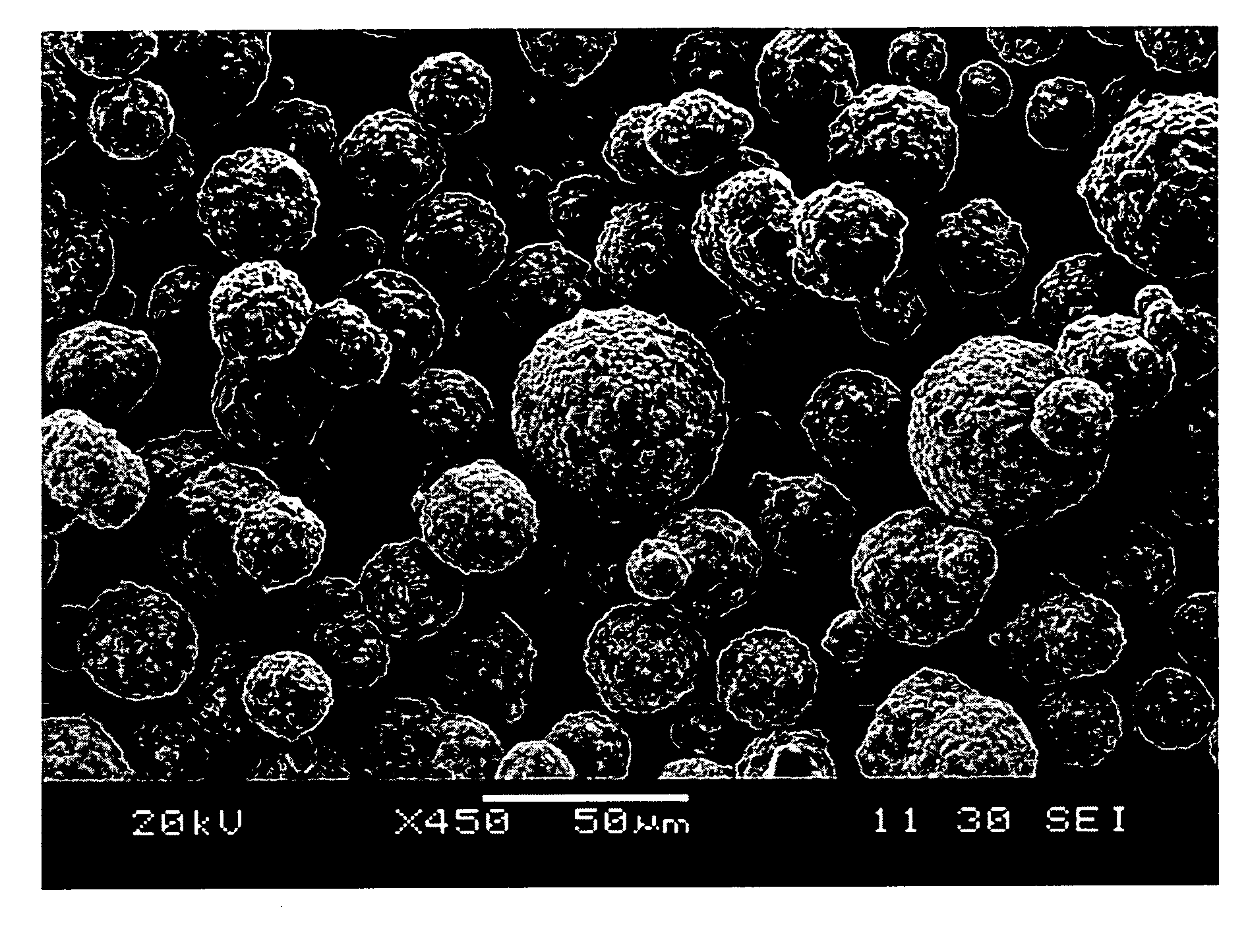

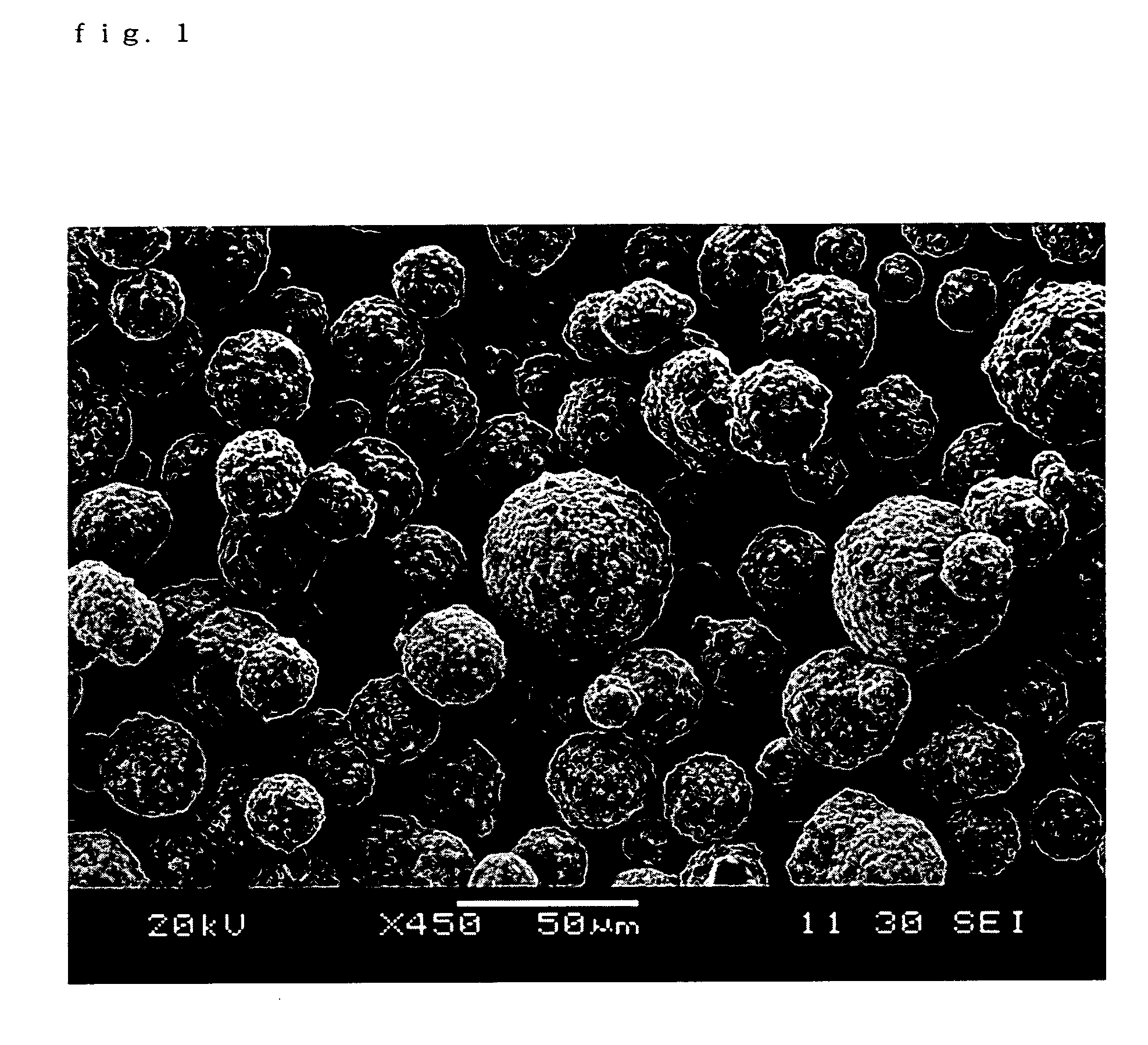

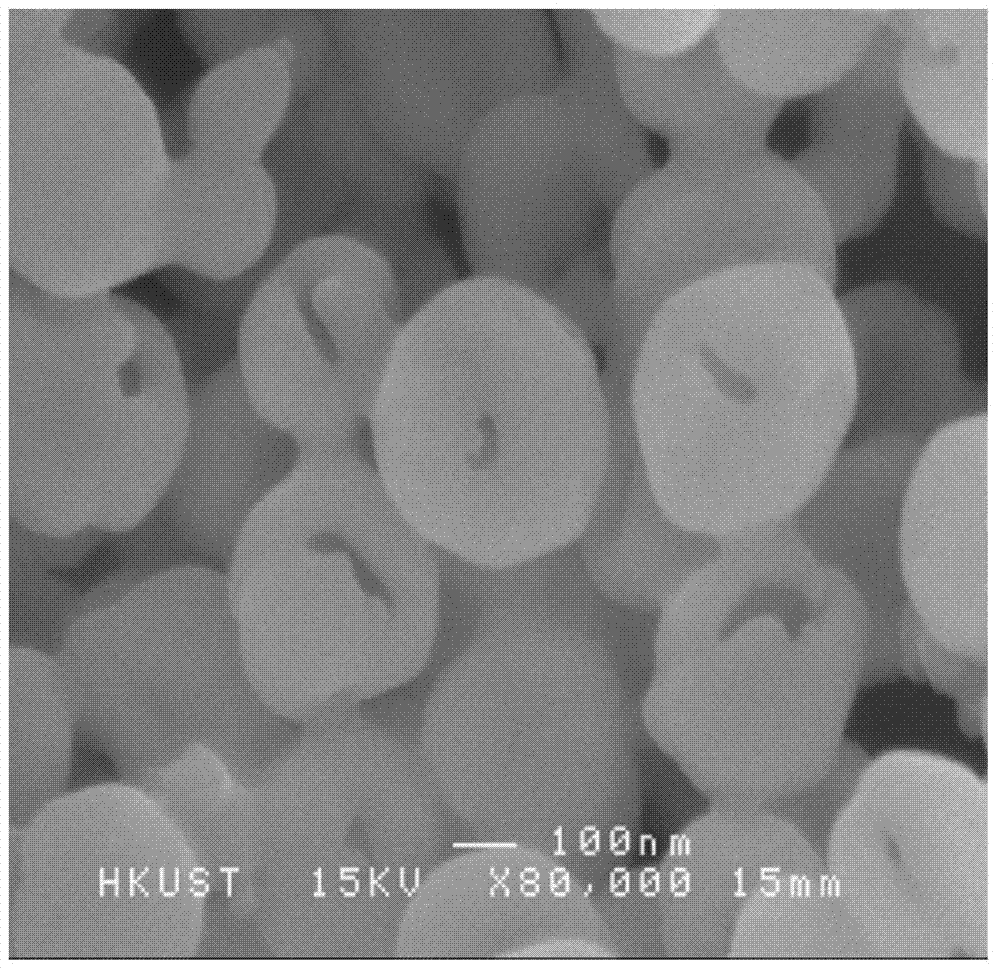

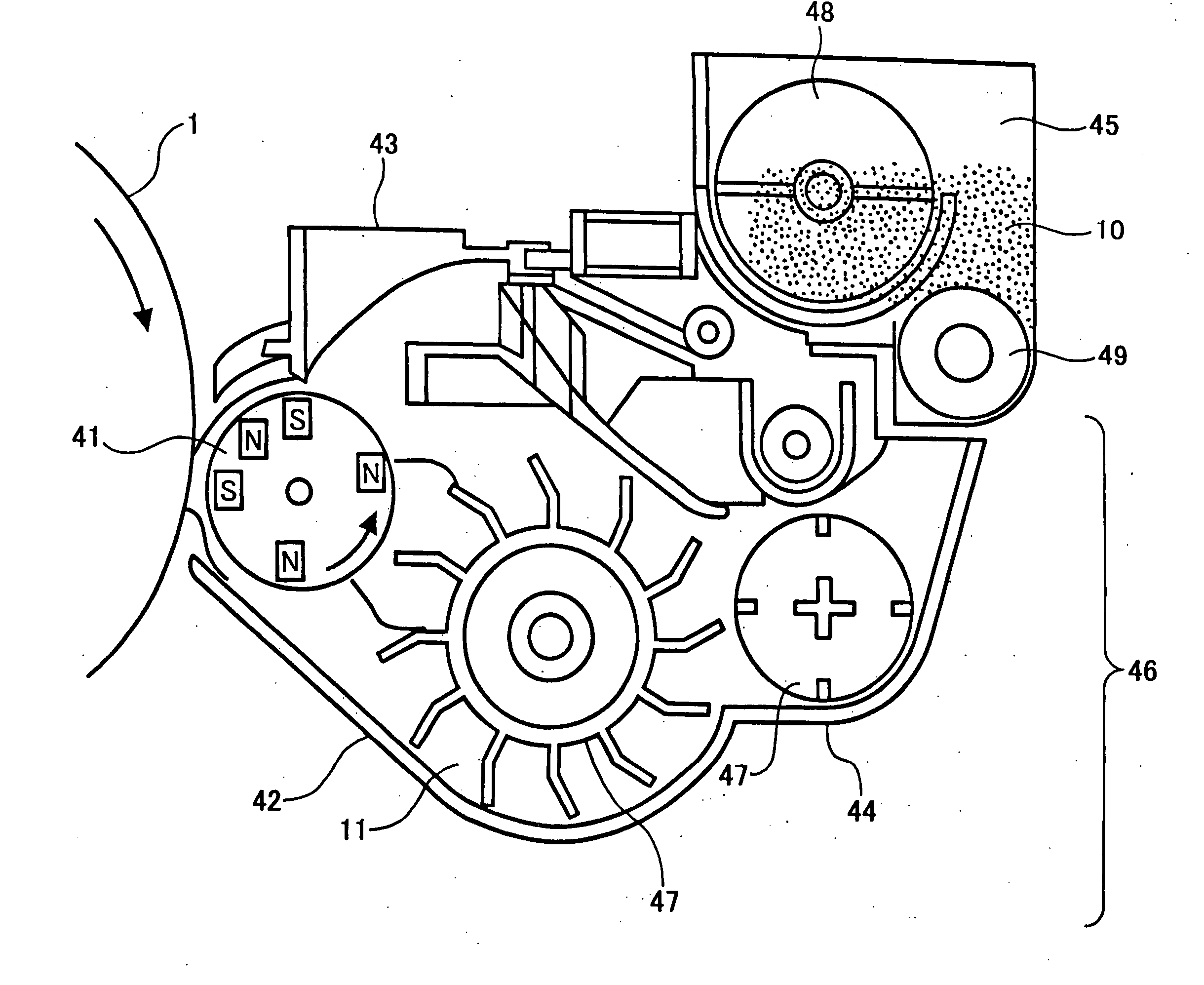

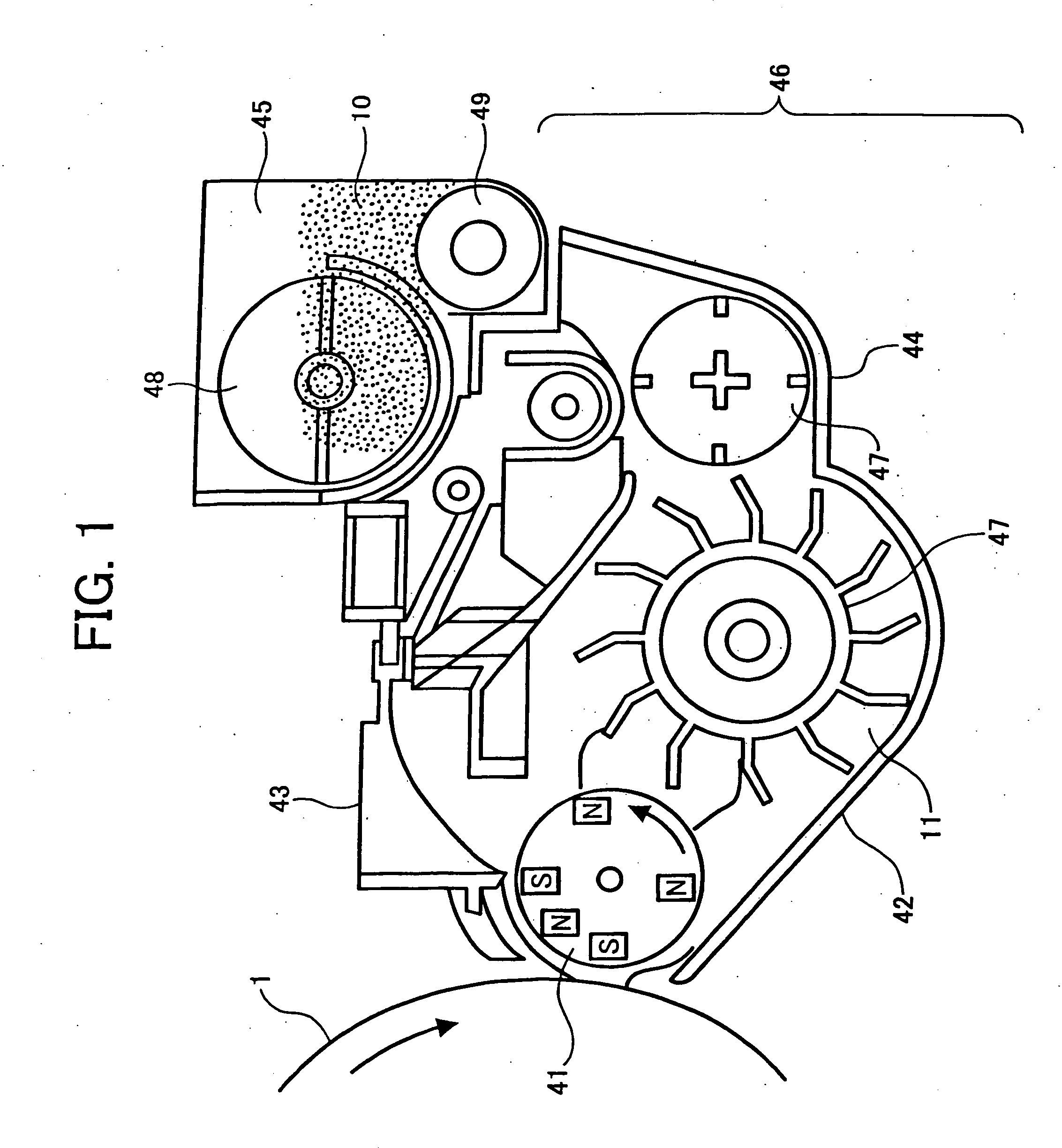

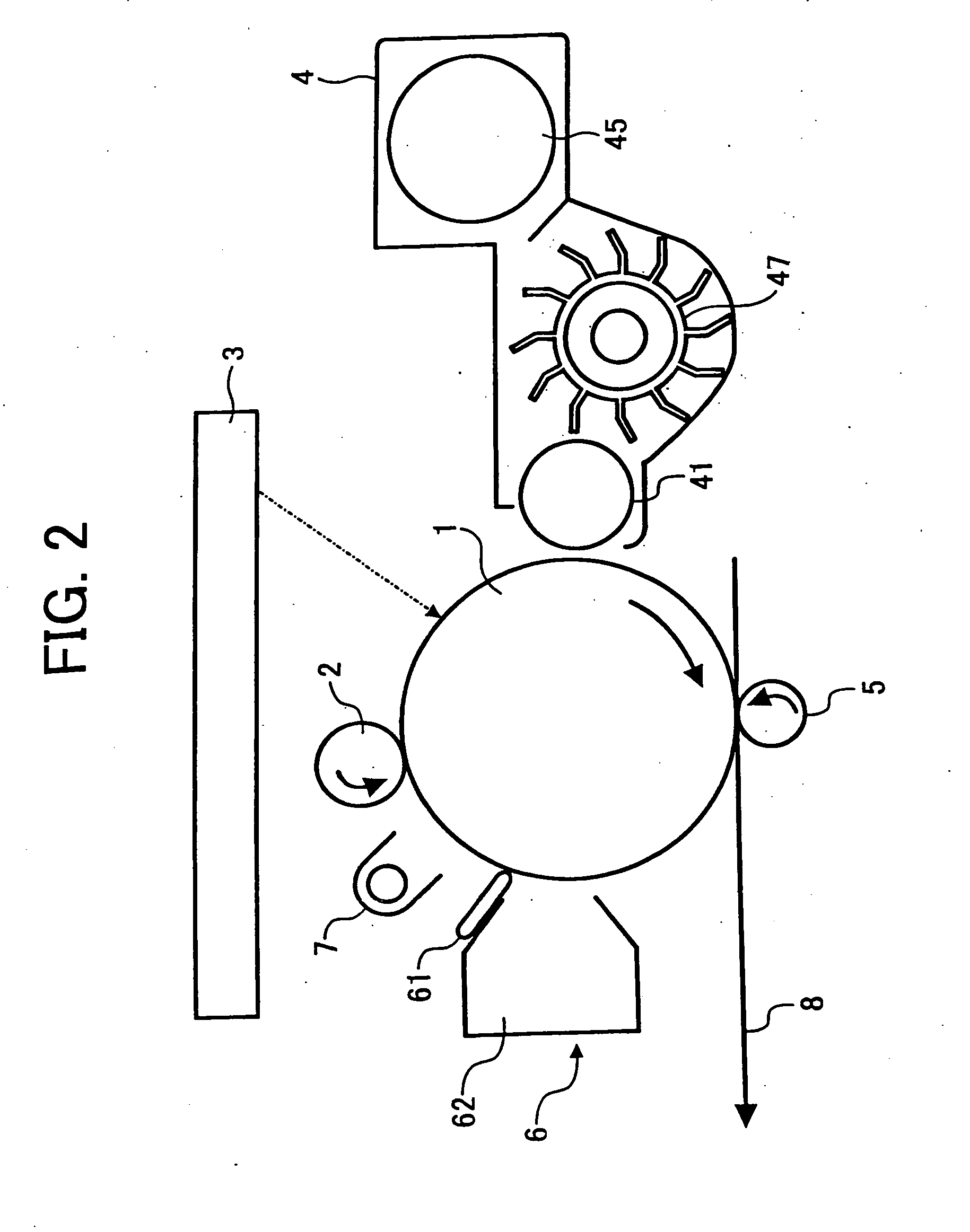

Ferrite carrier core material for electrophotography, ferrite carrier for electrophotography and methods for producing them, and electrophotographic developer using the ferrite carrier

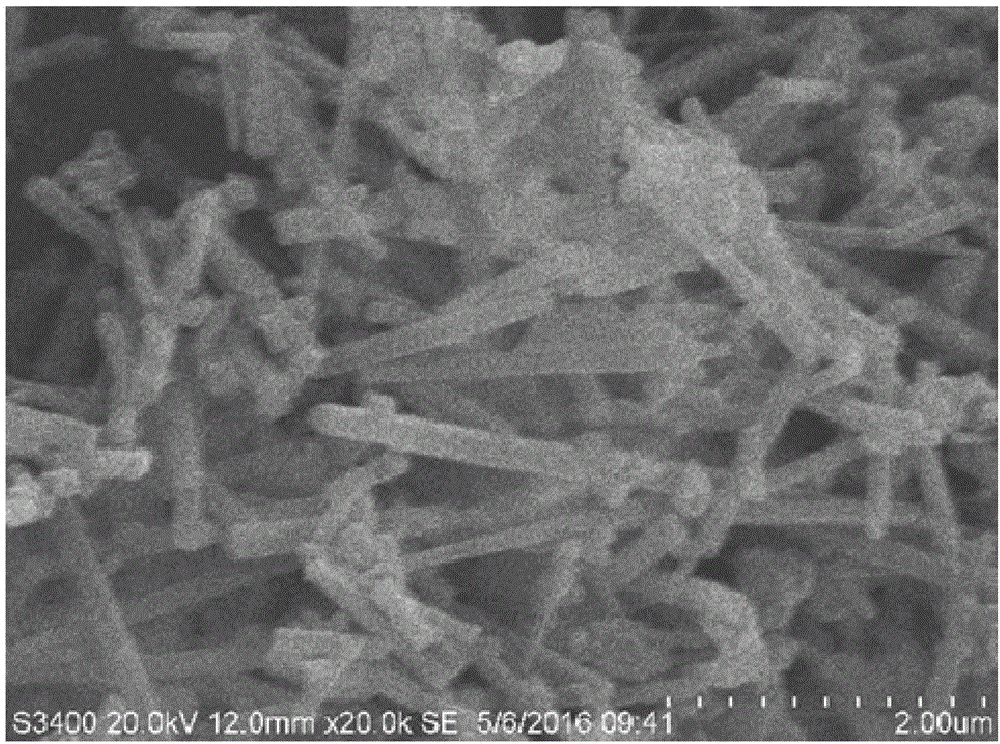

A ferrite carrier core material for electrophotography having a homogeneous composition, a certain surface property, a favorable fluidity, a high magnetization and a low resistance, and a ferrite carrier for electrophotography methods for producing them, and an electrophotographic developer using the ferrite carrier-core material, which exhibits a fast charge rising and a stable charge quantity with time, are provided. A ferrite carrier core material for electrophotography whose surface is divided by grooves or streaks into 2 to 50 regions per 10 μm and which has a manganese ferrite as a main component, and a method for producing the ferrite carrier core material for electrophotography using an Fe—Mn composite oxide as the raw material, and a method for producing a ferrite carrier for electrophotography are employed.

Owner:POWDERTECH

Double-effect optical Fenton denitrification method of manganese ferrite or carbon composite material of manganese ferrite

ActiveCN104445508AQuick releaseEfficient releaseWater/sewage treatment by irradiationWater treatment compoundsCarbon compositesCatalyst degradation

The invention discloses a double-effect optical Fenton denitrification method of manganese ferrite or a carbon composite material of the manganese ferrite. The method comprises the following steps: at least under irradiation of ultraviolet light or visible light, preferably under the irradiation of the sunshine, degrading ammonia nitrogen in water by taking manganese ferrite and / or a manganese ferrite-carbon composite material as an optical Fenton catalyst, wherein the manganese ferrite-carbon composite material mainly comprises manganese ferrite, graphene and / or active carbon; and the manganese ferrite is distributed on a graphene interface or coated by the active carbon. By utilizing catalytic circulation of Mn (III) and Mn (II) and the catalytic circulation of Fe (III) and Fe (II), the method disclosed by the invention can be used for oxidizing the ammonia nitrogen into nitrogen gas by one step under the irradiation of various wavelengths so as to realize rapid and high-efficiency degradation of the ammonia nitrogen in water; and moreover, the adopted optical Fenton catalytic material can be separated from water by an externally applied magnetic field and is recyclable, low in cost and beneficial for environmental protection.

