Patents

Literature

45results about How to "Accurate heating control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

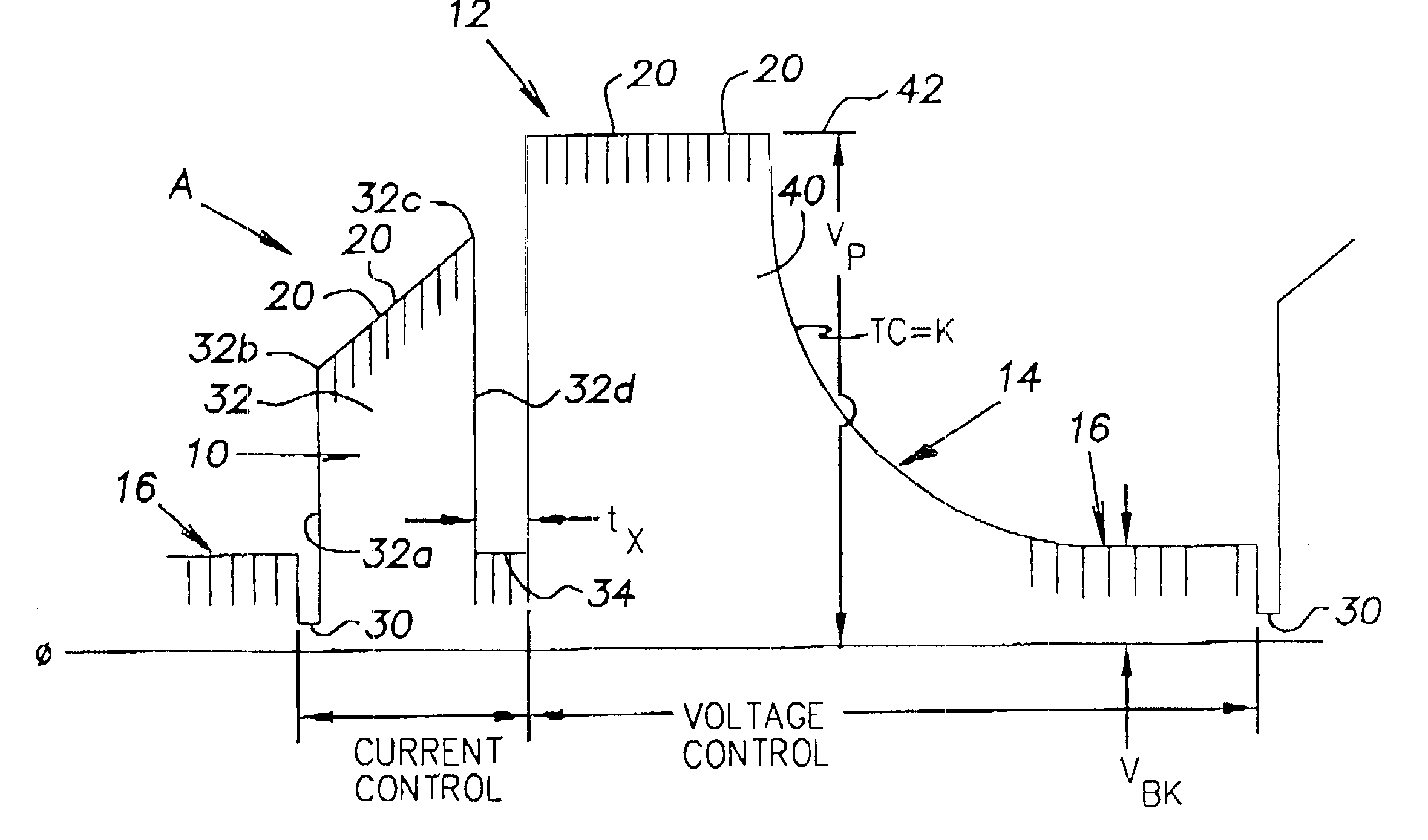

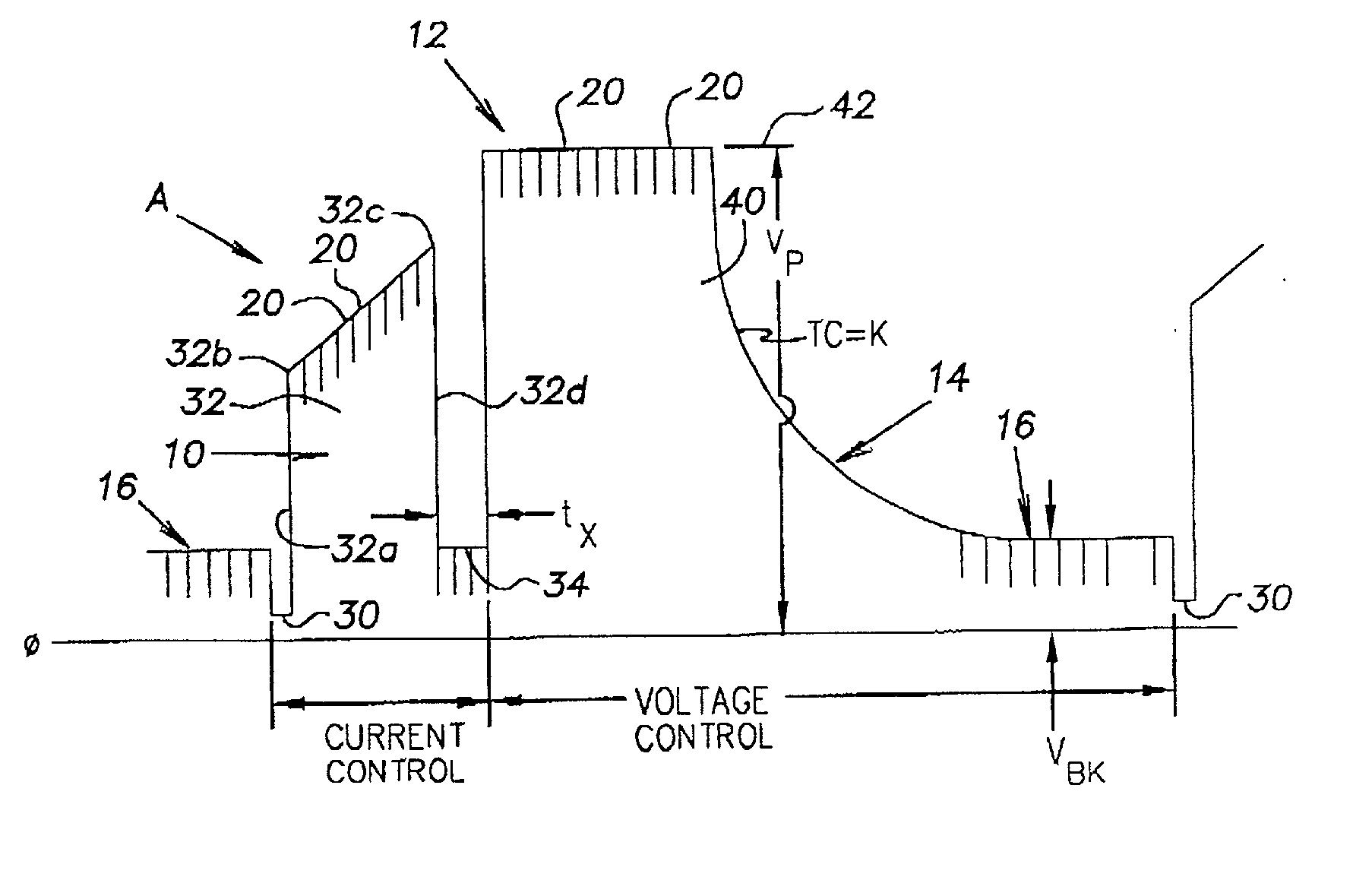

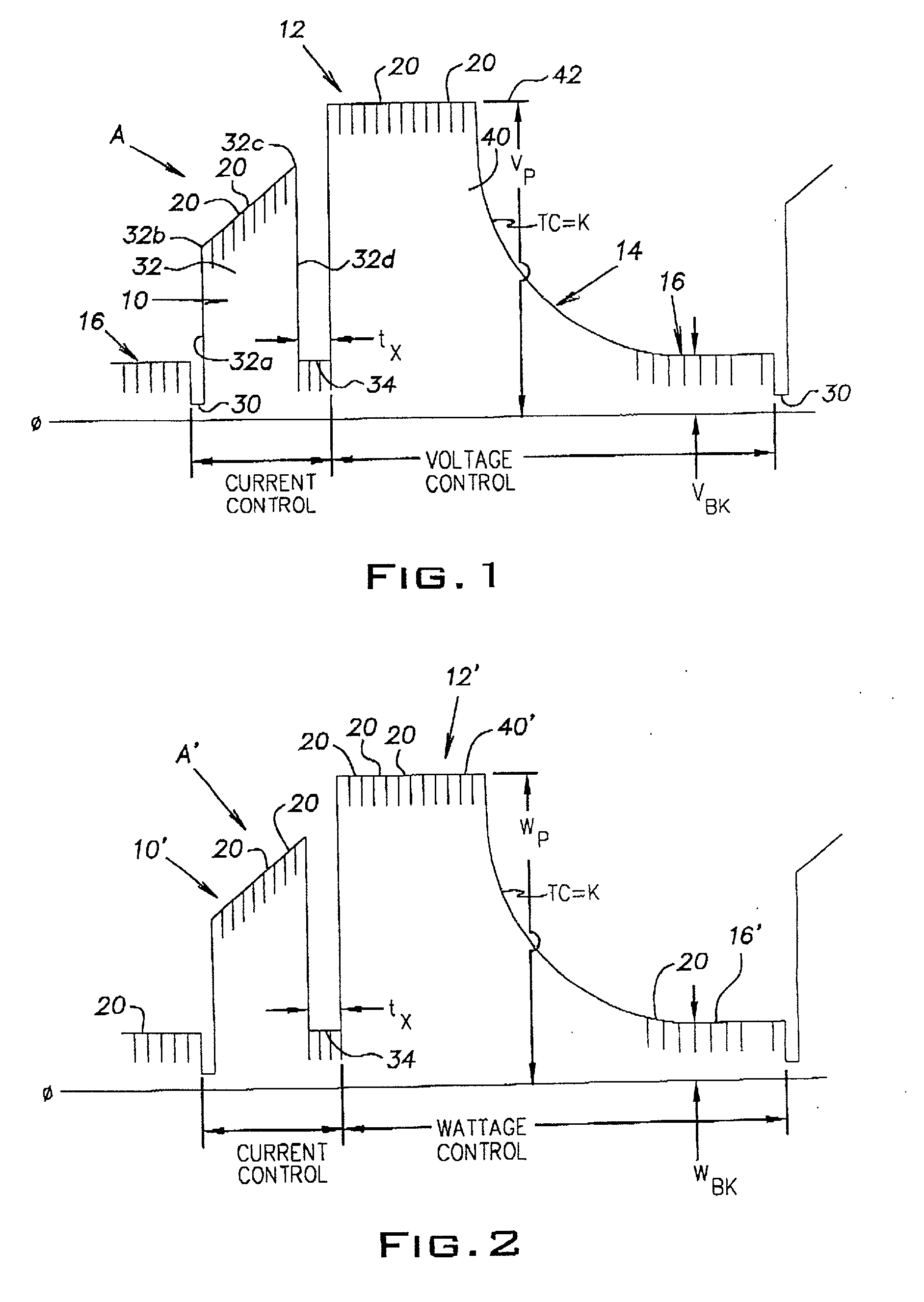

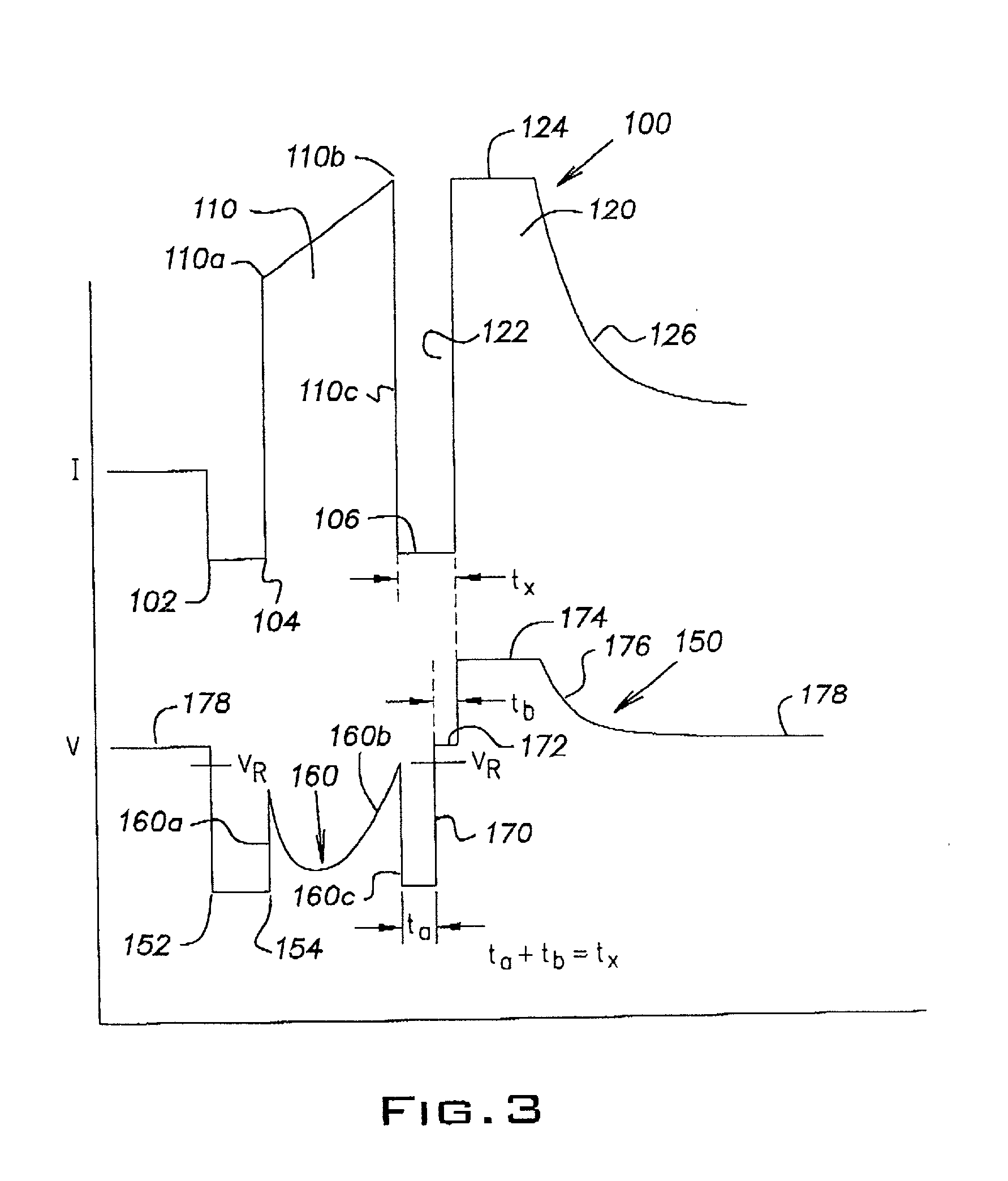

Short circuit arc welder and method of controlling same

InactiveUS6501049B2Easy to controlAccurate heating controlArc welding apparatusTubular articlesEngineeringComparator

An electric arc welder operated to perform a short circuit process with a first waveform controlling a short condition followed by a second waveform controlling an arc condition, wherein the welder includes a comparator to create an arc signal when the short condition terminates and a controller shifting the welder from control by the first waveform to control by the second waveform in response to creation of the arc signal.

