Buffering noise reduction ball mill

A ball mill and noise reduction technology, which is applied in grain processing, etc., can solve the problems of high noise, large impact of lining board, and affecting production efficiency, etc., to achieve the effect of blocking sound transmission, increasing service life, and reducing impact force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

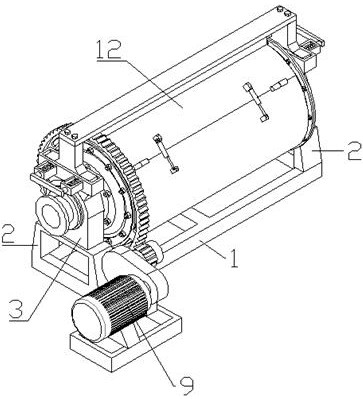

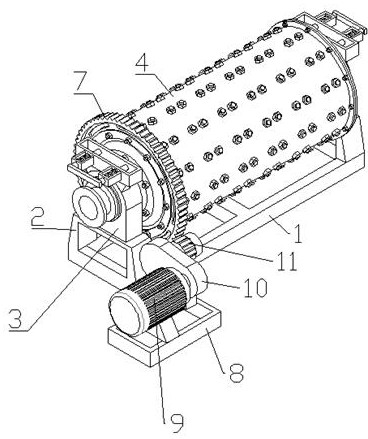

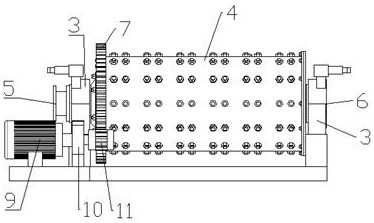

[0022] like Figure 1-8 As shown, a buffer noise-reducing ball mill includes a base frame 1, a support frame 2, a bearing seat 3, a cylinder body 4, a discharge port 5, a feed port 6, a driven gear 7, a motor base 8, a motor 9, a speed reducer Machine 10, driving gear 11, soundproof cover 12, the left and right ends of the bottom frame 1 are vertically welded with a support frame 2, the top of the support frame 2 is respectively fixed with a bearing seat 3, and a Cylinder 4, the left and right ends of the cylinder 4 are respectively provided with a discharge port 5 and a feed port 6, the left end of the cylinder 4 is fixed with a driven gear 7, and the top of the motor seat 8 is equipped with a motor 9, so The output shaft of the motor 9 is installed with the reducer 10, the output shaft of the reducer 10 is installed with the driving gear 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com