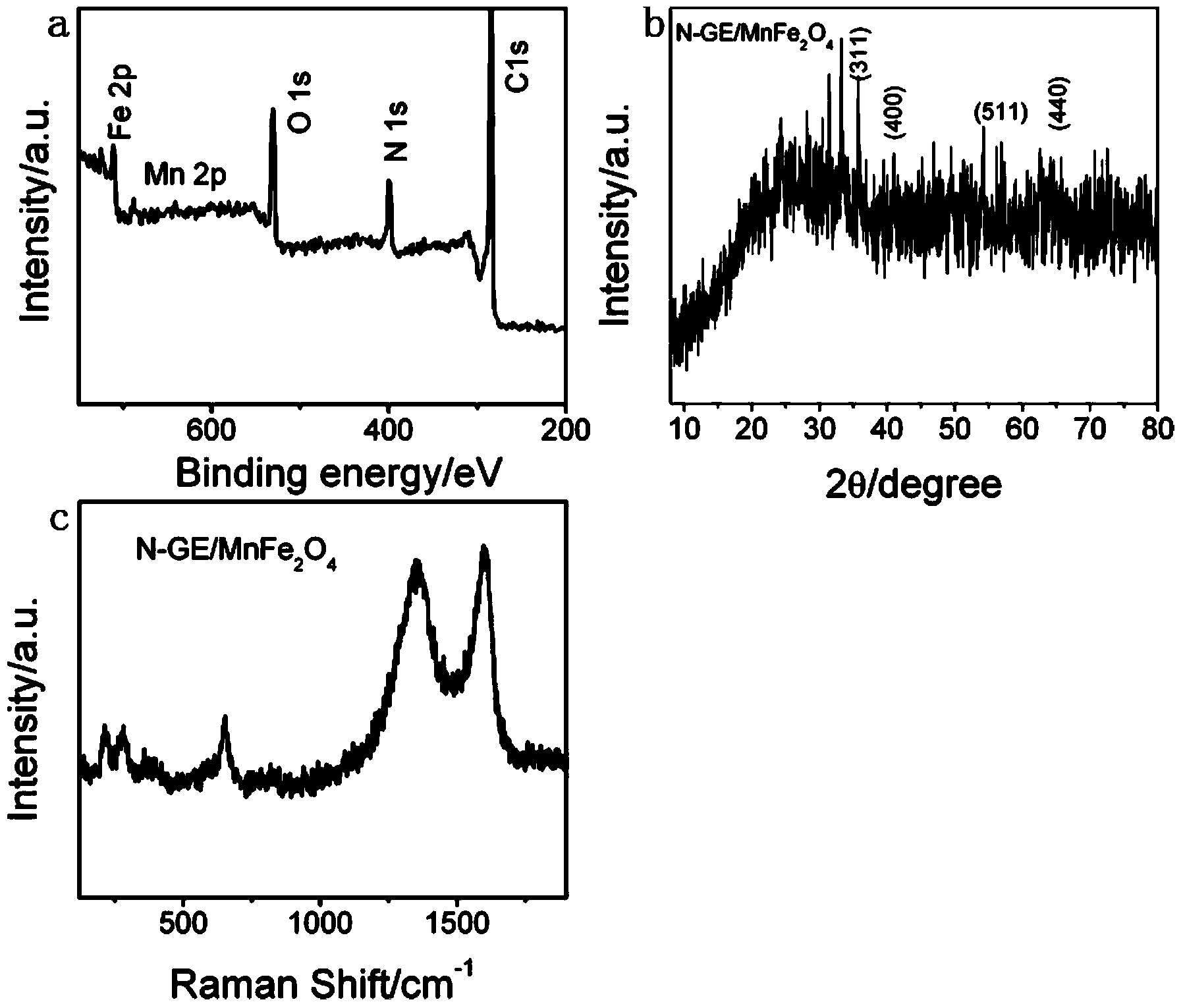

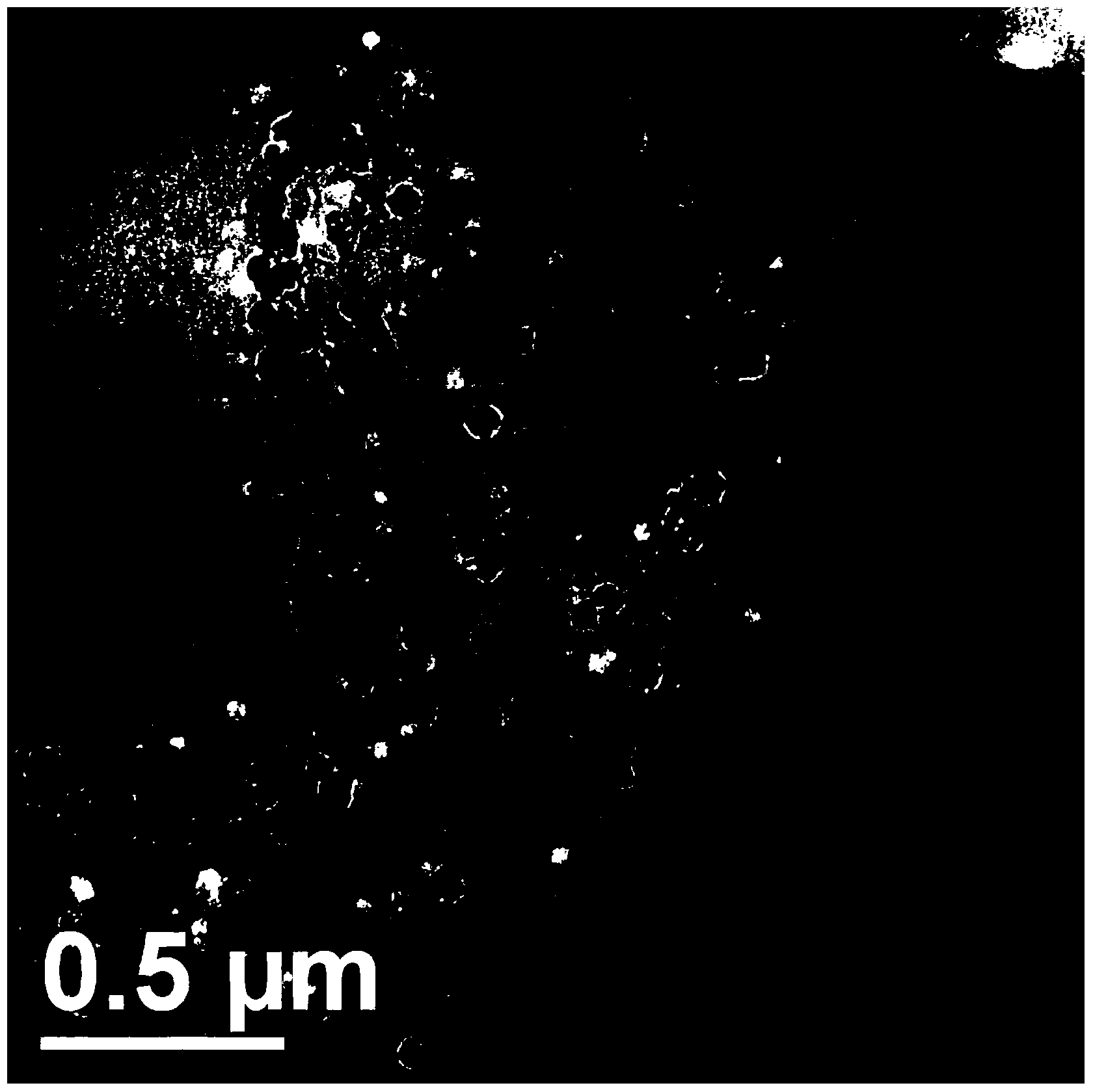

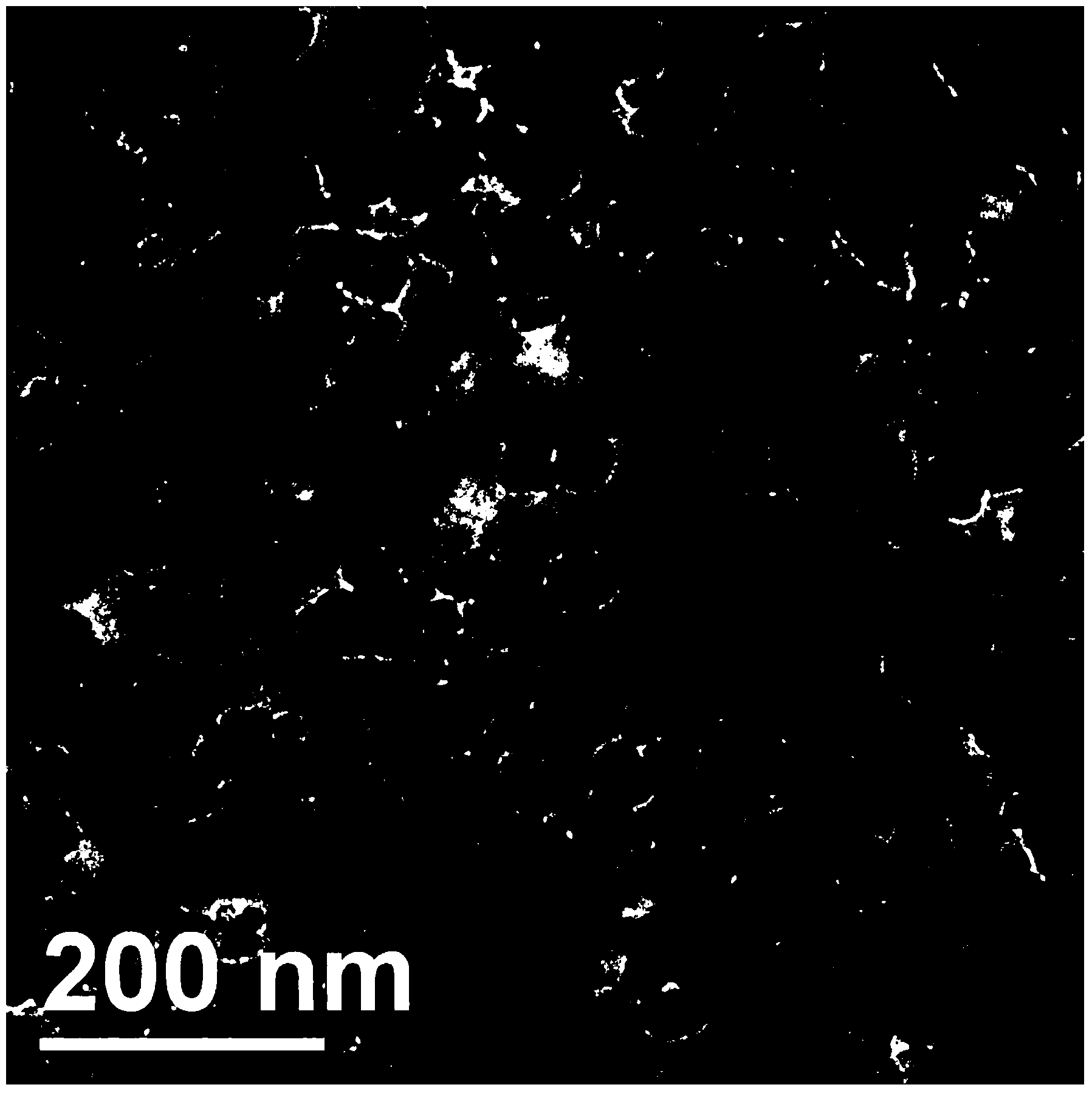

Nanocomposite material of nitrogen doped with graphene/manganese ferrite and preparation method thereof

A nitrogen-doped graphene and manganese ferrite nanotechnology, which is applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of limited application of specific capacitance, harsh reaction conditions, and high production cost , to achieve low-cost large-scale production, excellent electrochemical performance, and the effect of improving electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Implementation Example 1: The preparation method of a nitrogen-doped graphene / manganese ferrite nanocomposite material (the mass ratio of graphite oxide to manganese ferrite is 1:1) with a nitrogen doping amount of 1%, comprising the following steps:

[0025] In the first step, ultrasonically disperse graphite oxide with a content of 50 mg in 100 mL of absolute ethanol to obtain a uniform graphene oxide solution, and the ultrasonic time is 1 h;

[0026] In the second step, pour 0.1752g of ferric nitrate and 0.0542g of manganese nitrate into the above-mentioned uniformly dispersed mixed solution, and stir for 10 minutes;