Owner:LINCOLN GLOBAL INC

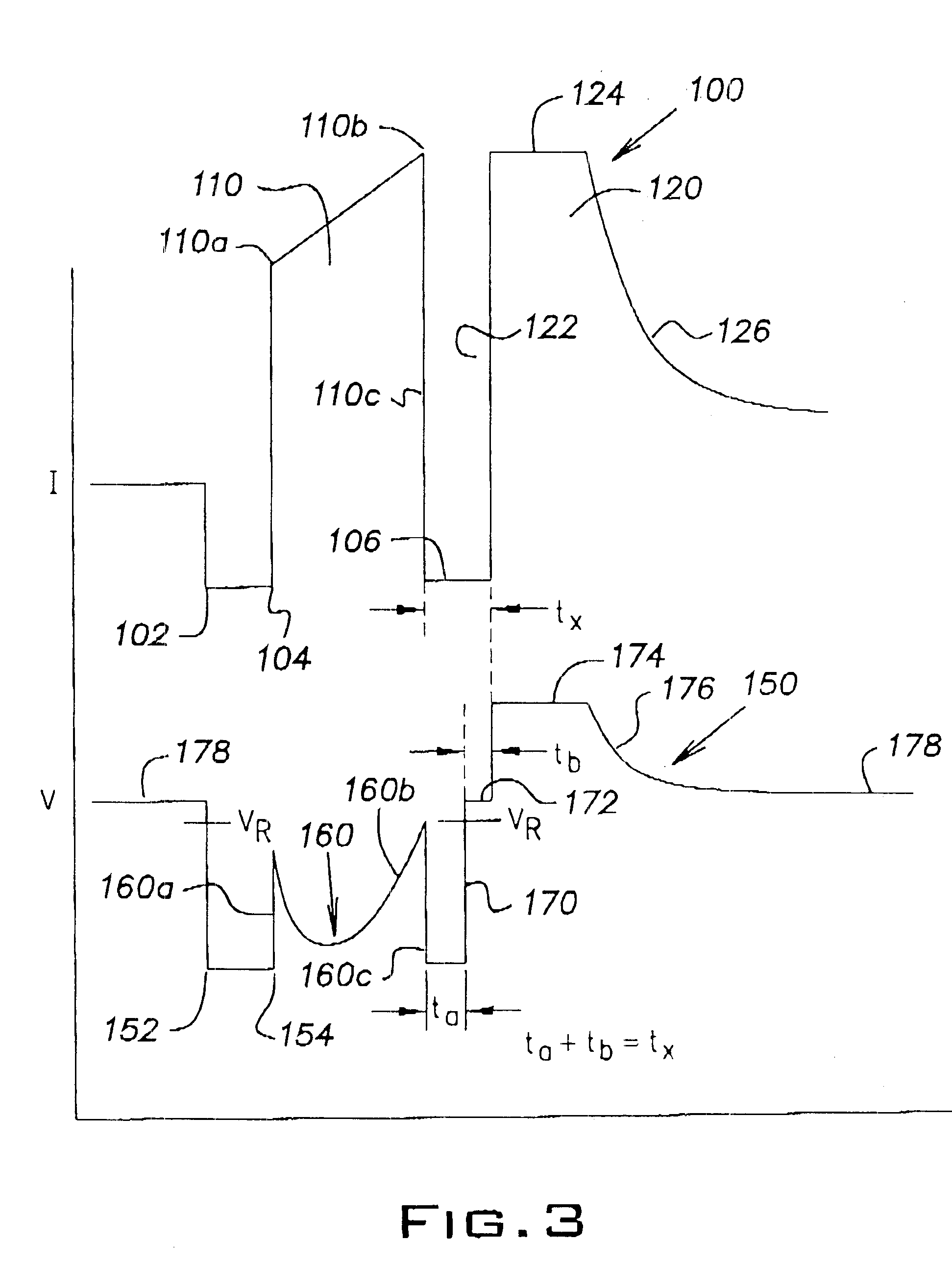

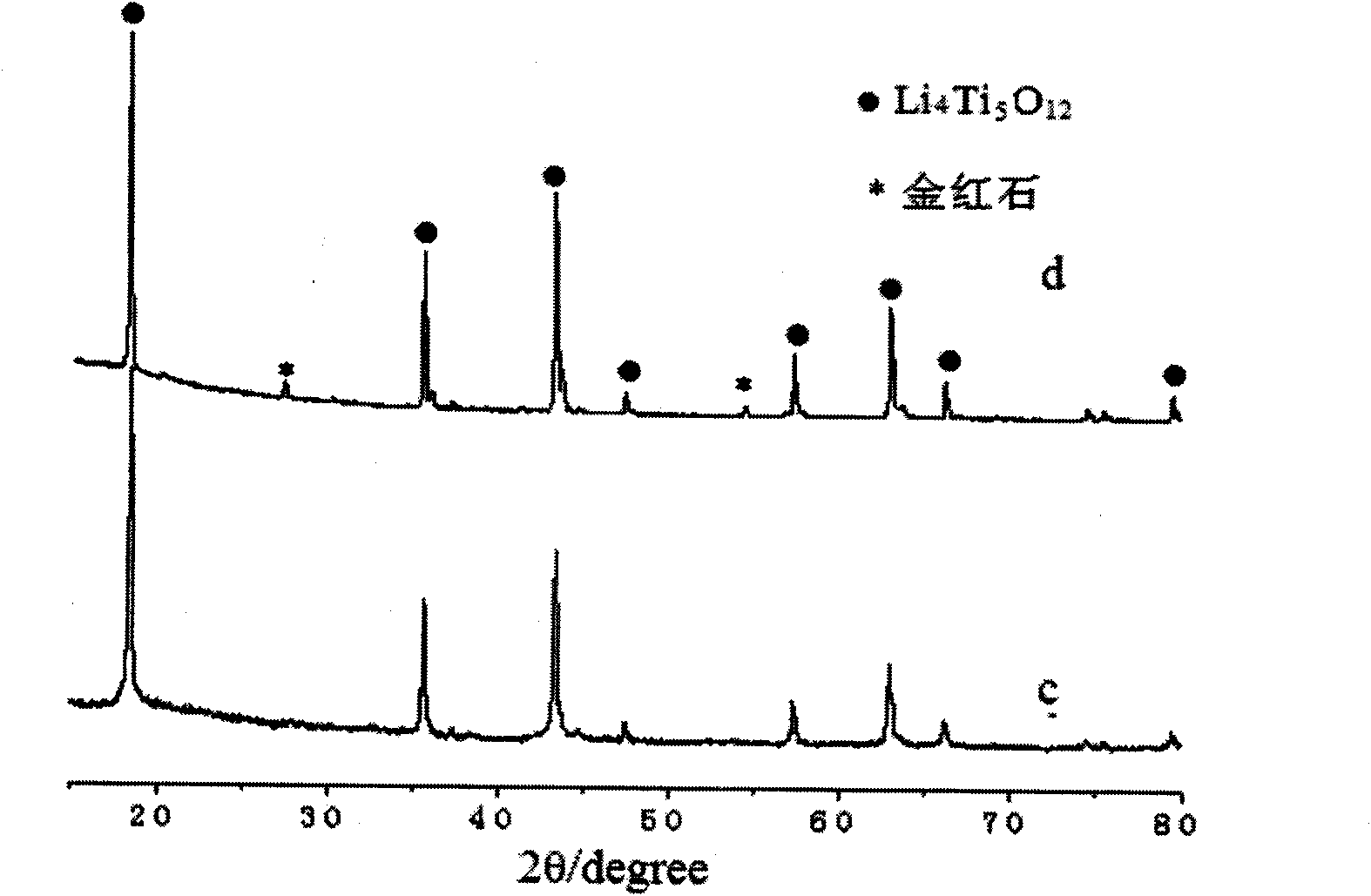

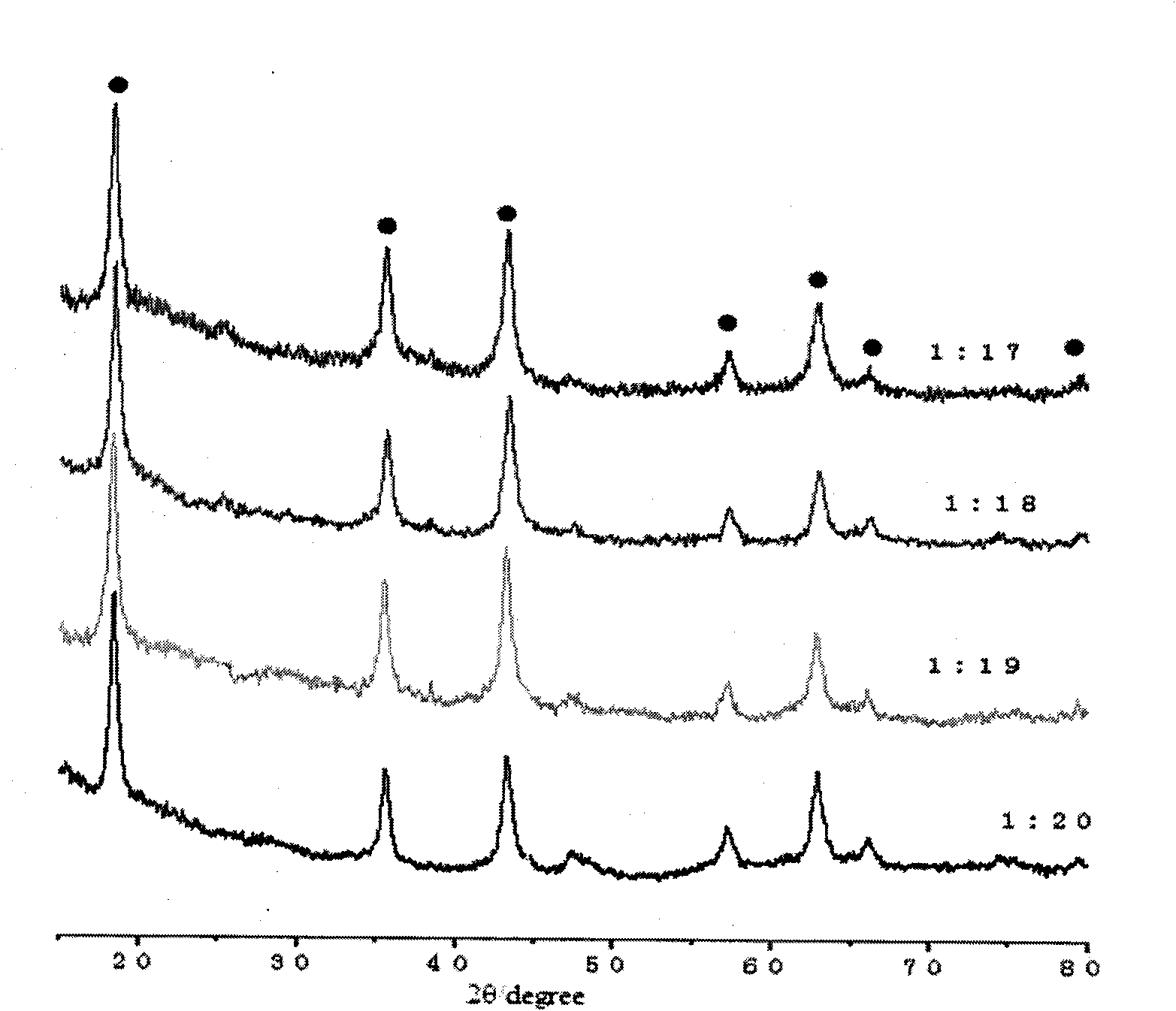

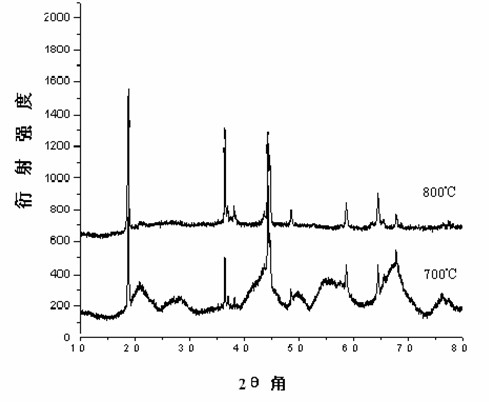

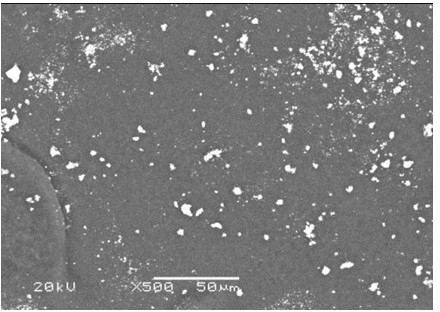

Method for preparing spinel lithium titanate of cathode material of lithium ion battery

InactiveCN101593830ALow costReduce energy consumptionElectrode manufacturing processesCombined methodMicroparticle

The invention relates to a method for preparing a cathode material Li4Ti5O12 of a high-performance lithium ion battery. The method comprises the following steps of: adopting the combined method of sol-gel and microwave treatment to prepare micro powder of nano-class Li4Ti5O12, and simultaneously modifying Li4Ti5O12 by carbon doping and metallic doping. The method utilizes the sol-gel method to effectively control chemical composition, phase composition and powder size of the Li4Ti5O12, thereby improving the uniformity and the electric conductivity of the Li4Ti5O12; simultaneously by utilizing the characteristics of the microwave technique of quick temperature rise, even heating and conglobation resistance, the high-power industrial microwave oven is used for treatment, so that the treatment time of the Li4Ti5O12 is greatly shortened, the yield is greatly improved, and the cost and the energy consumption of the material are reduced, the process is simplified, the efficiency on the industrialized production of the lithium ion battery is improved, and the industrialized application is easily achieved; and by doping carbon and metallic elements, the electric conductivity of lithium iron phosphate is greatly improved, and the charging and discharging capacities and the cycle index of the lithium iron phosphate are simultaneously and effectively increased.

