Water system neutral electrolyte-based asymmetric supercapacitor and preparation method thereof

A technology of supercapacitor and electrolyte, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, hybrid capacitor electrolytes, etc., can solve the problems of low specific capacitance of activated carbon, limiting specific energy and specific power of asymmetric supercapacitors, etc. Achieve the effect of increasing porosity and specific surface area, good electrochemical performance, improving conductivity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

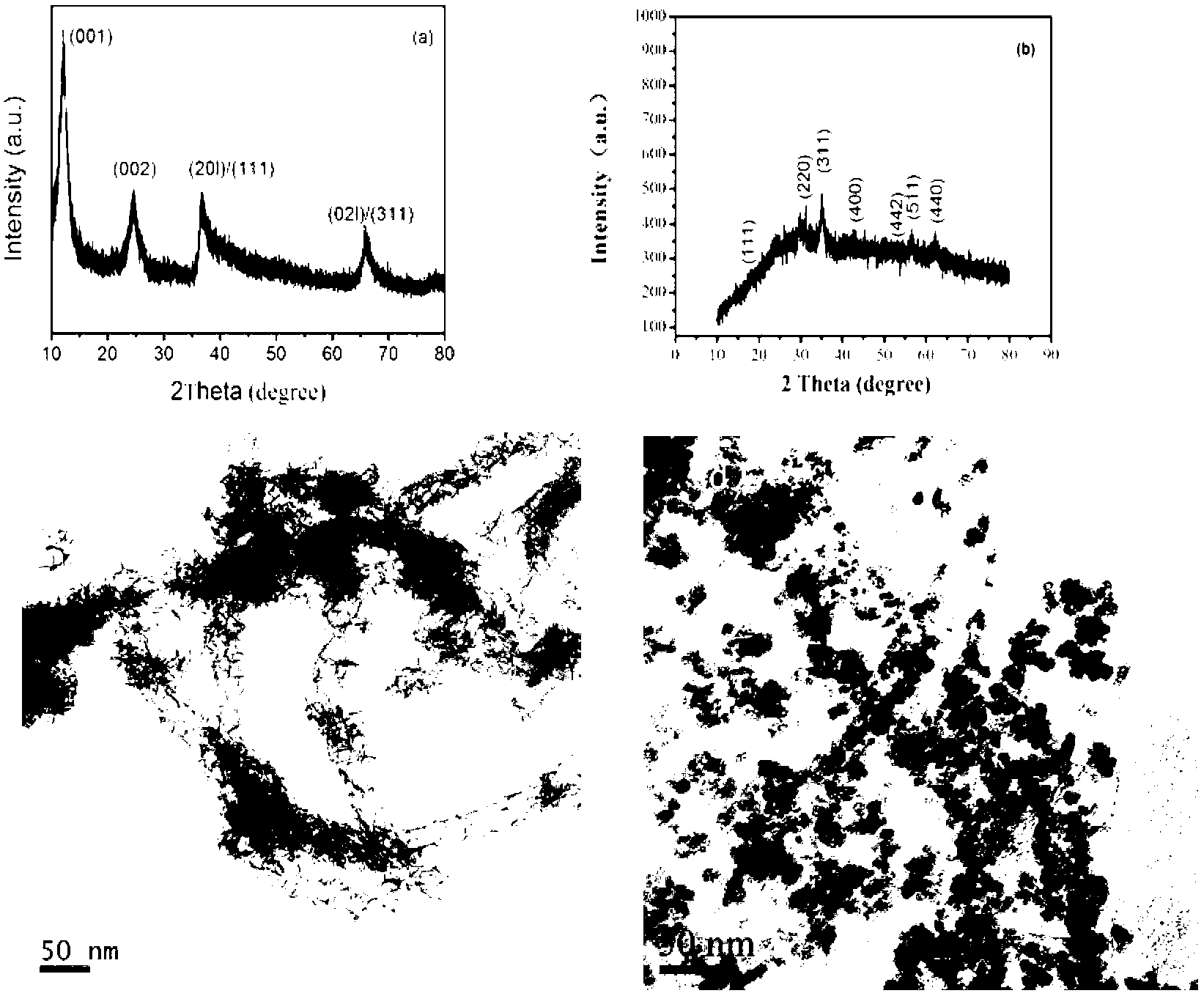

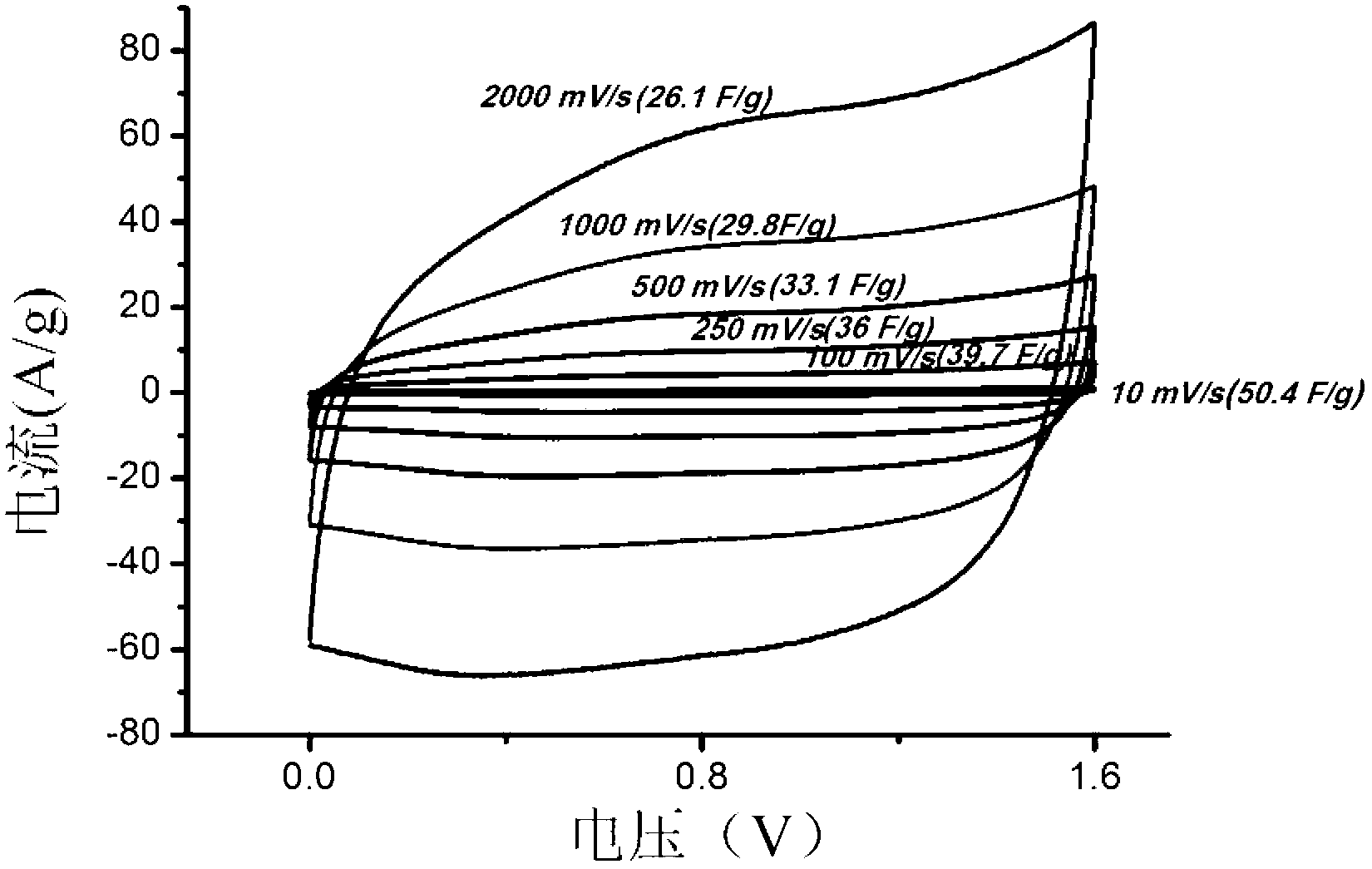

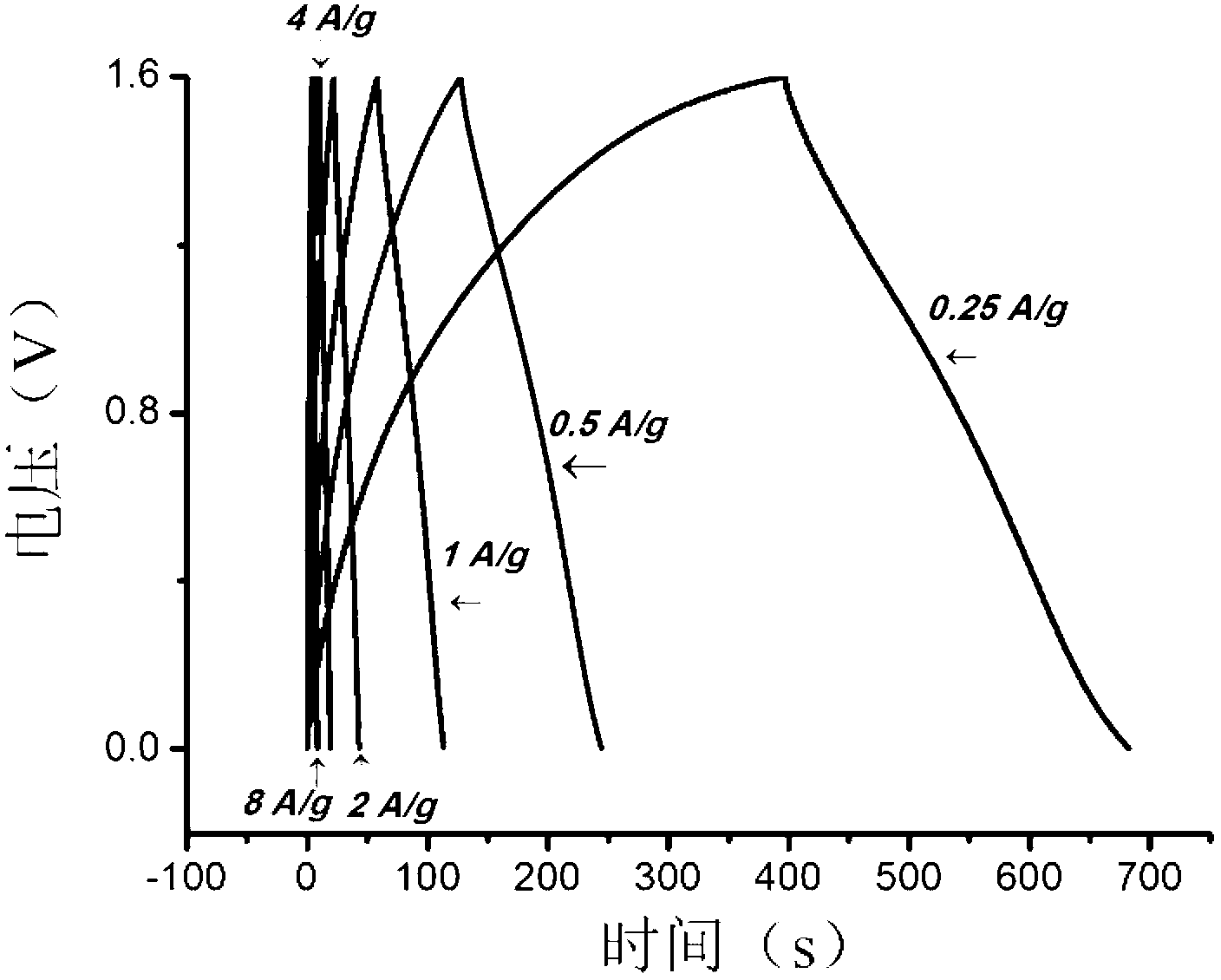

[0031] (1) Preparation of positive electrode active material: Weigh 0.1 g of industrial carbon nanotubes treated with nitric acid in 25 mL of deionized water for 2 h, add 0.3 g of potassium permanganate, stir for 6 h, and then transfer the mixed liquid to special In the hydrothermal kettle with Teflon liner, after hydrothermal reaction at 150 ℃ for 1 h, it was washed with deionized water and dried at 100 ℃ for 12 h to prepare manganese dioxide nanosheet / carbon nanotube composite material. The content of carbon nanotubes is 20%. The XRD and TEM images are attached figure 1 In (a), (c).

