A kind of low microwave reflection lead-doped barium ferrite and preparation method thereof

A technology of barium ferrite and microwave reflection, which is applied in the field of microwave-absorbing materials, can solve problems such as little influence of microwave loss, and achieve the effects of low microwave reflection coefficient, good crystal phase, and high coercive force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1) Prepare the sol, mix barium nitrate, lead nitrate, and ferric nitrate according to the molar ratio of 0.9:0.1:11, add distilled water and stir until fully dissolved, use citric acid solution as the compounding agent, according to Ba 2+ +Pb 2+ +Fe 3+ : Citric acid=1:1.2 molar ratio, add citric acid solution in the middle of the mixture, mix evenly to form a sol.

[0030] 2) To prepare a gel, adjust the sol prepared in step 1) to pH=6 with ammonia water, stir in a water bath at 60°C to form a gel, and dry it in a blower oven at 120°C to form a xerogel.

[0031]3) Carbonization and calcination, put the xerogel prepared in step 2) into a muffle furnace, carbonize at 200°C for 1h, take it out and grind it, and calcinate at 1100°C for 6h at a heating rate of 15°C / min to obtain lead-doped Barium ferrite powder.

[0032] 4) Grinding, grinding the lead-doped barium ferrite powder prepared in step 3) in a mortar for 30 minutes, the obtained black powder is low microwave ref...

Embodiment 2

[0035] The difference from Example 1 is that barium nitrate; lead nitrate=0.5:0.5 (molar ratio), the low microwave reflection lead-doped barium ferrite molecular formula that makes is Ba 0.5 Pb 0.5 Fe 12 o 19 .