Owner:ZHENGZHOU UNIV +1

Short circuit arc welder and method of controlling same

InactiveUS20020125235A1Accurately controlEasy to controlArc welding apparatusTubular articlesElectric arcEngineering

An electric arc welder operated to perform a short circuit process with a first waveform controlling a short condition followed by a second waveform controlling an arc condition, wherein the welder includes a comparator to create an arc signal when the short condition terminates and a controller shifting the welder from control by the first waveform to control by the second waveform in response to creation of the arc signal.

Owner:LINCOLN GLOBAL INC

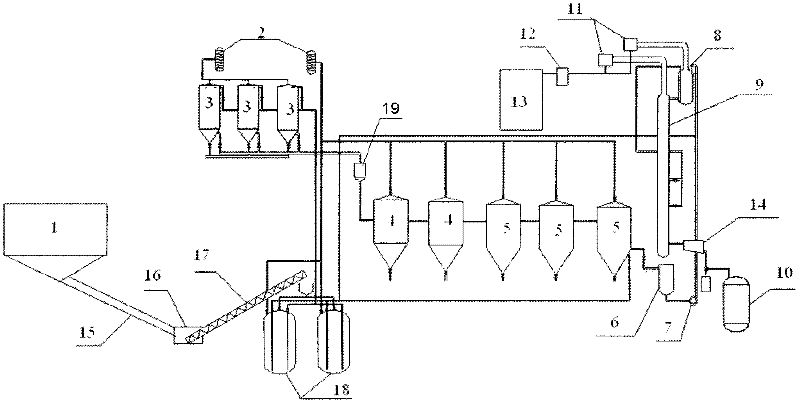

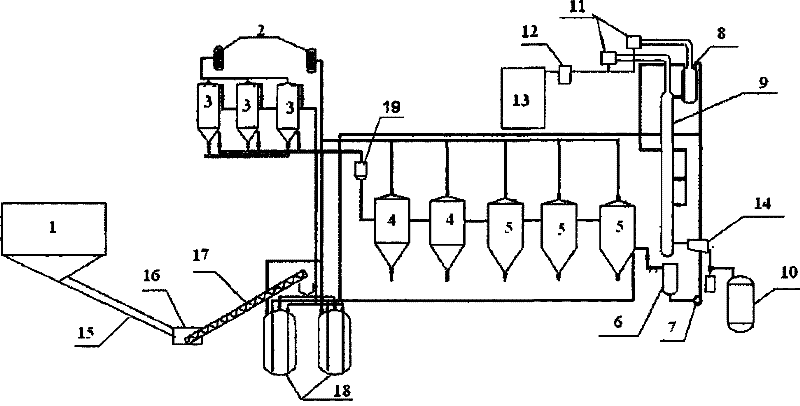

Method for producing rosin

ActiveCN102311705AQuality achievedReduce refluxTurpentine spiritsNatural resin purificationTurpentineRosin

The invention provides a method for producing rosin by turpentine, which comprises the following steps of melting, clarifying and distilling. The melted turpentine liquid is pressed in at least two higher-placed furnaces by vapor pressure in the melting process. The subsequent clarifying process is performed after the melted turpentine liquid is stayed in the higher-placed furnaces. The rosin product obtained by the method of the present invention can reach the grade of national superfine standard.