[0027] In the third step, 5 g of urea is added to the obtained mixed system, and stirred again for 30 minutes to make it uniformly dispersed;

[0028] The fourth step is to transfer the obtained mixed solution into a flask and react at 200°C for 12 hours;

[0029] Step 5: The obtained product is subjected to centrifugation, washed and dried to obtain ...

Embodiment 2

[0031] Implementation Example 2: The preparation method of a nitrogen-doped graphene / manganese ferrite nanocomposite material (the mass ratio of graphite oxide to manganese ferrite is 1:5) with a nitrogen doping amount of 1.5%, comprising the following steps:

[0032] In the first step, ultrasonically disperse graphite oxide with a content of 80 mg in 100 mL of absolute ethanol to obtain a uniform graphene oxide solution, and the ultrasonic time is 2 h;

[0033] In the second step, pour 1.4015g of ferric nitrate and 0.4336g of manganese nitrate into the above-mentioned uniformly dispersed mixed solution, and stir for 20min;

[0034] In the third step, 15g of urea was added to the obtained mixed system, and stirred again for 40 minutes to make it uniformly dispersed;

[0035] The fourth step is to transfer the obtained mixed solution into a flask and react at 180°C for 16 hours;

[0036] Step 5: The obtained product is subjected to centrifugation, washed and dried to obtain a ...

Embodiment 3

[0038] Implementation Example 3: The preparation method of a nitrogen-doped graphene / manganese ferrite nanocomposite material (the mass ratio of graphite oxide to manganese ferrite is 1:10) with a nitrogen doping amount of 2% comprises the following steps:

[0039] In the first step, ultrasonically disperse graphite oxide with a content of 100 mg in 100 mL of absolute ethanol to obtain a uniform graphene oxide solution, and the ultrasonic time is 3 h;

[0040] In the second step, pour 3.5036g of ferric nitrate and 1.0840g of manganese nitrate into the above-mentioned uniformly dispersed mixed solution, and stir for 30min;

[0041] The third step is to add 20g of urea into the obtained mixed system, and stir again for 60min to make it evenly dispersed;

[0042] The fourth step is to transfer the obtained mixed solution into a flask and react at 120°C for 20 hours;

[0043] Step 5: The obtained product is subjected to centrifugation, washed and dried to obtain a nitrogen-doped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com