Method for mixing solid granules and syrup uniformly

A technology for solid granules and syrup, applied in confectionery, confectionery industry, food science and other directions, can solve the problems of destroying the chemical composition of mixtures, difficult to process products, difficult to stir, etc., to improve quality, reduce energy consumption, and reduce production noise Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention uses two-pipe parallel hybrid type such as Figure 4 Shown as the best embodiment illustrates the specific implementation method:

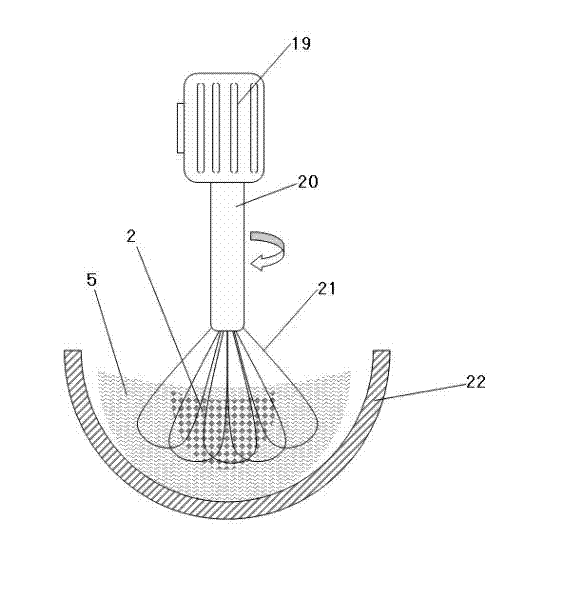

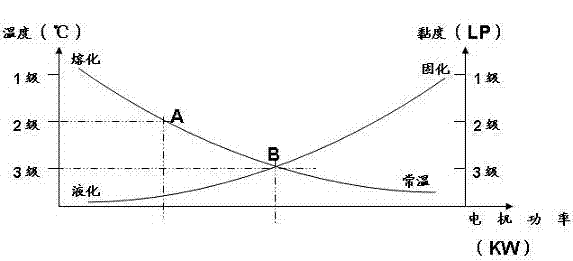

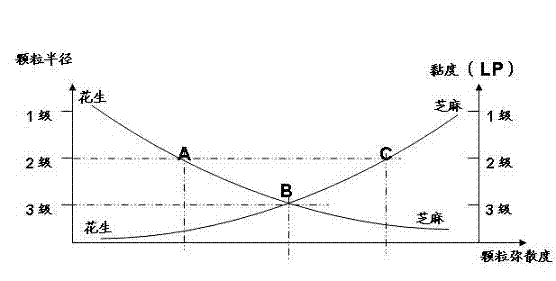

[0031] The mixing method of traditional solid particles 2 and syrup 5 all adopts figure 1 In the method of stirring and mixing with the agitator shown, since the viscosity of the syrup 5 increases greatly as the temperature decreases, the friction with the wall of the stirring pot 22 and the stirring blade 21 increases thereupon, and the syrup 5 will produce high temperature immediately. The agitator in the center of the round-bottomed pot, the fluid vortex generated by the syrup 5 after stirring, will draw most of the solid particles 2 with a small specific gravity and suspended on the surface of the syrup 5 into the stirring blade 21, causing the solid particles 2 to break and coke. Poor taste and serious loss of nutrition.

[0032] The present invention uses a steam heating method to humidify and heat the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com