Owner:景东力奥林产集团林业化工有限公司

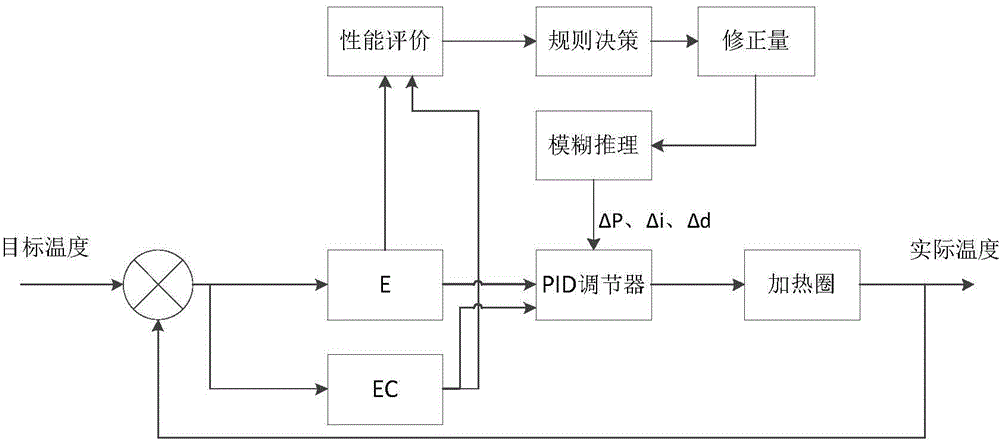

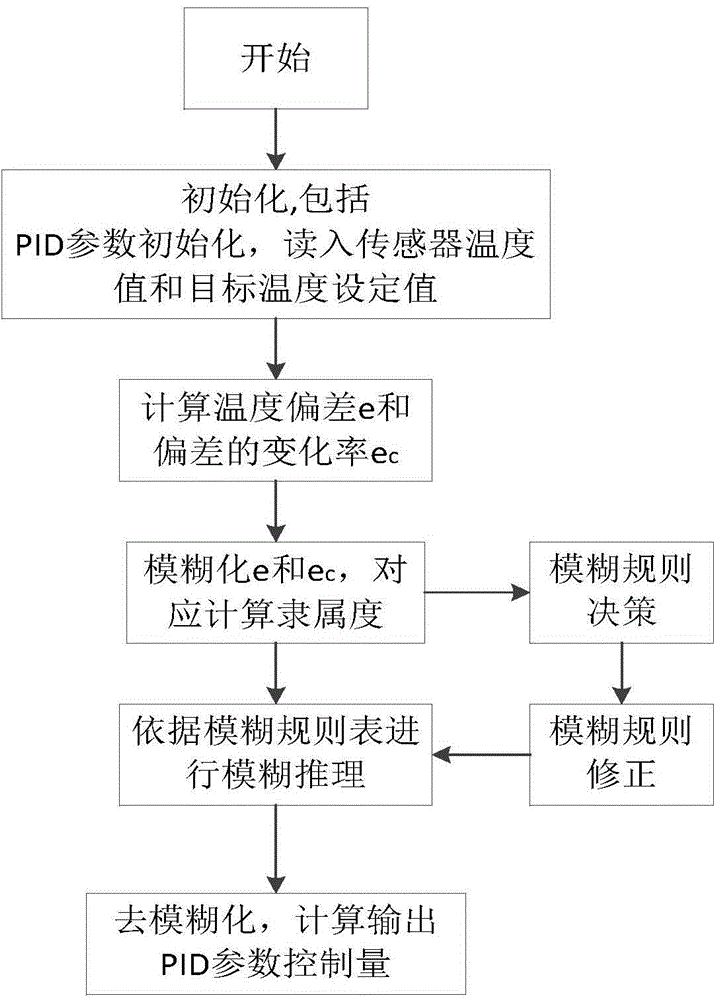

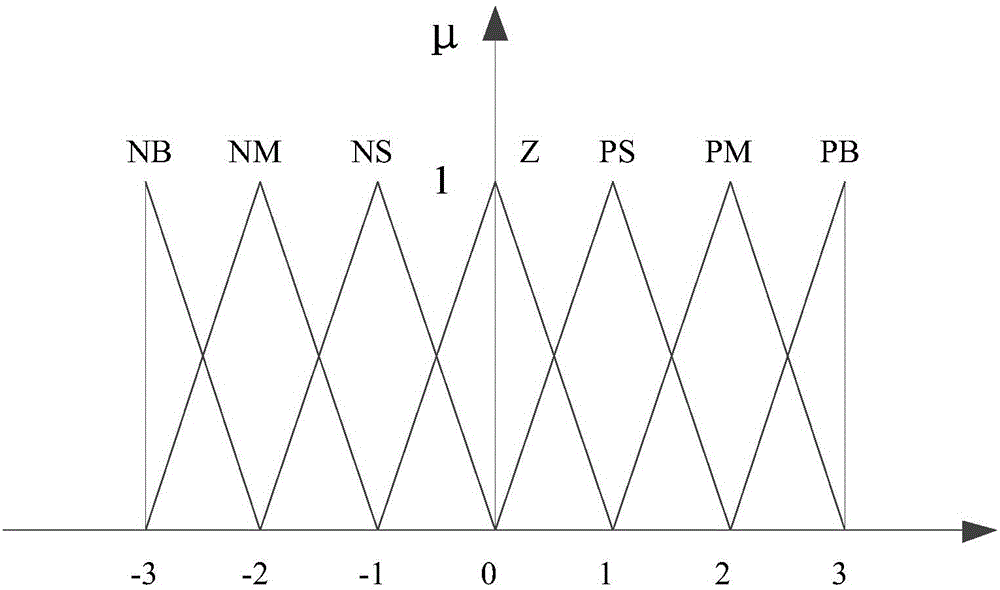

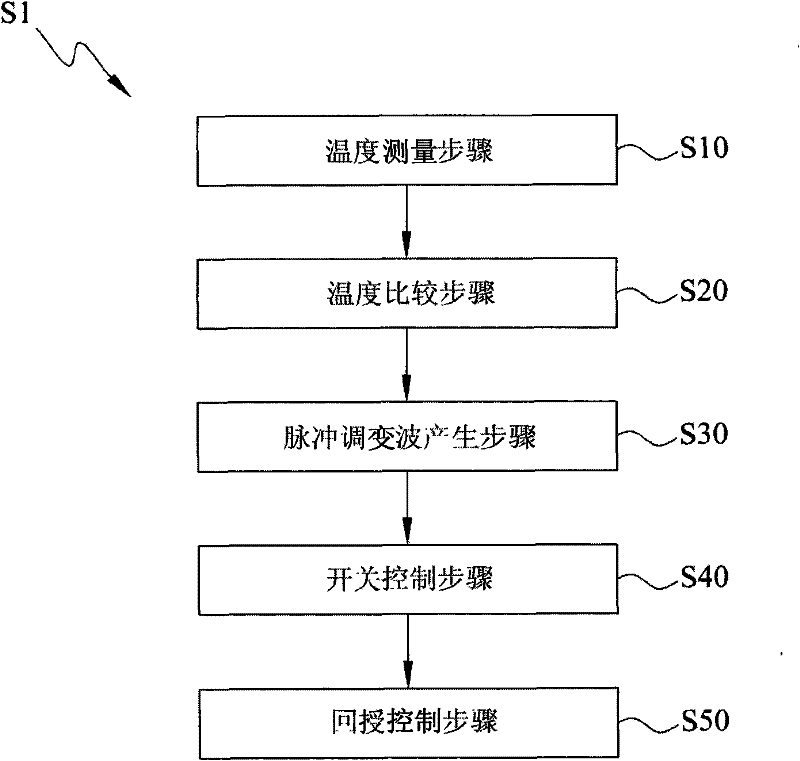

Barrel temperature control method of injection molding machine

The invention discloses a barrel temperature control method of an injection molding machine. The method comprises the following steps: S1, a fuzzy value E of temperature deviation between measured temperature and target temperature in a current sampling period k and a fuzzy value EC of temperature deviation variation rate between the measured temperature in the current sampling period and measured temperature in the last sampling period are calculated; S2, PID fuzzy reasoning operation of the current sampling period is carried out, and fuzzy rule of the current sampling period during the operation is corrected; S3, PID controlled quantities of the current sampling period are calculated, and current heating control is carried out according to the controlled quantities of the current sampling period; and S4, the Steps S1 to S3 are repeated successively in the next sampling period (k+1). The fuzzy rule is corrected continuously by the method, and three quantities of PID are obtained according to the corrected fuzzy rule. Control precision can be raised, temperature overshoot can be effectively reduced, and time spend in heating to a specified temperature can be shortened.

Owner:HUAZHONG UNIV OF SCI & TECH

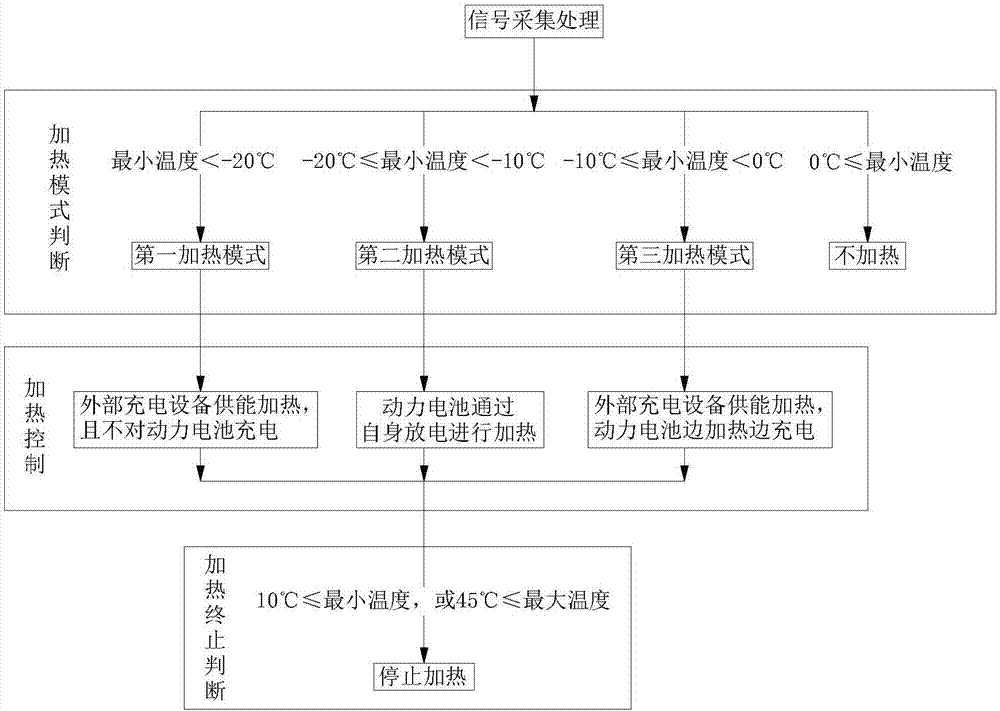

Power battery heating method based on self-adaption

InactiveCN107878234AProtect power batteryHeating fastVehicular energy storageBattery/fuel cell control arrangementSelf adaptiveEngineering

The invention relates to the field of power battery heating control and aims to provide a power battery heating method based on self-adaption. According to the adopted technical scheme, the power battery heating method based on self-adaption comprises the following steps of signal collecting treatment, judgment of heating modes, heating control and heating stopping judgment. According to the powerbattery heating method based on self-adaption, accurate heating control over a power battery is achieved, the targeted heating modes can be automatically selected according to the actual temperatureof the power battery, and the heating effect is better.

