Method for preparing Mn-Zn-Ni ferrite magnetic material by using low-grade nickel resource

A technology of nickel ferrite and magnetic materials, which is applied in the fields of magnetism of inorganic materials, manufacturing of inductors/transformers/magnets, electrical components, etc., can solve problems such as high cost, heavy pollution, and low added value of products, and achieve high-efficiency separation and high-efficiency performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

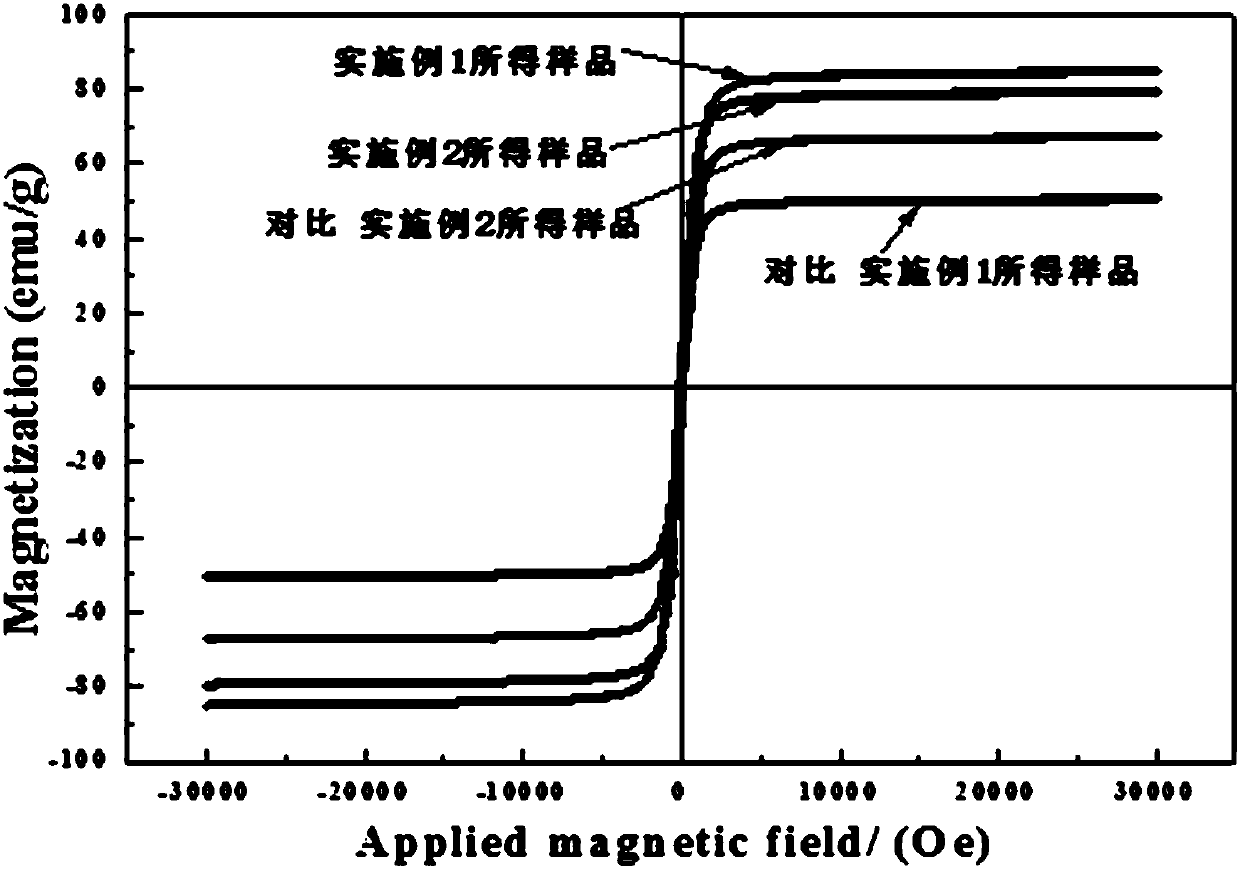

Embodiment 1

[0033] TNi0.9% laterite nickel ore, manganese oxide ore, hematite, and quicklime are mixed together to obtain mixture A. The chemical composition of mixture A (TMn 3.1%, TFe 25.8%, TNi0.3%, TZn 1.2%), Mixture, CaO / SiO in A 2 is 0.05, the mass percentage of the mixture-325 mesh particle size is 95%, and the specific surface area is 2550cm 2 / g, add 0.25% bentonite and 8% moisture to make pellets, then dry, roast the dried samples in a muffle furnace, the roasting temperature is 1300°C, the roasting time is 90min, and the roasted samples are ground after cooling The mass percentage of particle size to -325 mesh is 99.5%. Magnetic separation is carried out in a magnetic field with a magnetic field strength of 800Gs, and the recovery rate of Ni in the process is 99.1%. The obtained magnetic product is mixed with zinc oxide and secondary zinc oxide to obtain a mixture B. In the mixture B, (Mn+Zn+Ni) / Fe is 0.45, Zn / (Mn+Zn+Ni) is 0.2, SiO 2 The content of the compound B is 0.01%, t...

Embodiment 2

[0035] TNi1.2% nickel smelting slag, manganese oxide ore, ferromanganese ore, hematite, goethite, quicklime, and limestone are mixed to obtain mixture A. The chemical composition of mixture A (TMn16.4%, TFe28.8% , TNi0.5%, TZn 1.5%), mixture, CaO / SiO in A 2 is 0.45, the mass percentage of the mixture-325 mesh particle size is 96%, and the specific surface area is 2650cm 2 / g, add 0.25% bentonite and 8% moisture to make pellets, then dry, roast the dried samples in a muffle furnace, the roasting temperature is 1100°C, the roasting time is 120min, and the roasted samples are ground after cooling The mass percentage of particle size up to -325 mesh is 100%, and the magnetic separation is carried out in a magnetic field with a magnetic field strength of 500Gs, and the recovery rate of Ni is 99.5% in the process. The obtained magnetic product is mixed with zinc oxide and secondary zinc oxide to obtain a mixture B. In the mixture B, (Mn+Zn+Ni) / Fe is 0.65, Zn / (Mn+Zn+Ni) is 0.5, and ...

Embodiment 3

[0037] The lateritic nickel ore of TNi0.9%, the nickel sulfide ore of TNi1.7%, manganese oxide ore, ferromanganese ore, hematite, goethite, quicklime, limestone are carried out batching to obtain mixture A, the chemical composition of mixture A (TMn 12.4%, TFe 25.2%, TNi0.6%, TZn0.8%), mixture, CaO / SiO in A 2 is 0.35, the mass percentage of the mixture-325 mesh particle size is 96%, and the specific surface area is 2650cm 2 / g, add 0.25% bentonite and 8% moisture to make pellets, then dry, roast the dried samples in a muffle furnace, the roasting temperature is 1250°C, the roasting time is 90min, and the roasted samples are ground after cooling The mass percentage of particle size up to -325 mesh is 100%, and the magnetic separation is carried out in a magnetic field with a magnetic field strength of 750Gs, and the recovery rate of Ni is 98.8% in the process. The obtained magnetic product is mixed with zinc oxide and secondary zinc oxide to obtain a mixture B. In the mixture ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com