Lithium sulfur battery composite cathode material and preparation method thereof

A technology for composite positive electrode materials and lithium-sulfur batteries, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of limited action sites, weak adsorption, and inability to effectively inhibit the dissolution of lithium polysulfide. The method is simple, The process is simple and the effect of mature technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

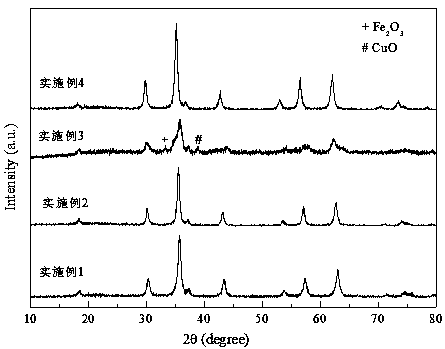

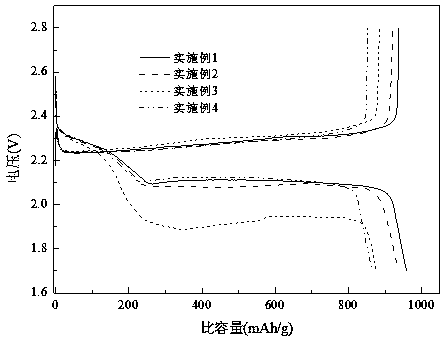

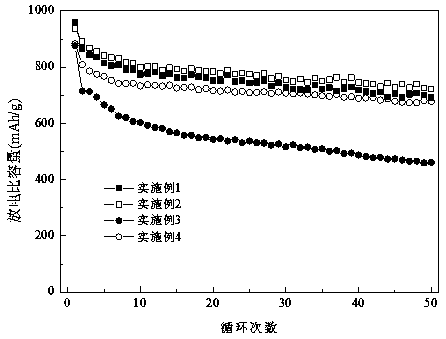

Embodiment 1

[0024] A composite cathode material for a lithium-sulfur battery, specifically prepared according to the following steps:

[0025] Magnesium ferrite (MgFe 2 o 4 ) preparation:

[0026] Add 2.5 mmol of magnesium acetate tetrahydrate and 5 mmol of ferric nitrate nonahydrate to a mixed solvent consisting of 5 mL of deionized water and 5 mL of absolute ethanol, and stir until the added compound is completely dissolved; then weigh 5 g of poly(polyethylene oxide) with a molecular weight of 58,000. Vinylpyrrolidone was added to the above solution, stirred until completely dissolved to obtain a polymer viscous fluid; then heated and stirred at 80°C until the solvent evaporated completely, and ground to obtain a powder precursor; finally, the powder precursor was put into a porcelain ark, and the Calcined in a Furnace at 500°C for 5h with a heating rate of 2 o C / min, and finally cooled to room temperature to obtain magnesium ferrite;

[0027] The magnesium ferrite obtained above is...

Embodiment 2

[0032] A composite cathode material for a lithium-sulfur battery, specifically prepared according to the following steps:

[0033] Zinc ferrite (ZnFe 2 o 4 ) preparation:

[0034] Add 2.5 mmol of zinc acetate dihydrate and 5 mmol of ferric nitrate nonahydrate to a mixed solvent consisting of 5 mL of deionized water and 5 mL of absolute ethanol, and stir until the added compound is completely dissolved; then weigh 5 g of poly(polyethylene oxide) with a molecular weight of 58,000 Vinylpyrrolidone was added to the above solution, stirred until completely dissolved to obtain a polymer viscous fluid; then heated and stirred at 80°C until the solvent evaporated completely, and ground to obtain a powder precursor; finally, the powder precursor was put into a porcelain ark, and the Calcined at 600°C for 5 hours in a Furnace with a heating rate of 2 o C / min, and finally cooled to room temperature to obtain zinc ferrite;

[0035] Combination of zinc ferrite and sulfur element:

[0...

Embodiment 3

[0039] A composite cathode material for a lithium-sulfur battery, specifically prepared according to the following steps:

[0040] Copper ferrite (CuFe 2 o 4 ) preparation:

[0041] Add 2.5 mmol of copper acetate monohydrate and 5 mmol of ferric nitrate nonahydrate to a mixed solvent consisting of 5 mL of deionized water and 5 mL of absolute ethanol, and stir until the added compound is completely dissolved; then weigh 5 g of poly(polyethylene oxide) with a molecular weight of 58,000. Vinylpyrrolidone was added to the above solution, stirred until completely dissolved to obtain a polymer viscous fluid; then heated and stirred at 80°C until the solvent evaporated completely, and ground to obtain a powder precursor; finally, the powder precursor was put into a porcelain ark, and the Calcined in a Furnace at 500°C for 5h with a heating rate of 2 o C / min, and finally cooled to room temperature to obtain copper ferrite;

[0042] Composite the obtained copper ferrite with sulfur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com