Owner:CHENGDU RAJA NEW ENERGY AUTOMOTIVE TECH CO LTD

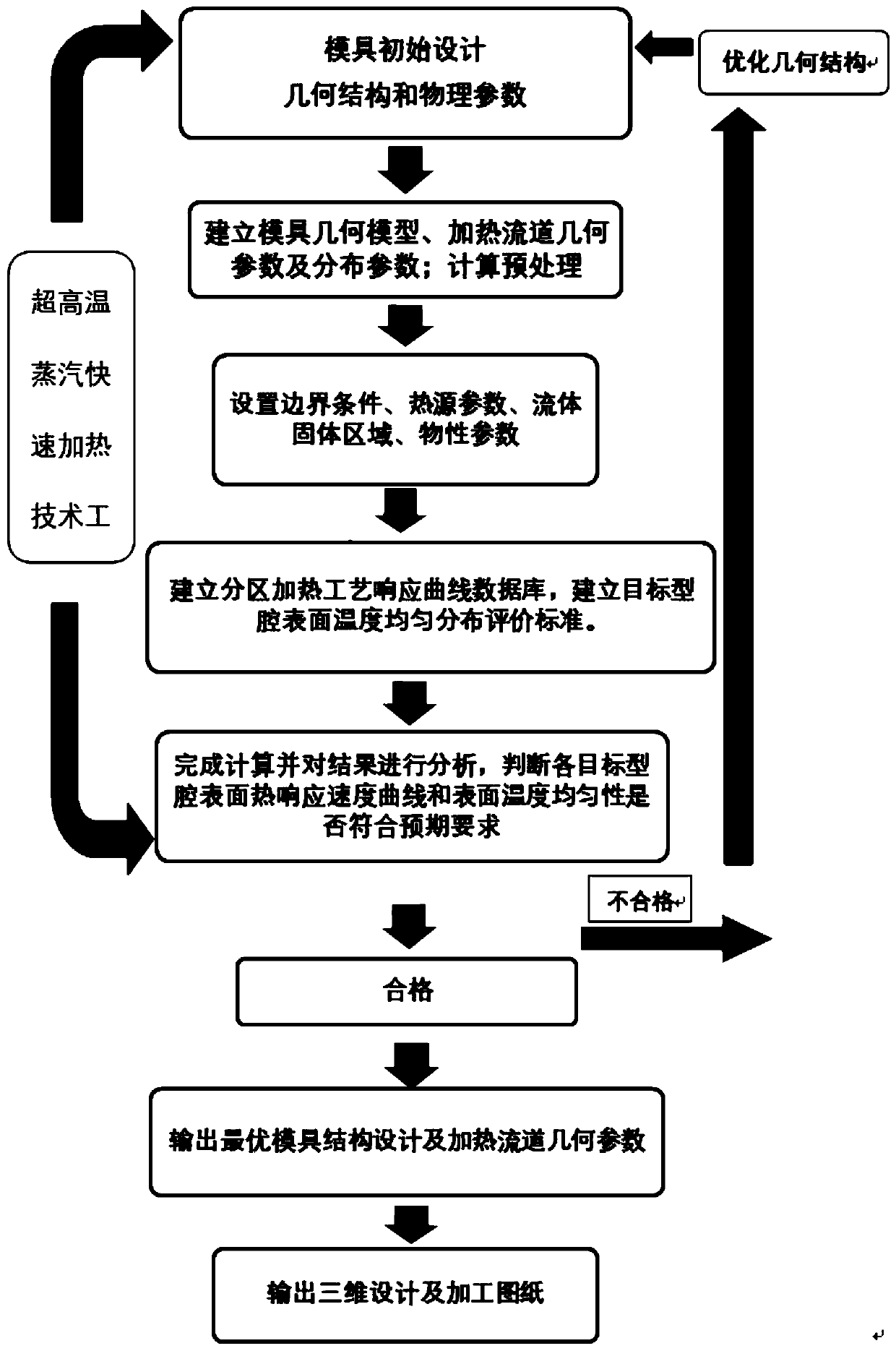

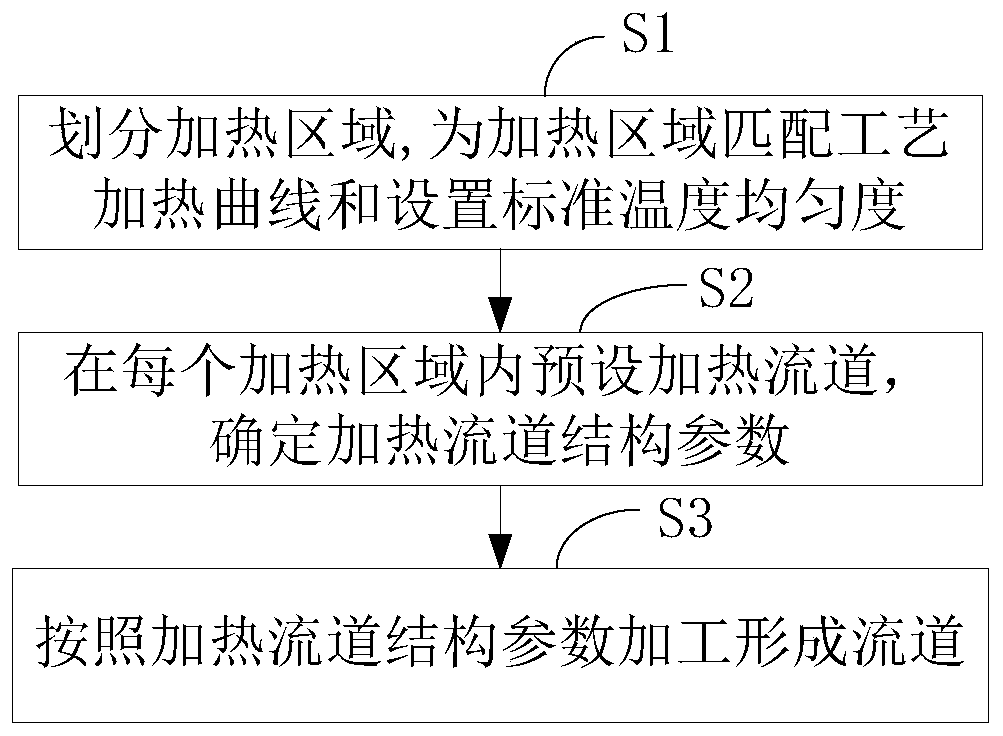

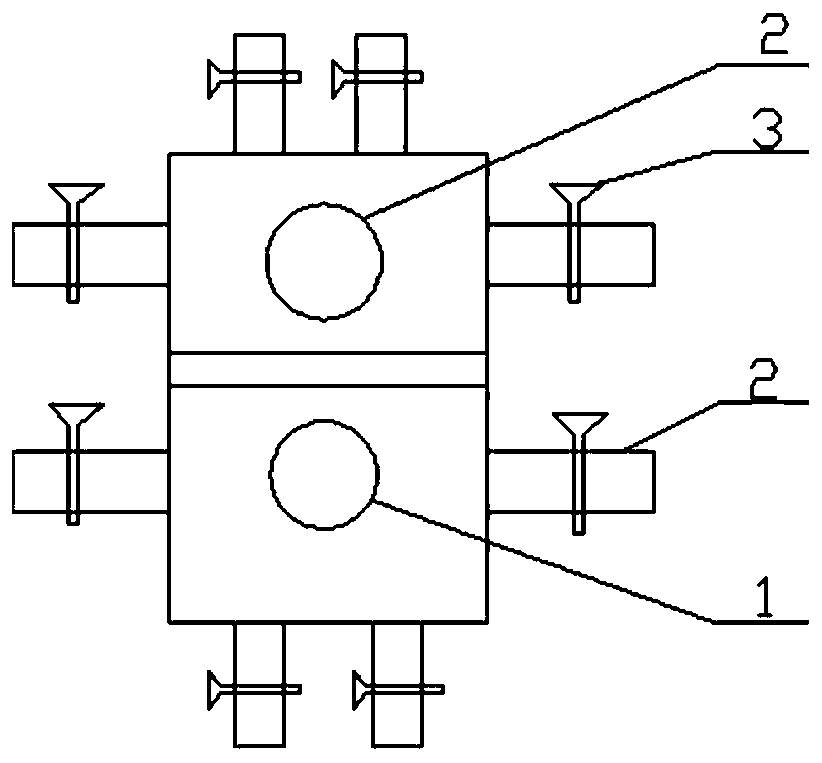

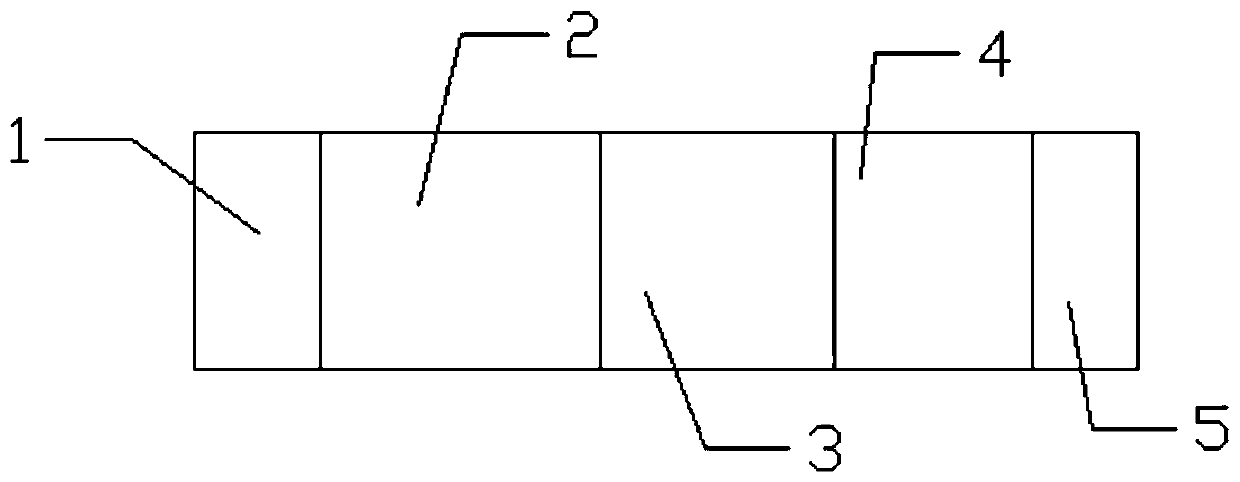

Mould preparation method, mould, mould heating system and heating controlling method

ActiveCN110027139AUniform temperatureMeet the needs of fast-changing mold temperatureThermometers using electric/magnetic elementsUsing electrical meansHot runnerModular unit

The invention discloses a mould preparation method, a mould, a mould heating system and a heating controlling method. The method comprises the following steps: S1, dividing heating areas; S2, pre-setting at least one heating flow channel in each of the heating areas, and the method for determining structural parameters of the heating flow channels comprises the following steps: S21, pre-setting the structural parameters of the heating flow channels; S22, obtaining an actual heating curve of each of the heating areas and actual temperature of each of position points of a mold cavity surface; S23, carrying out deviation analysis and adjusting the structural parameters of the heating flow channels according to a deviation analysis result; S24, repeatedly carrying out the steps S22 and S23; and S3, carrying out processing according to the structural parameters of the heating flow channels to form flow channels. The mould is heated in subareas, and the structural parameters of the flow channels are determined separately in each of the heating areas, so that the phenomena that the overall heat response speed of the mould and the temperature uniformity of the whole mold cavity can meet the requirement can be ensured, and by adopting the method, the requirement on quick change of the mould temperatures of complicated modular unit structures can be met, and subarea heating can be conveniently carried out.

