Biological preparation method of nano copper sulfide based on loading of zinc manganese ferrites

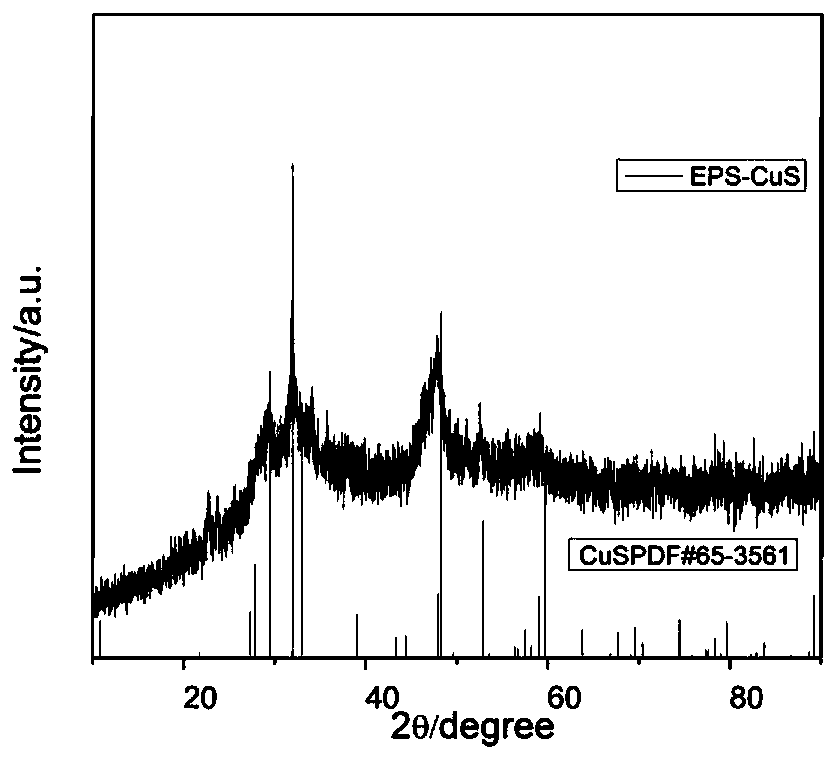

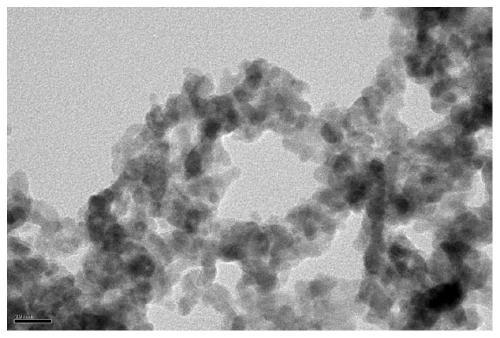

A zinc-manganese-ferro, copper sulfide technology, applied in chemical instruments and methods, chemical/physical processes, water pollutants, etc., can solve the problems of high recycling cost of zinc-manganese batteries, difficult recovery of photocatalysts, low resource utilization, etc. Achieve the effect of good crystal phase, strong photocatalysis, and less environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

