Preparation method of cysteine-functionalized magnetic hollow manganese ferrite nano composite adsorbent

A manganese ferrite nanometer, cysteine technology, applied in chemical instruments and methods, alkali metal compounds, inorganic chemistry and other directions, can solve problems such as low adsorption efficiency, and achieve the effects of saving resources, reducing costs, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

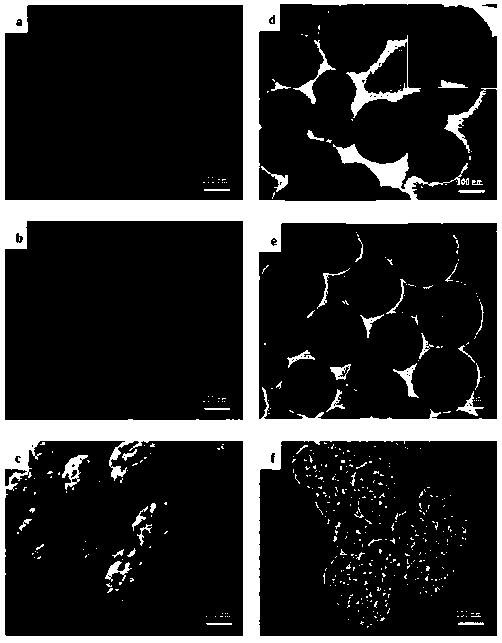

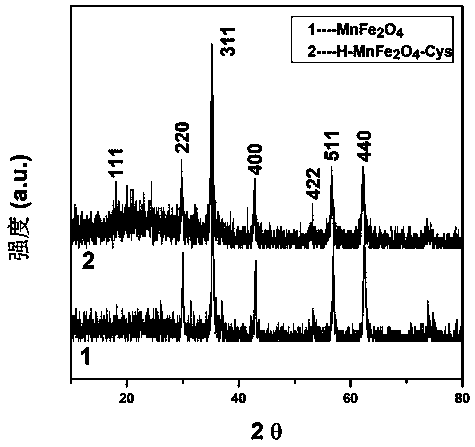

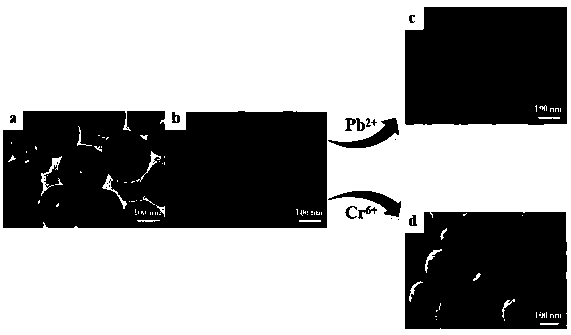

[0034]A preparation method of a cysteine-functionalized magnetic hollow manganese ferrite nanocomposite adsorbent, comprising the following steps:

[0035] Step 1, MnFe 2 o 4 Preparation of magnetic particles

[0036] Weigh 2.5 mmol MnCl 2 4H 2 O and 5 mmol FeCl 3 ·6H 2 O was dissolved in 20mL of ethylene glycol, stirred and mixed until the solution was clear, and then 3.6g of CH was added to the solution 3 COONa and 1.2g polyethylene glycol were stirred rapidly for 30 minutes, then the solution was transferred to a 25mL polytetrafluoroethylene stainless steel autoclave, and the temperature was gradually raised to 200°C and kept for 8h; cooled to room temperature, the resulting product was washed and vacuum Drying to produce spherical MnFe of 150~250nm 2 o 4 Nanoparticles, whose saturation magnetization is 73.5~81.1 emu / g;

[0037] Step 2. Magnetic Hollow MnFe 2 o 4 Preparation of nanoparticles

[0038] Weigh 0.5g of spherical MnFe prepared in step one 2 o 4 Nano...

Embodiment 2

[0042] A preparation method of a cysteine-functionalized magnetic hollow manganese ferrite nanocomposite adsorbent, comprising the following steps:

[0043] Step 1, MnFe 2 o 4 Preparation of magnetic particles

[0044] Weigh 2.5 mmol MnCl 2 4H 2 O and 5 mmol FeCl 3 ·6H 2 O was dissolved in 20mL of ethylene glycol, stirred and mixed until the solution was clear, and then 3.6g of CH was added to the solution 3 COONa and 1.2g polyethylene glycol were stirred rapidly for 30 minutes, then the solution was transferred to a 25mL polytetrafluoroethylene stainless steel autoclave, and the temperature was gradually raised to 200°C and kept for 8h; cooled to room temperature, the resulting product was washed and vacuum Drying to produce spherical MnFe of 150~250nm 2 o 4 Nanoparticles, whose saturation magnetization is 73.5~81.1 emu / g;

[0045] Step 2. Magnetic Hollow MnFe 2 o 4 Preparation of nanoparticles

[0046] Weigh 0.5g of spherical MnFe prepared in step one 2 o 4 Nan...

Embodiment 3

[0050] A preparation method of a cysteine-functionalized magnetic hollow manganese ferrite nanocomposite adsorbent, comprising the following steps:

[0051] Step 1, MnFe 2 o 4 Preparation of magnetic particles

[0052] Weigh 2.5 mmol MnCl 2 4H 2 O and 5 mmol FeCl 3 ·6H 2 O was dissolved in 20mL of ethylene glycol, stirred and mixed until the solution was clear, and then 3.6g of CH was added to the solution 3 COONa and 1.2g polyethylene glycol were stirred rapidly for 30 minutes, then the solution was transferred to a 25mL polytetrafluoroethylene stainless steel autoclave, and the temperature was gradually raised to 200°C and kept for 8h; cooled to room temperature, the resulting product was washed and vacuum Drying to produce spherical MnFe of 150~250nm 2 o 4 Nanoparticles, whose saturation magnetization is 73.5~81.1 emu / g;

[0053] Step 2. Magnetic Hollow MnFe 2 o 4 Preparation of nanoparticles

[0054] Weigh 0.5g of spherical MnFe prepared in step one 2 o 4 Nan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Saturation magnetization | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Saturation magnetization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com