Owner:宁波柚贝儿童用品有限公司

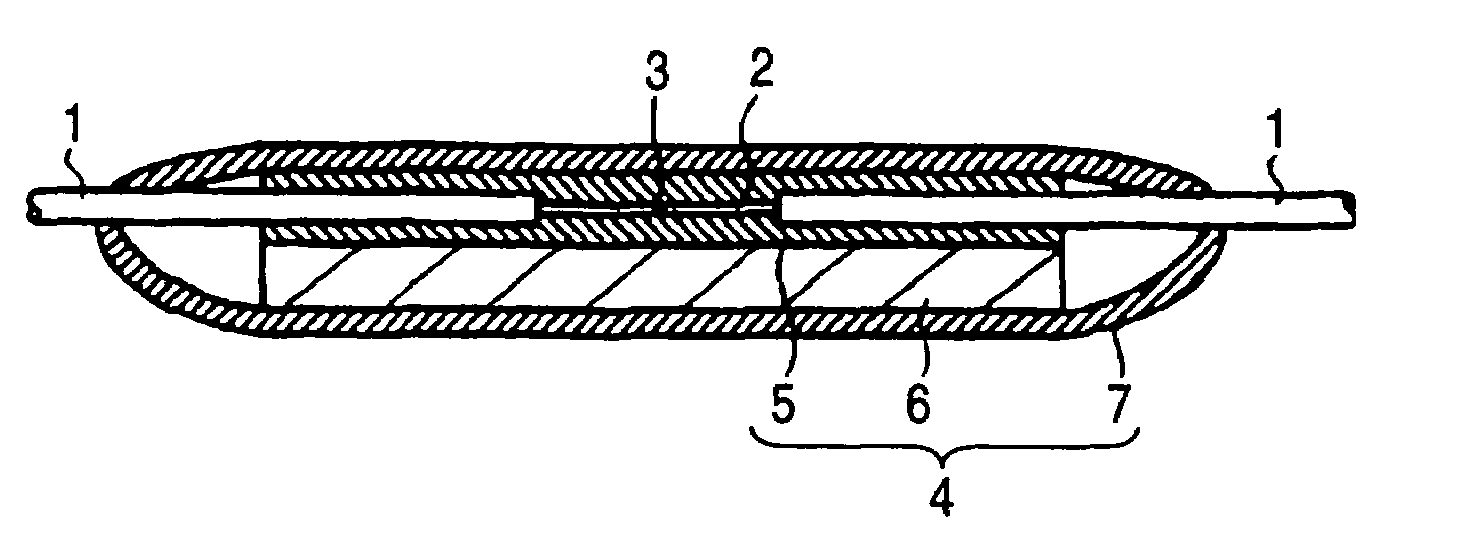

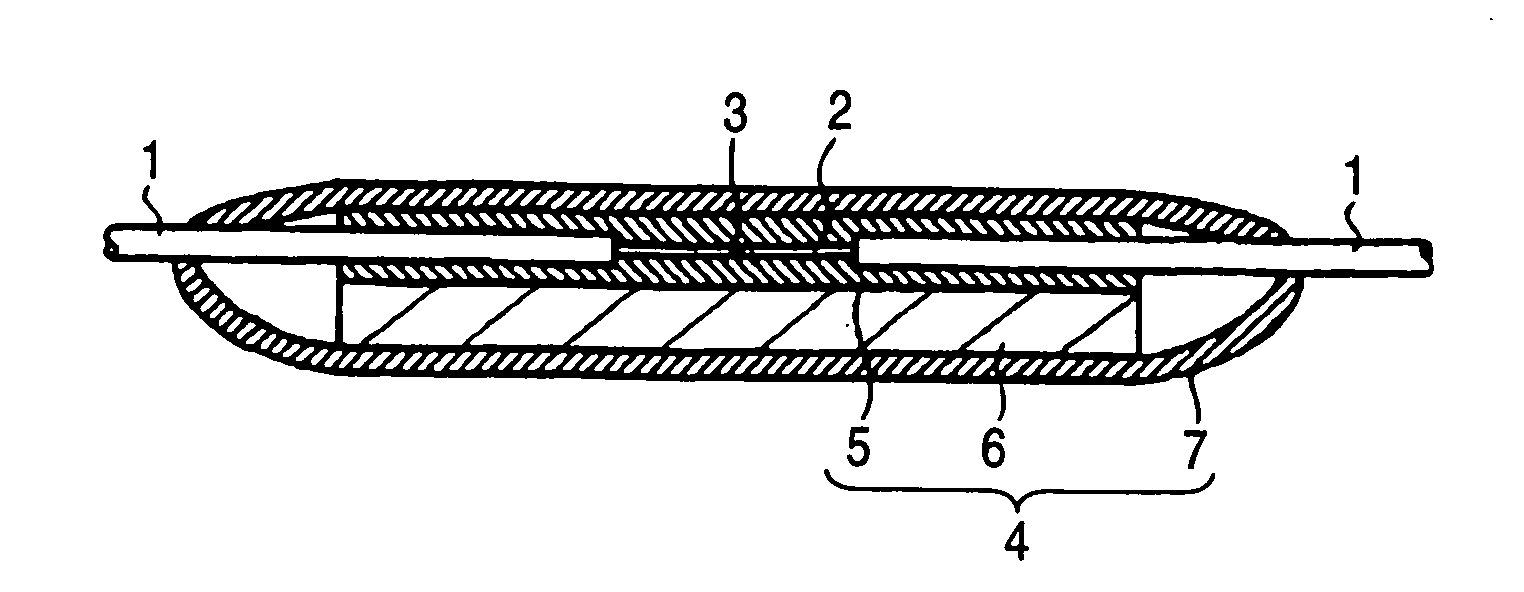

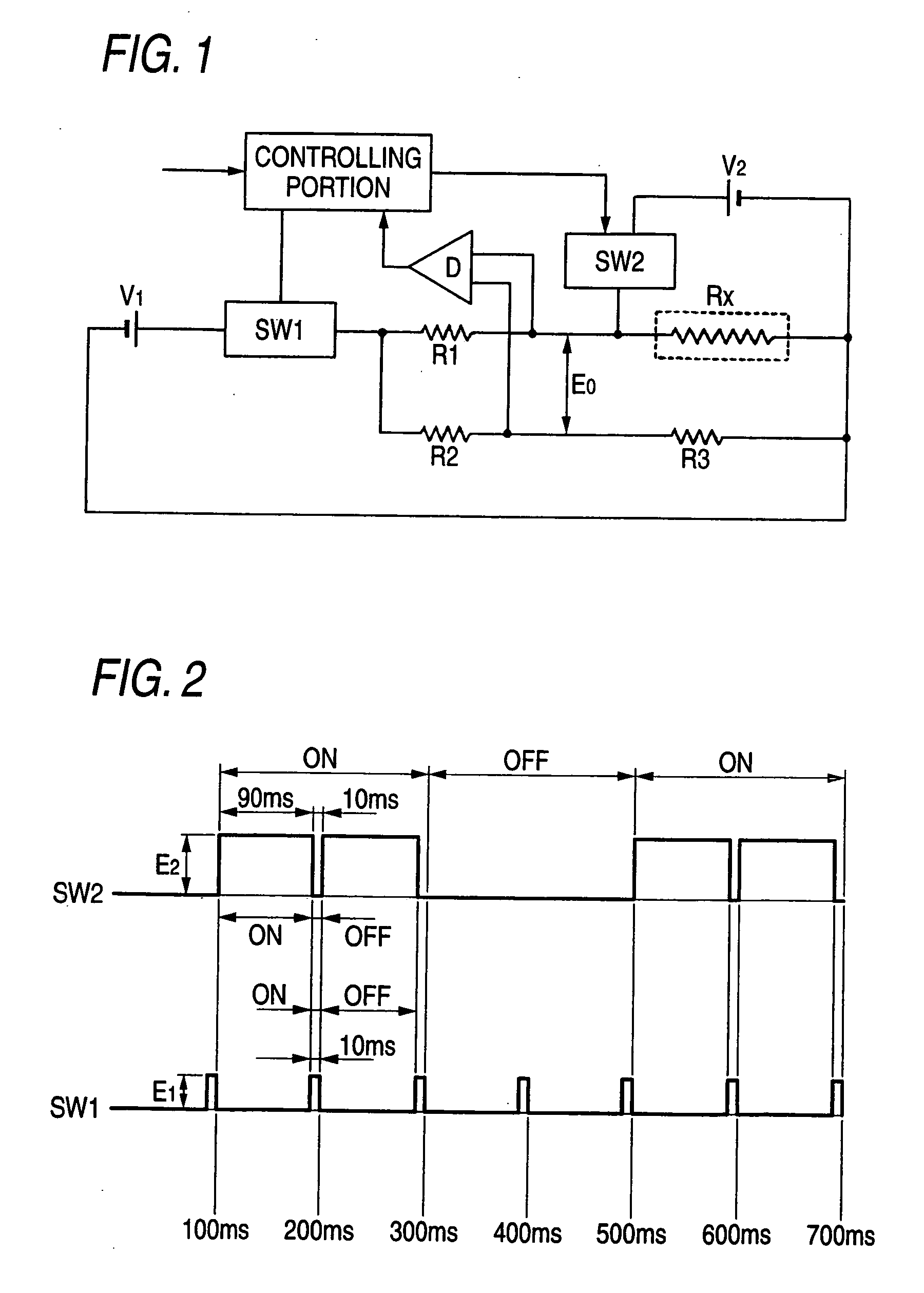