[0032] (2) Preparation of negative electrode active material: Weigh 0.716 g of manganese nitrate and 1.616 g of ferric nitrate, add them to 20 mL of pure ethanol and stir for 30 minutes, weigh 200 mg of graphene oxide (GO), add to pure ethanol, and vibrate ultrasonically, then Mix the above two parts of liquid, stir for 30 min, adjust the pH of the mixture to 10 with 6 mol / L NaOH solution, sti...

Embodiment 2

[0040] (1) Preparation of positive electrode active material: Weigh 0.05 g of industrial carbon nanotubes treated with nitric acid in 25 mL of deionized water for 2 h, add 0.3 g of potassium permanganate, stir for 6 h, and then transfer the mixed liquid to the special In the hydrothermal kettle with Teflon liner, after hydrothermal reaction at 150 ℃ for 1 h, it was washed with deionized water and dried at 100 ℃ for 12 h to prepare manganese dioxide nanosheet / carbon nanotube composite material. The content of carbon nanotubes is 10%.

[0041] (2) Preparation of negative electrode active material: Weigh 0.716 g of manganese nitrate and 1.616 g of ferric nitrate, add them to 20 mL of pure ethanol and stir for 30 min, weigh 80 mg of graphene oxide (GO), add to pure ethanol and vibrate ultrasonically, then Mix the above two parts of liquid, stir for 30 min, adjust the pH of the mixture to 10 with 6 mol / L NaOH solution, stir for 30 min, and then transfer the mixture to a Teflon line...

Embodiment 3

[0045] (1) Preparation of positive electrode active material: Weigh 0.3 g of potassium permanganate and dissolve in 25 mL of deionized water, stir for 6 h, then add 0.2 mol / L sulfuric acid solution (95%) under strong stirring, and then mix the liquid It was transferred to a hydrothermal kettle with a Teflon liner. After hydrothermal reaction at 150 ℃ for 1 h, it was washed with deionized water and dried at 100 ℃ for 12 h to prepare manganese dioxide nanosheets.

[0046] (2) Preparation of negative electrode active material: Weigh 0.716 g of manganese nitrate and 1.616 g of ferric nitrate, add them to 20 mL of pure ethanol and stir for 30 minutes, adjust the pH of the solution to 10 with 6 mol / L NaOH solution, stir for 30 minutes, and then The solution was transferred to a hydrothermal kettle with a Teflon liner. After a hydrothermal reaction at 180°C for 2 hours, it was washed with deionized water and dried at 60°C for 12 hours to prepare manganese ferrite nanoparticles.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific capacitance | aaaaa | aaaaa |

| Energy density | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com