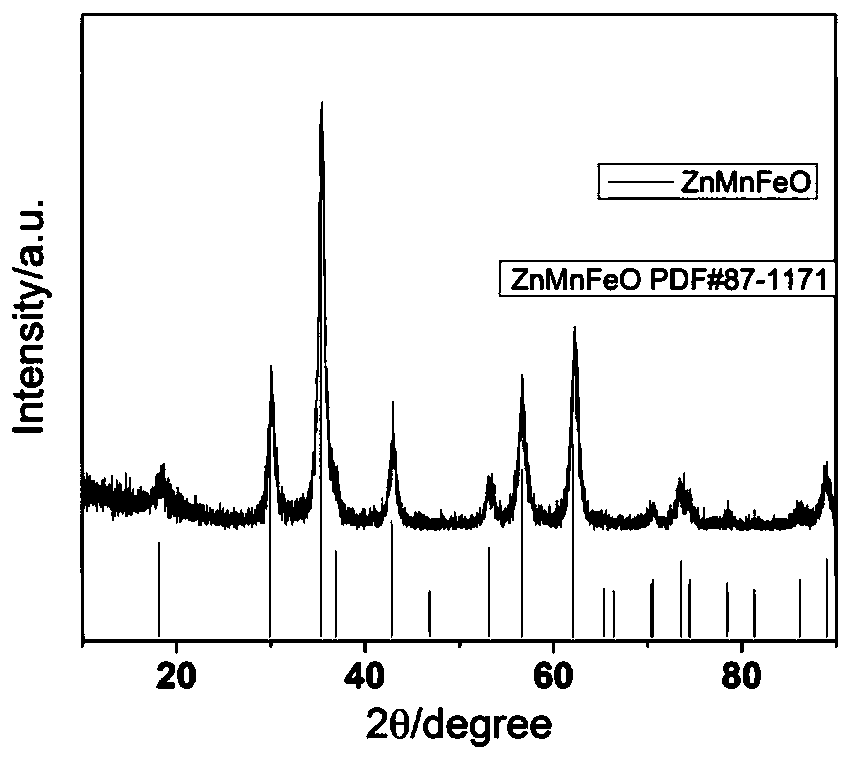

[0036] Implementation case 1: Step 1, preparation of zinc-manganese ferrite

[0037] (1) Determination of the content of zinc ion, manganese ion and iron ion in the biological leach solution of discarded zinc-manganese batteries in the laboratory; Wherein the ratio of manganese ion and zinc ion concentration is controlled at 1.5, and the ratio of manganese ion, zinc ion and iron ion is controlled at 0.5.

[0038] (2) Add manganese source, zinc source, and iron source according to the requirements in step 1 (1), and stir with a magnetic stirrer at room temperature for 24 hours.

[0039] Described manganese source, zinc source, iron source are respectively MnSO 4 , ZnSO 4 , Fe 2 SO 4

[0040] (3) Transfer the solution in step 1 (2) to an autoclave, add coprecipitant to make the pH to 10, and stir thoroughly.

[0041] Described coprecipitant is NaOH

[0042] (4) React the high-pressure reactor in step 1 (3) at a temperature of 180°C for 6 hours; after the reaction, age at ...

Embodiment example 2

[0051] Implementation case 2: Step 1, preparation of zinc-manganese ferrite

[0052] (1) Same as (1) in Step 1 in Implementation Case 1.

[0053] (2) Same as (2) of Step 1 in Implementation Case 1.

[0054] (3) Same as (3) of Step 1 in Implementation Case 1.

[0055] (4) Same as (4) of Step 1 in Implementation Case 1.

[0056] Step 2, preparation of zinc-manganese ferrite-loaded nano-copper sulfide material

[0057] (1) Cultivation of sulfate-reducing bacteria; preparation of medium; solute: 0.6mol / L lactic acid, 14.28g / LNa 2 SO 4 , 1.0g / L NH 4 Cl, 0.5g / L KH 2 PO 4 , 0.5g / L MgSO 4 , 0.1g / L CaCl 2 , 0.5g / L yeast extract powder, and then use 6mol / L NaOH to adjust the pH value of the medium to 7.

[0058] (2) Same as (2) in Step 2 in Implementation Case 1.

[0059] (3) Same as (3) in Step 2 in Implementation Case 1.

[0060] (4) Preparation of zinc-manganese ferrite-loaded nano-copper sulfide material; the EPS in step two (2), the copper precursor in step two (3), and...

Embodiment example 3

[0064] Implementation case 3: Step 1, preparation of zinc-manganese ferrite

[0065] (1) Determination of the content of zinc ion, manganese ion and iron ion in the biological leach solution of discarded zinc-manganese batteries in the laboratory; The concentration ratio of manganese ions and zinc ions is controlled at 2, and the ratio of manganese ions, zinc ions and iron ions is controlled at 0.6.

[0066] (2) Same as (2) of Step 1 in Implementation Case 1.

[0067] (3) Same as (3) of Step 1 in Implementation Case 1.

[0068] (4) Same as (4) of Step 1 in Implementation Case 1.

[0069] Step 2, preparation of zinc-manganese ferrite-loaded nano-copper sulfide material

[0070] (1) Same as (1) in Step 2 in Implementation Case 1.

[0071] (2) Same as (2) in Step 2 in Implementation Case 1.

[0072] (3) Same as (3) in Step 2 in Implementation Case 1.

[0073] (4) Preparation of zinc-manganese ferrite-loaded nano-copper sulfide material; the EPS in step two (2), the copper p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com