Method for preparing manganese-zinc ferrite soft magnet by using waste zinc-manganese battery biological leachate as material

A technology of biological leaching and zinc-manganese batteries, which is applied in the direction of magnetic objects, battery recycling, and waste collector recycling, can solve the problems of poor uniformity, high energy consumption, and high cost, and achieve excellent magnetization, low energy consumption, and low cost. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

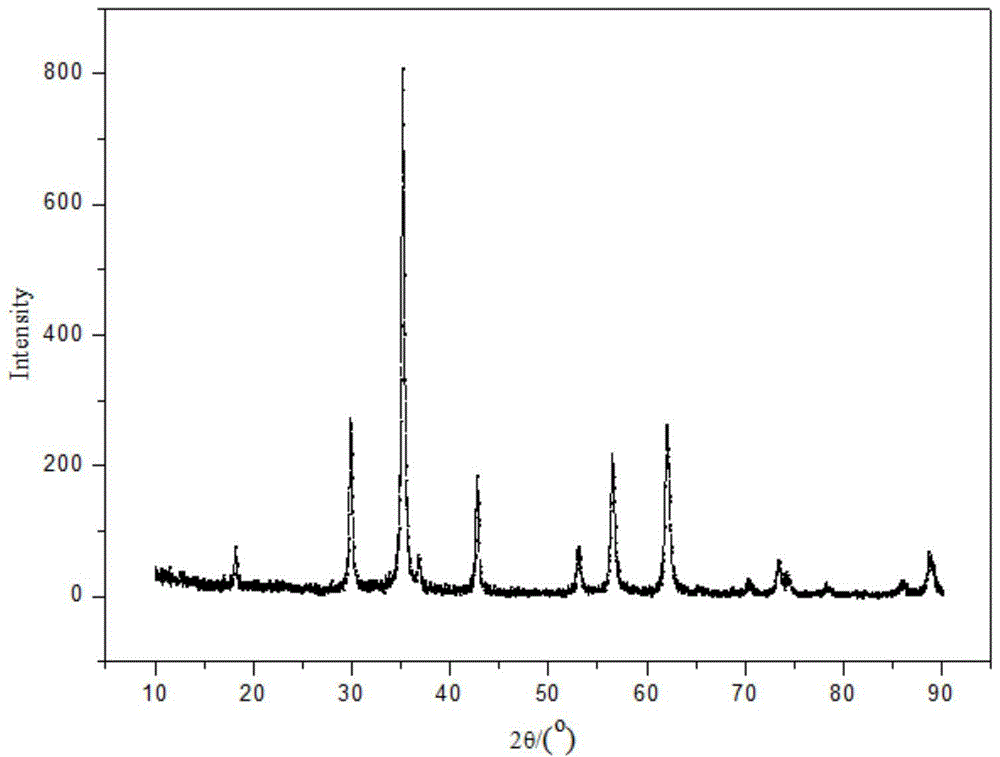

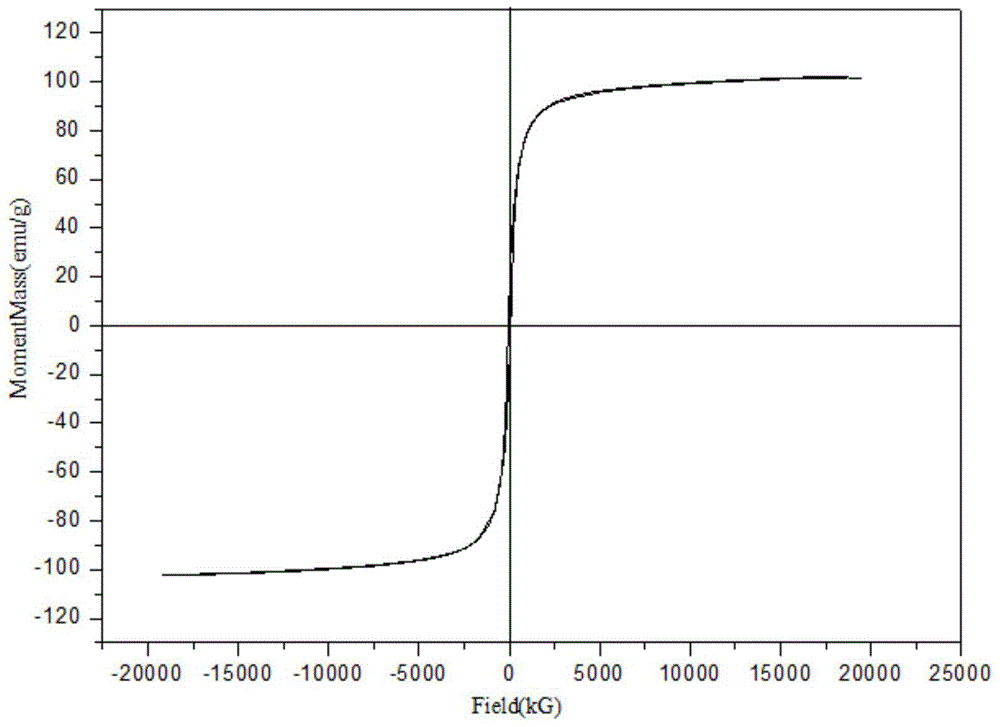

Image

Examples

Embodiment 1

[0031] Step 1. Preparation of bioleachate

[0032] 1. Disassemble the waste zinc-manganese battery, remove single components such as zinc skin, copper cap, carbon rod, etc., collect the positive and negative electrode materials of the battery with complex components and the most concentrated heavy metal content, crush and sieve, and the particle size is 100 microns.

[0033] 2. Preparation of biological leaching medium. Bioleaching medium: (NH 4 ) 2 SO 4 ,2.0g / L;MgSO 4 ,0.5g / L; CaCl 2 ,0.25g / L; KH 2 PO 4 ,1.0g / L;FeSO 4 ,0.1g / L; The solvent is distilled water. The reducing energy substrate is a mixture of sulfur powder and pyrite with a concentration of 12g / L. Simultaneous inoculation of Thiobacillus thiooxidans and Thiobacillus ferrooxidans, the inoculation amount is 5% (v / v);

[0034] 3. After cultivating the bioleaching medium (30°C, 120 rpm) on a shaking table for 7 days, the pH value of the bioleaching solution dropped to 0.8. At this time, the electrode materia...

Embodiment 2

[0048] Step 1. Preparation of bioleachate

[0049] 1. Disassemble the waste zinc-manganese battery, remove single components such as zinc skin, copper cap, carbon rod, etc., collect the positive and negative electrode materials of the battery with complex components and the most concentrated heavy metal content, crush and sieve, and the particle size is 50 microns.