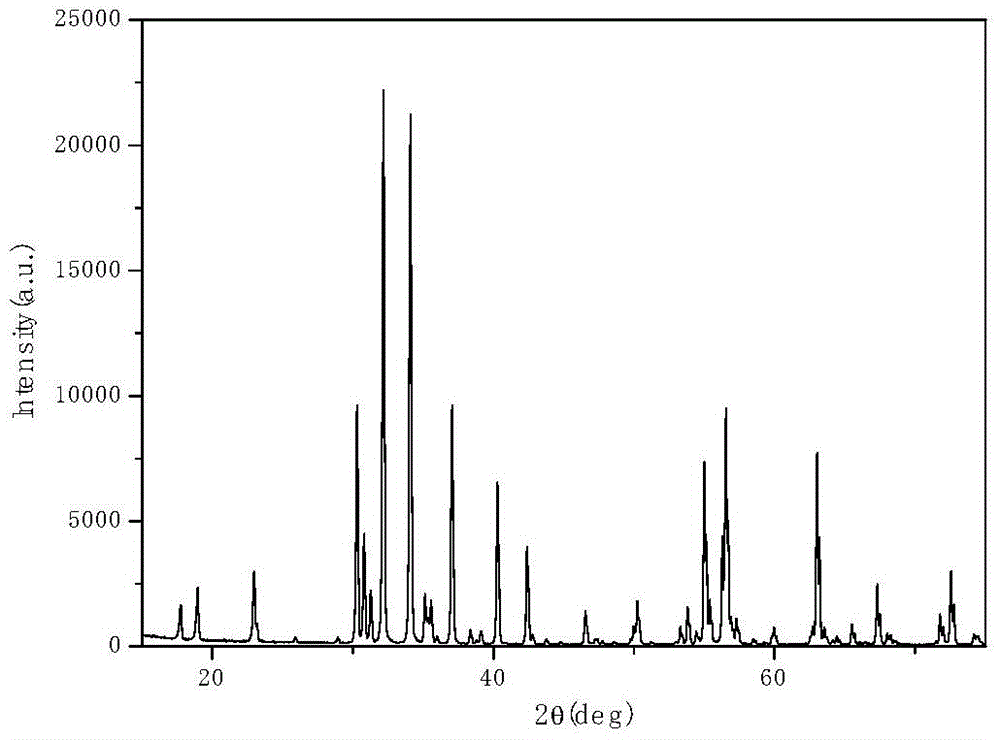

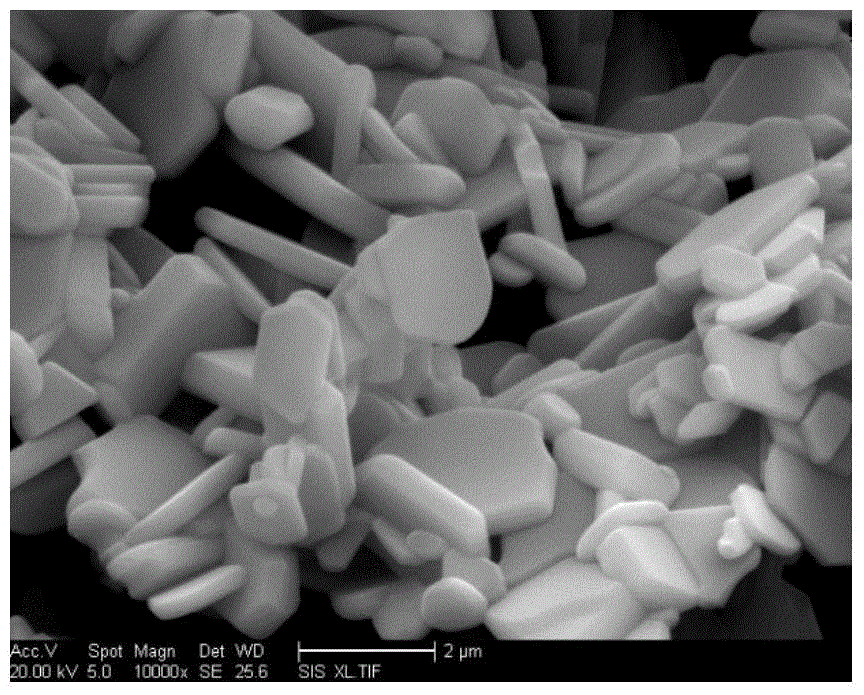

[0036] Will Ba 0.5 Pb 0.5 Fe 12 o 19 Perform XRD to obtain its spectrum, such as image 3 As shown, the obtained spectrum is consistent with that of BaFe 12 o 19 The standard spectrograms are completely consistent, indicating that the resulting product is a single-phase M-ferrite; the Ba 0.5 Pb 0.5 Fe 12 o 19 Electron microscope scanning test was carried out, and the results were as follows: Figure 4 As shown, the sample is a plane hexagon with a maximum diameter of about 2.5 μm, and the grain size distribution is uneven.

Embodiment 3

[0038] The difference from Example 1 is that no barium nitrate is added, and lead nitrate and ferric nitrate are mixed according to the molar ratio of 1:11, and the molecular formula of the obtained lead ferrite wave-absorbing material is PbFe 12 o 19 .

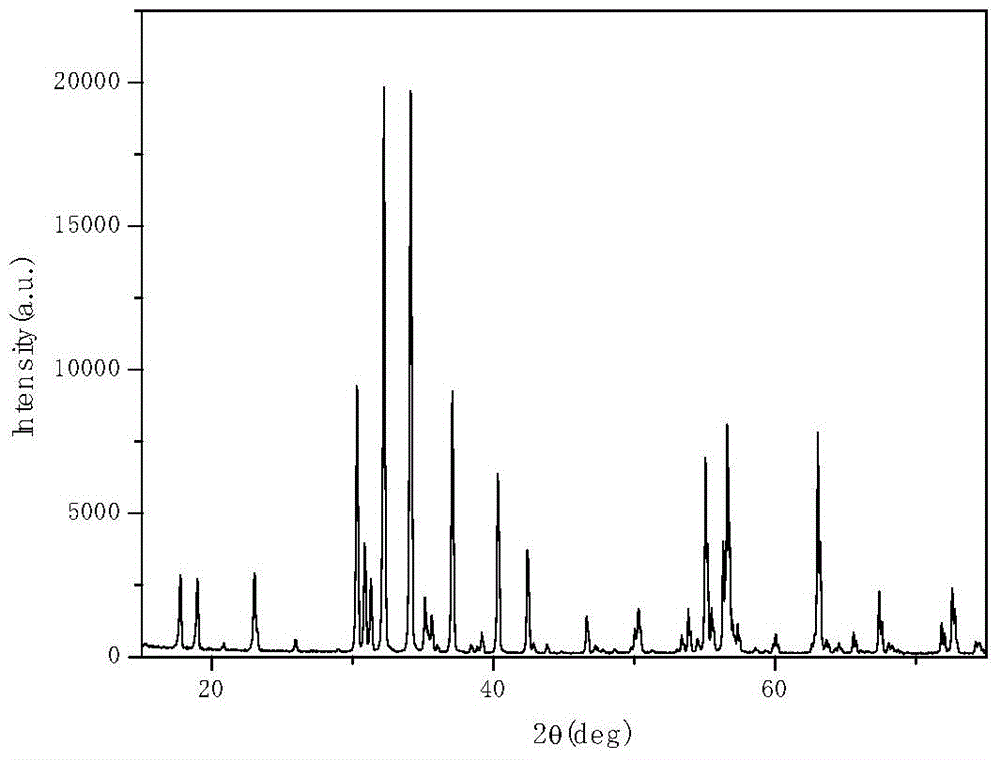

[0039] PbFe 12 o 19 Perform XRD to obtain its spectrum, such as Figure 5 As shown, the obtained spectrum is consistent with that of BaFe 12 o 19 The standard spectrograms are completely consistent, indicating that the obtained product is a single-phase M-ferrite. PbFe 12 o 19 Scanning electron microscopy was carried out, and the results were as follows Figure 6 As shown, the sample is a plane hexagon with a diameter of about 2 μm and a thickness of about 0.2 μm, and the grain size distribution is relatively uniform.

[0040] Such as Figure 7 Shown, is the substitution amount x to Ba 1-x Pb x Fe 12 o 19 The influence of magnetic properties of magnetic powder, the abscissa is Pb 2+ The doping ratio of , the or...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com