Deep groove ball bearing retainer and bearing

A technology for deep groove ball bearings and cages, which is applied to ball bearings, bearing components, shafts and bearings, and can solve problems such as noise, rivets increasing production costs, and rivets falling off.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to clearly illustrate the technical characteristics of this solution, the following will describe this solution through specific implementation modes and in conjunction with the accompanying drawings.

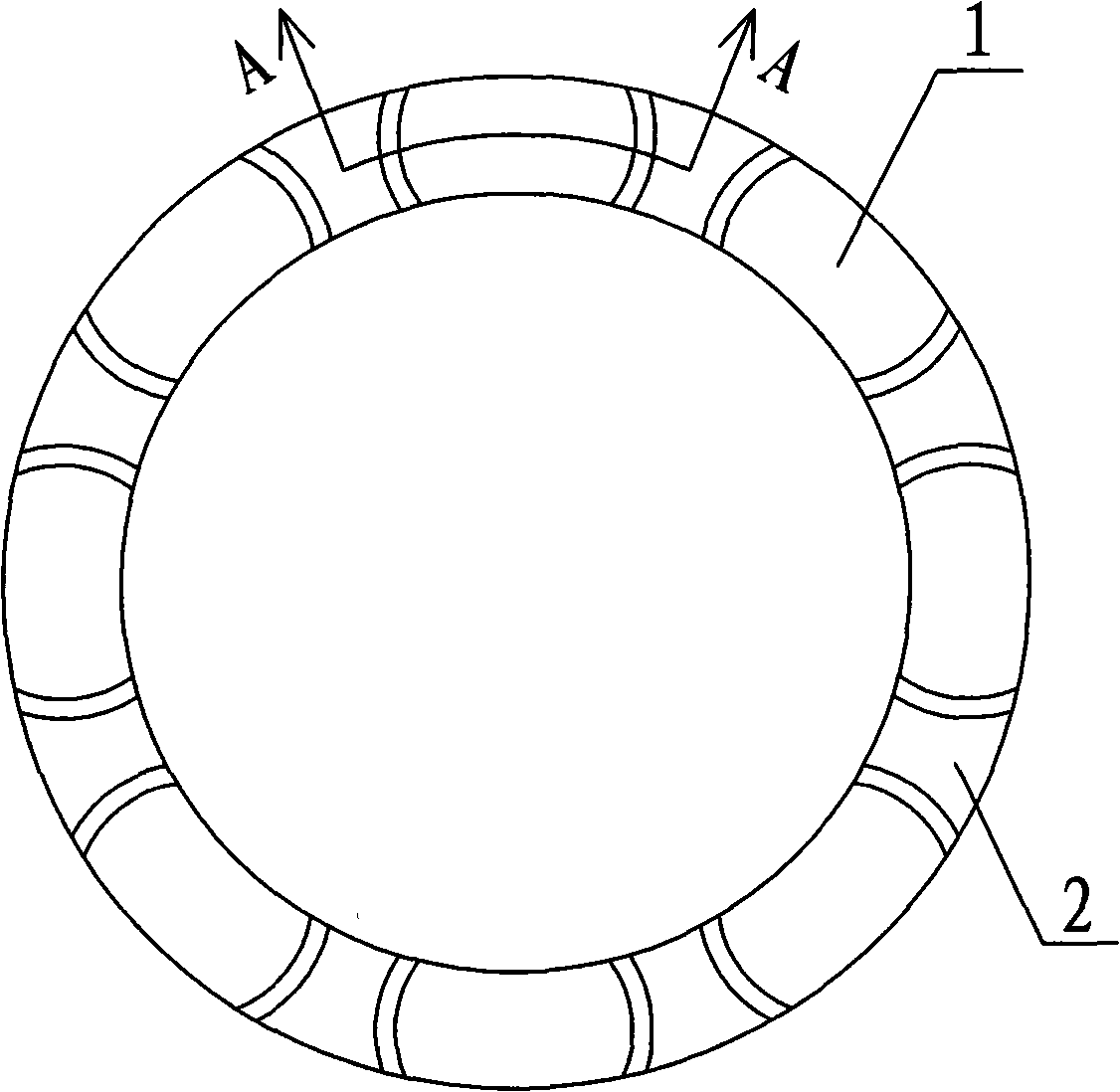

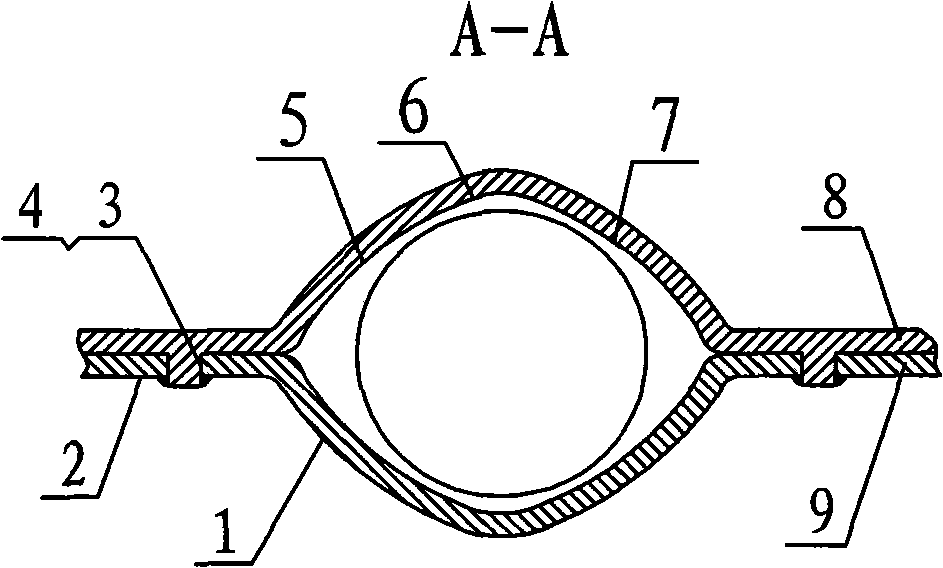

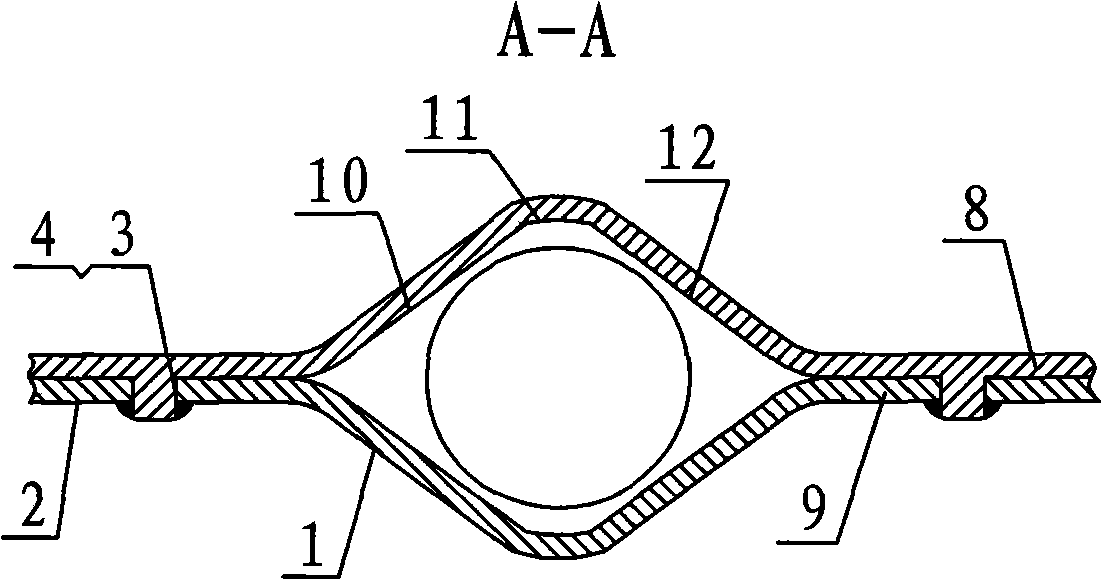

[0015] A deep groove ball bearing cage, such as figure 1 , figure 2 and image 3 As shown, it includes a frame body I8 and a frame body II 9 that are docked with each other. The frame body I 8 and the frame body II 9 are composed of a ball pocket 1 and a plane 2 that connects each ball pocket 1 into a ring shape. The frame body I 8 Protrusions 3 are provided on at least three planes 2 above, and positioning holes 4 corresponding to the protrusions 3 are provided on the corresponding planes 2 of the frame body II 9 . After the protrusion 3 passes through the positioning hole 4, the end of the protrusion 3 is welded to the frame body II 9 together.

[0016] The contour line of the inner surface of the single ball bag 1 on the frame body I 8 and the frame body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com