Preparation method of nano-scale manganese ferrite catalyst with high specific surface area

A technology of manganese ferrite catalyst and high specific surface area, which is applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems that catalysts have not been reported, and achieve The effect of less energy consumption, high speed and good application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

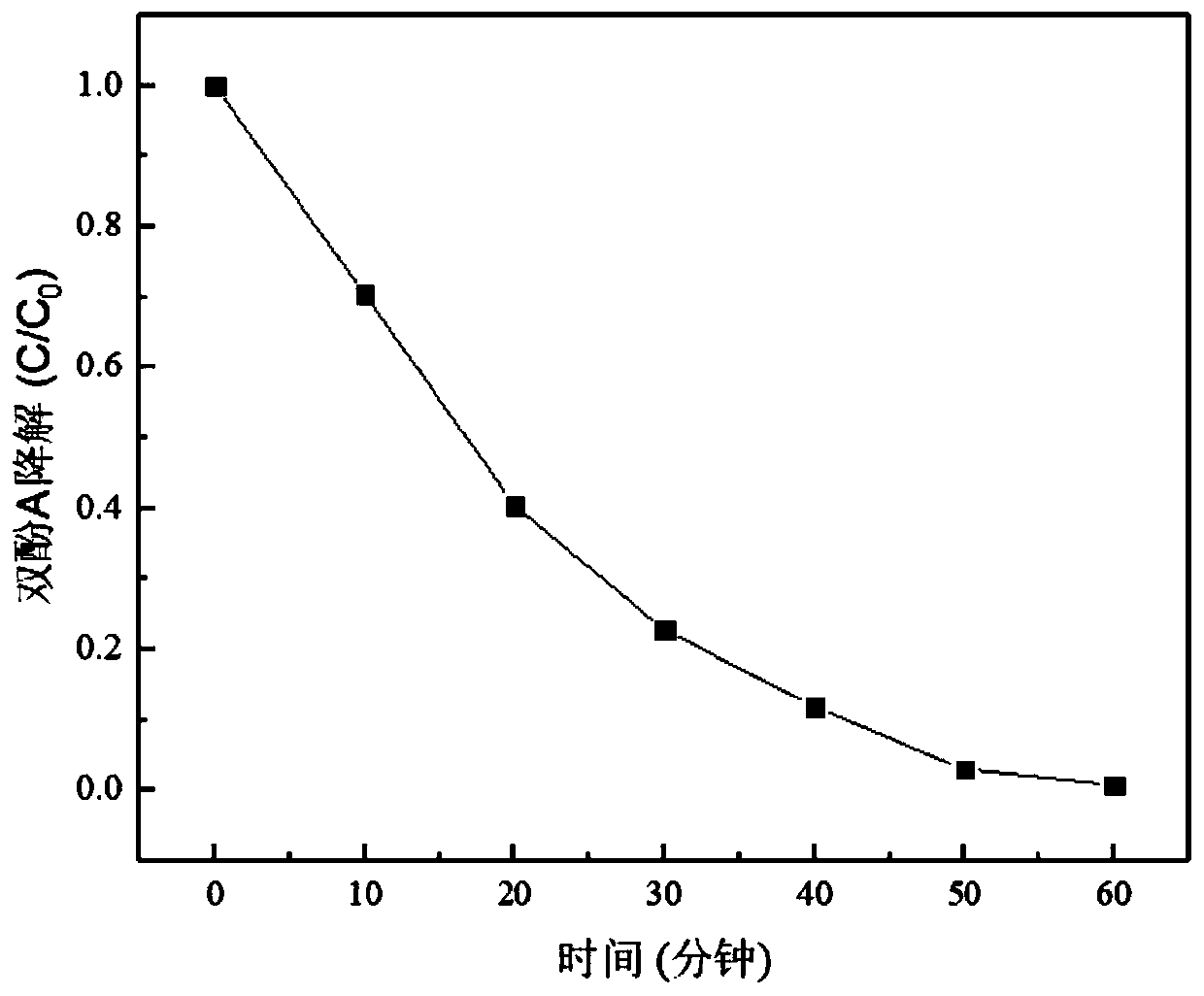

Examples

Embodiment 1

[0035] A kind of preparation method of nano-scale manganese ferrite catalyst, comprises steps as follows:

[0036] (1) Add 0.01mol Fe(NO 3 ) 3 9H 2 O with 0.005mol 50% Mn(NO 3 ) 2 The solution was placed in a 100ml beaker, and after dissolving with 5ml deionized water, solution A was obtained;

[0037] (2) Add 0.0112mol citric acid to the solution A prepared in step (1), then add 0.015mol NaCl, dissolve, add dropwise ammonia water until the pH of the solution is 7.0, and obtain a raw material solution;

[0038] (3) Put the raw material solution prepared in step (2) into a muffle furnace preheated to 300°C and keep it for 1 hour, and burn it fully; the obtained product is washed with deionized water and dried at 80°C for 8 hours to obtain a Surface area nanoscale manganese ferrite catalyst.