[0050] 2. Preparation of biological leaching medium. Bioleaching medium: (NH 4 ) 2 SO 4 ,2.0g / L;MgSO 4 ,0.5g / L; CaCl 2 ,0.25g / L; KH 2 PO 4 ,1.0g / L;FeSO 4 ,0.1g / L; The solvent is distilled water. The reducing energy substrate is a mixture of sulfur powder and pyrite with a concentration of 12g / L. Simultaneous inoculation of Thiobacillus thiooxidans and Thiobacillus ferrooxidans, the inoculation amount is 5% (v / v);

[0051] 3. After cultivating the bioleaching medium (30°C, 120 rpm) on a shaking table for 7 days, the pH value of the bioleaching solution dropped to 0.8. At this time, the electrode material...

Embodiment 3

[0064] Step 1. Preparation of bioleachate

[0065] 1. Disassemble the waste zinc-manganese battery, remove single components such as zinc skin, copper cap, carbon rod, etc., collect the positive and negative electrode materials of the battery with complex components and the most concentrated heavy metal content, crush and sieve, and the particle size is 50 microns.

[0066] 2. Preparation of biological leaching medium. Bioleaching medium: (NH 4 ) 2 SO 4 ,1.0g / L;MgSO 4 ,0.25g / L; CaCl 2 ,0.1g / L; KH 2 PO 4 ,0.5g / L;FeSO 4 ,0.05g / L; The solvent is distilled water. The reducing energy substrate is a mixture of sulfur powder and pyrite, the concentration of which is 8g / L. Simultaneous inoculation of Thiobacillus thiooxidans and Thiobacillus ferrooxidans, the inoculation amount is 2.5% (v / v);

[0067] 3. After cultivating the bioleaching medium (30°C, 120 rpm) on a shaking table for 7 days, the pH value of the bioleaching solution dropped to 0.8. At this time, the electrode...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com