Hollow spherical nano manganese ferrite, and preparation method and application thereof

A nano-iron, spherical technology, applied in separation methods, chemical instruments and methods, iron compounds, etc., can solve the problems of high process conditions and complex processes, and achieve the effect of simple preparation method and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

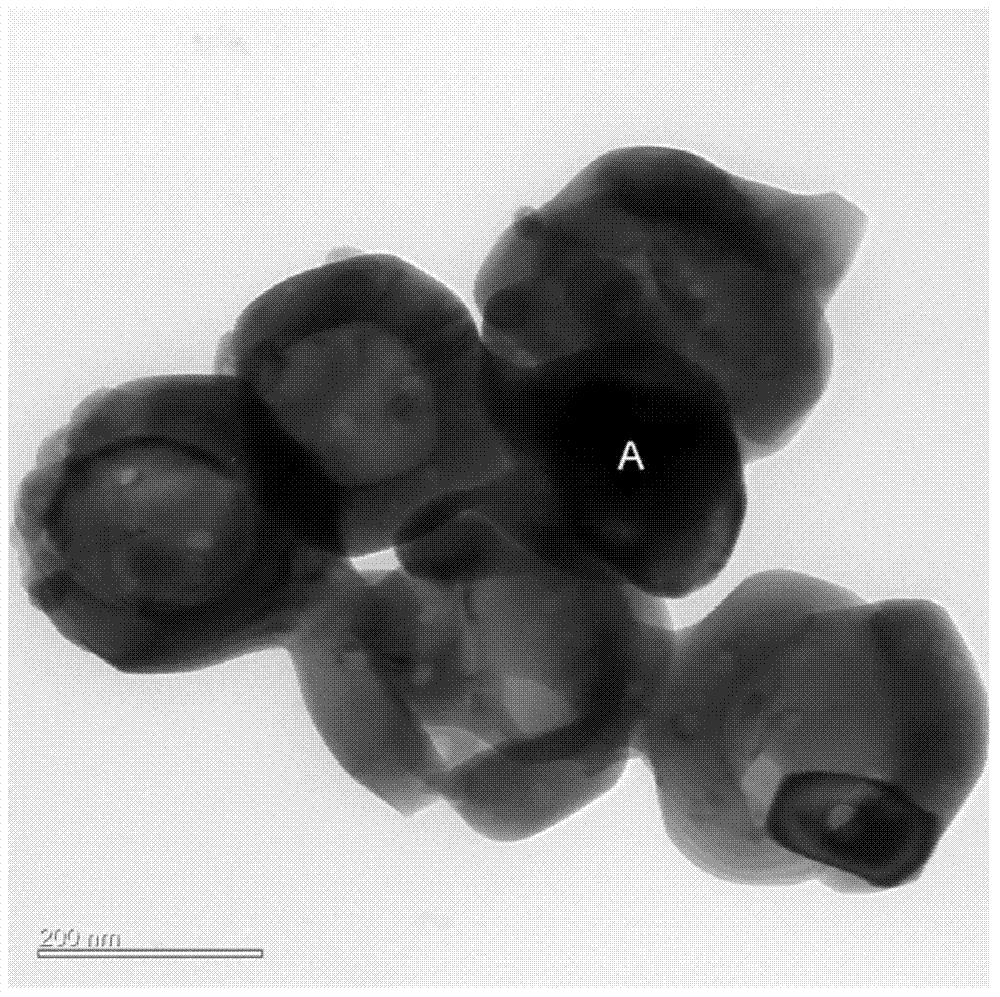

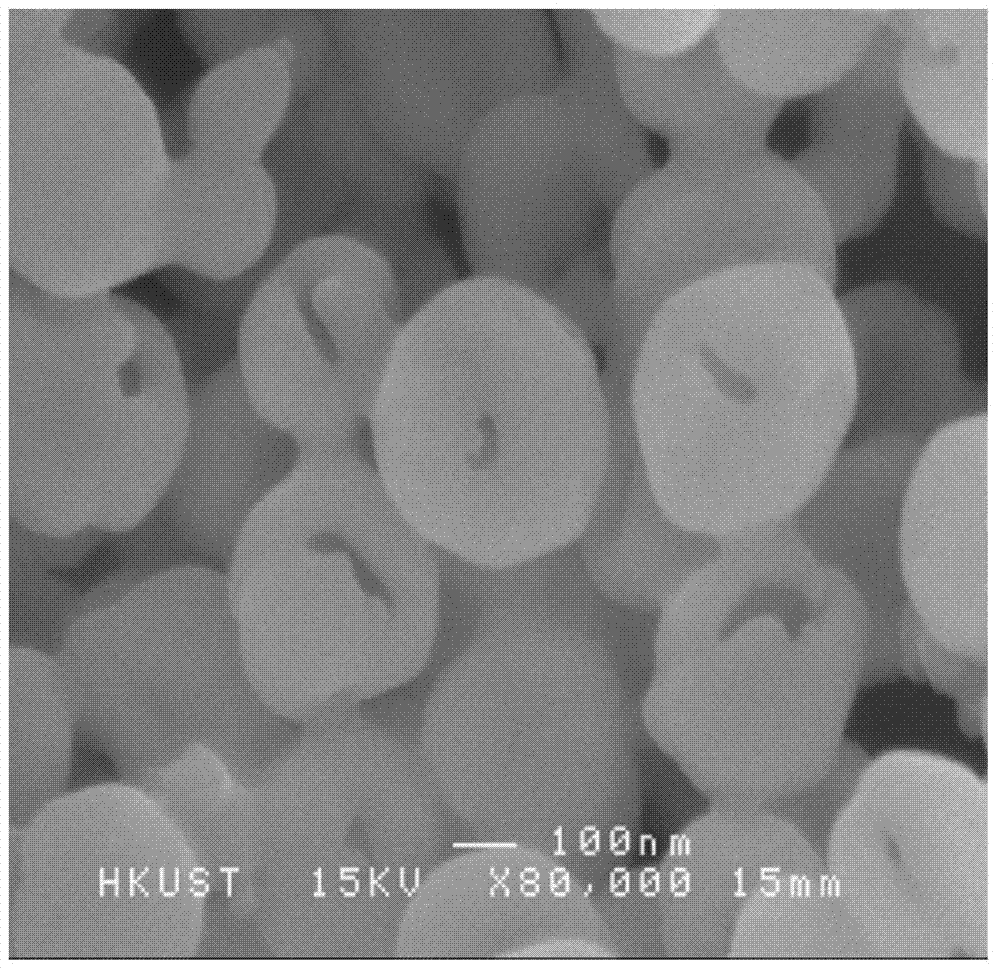

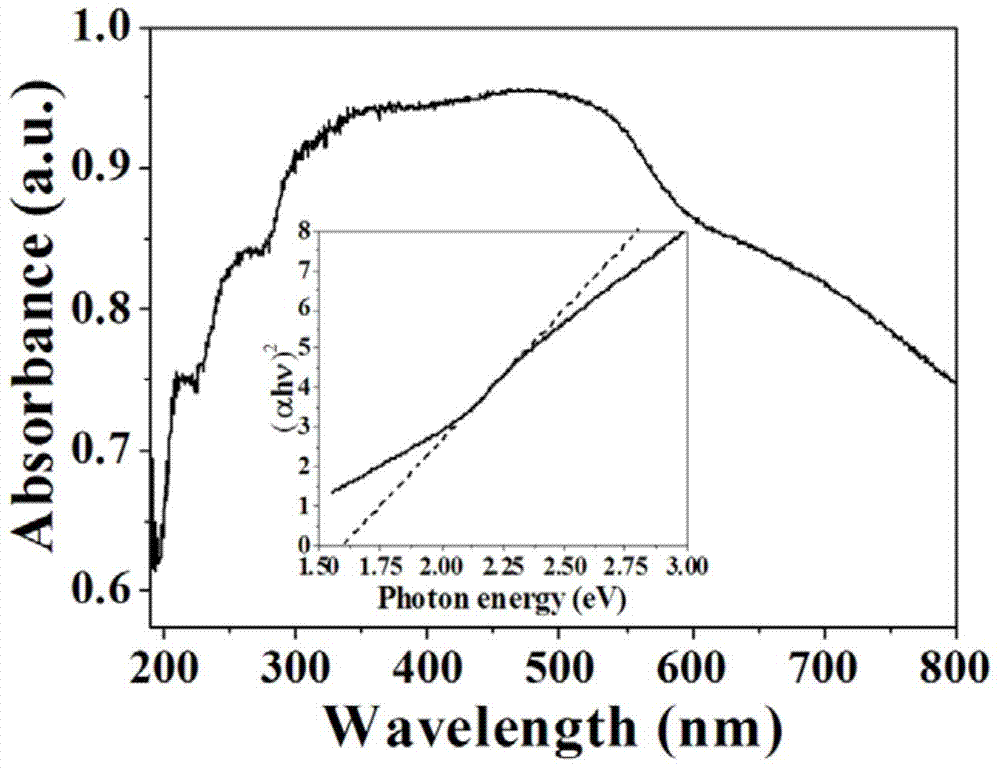

[0031]Take 0.9892g MnCl 2 4H 2 O and 2.7020 g FeCl 3 ·6H 2 O powder was added to 80ml of ethylene glycol solution with a purity of 99%, and magnetically stirred at room temperature to form a transparent solution. Add 7.2g NaAc and 2.0g polyethylene glycol 20000 powder and continue stirring for 90min. The above solution was added into a polytetrafluoroethylene autoclave with a specification of 100ml, and solvothermally reacted at 200°C for 20h. The black substance generated by the solvothermal reaction was centrifuged, washed thoroughly with deionized water and absolute ethanol to remove impurity ions, then dried in an oven at 60°C for 6 hours, and finally placed in a muffle furnace at 2°C / min Heating rate, calcined at 650°C for 2h. The calcined product was evenly ground for 30 minutes with an agate mortar, and then a brown-black powder with a particle size of 20 nm could be obtained after grinding.

Embodiment 2

[0033] Get 0.02g of the product obtained in Example 1 and put it into an infrared reaction tank, inject a small amount of liquid benzene, and the initial concentration of benzene after volatilization is 200mg / m 3 about. After 30 minutes of dark state adsorption, turn on the xenon lamp, radiate visible light with a wavelength above 400nm to irradiate the reaction cell, and use in-situ infrared spectroscopy to detect the visible photocatalytic degradation of gas-phase benzene. After 6 hours, the degradation rate of benzene reached 55%.

Embodiment 3

[0035] Get 0.02g of the product obtained in Example 1 and put it into an infrared reaction tank, inject a small amount of liquid benzene, and the initial concentration of benzene after volatilization is 300mg / m 3 about. After 30 minutes of dark state adsorption, turn on the xenon lamp, radiate visible light with a wavelength above 400nm to irradiate the reaction cell, and use in-situ infrared spectroscopy to detect the visible photocatalytic degradation of gas-phase benzene. After 6 hours, the degradation rate of benzene reached 48%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com