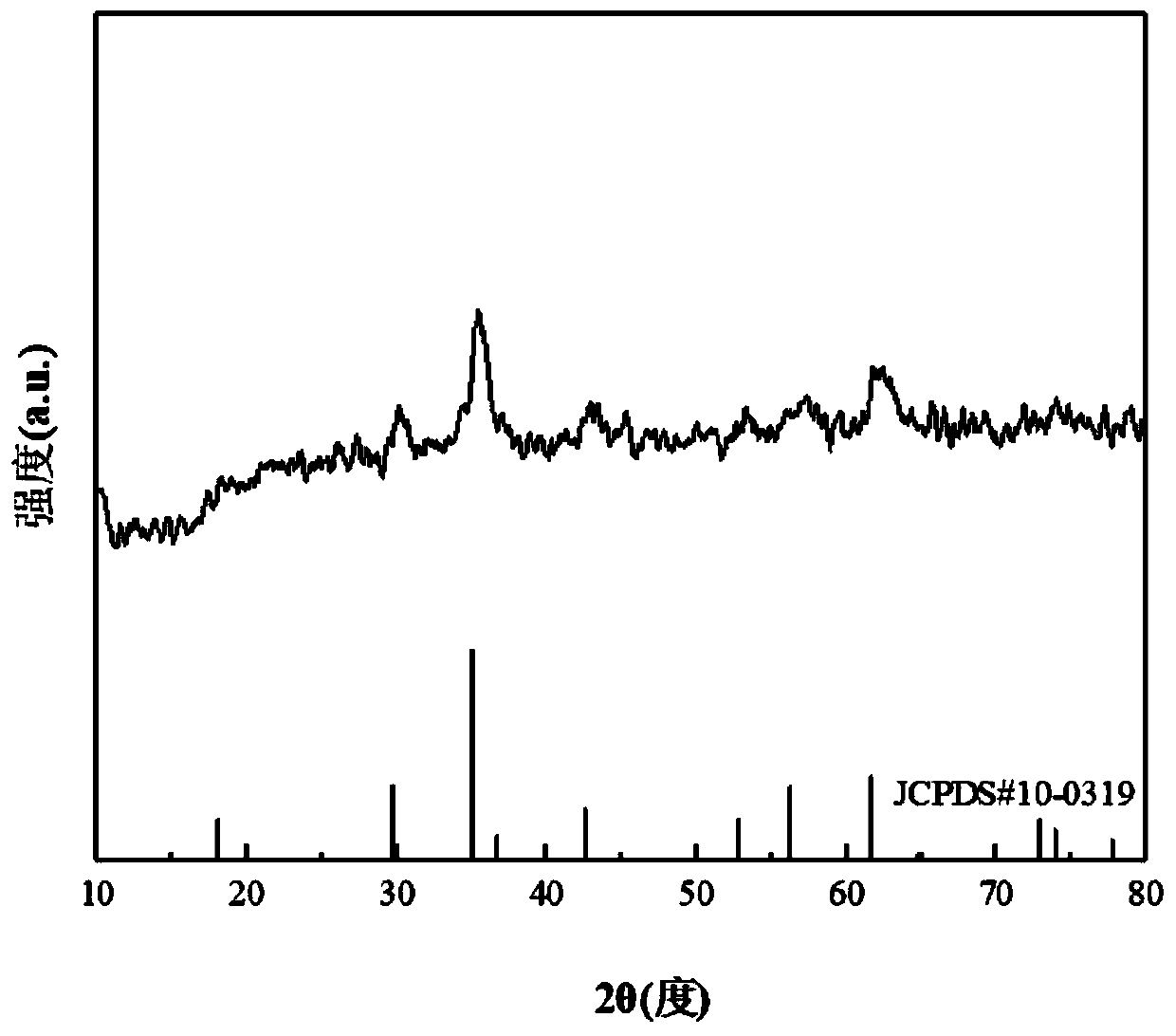

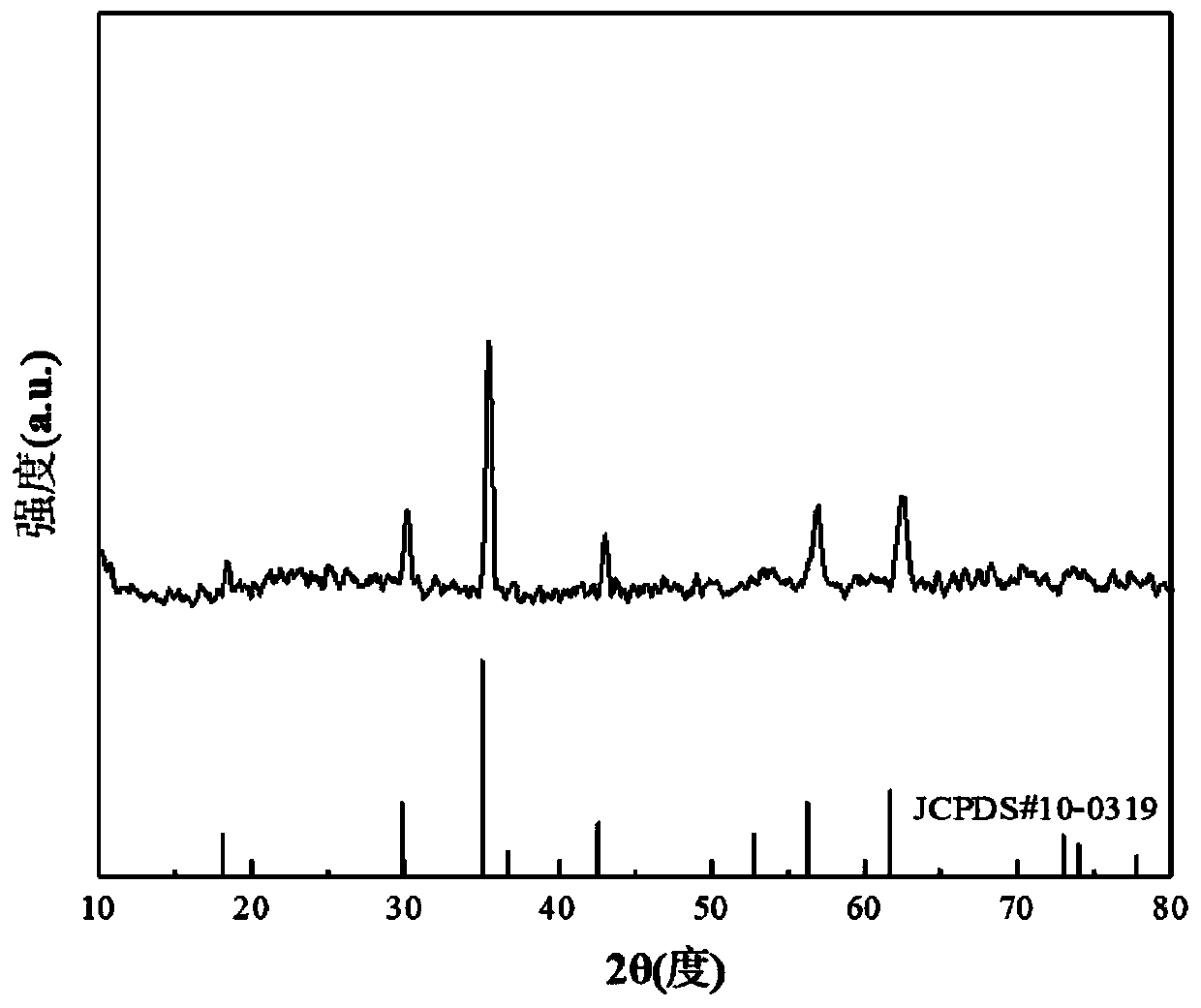

[0039] The product that obtains in the present embodiment 1 is carried out X-ray diffraction test, and the result is as follows figure 1 As shown, the obtained material has obvious ch...

Embodiment 2

[0041] Preparation method as described in Example 1, the difference is:

[0042] The addition amount of NaCl in the step (2) is respectively 0.01mol and 0.005mol.

Embodiment 3

[0044] Preparation method as described in Example 1, the difference is:

[0045] Citric acid is replaced by glycine in step (2).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com