Owner:苏州尼普环境科技有限公司

Ferrate/polyaniline magnetic nanometer catalytic agent and preparation method thereof

InactiveCN102626658AMagnetic hasEasy to recycleWater/sewage treatment by irradiationOrganic-compounds/hydrides/coordination-complexes catalystsNano catalystPolymer science

The invention adopts an in-situ oxidation polymerization method and enables the polyaniline to be wrapped on the surface of the magnetic ferrate, and a series of ferrate / polyaniline magnetic nano composite materials can be prepared by using the method and comprise cobalt ferrite / polyaniline, nickel ferrite / polyaniline, copper ferrite / polyaniline, zinc ferrite / polyaniline and manganese ferrite / polyaniline and the like. A prepared ferrate / polyaniline magnetic nanometer catalytic agent has obvious preferential adsorption performance and good photoelectrical activity, and has good application prospects and economic benefits in the fields of adsorption, photocatalysis, lithium ion batteries and the like.

Owner:NANJING UNIV OF SCI & TECH

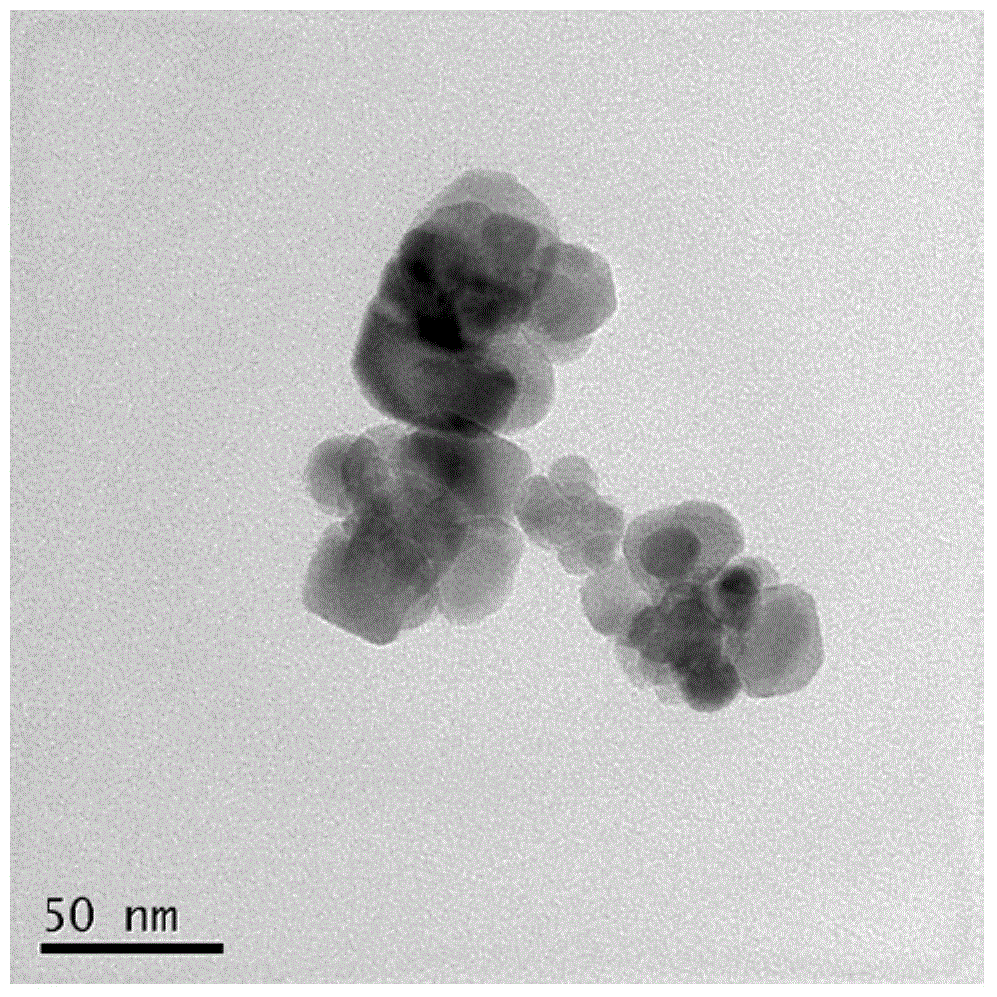

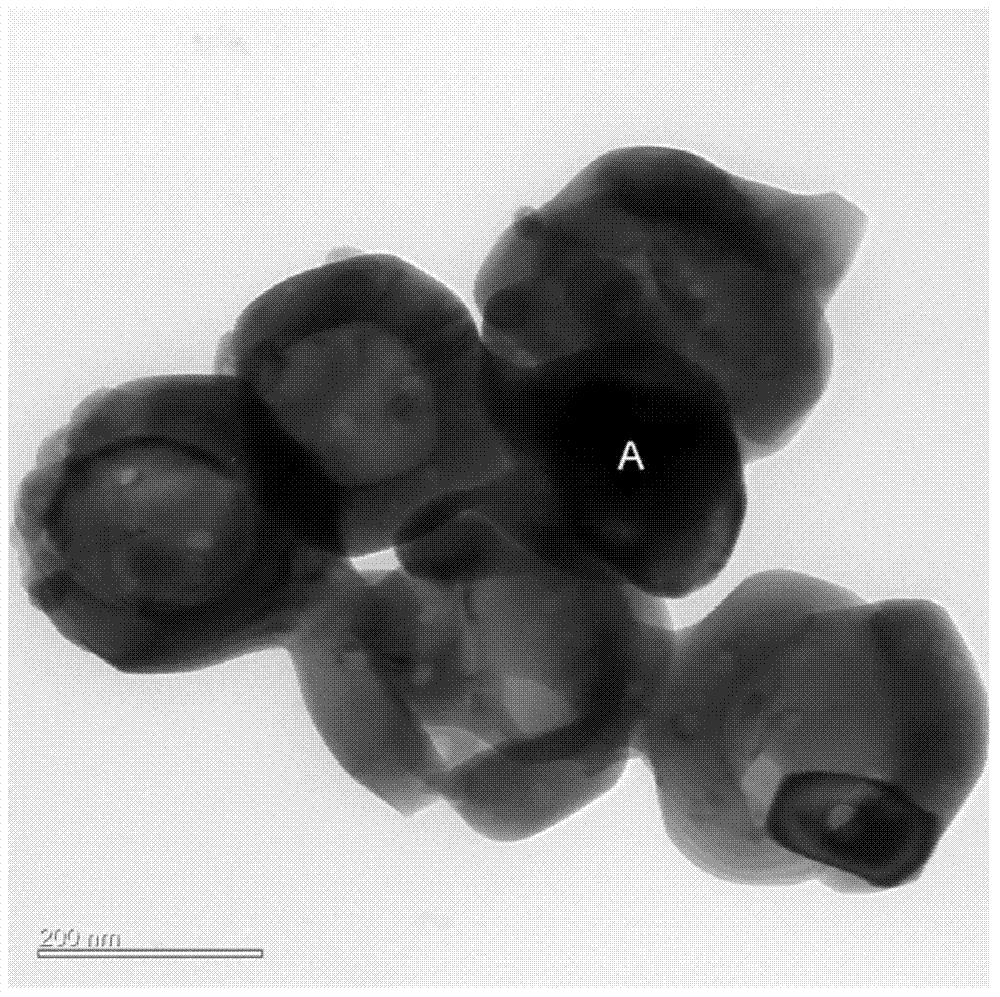

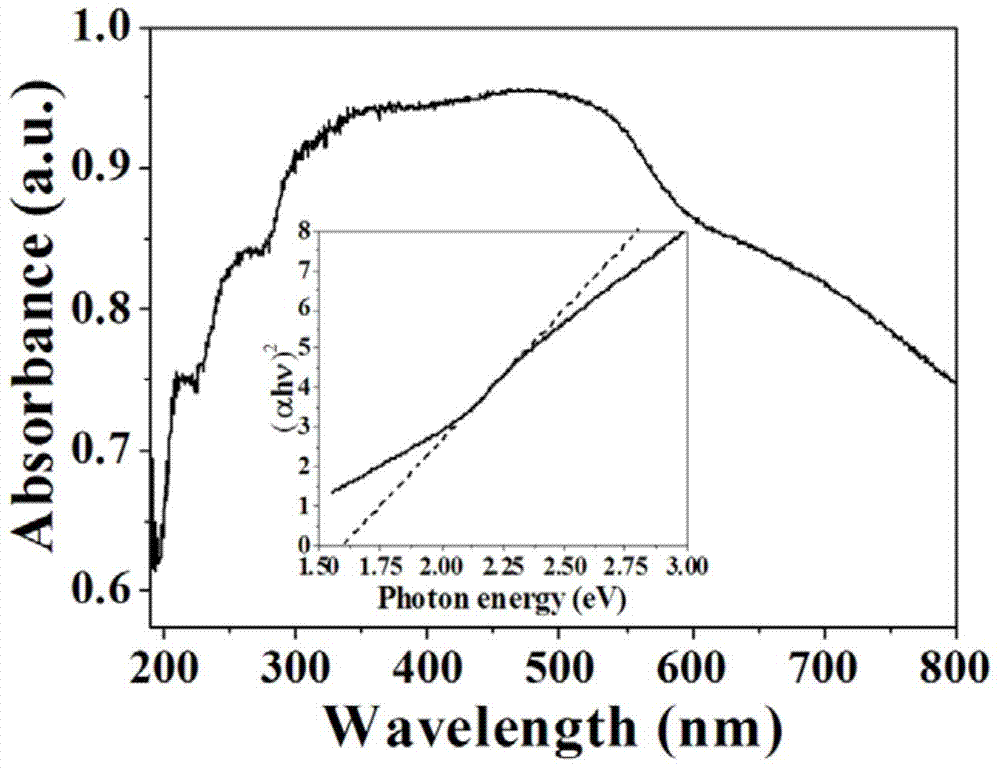

Hollow spherical nano manganese ferrite, and preparation method and application thereof

ActiveCN103482706APromote formationEasy to prepareDispersed particle separationIron compoundsBenzeneGas phase

The invention discloses hollow spherical nano manganese ferrite, and a preparation method and application thereof. The preparation method of the hollow spherical nano manganese ferrite comprises the following steps: adding manganese salt and iron salt into an ethylene glycol solution, adding polyethylene glycol, and performing solvothermal reaction; and after performing the procedures such as separation, washing, calcining and the like, grinding. The preparation method is convenient and low in cost; and the prepared hollow spherical nano manganese ferrite has ideal hollow spherical microscopic appearance, visible light can be well utilized, and degradation activity on gas-phase benzene under catalytic action of visible light is high. Thus, the hollow spherical nano manganese ferrite has dual application prospects in the aspects of solar energy utilization and environmental pollution regulation.

