Prefabrication combined box type underground diaphragm wall and construction method thereof

An underground diaphragm wall and construction method technology, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of pre-embedded steel bars on floors, inaccurate positioning of connectors, high civilized construction costs, and difficult construction. Achieve the effects of improving civilized construction standards and intelligence, reducing building sheds and material stacking, reducing noise and environmental management costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

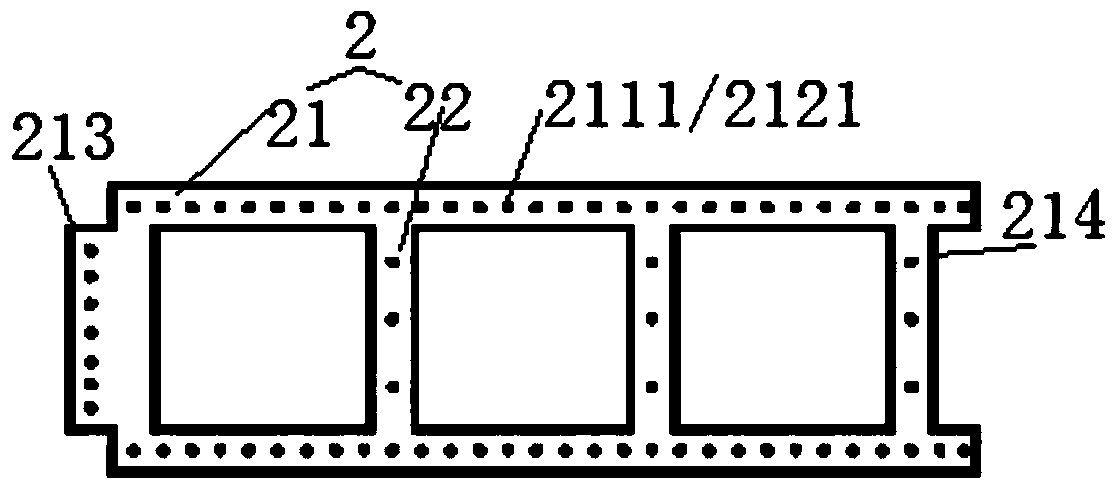

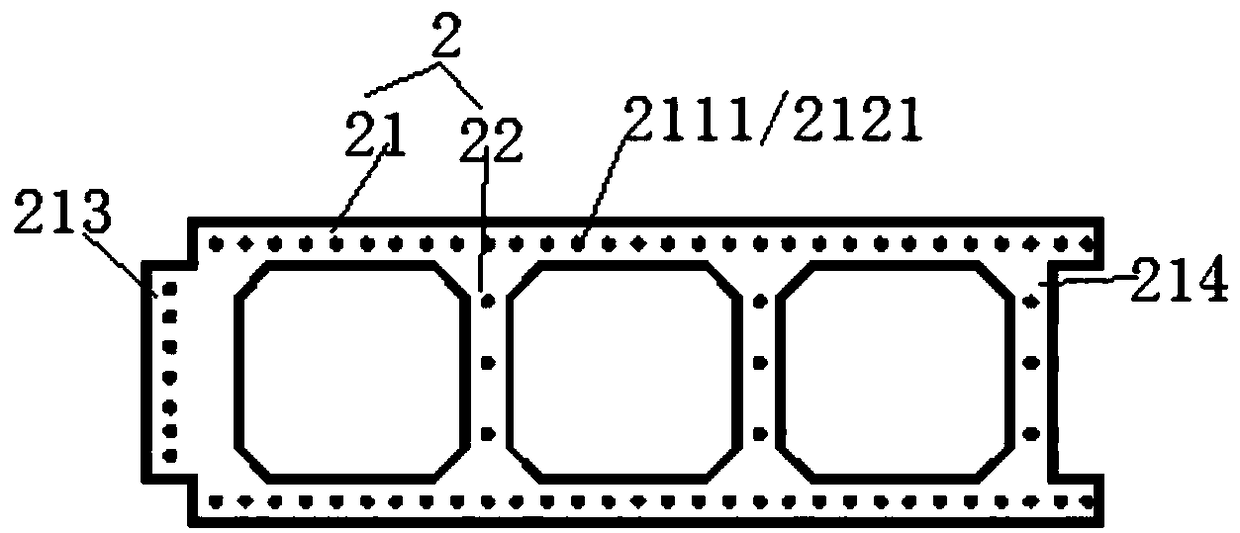

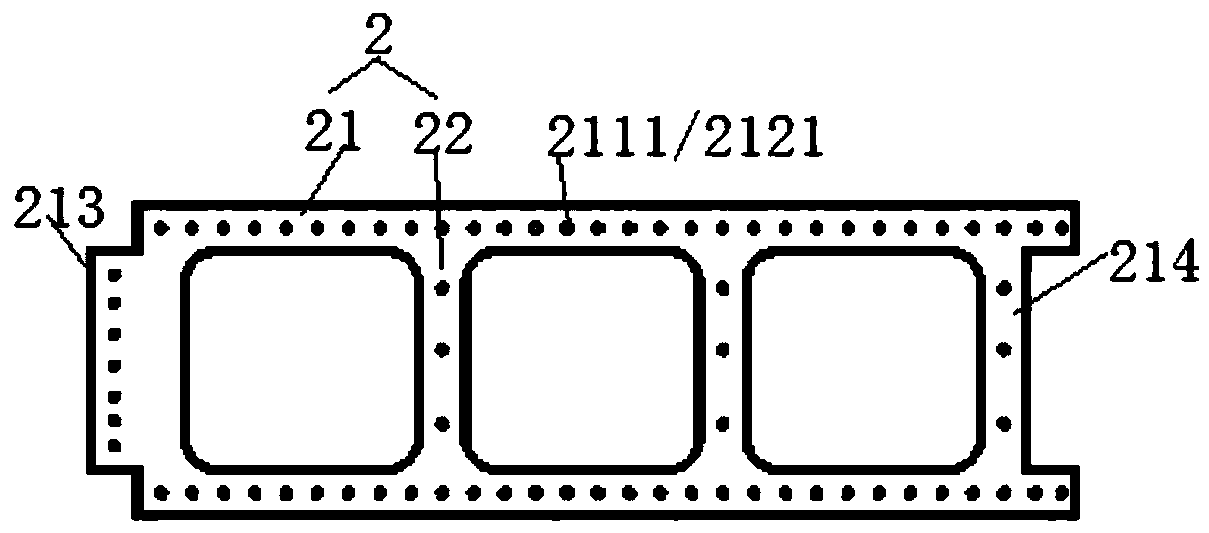

[0052] The invention discloses a prefabricated combined box type underground continuous wall, such as Figure 1-18 As shown, it includes a prefabricated box-type underground diaphragm wall component 2 as a retaining structure for the foundation pit. The prefabricated box-type underground diaphragm wall component 2 includes a box body 21 with a hollow portion 215 and a web 22 arranged in the box body 21. ;

[0053] The vertical ends of the box 21 are provided with a first tenon 211 or a first mortise 212; the lateral ends of the box 2 are provided with a second tenon 213 or a second mortise 214; adjacent prefabricated box-type underground continuous wall components ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com