Method for applying ferrite MFe2O4 magnetic nano-particles to removal of tellurium-containing wastewater and application of ferrite MFe2O4 magnetic nano-particles

A magnetic nanoparticle, ferrite technology, applied in chemical instruments and methods, water pollutants, other chemical processes, etc., can solve the difficulty of recovering tellurium, large area, large investment cost and operating cost, power consumption, etc. It can achieve the effect of large adsorption capacity, high removal efficiency and broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1) The adsorbent ferromanganese oxide magnetic nanoparticles prepared above, with a dosage of 0.2g / L, is added to a reaction vessel with a concentration of tellurium-containing wastewater of 40mg / L, and the concentration of the wastewater is adjusted with sodium hydroxide or nitric acid. The pH value is 7±0.2;

[0033] 2) Under the condition of 25°C, vibrate the reaction vessel at a speed of 180rpm / min to fully mix the adsorbent and tellurium-containing wastewater, and the reaction time is 12h;

[0034] 3) After adsorption equilibrium, use a magnet to separate the ferromanganese oxides to obtain a clear liquid to be tested.

Embodiment 2

[0036]The method of Example 1 is used, except that the iron cuprite magnetic nanoparticles are used instead of the iron manganese oxide magnetic nanoparticles.

Embodiment 3

[0038] The method of Example 1 is used, except that the iron-cobalt oxide magnetic nanoparticles are used instead of the iron-manganese oxide magnetic nanoparticles.

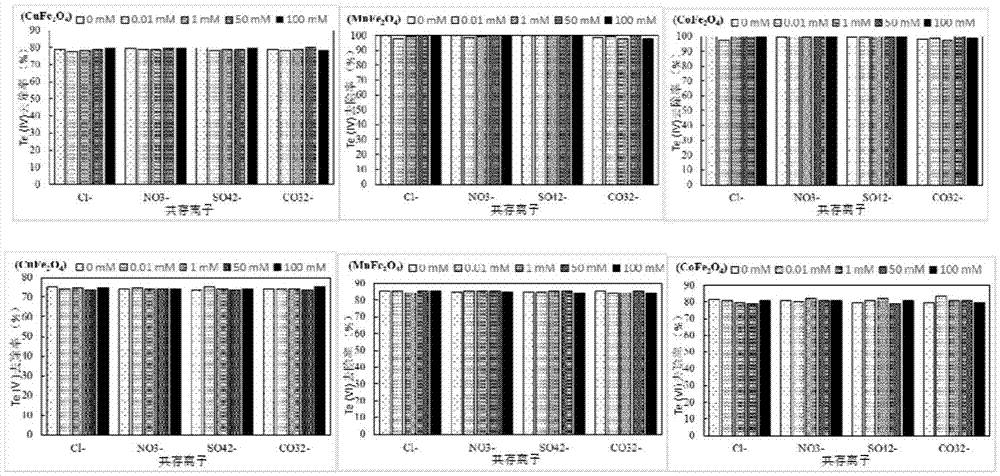

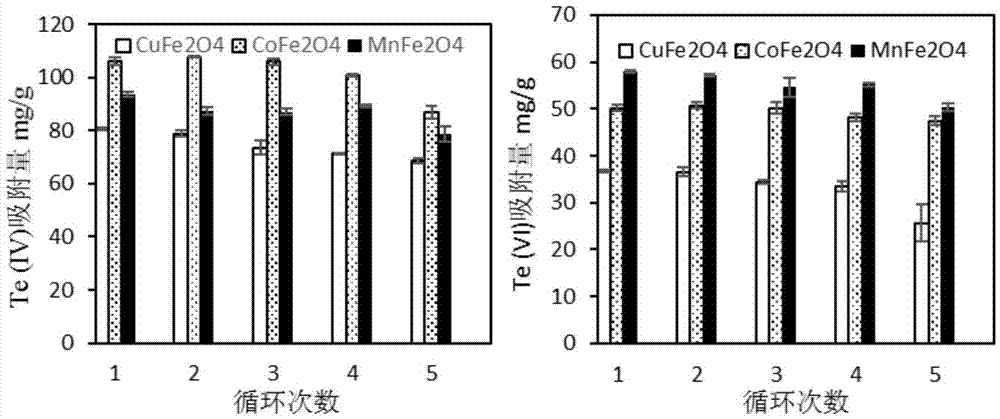

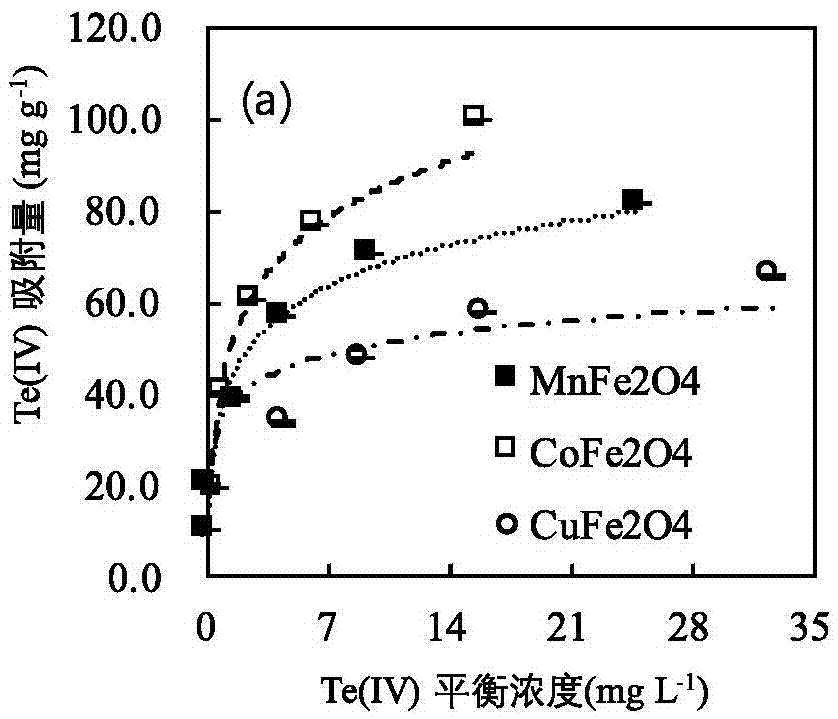

[0039] In order to determine the effect of iron-cobalt oxide, iron-cuprite, and iron-manganese oxide on treating tellurium-containing wastewater, a series of experiments of simulating wastewater were carried out first. Since tellurate and tellurite are the main forms of tellurium in water, sodium tellurate and sodium tellurite are used to prepare tellurium-containing wastewater. The adsorbent was mixed with the simulated wastewater, put into the Erlenmeyer flask, oscillated in a constant temperature shaking incubator, and the mixed reaction was repeated. After the reaction, the mixed solution was separated by magnetic force, and the concentration of tellurium in the supernatant was determined by ICP-OES. The formula for calculating the adsorption capacity is as follows:

[0040] q e =(C 0 -C e )V / W

[0041]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com