Owner:DALIAN JIAOTONG UNIVERSITY

Preparation method of multiaperture ferrite

InactiveCN103101980AEasy to prepareThe reaction raw materials are simple and cheapIron compoundsCobalt compoundsFluid phaseFerrite powder

The invention provides a method for preparing multiaperture spherical magnetic ferrite (zinc ferrite, nickel ferrite, cobalt ferrite and manganese ferrite) by taking dodecylamine as a precipitator by a solvothermal method. The preparation method is characterized in that an ethylene glycol solution of ferric trichloride and chloride is used as a reaction solution; dodecylamine is used as the precipitator; and the ethylene glycol solution and the dodecylamine are stirred and mixed uniformly at the room temperature to form a liquid phase reaction solution; and the liquid phase reaction solution is transferred to a reaction kettle for hydrothermal reaction at 180-250 DEG C. Products are separated, washed and dried to obtain corresponding multiaperture ferrite powder after reaction. The preparation method has the characteristics of being low in raw materials, simple in process, convenient in operation, controllable in shape, and the like.

Owner:LUDONG UNIVERSITY

Mesoporous manganese ferrite Fenton-like catalyst and preparation method and application thereof

InactiveCN106391042ALarge specific surface areaGood mesoporous structureWater treatment compoundsWater contaminantsFenton reactionWastewater

Owner:NANJING UNIV

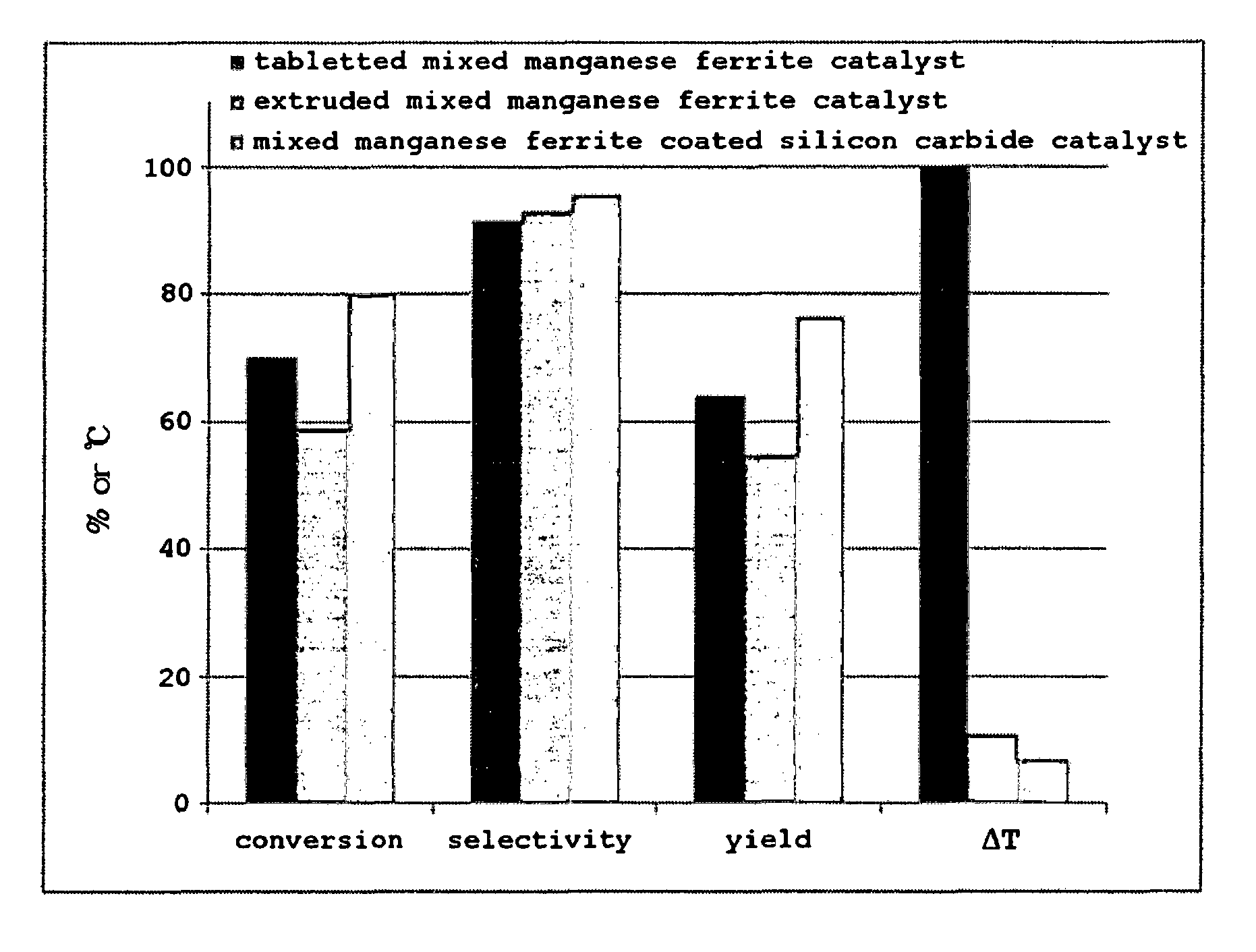

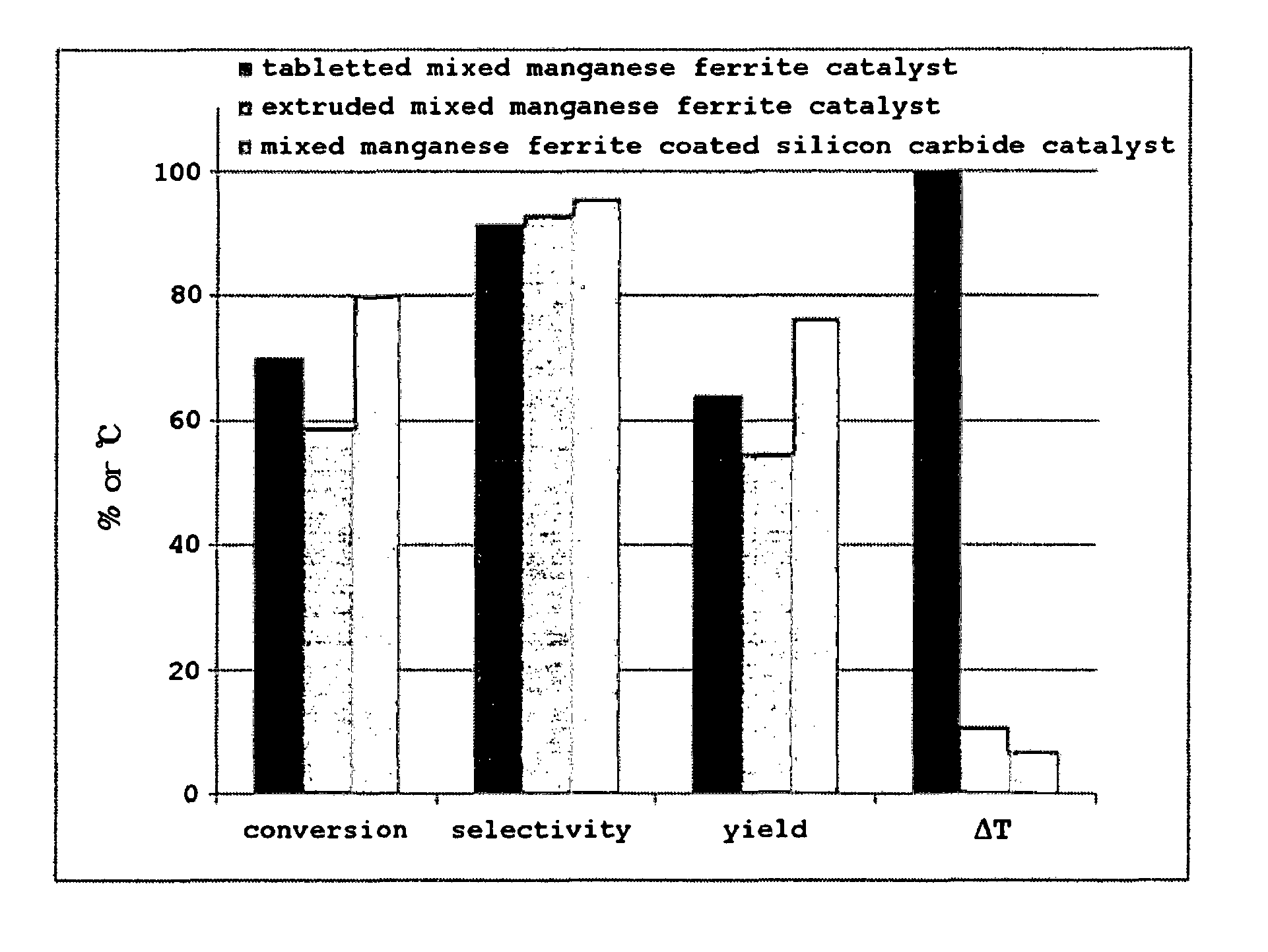

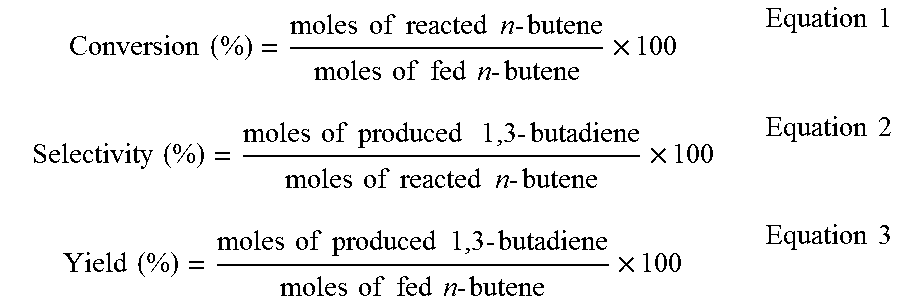

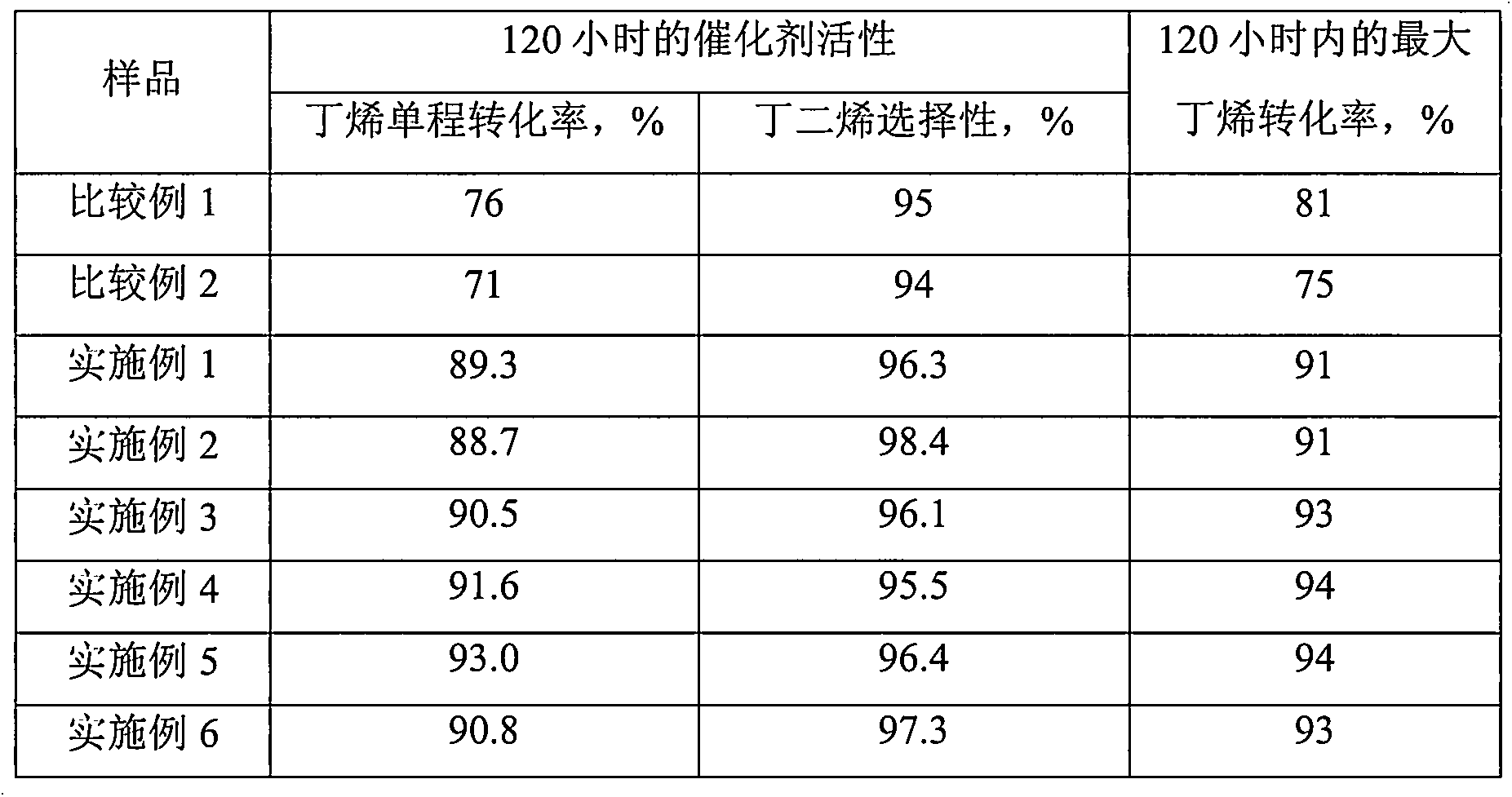

Mixed manganese ferrite catalysts, method of preparing thereof and method of preparing 1,3-butadiene using thereof

ActiveCN101896267ASimple structureThe synthesis steps are simpleHeterogenous catalyst chemical elementsCatalystsHybrid typeHigh concentration

The present invention provides a method of producing a mixed manganese ferrite catalyst, and a method of preparing 1,3 -butadiene using the mixed manganese ferrite catalyst. Specifically, the present invention provides a method of producing a mixed manganese ferrite catalyst through a coprecipitation method which is performed at a temperature of 10 - 40 DEG C, and to a method of preparing 1,3 -butadiene using the mixed manganese ferrite catalyst through an oxidative dehydrogenation reaction, in which a C4 mixture containing n-butene, n-butane and other impurities is directly used as reactants without performing additional n-butane separation process or n-butene extraction. The present invention is advantageous in that 1,3-butadiene can be prepared directly using a C4 mixture including n-butane at a high concentration as a reactant through an oxidative hydrogenation reaction without performing an additional n-butane separation process, and 1,3-butadiene, having high activity, can be also obtained in high yield for a long period of time.

