Method for degrading organic wastewater through heterogeneous ultraviolet catalytic oxidation

A technology for organic wastewater and catalytic oxidation, which is applied in the fields of heterogeneous catalyst chemical elements, chemical instruments and methods, and oxidized water/sewage treatment, etc. The effect of easy magnetic separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

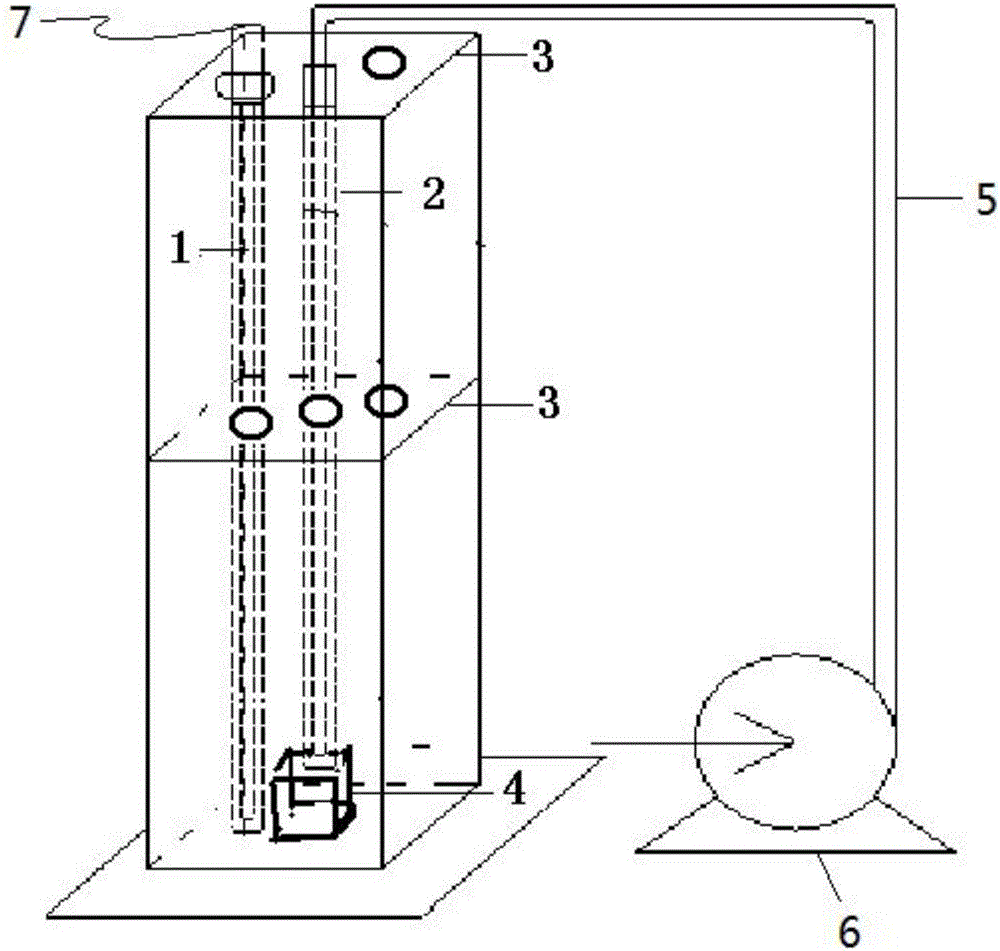

Method used

Image

Examples

Embodiment 1

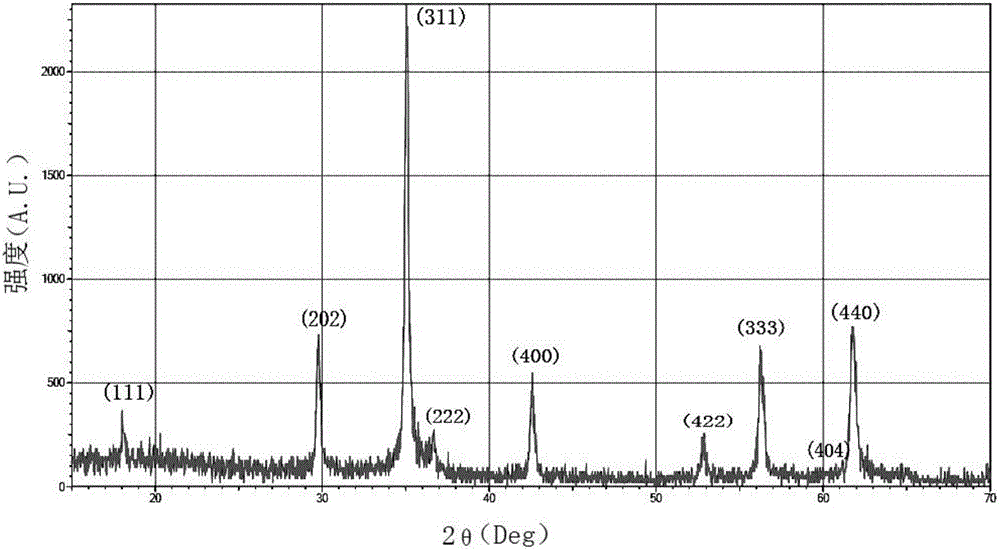

[0022] Preparation of ferromanganese oxide:

[0023] Accurately weigh 27.029g FeCl with an electronic balance 3 ·6H 2 O was dissolved in distilled water, poured into a 100ml volumetric flask to constant volume; accurately weighed 9.895g MnCl with an electronic balance 2 4H 2 O was dissolved in distilled water and poured into a 100ml volumetric flask to constant volume. Pipette 10ml FeCl 3 solution, 5ml MnCl 2 The solution is mixed in a 100ml beaker, and sodium hydroxide is weighed with an electronic balance (sodium hydroxide is measured by Fe 3+ and Mn 2+ 3 times of the amount of substance and take by weighing, slightly more than theoretical value, be made into the solution of mass fraction 10%), dissolve in conical flask with distilled water. Set the water temperature of the constant temperature water bath to 60°C. After the temperature is constant, put the beaker containing the mixed solution and the Erlenmeyer flask containing sodium hydroxide in the constant tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com