Owner:SK INNOVATION CO LTD +1

Preparation method and application of graphene/cobalt-nickel-manganese ferrite nano-composite material

ActiveCN109021919AImprove performanceShort synthesis timeOther chemical processesMagnetic/electric field screeningFerrite nanoparticlesCobalt

The invention discloses a preparation method and application of a graphene / cobalt-nickel-manganese ferrite nano-composite material. The preparation method comprises: adding a solution containing an iron source, a cobalt source, a nickel source and a manganese source into a dispersion containing graphene oxide drop by drop to obtain a mixed solution, adjusting pH of the mixed solution to greater than or equal to 8, adding a reducing agent into the mixed solution to obtain a precursor solution, transferring the precursor solution into a reactor, and carrying out microwave synthesis to obtain thegraphene / cobalt-nickel-manganese ferrite nano-composite material. The graphene / cobalt-nickel-manganese ferrite nano-composite material is composed of layered graphene and spherical cobalt-nickel-manganese ferrite nanoparticles. The spherical cobalt-nickel-manganese ferrite nanoparticles are uniformly dispersed on the layered graphene surface and between the layers. The graphene / cobalt-nickel-manganese ferrite nano-composite material has the characteristics of strong absorption intensity, effective absorption frequency bandwidth, thin thickness and light weight.

Owner:CENT SOUTH UNIV

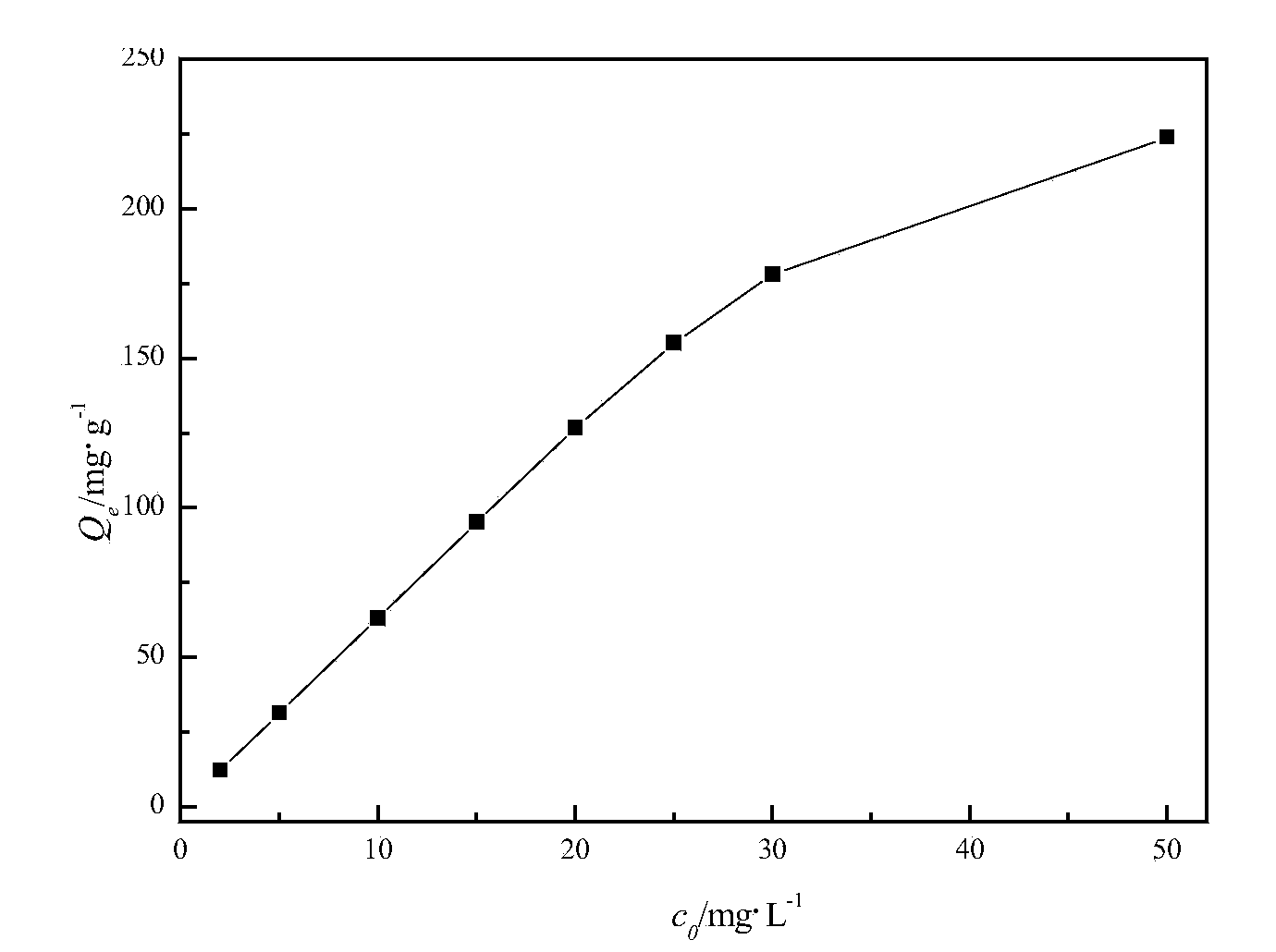

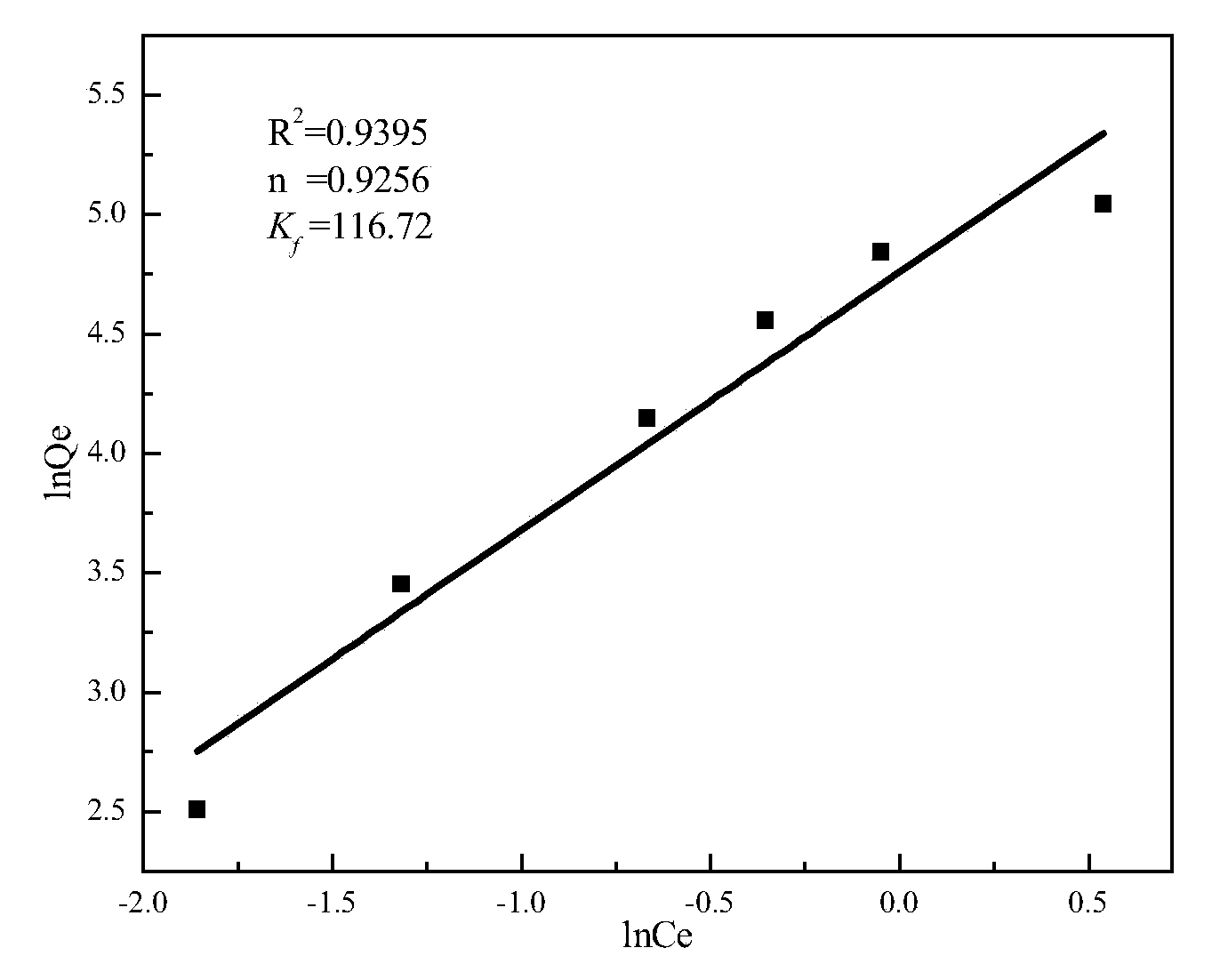

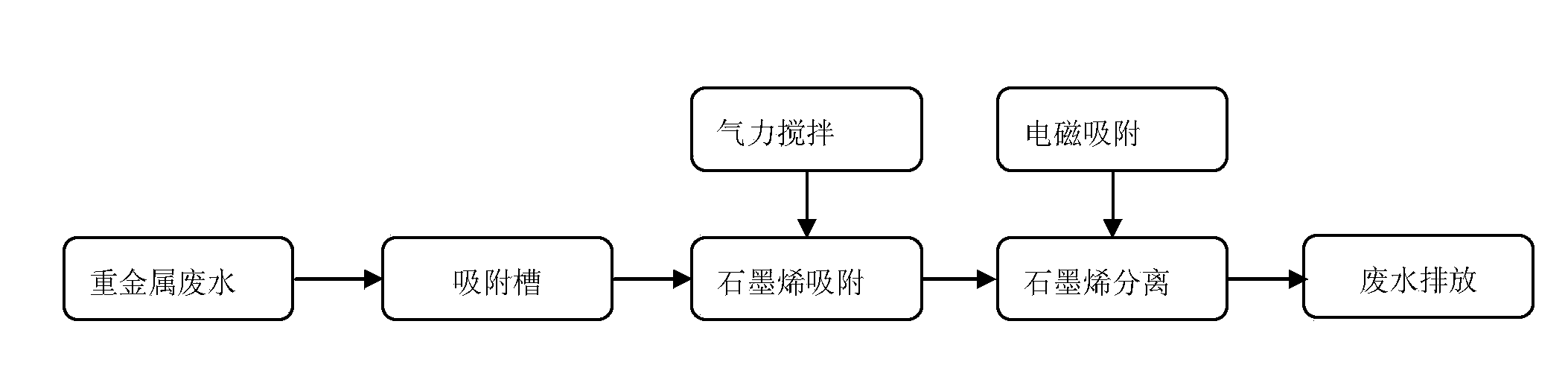

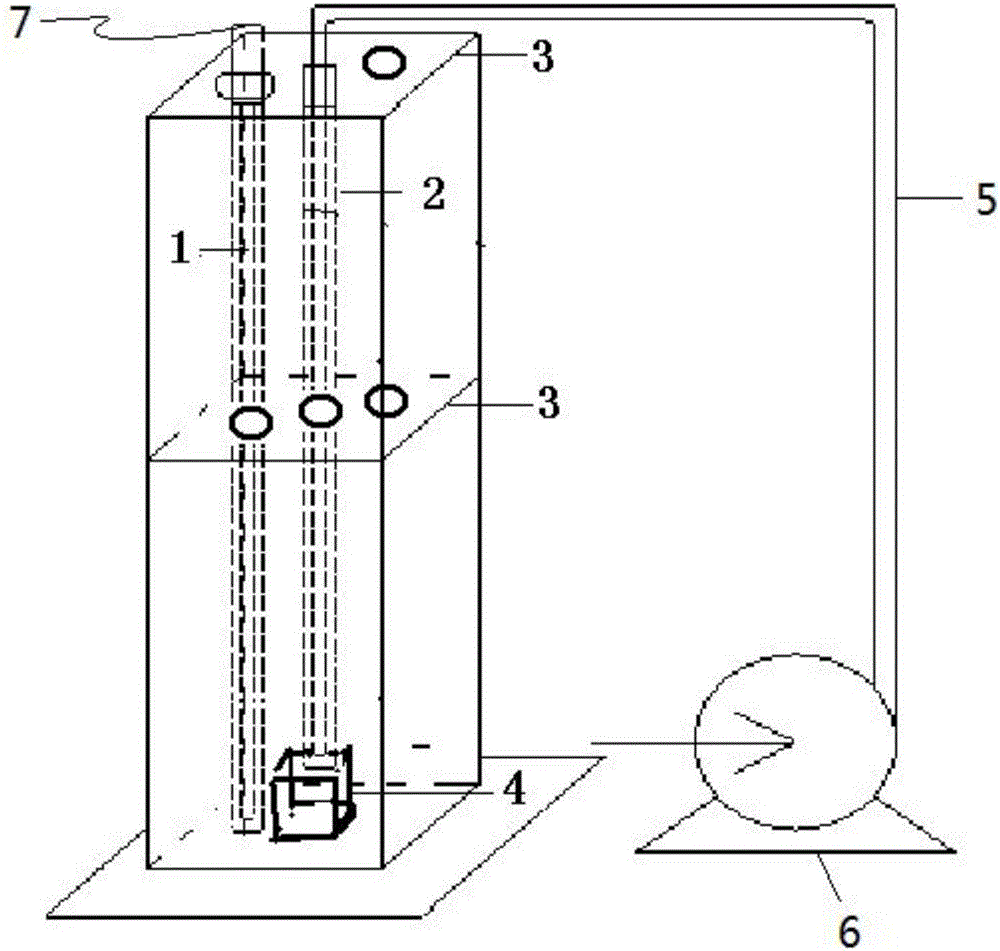

Method for adsorbing heavy metal ions by manganese ferrite nanoparticle and graphene compound

InactiveCN103723788AMeet emission standardsOther chemical processesWater/sewage treatment by sorptionSorbentCentrifugation

The invention discloses a method for adsorbing heavy metal ions by a manganese ferrite nanoparticle and graphene compound. The absorbing method comprises the following steps: under conditions of 25 DEG C, pH of about 10 and C0(Ni<2+>) of 20mg / L, adding a manganese ferrite nanoparticle and graphene compound adsorbent, wherein the mass ratio of the adsorbent to heavy metal containing wastewater is 1: (400-600); after mixing for 20 hours, taking mixed liquor, and carrying out high speed centrifugation and magnetic separation, and taking a supernatant liquid; and separating the adsorbent from the wastewater under a magnetic condition after the adsorbent fully contacts the heavy metal containing wastewater. The invention provides an application of the manganese ferrite nanoparticle and graphene compound. According to the method disclosed by the invention, the nano material is used as a heavy metal adsorbent, and the heavy metal absorbent has an excellent performance in heavy metal containing wastewater treatment.

Owner:JIANGSU PROVINCIAL ACAD OF ENVIRONMENTAL SCI +1

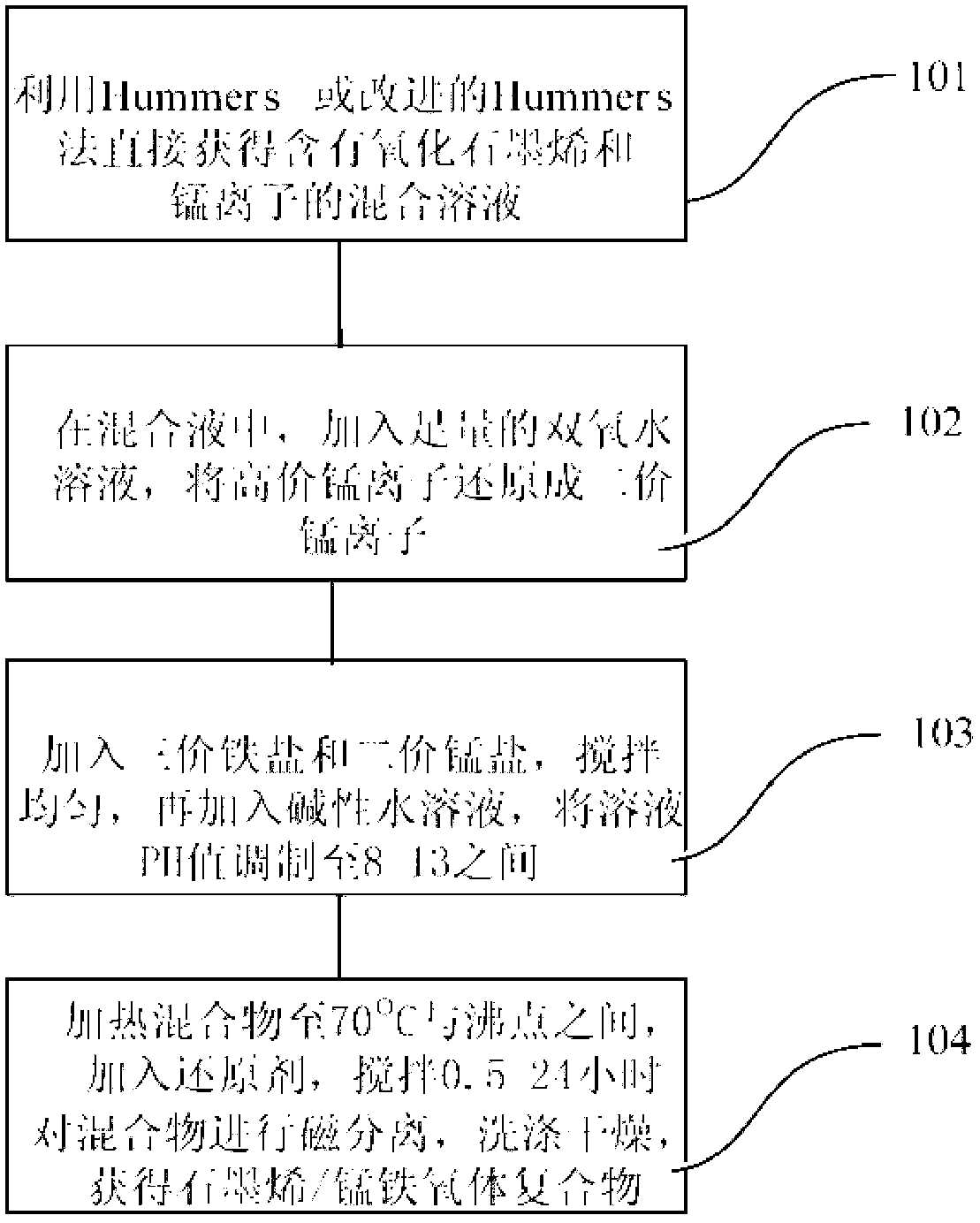

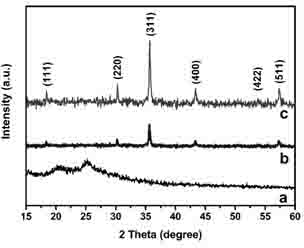

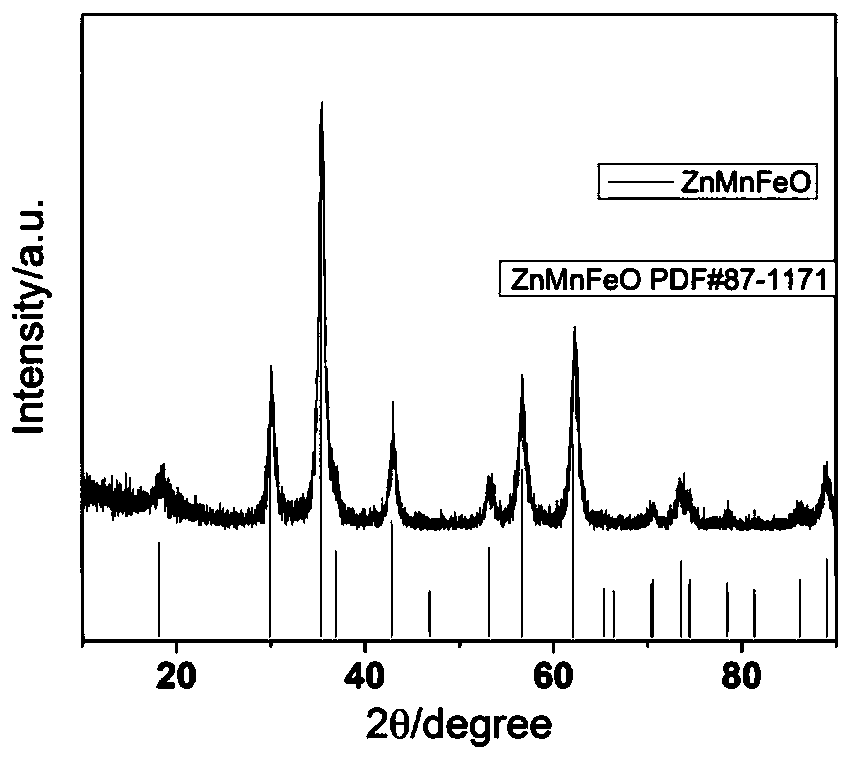

Method for degrading organic wastewater through heterogeneous ultraviolet catalytic oxidation

InactiveCN106745662AAdsorptiveGood photocatalytic oxidation treatment effectWater/sewage treatment by irradiationWater treatment compoundsFully developedCatalytic oxidation

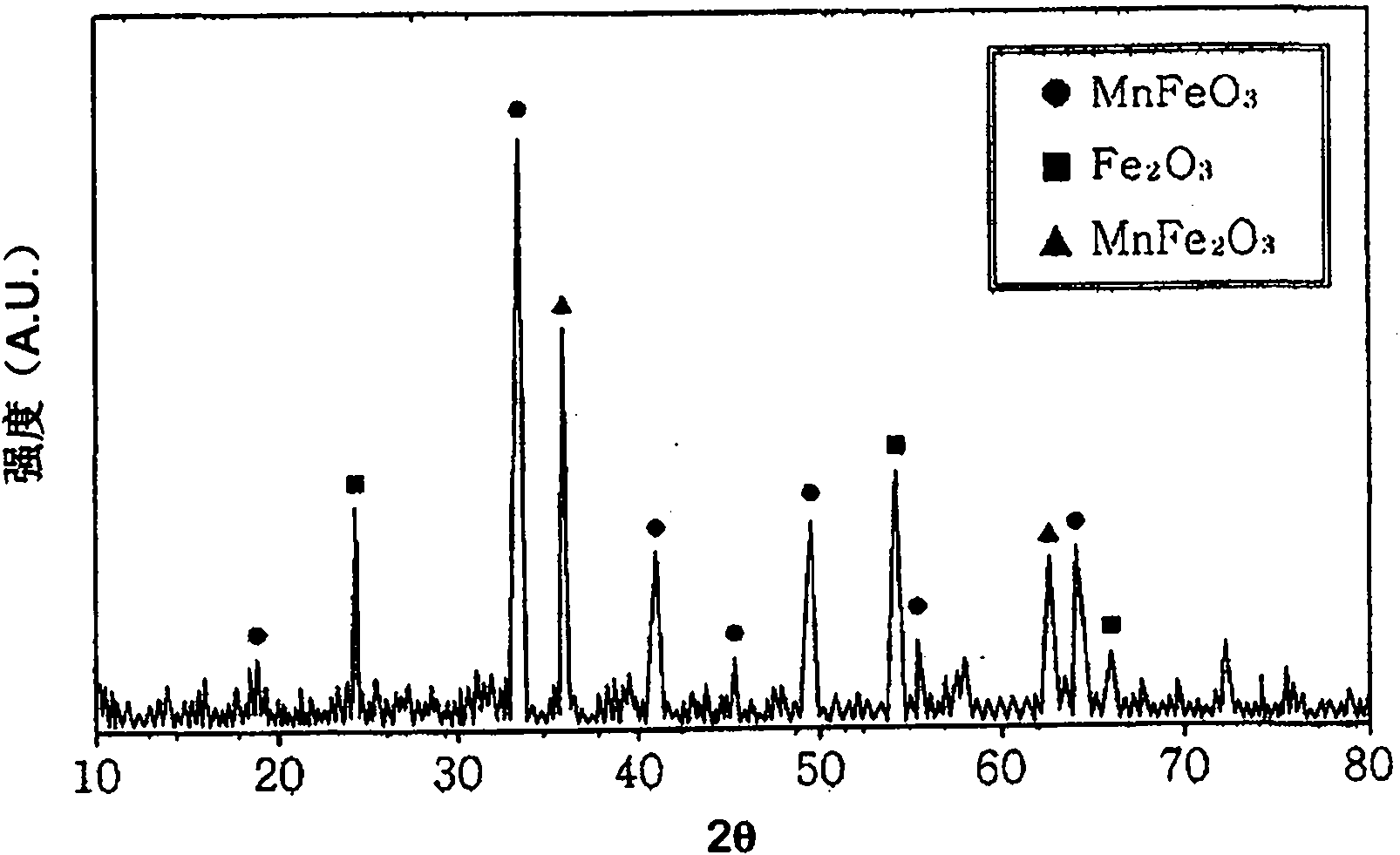

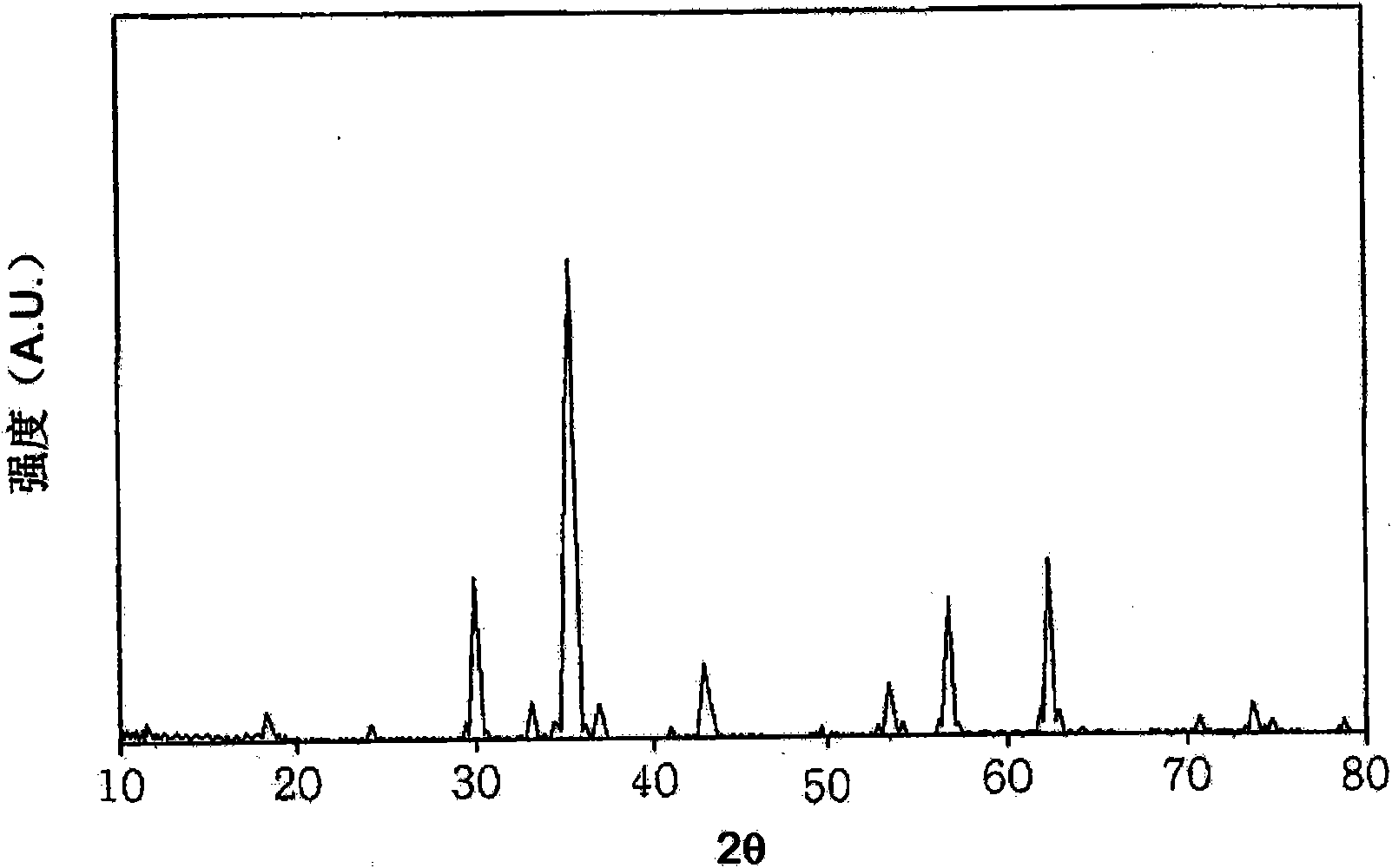

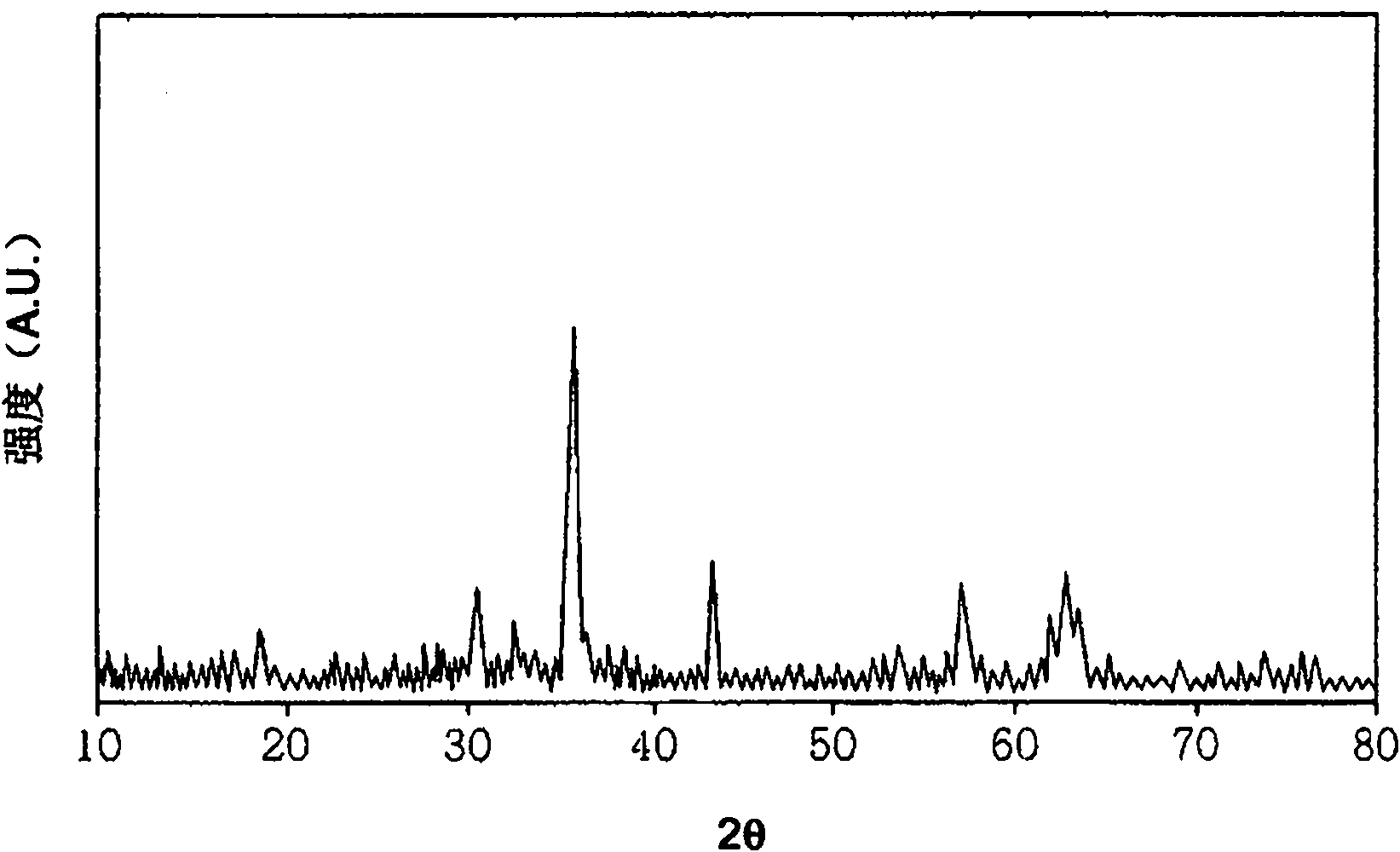

The invention discloses a method for degrading organic wastewater through heterogeneous ultraviolet catalytic oxidation. The method comprises the following steps of firstly preparing manganese ferrite by adopting a chemical co-precipitation method; sequentially adding the manganese ferrite, organic wastewater and hydrogen peroxide to an organic wastewater treatment device; and finally opening an ultraviolet source of the organic wastewater treatment device for radiation treatment of the organic wastewater. Through common action of ultraviolet Fenton reaction, the manganese ferrite and the hydrogen peroxide, the advantages of the ultraviolet Fenton reaction, the manganese ferrite and the hydrogen peroxide are fully developed to obtain a good organic wastewater treatment effect; H2O2 is catalyzed by using ultraviolet light and the manganese ferrite to degrade 50mg / L of 1.2.4-acid-simulated dye wastewater, so that the degradation rate can reach 85.93%; and representation is carried out by virtue of an X-ray diffractometer, and the result shows that the crystal structure of the manganese ferrite is free of an obvious difference before and after wastewater degradation, and the effect of catalytically degrading 1.2.4-acid by the manganese ferrite is free of an obvious change after being used for multiple times.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

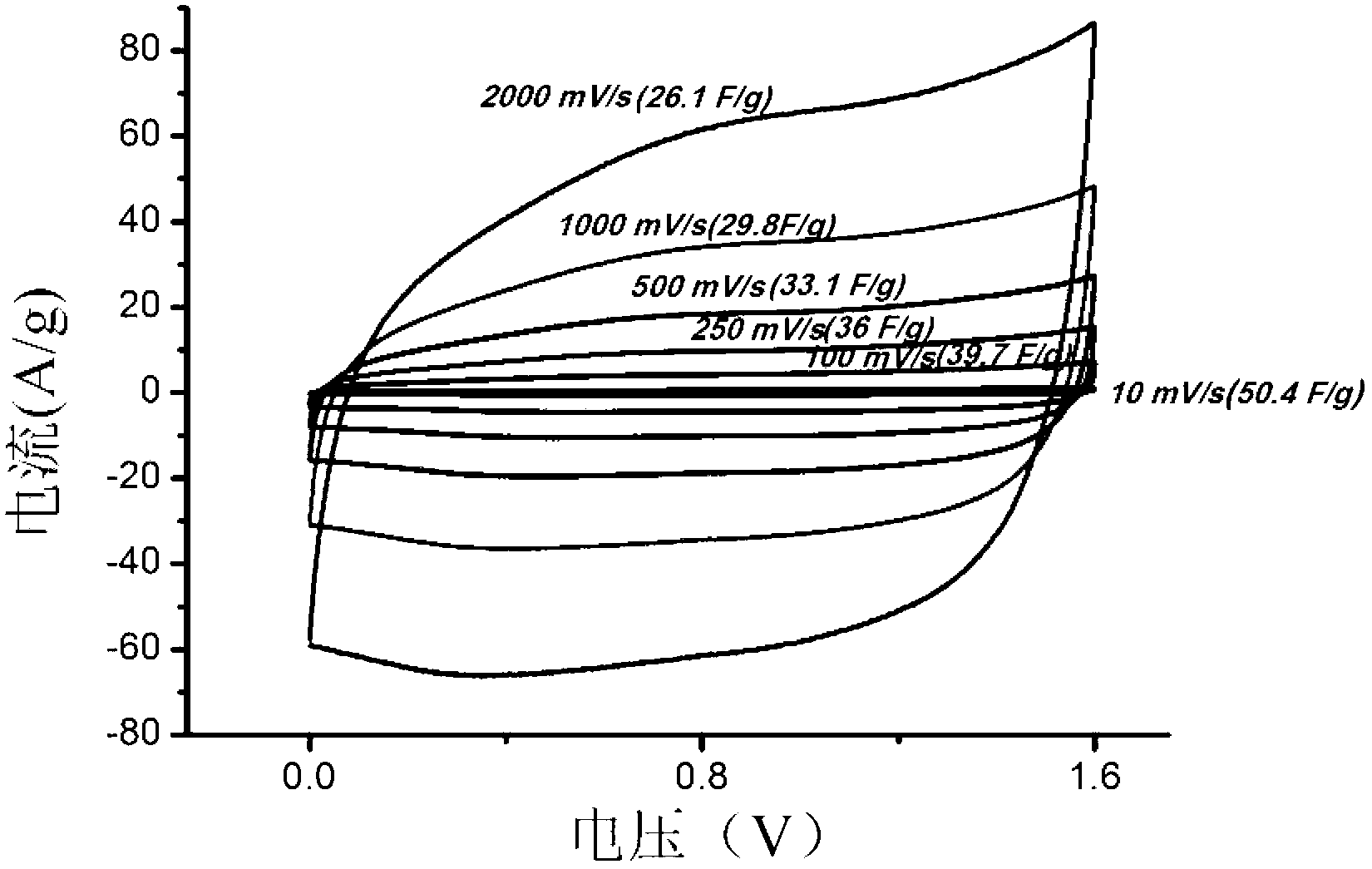

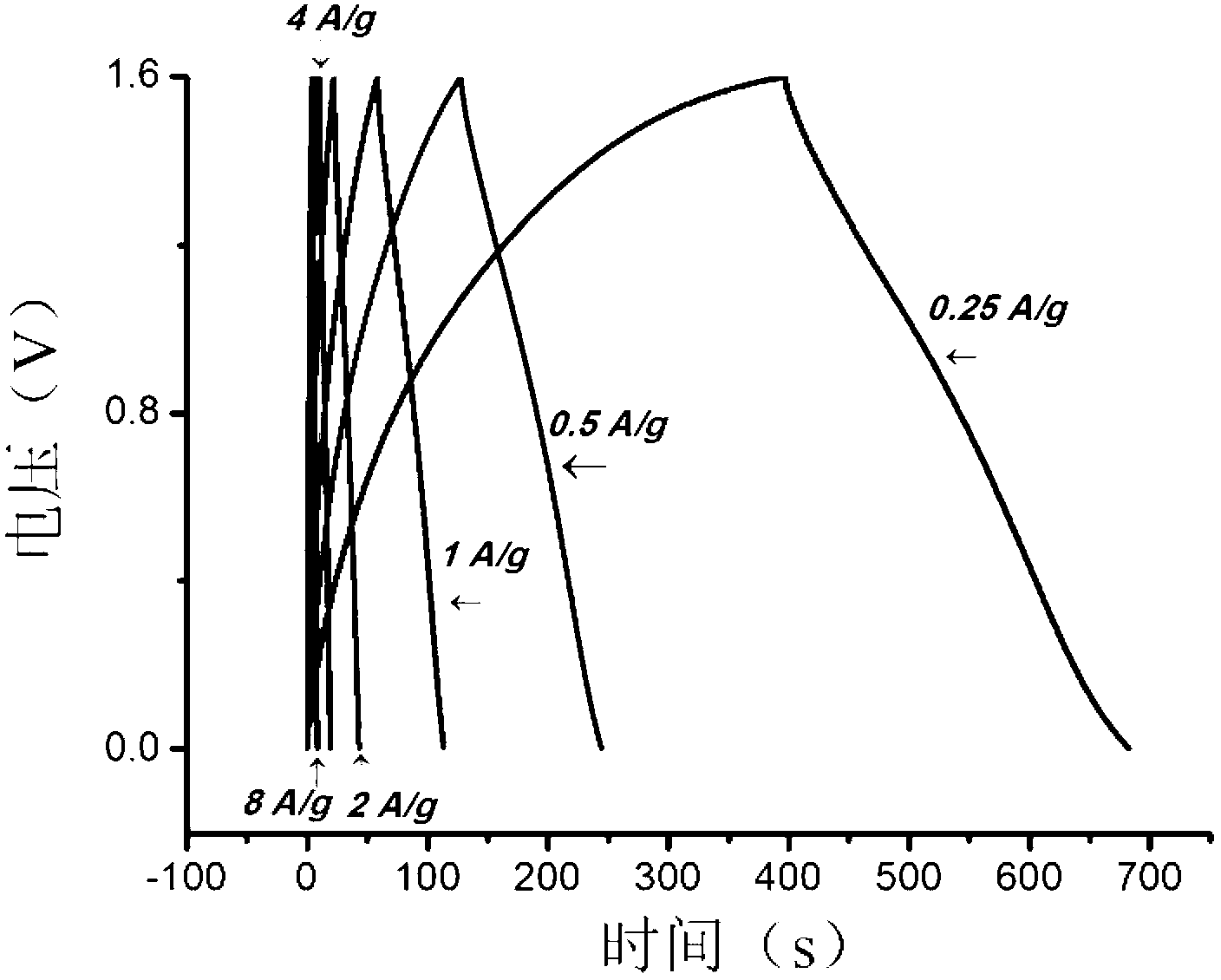

Water system neutral electrolyte-based asymmetric supercapacitor and preparation method thereof

InactiveCN103077834AImprove ionic conductivityLow costHybrid capacitor electrolytesHybrid capacitor electrodesCapacitanceCarbon nanotube

The invention relates to a water system neutral electrolyte-based asymmetric supercapacitor and a preparation method thereof, wherein the working voltage of the water system neutral electrolyte-based asymmetric supercapacitor is 1.6V. An anode active material of the water system neutral electrolyte-based asymmetric supercapacitor is made of a manganese dioxide nano sheet or manganese dioxide nano sheet / carbon nanotube composite material, and a cathode active material of the water system neutral electrolyte-based asymmetric supercapacitor is made of a manganese ferrite nano particles or a manganese ferrite nano particle / graphene composite material. A super capacitor electrolyte adopts a water system neutral sodium sulfate solution and is packaged into the super capacitor. The water system neutral electrolyte-based asymmetric supercapacitor has the advantages of high specific capacitance and energy density and excellent rate performance and cycle performance.

Owner:NANJING UNIV OF SCI & TECH

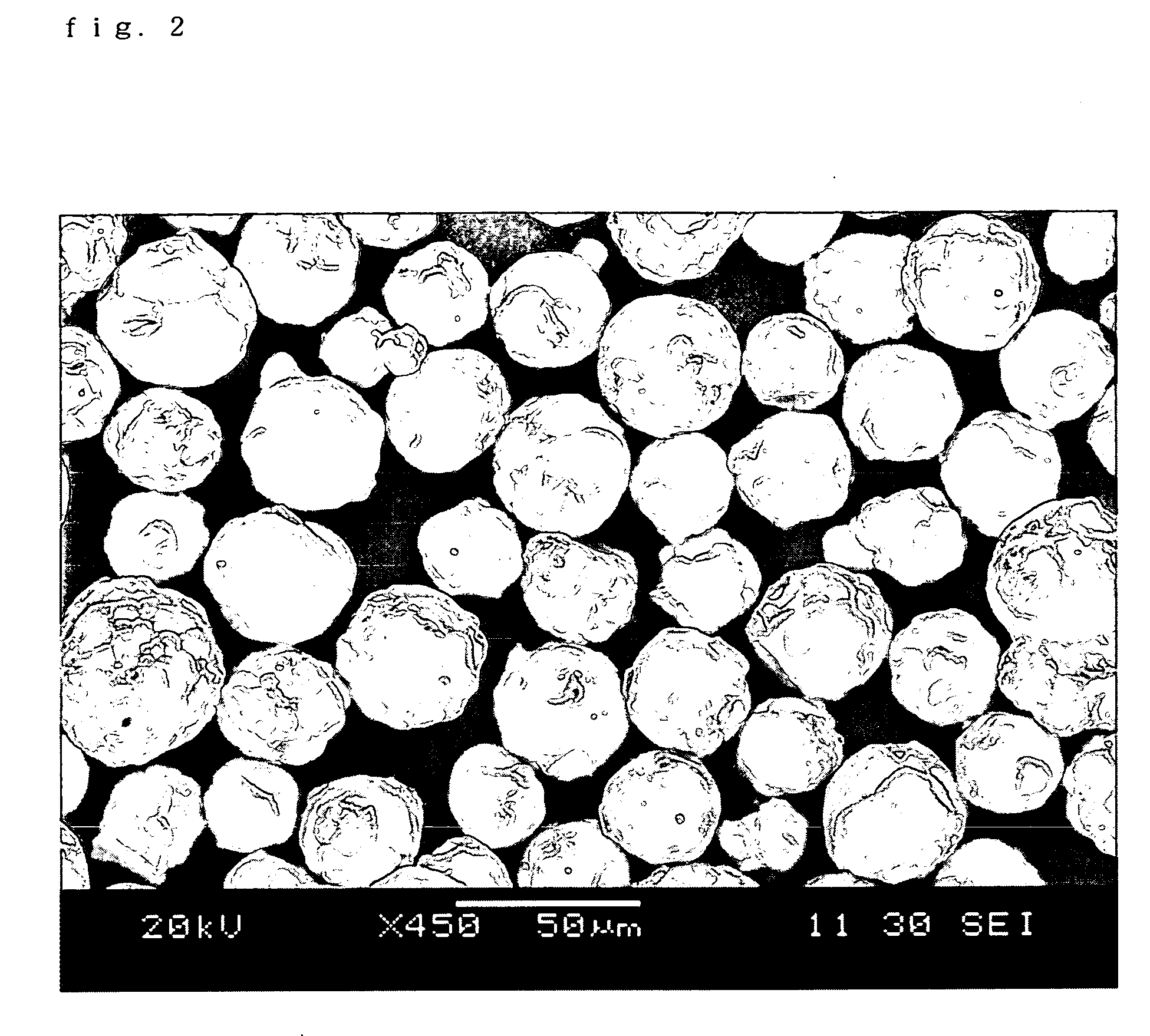

Carrier, developer, image forming apparatus and process cartridge

InactiveUS20060291911A1Maintain propertiesElectrographic process apparatusDevelopersImaging equipmentMaterials science

A carrier including a manganese ferrite core material having a layer on its surface such that 0.1≦K≦30, where K=(S / M)×100, S and M represent the standard deviation and average of M2 / (M1+M2), respectively, M ranging from 0.05 to 0.45, and M1 and M2 represent the content of iron and manganese, respectively, in a carrier particle. The carrier has a magnetization ranging from 45 to 75 emu / g at 1,000 Oe, a mass-averaged particle diameter, D4, ranging from 25 to 65 μm and carrier particles having a particle diameter not greater than 12 μm are included in an amount not greater than 0.3% by weight, and a ratio, D4 / D1, ranging from 1 to 1.3, where D1 is a number-averaged particle diameter of the carrier.

Owner:YAMASHITA MASAHIDE +2

Seedling raising matrix and seedling raising method for soilless rice plate

ActiveCN102584422AImprove practicalityStrong water absorptionSeed and root treatmentAgriculture gas emission reductionRoom temperatureCrusher

The invention relates to a seedling raising matrix and a seedling raising method for a soilless rice plate, and belongs to the technical field of plate raising matrixes of crop seedlings. The seedling raising matrix is characterized by being prepared by the following steps of: preparing a phosphate buffer solution of which the pH value is 4.0 to 5.5, preparing acrylic acid and / or an acrylamide solution by using the phosphate buffer solution, adding N,N'-methylene bisacrylamide serving as a crosslinking agent, stirring, dissolving, adding water and manganese ferrite black or fine earth before polymerization, and stirring uniformly; adding an initiator and a stabilizer into a reaction mixed solution, stirring uniformly, and performing crosslinking reaction at room temperature to generate a solidified substance; and after the reaction is finished, crushing the solidified substance by using a crusher, and sieving to obtain the final product. According to the seedling raising matrix and the seedling raising method for the soilless rice plate, the matrix is high in hydroscopicity and water-retaining property, the cultivation of seedlings with robust roots is facilitated, and particularly, the seedling raising matrix and the seedling raising method are suitable for the plate seedling raising of a mechanical rice transplanter; and the seedling raising matrix and the seedling raising method are easy and convenient to operate by farmers or seedling raising factories, little in using amount and low in cost, and the acrylic acid and acrylamide polymers are easy to degrade in fields.

Owner:CHINA NAT RICE RES INST +1

Bismuth manganese iron alloy

The invention discloses a bismuth-manganese-ferrite alloy. The alloy is characterized in that the weight percentages of the components of the alloy are as follows: 20 percent to 70 percent of bismuth, 20 percent to 70 percent of manganese, less than or equal to 2 percent of carbon, less than or equal to 0.8 percent of inevitable impurities, and the balance of ferrite. The alloy has the advantages of having practical alloying treatment and high yielding rate of bismuth and is an additive for free-cutting steel alloying treatment.

Owner:WUFAN ALLOY ALUMINUM WUJIN

Mixed manganese ferrite coated catalyst, method of preparing the same, and method of preparing 1,3-butadiene using the same

ActiveUS9550174B2Enhanced inhibitory effectImprove conductivityHydrocarbon by hydrogenationCatalystsButeneDehydrogenation

This invention relates to a method of preparing a mixed manganese ferrite coated catalyst, and a method of preparing 1,3-butadiene using the same, and more particularly, to a method of preparing a catalyst by coating a support with mixed manganese ferrite obtained by co-precipitation at 10˜40° C. using a binder and to a method of preparing 1,3-butadiene using oxidative dehydrogenation of a crude C4 mixture containing n-butene and n-butane in the presence of the prepared catalyst. This mixed manganese ferrite coated catalyst has a simple synthetic process, and facilitates control of the generation of heat upon oxidative dehydrogenation and is very highly active in the dehydrogenation of n-butene.

Owner:SK INNOVATION CO LTD

Preparation method of phase-change solar heat-absorption coating with high heat absorption rate

InactiveCN108976880AImprove thermal conductivityImprove efficiencyChemical industryPolyurea/polyurethane coatingsHigh energyPolyethylene glycol

The invention discloses a preparation method of phase-change solar heat-absorption coating with a high heat absorption rate and belongs to the technical field of preparation of coating. According to the preparation method, after an emulsifier OP-10, liquid paraffin and hydrochloric acid are acidified and dissolved, a mixture is homogenized and emulsified under a heating state to obtain oil-in-water emulsion; outer holes of organic dispersion carbon nanotubes are blocked through black absorbents including a manganese ferrite black spinel pigment, carbon black, copper oxide powder and the like;on one hand, added titanium white has a light extinction effect; on the other hand, titanium dioxide is used as a photo-thermal absorption catalyst and can be compounded with silicon dioxide in thermal phase-change microcapsules, so that adjustable phase change temperature, shaping and phase change energy storage, and high energy storage density of a material are realized; polyethylene glycol 10000 with high latent heat and the liquid paraffin which easily has phase change at room temperature are utilized, so that the energy storage efficiency of the phase change material is improved; the surface of a carbon nanotube material is modified by utilizing p-nitroaniline diazonium salt; the distribution of a phase change substance in the phase change material is more uniform through high heat conductivity and high specific surface area of the carbon nanotube material, and convection and heat dissipation of the coating are reduced, so that the preparation method has a wide application prospect.

Owner:FOSHAN TENGLI NEW ENERGY TECH CO LTD

Magnetic adsorption material, preparation of magnetic adsorption material and method for treating thallium-containing wastewater

The invention discloses a magnetic adsorption material, preparation of the magnetic adsorption material and a method for treating thallium-containing wastewater. The magnetic adsorption material is manganese dioxide loaded manganese ferrite. The preparation method is characterized in that manganese acetate is dissolved in water; citric acid is added for dissolution and dilution; manganese ferriteis added; after uniform mixing, drying, crushing and roasting are performed, the magnetic adsorption material can be obtained. The method for treating thallium-containing wastewater by using the magnetic adsorption material is characterized in that 1, the manganese dioxide loaded manganese ferrite is added into thallium-containing industrial wastewater; the magnetic adsorption material adsorbs thethallium in the industrial wastewater; 2, an external magnetic field is used for attracting the magnetic adsorption material attached with the thallium; 3, solid liquid separation is performed; supernate is treated water removing the thallium element. The process for recovering the thallium element by the magnetic adsorption material is characterized in that nitric acid is added into the magnetic adsorption material attached with the thallium for regulating the pH value; the external magnetic field attracts the magnetic adsorption material completing the desorption; solid and liquid separation is performed; the supernate is enriched recovery liquid concentrating the thallium element.

Owner:CHONGQING UNIV

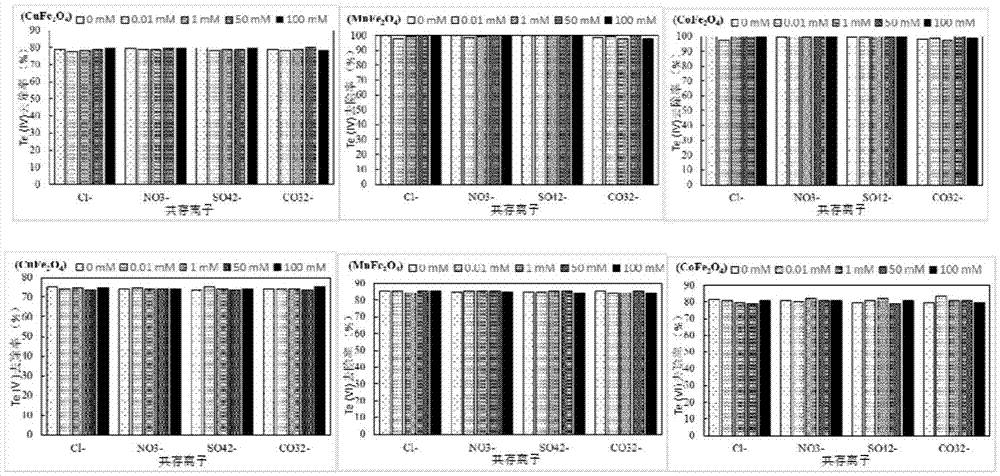

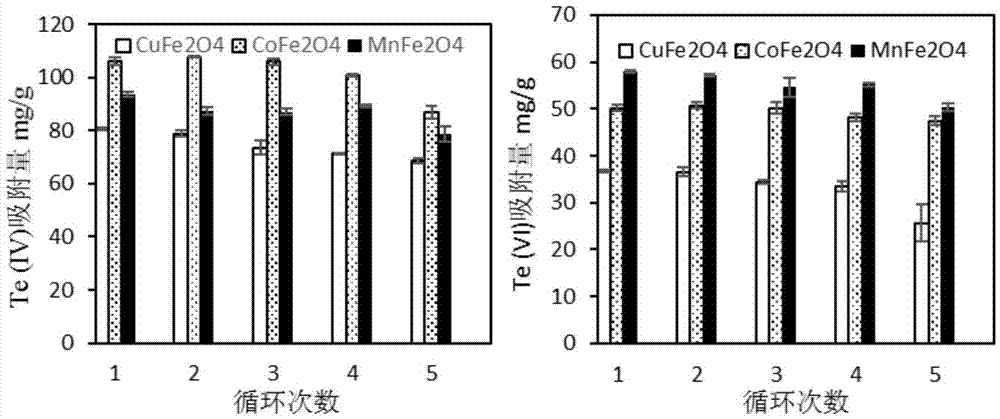

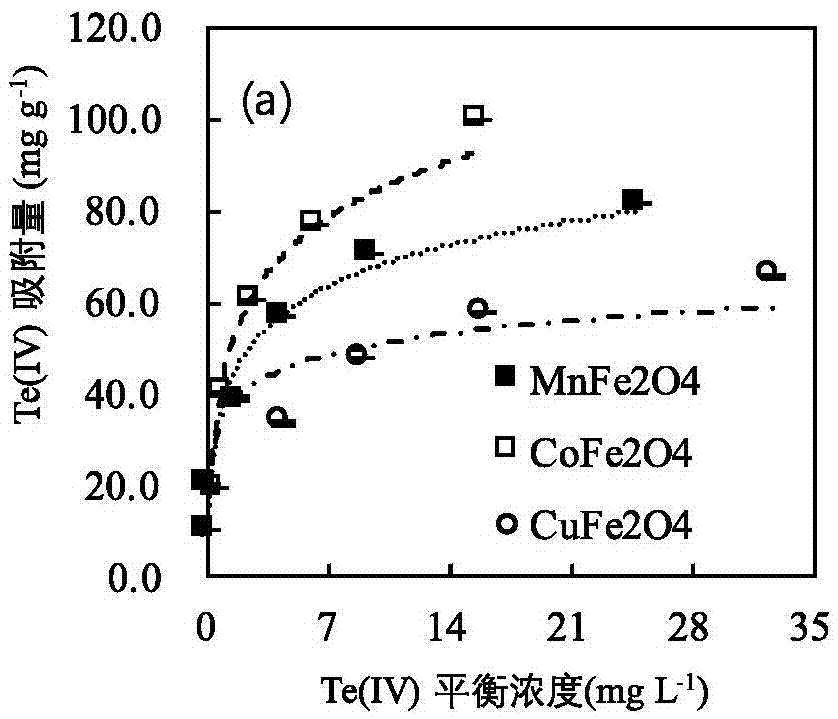

Method for applying ferrite MFe2O4 magnetic nano-particles to removal of tellurium-containing wastewater and application of ferrite MFe2O4 magnetic nano-particles

ActiveCN105439272ALarge adsorption capacityImprove removal efficiencyOther chemical processesWater treatment compoundsMagnetite NanoparticlesMaterials science

The invention relates to a method for applying ferrite MFe2O4 magnetic nano-particles to removal of tellurium-containing wastewater and an application of the ferrite MFe2O4 magnetic nano-particles. The method for applying the ferrite magnetic nano-particles to removal of the tellurium-containing wastewater is described in details in the description. Three types of the ferrite magnetic nano-particles of iron cobalt ferrite, iron copper ferrite and iron manganese ferrite are provided. The method provided by the invention has the advantages that: the ferrite magnetic nano-particles are large in specific area, high in adsorption capacity to tellurium and high in removal rate; the technology, when used for removing the tellurium-containing wastewater, is little influenced by coexisting anions of Cl, SO4<2>, CO3<2> and NO3 in the tellurium-containing wastewater; materials used in the technology are strong in magnetism, and can be easily separated from a water body in a short time for recycling by virtue of an external magnetic field after absorbing pollutants; and the desorbed tellurium can be recycled easily. According to the method, the treatment of the wastewater is finished, and the recycling of tellurium is realized at the same time, therefore, the ferrite magnetic nano-particles have a broad application prospect in removal of metal anions. The ferrite magnetic nano-particles provided by the invention are mainly applied to the removal of tellurium, including tellurate radical and tellurite radical ions in the tellurium-containing wastewater.

Owner:PEKING UNIV

Catalyst for preparing butadiene from mixed C4 and preparation method thereof

InactiveCN103316688AHigh activityImprove stabilityHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsIron saltsAdhesive

The invention discloses a catalyst for preparing butadiene from mixed C4 and a preparation method thereof. According to the catalyst, zinc ferrite serves as an active main body, and manganese ferrite and calcium ferrite serve as auxiliary active ingredients. The method comprises the following steps: mixing an iron salt solution, a zinc salt solution, a manganese salt solution and a calcium salt solution according to a certain ratio, so as to obtain a coprecipitation solution under the action of an alkaline solution; filtering and washing to obtain a catalyst sol, molding, drying and roasting the sol to obtain an axial fixed bed or constant-temperature fixed bed catalyst used for a fixed bed reaction process; preparing slurry from the sol and an adhesive with a certain ratio, and performing spray drying forming, drying and roasting to obtain a fluidized bed catalyst used for a fluidized bed reaction process. The catalyst has high activity and stability on dehydrogenation production of butadiene through the mixed C4 under the condition of the presence of oxygen, the conversion per pass of the butane in the mixed C4 is 88-93 percent, the selectivity on the butadiene is over 95 percent, and the catalyst can be applied to the field of industrial production of the butadiene.

Owner:王伟跃

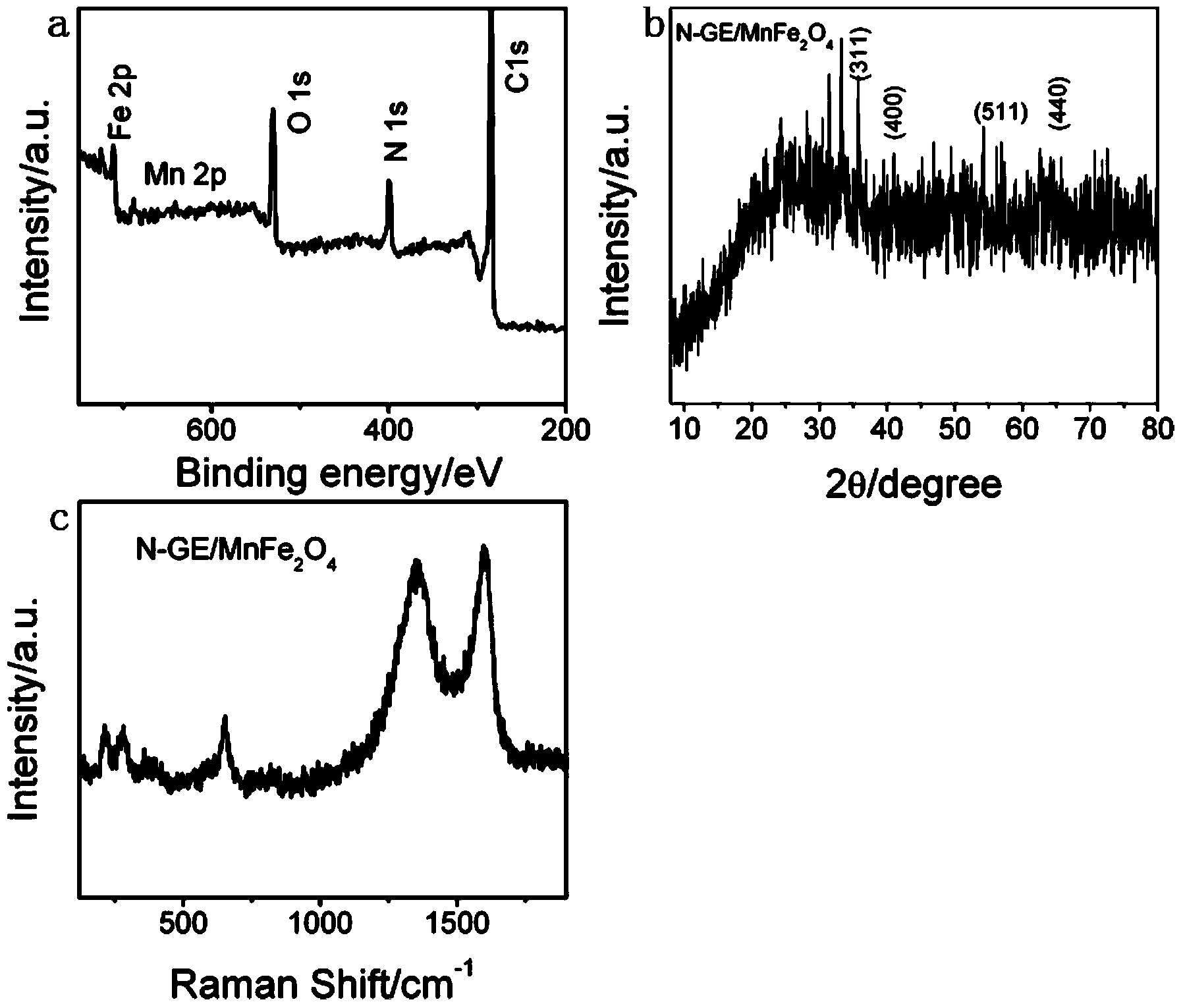

Nanocomposite material of nitrogen doped with graphene/manganese ferrite and preparation method thereof

ActiveCN103887079AReduce pollutionPrevent buildup agglomerationMaterial nanotechnologyHybrid capacitor electrodesNitrogen doped grapheneUltrasonic dispersion

The invention discloses a preparation method of a nanocomposite material of nitrogen doped with graphene / manganese ferrite. The method comprises the steps that prepared graphite oxides are put in absolute ethyl alcohol for conducting ultrasonic dispersion; afterwards, weighed manganous nitrate and ferric nitrate are added into the above dispersion solution and stirred until the manganous nitrate and the ferric nitrate are completely dissolved; at last, a certain amount of urea is added in the mixed solution, after the urea is stirred and dissolved, the mixed solution is moved into a flask, and the nanocomposite material of the nitrogen doped with the grapheme / manganese ferrite can be obtained after reaction. According to the nanocomposite material of the nitrogen doped with the graphene / manganese ferrite and the preparation method thereof, the urea is used for reduction of the graphite oxides, in the reduction process, nitrogen atoms are doped on the surface of graphene, the doping of the nitrogen atoms changes the surface chemical property of the graphene, and the alkalinity of the urea enables the manganese ferrite to be formed on the surface of the nitrogen doped with the graphene while the surface defect of the graphene prepared through a chemical method is overcome. Manganese ferrite nano particles can further prevent graphene from being piled up together between layers, and the electrochemical property of the nanocomposite material of the nitrogen doped with the graphene / manganese ferrite is improved.

Owner:NANJING UNIV OF SCI & TECH

Method for preparing Mn-Zn-Ni ferrite magnetic material by using low-grade nickel resource

ActiveCN107602108AEfficient separationImprove performanceInorganic material magnetismInductances/transformers/magnets manufactureLower gradeLow graded

The invention discloses a method for preparing a Mn-Zn-Ni ferrite magnetic material by using a low-grade nickel resource. The method comprises the following steps: performing fine grinding on a low-grade nickel resource, a manganese source, an iron source, a calcareous flux and a binder to prepare agglomerate; drying the agglomerate, performing primary roasting, and performing fine grinding and magnetic separating on the roasted agglomerate to obtain magnetic concentrate; mixing the magnetic concentrate and a zinc source, compacting the materials, and performing secondary roasting on a mouldedmaterial to obtain the Mn-Zn-Ni ferrite magnetic material. Compared with a traditional magnetic method that a pure substance is roasted to prepare the manganese ferrite, the method can directly employ mineral or secondary resource with large reserves as a raw material, the purity of the Mn-Zn-Ni ferrite is high, the magnetic property is good, and the method has the advantages of wide raw materialsource, simple process, low cost, and easy realization of industrial production.

Owner:CENT SOUTH UNIV

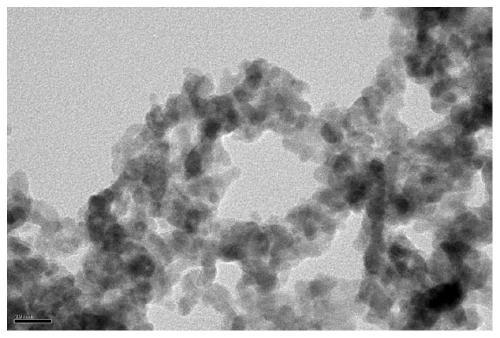

Preparation method of nano-scale manganese ferrite catalyst with high specific surface area

InactiveCN109745996ALow priceAvoid reunionWater contaminantsMetal/metal-oxides/metal-hydroxide catalystsOrganic fuelEnergy consumption

The invention relates to a preparation method of nano-scale manganese ferrite catalyst with high specific surface area. The method comprises the following steps: (1)dissolving ferric salt and manganese slat in deionized water according to the proportion that the mole ratio of the Fe element to the Mn element is (1.8-2.2):1, and preparing a solution A; (2) adding an organic fuel in the solution A prepared in the step (1), then adding inert salt NaCl, dissolving and regulating pH to prepare a raw material solution; (3) burning the raw material solution prepared in the step (2), cleaning and drying to prepare the nano-scale manganese ferrite catalyst with high specific surface area. The method disclosed by the invention is relatively low in ignition temperature, less in preparation energy consumption, short in reaction time and high in speed.

Owner:SHANDONG UNIV

Fly ash glass bead-ferrite compound microwave absorbing material and preparation method thereof

InactiveCN108949103AImprove absorbing performanceWith sound absorption effectOther chemical processesMagnetic/electric field screeningMicrowaveAbsorption effect

The invention provides a fly ash glass bead-ferrite compound microwave absorbing material and a preparation method thereof. The compound microwave absorbing material comprises fly ash glass beads andferrite coating the surface of the fly ash glass beads, wherein the ferrite is selected from one or more of barium ferrite BaFe12O19, barium cobalt ferrite BaCox1Fe(12-x1)O19, nickel barium ferrite BaNix2Fe(12-x2)O19 and manganese ferrite MnFe12O19, wherein x1 is 0.5-1, and x2 is 0.5-1. The compound microwave absorbing material has excellent microwave absorbing performance by coating the fly ash glass beads with a specific type of ferrite, has light weight and certain sound absorption effect. The compound microwave absorbing material has a density of 0.6-1g / cm<3>, and has a sound absorption coefficient of 0.34-0.66 and echo reduced by 5-8dB in 1-5kHz.

Owner:GUANGDONG TSINGDA TONGKE ENVIRONMENTAL PROTECTION TECH CO LTD

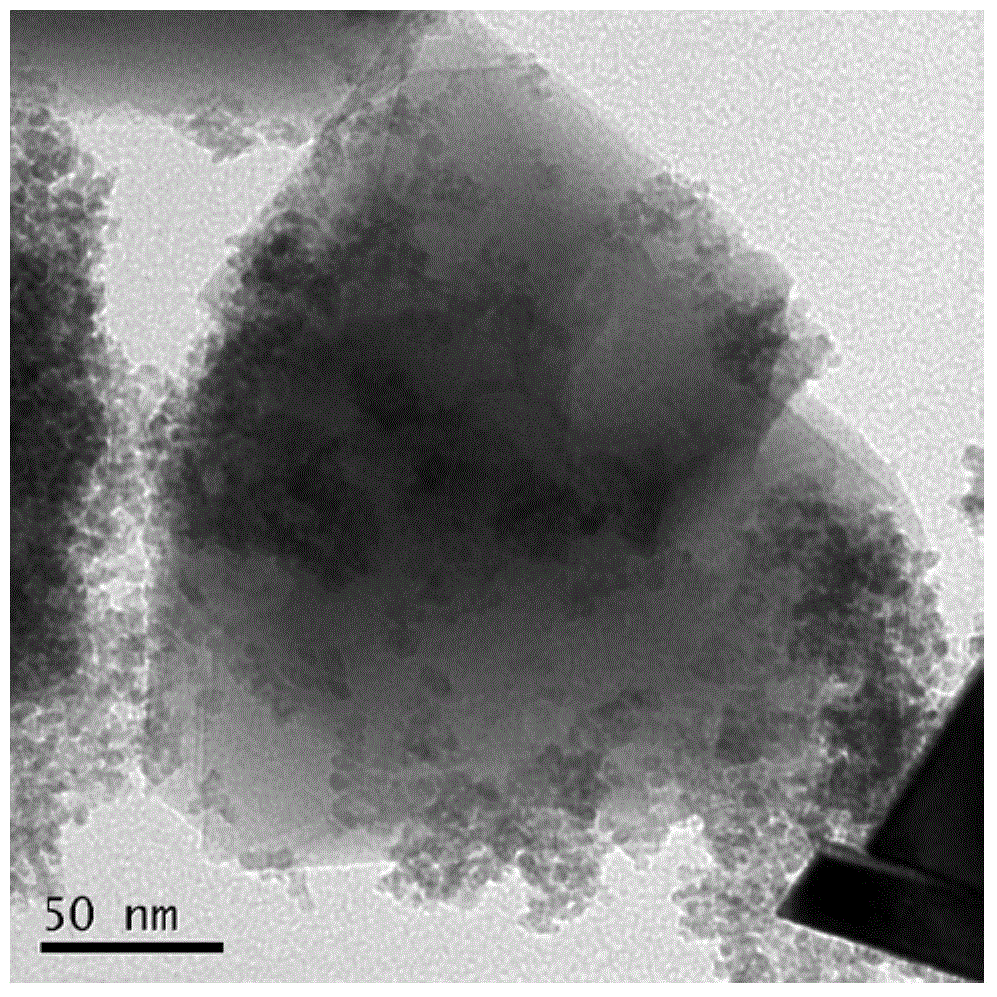

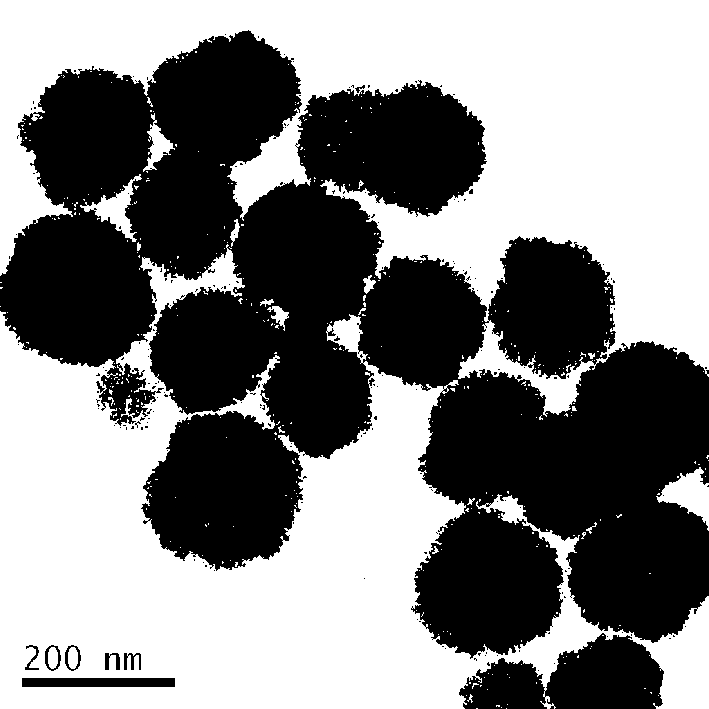

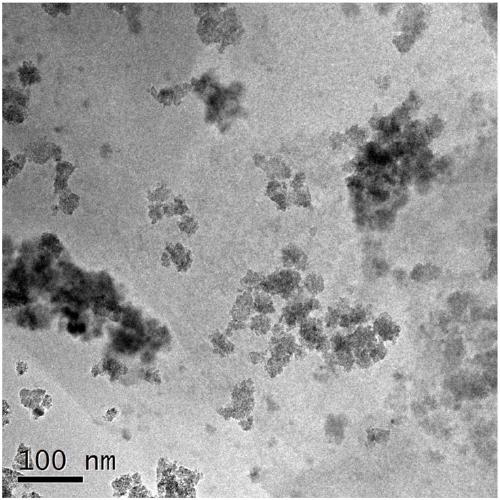

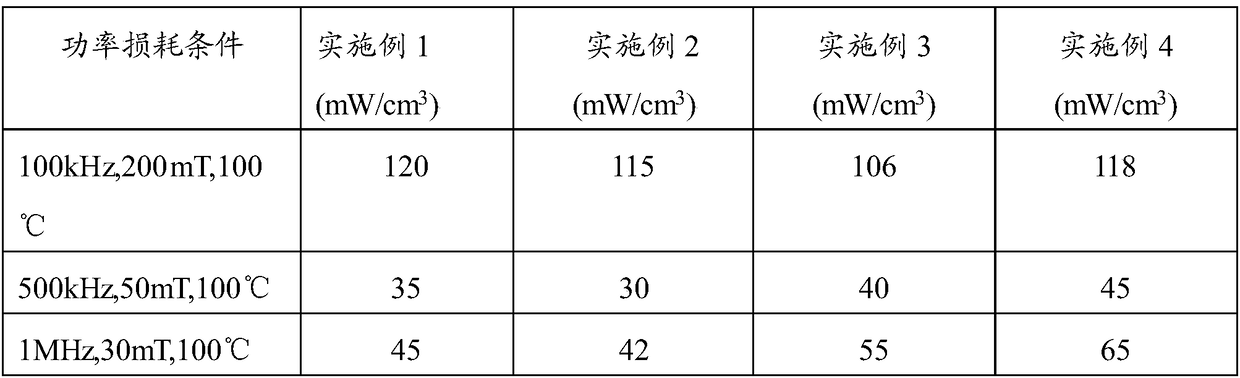

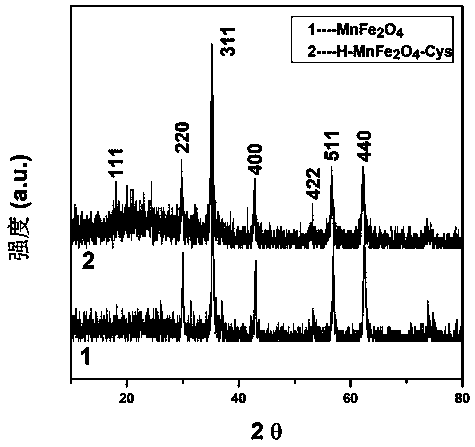

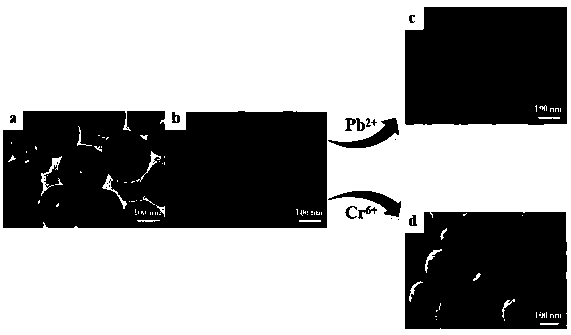

Preparation method of cysteine-functionalized magnetic hollow manganese ferrite nano composite adsorbent

ActiveCN109569518ASimple processHigh yieldOther chemical processesAlkali metal oxides/hydroxidesMagnetizationMesoporous material

The invention discloses a preparation method of a cysteine-functionalized magnetic hollow manganese ferrite nano composite adsorbent. The preparation method includes preparation of MnFe2O4 magnetic particles, preparation of magnetic hollow MnFe2O4 nano particles and surface cysteine functionalization of the magnetic hollow MnFe2O4 nano particles and other steps; MnFe2O4 having particle size of 150-250 nm is used as a base to prepare a hollow composite by using a mixed acid as an etching preparation; the hollow composite reaches 10-45 nm in pore size, 26.67-92.08 m<2> / g in specific surface area, and 32.4-41.18 emu / g in saturated magnetization intensity; in addition, the inner and outer surfaces of the hollow structure are subjected to cysteine functionalization at the same time; the hollowcomposite can better adsorb lead, chromium and other heavy metal ions to 79-81.5%. The preparation method herein is derived from traditional hydrothermal processes; the process is simple, and the yield is high; as the need of traditional preparation of mesoporous materials for adding a pore-forming agent template is omitted, the process steps are simplified, resources are saved, and the cost is lowered.

Owner:LANZHOU JIAOTONG UNIV

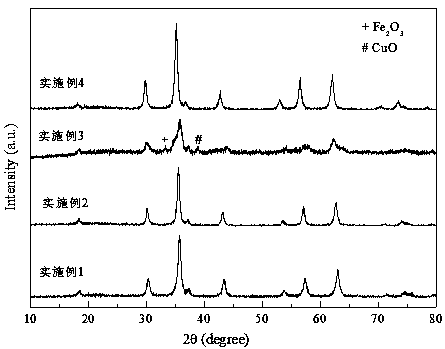

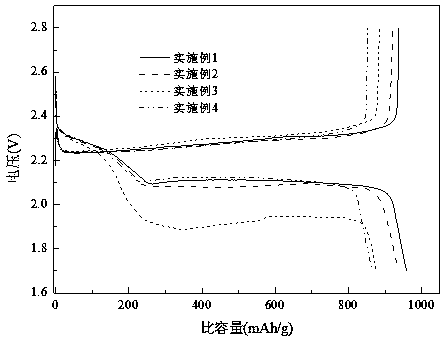

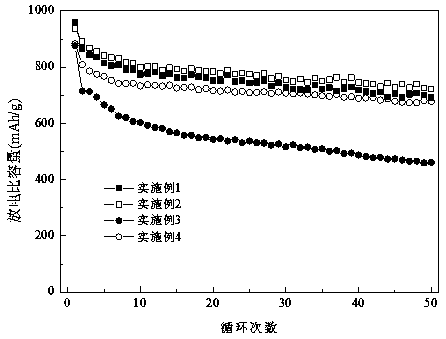

Lithium sulfur battery composite cathode material and preparation method thereof

ActiveCN108054350AMature technologySimple processCell electrodesSecondary cellsChemical adsorptionSulfur utilization

The invention relates to a lithium sulfur battery composite cathode material and a preparation method thereof. The composite cathode material is prepared by compounding ferrite with elemental sulfur.The ferrite is one of magnesium ferrite, zinc ferrite, copper ferrite or manganese ferrite. The preparation method includes: preparing a ferrite material by high temperature calcination method, and then conducting compounding with elemental sulfur by liquid phase method. The preparation method has a mature process and simple procedure, and is easy to acquire a high sulfur content composite cathodematerial. The lithium sulfur battery composite cathode material prepared by the invention utilizes the strong chemical adsorption effect of ferrite on polar lithium polysulfide, greatly inhibits thedissolution of lithium polysulfide in an ether electrolyte solution, accordingly slows down the shuttle effect, and then shows characteristics of high sulfur content, high sulfur utilization and highcycle stability.

Owner:NANKAI UNIV

Method for removing high-concentration thallium-containing industrial wastewater by manganese ferrite

InactiveCN109437465AEasy to produceReduce manufacturing costWater contaminantsMultistage water/sewage treatmentHigh concentrationSorbent

The invention discloses a method for removing high-concentration thallium-containing industrial wastewater by manganese ferrite. The method comprises the steps as follows: 1, adding an oxidizing agentto high-concentration thallium-containing wastewater, performing stirring and oxidizing part of univalent thallium in water into trivalent thallium; 2, adding nanoscale manganese ferrite or a nanoscale manganese ferrite adsorbent coated with humic acid to the wastewater obtained in the step 1 to adsorb trivalent thallium and univalent thallium in water; 3, applying a magnetic field around the wastewater obtained in the step 2, taking a supernatant as obtained treated water, and performing solid-liquid separation on the wastewater; 4, removing the magnetic field after solid-liquid separation in the step 3, taking out a nanoscale manganese ferrite adsorbent solid, and performing desorption to obtain an enriched recovered thallium solution and a regenerated nanoscale manganese ferrite adsorbent. The method has the advantages as follows: nanoscale manganese ferrite is convenient to produce and low in preparation cost and can be repeatedly recycled after being prepared once, and heavy metal thallium can be recovered efficiently.

Owner:CHONGQING UNIV

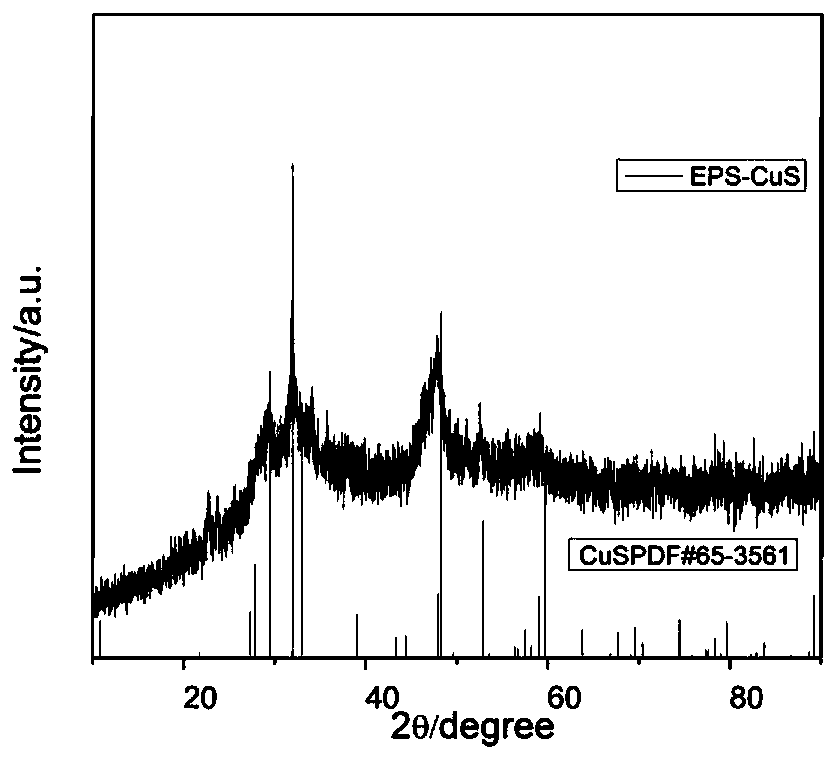

Biological preparation method of nano copper sulfide based on loading of zinc manganese ferrites

PendingCN110064407AGood crystal phaseUniform particle sizePhysical/chemical process catalystsWater/sewage treatment by irradiationPOLYMER SUBSTANCEOrganic dye

The invention relates to a method of loading zinc manganese ferrites with nano copper sulfide, in particular to a method of preparing the nano copper sulfide by loading the zinc manganese ferrites prepared through a bioleachate of waste zinc manganese batteries with copper-containing wastewater, and belongs to the field of solid waste recycling. The method comprises the steps of adding a certain quantity of zinc sources, a certain quantity of manganese sources and a certain quantity of iron sources into the bioleachate of the waste zinc manganese batteries to prepare a solution with corresponding ratio, and synthesizing the zinc manganese ferrites through a hydrothermal method; making extracellular polymeric substances, copper precursors and the zinc manganese ferrites in sufficient contact with one another, conducting standing for 4 hours, adding a sodium sulfide solution dropwise, and obtaining the composite material of loading the zinc manganese ferrites with the nano copper sulfide. In the synthesizing process, the waste zinc manganese batteries and the copper-containing wastewater are utilized as the raw materials and are recycled; the composite material has good magnetism andphotocatalysis, can effectively break down organic dyes in water, is convenient to recycle, and has good application prospects.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com