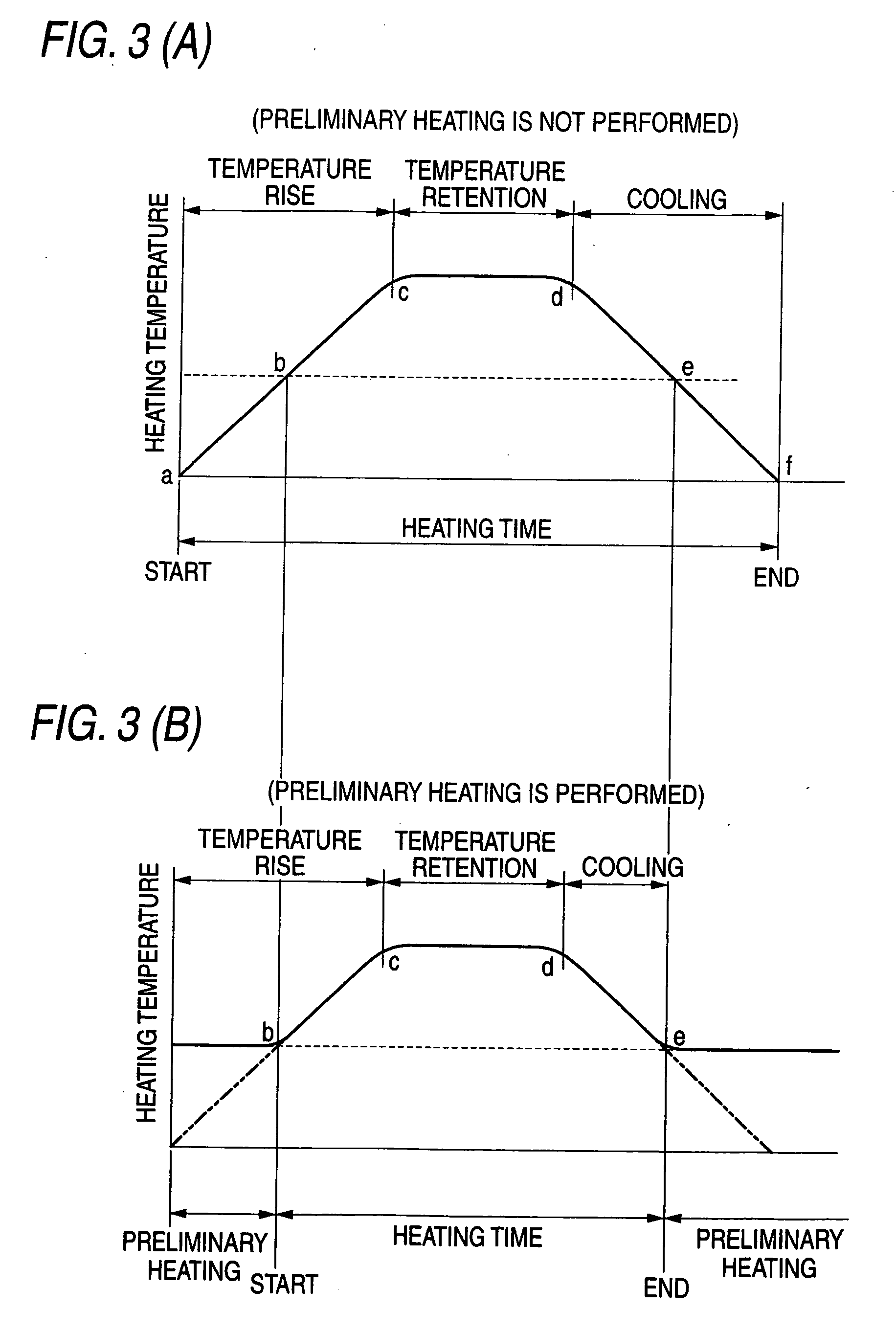

Optical fiber reinforcement processing apparatus and optical fiber reinforcement processing method

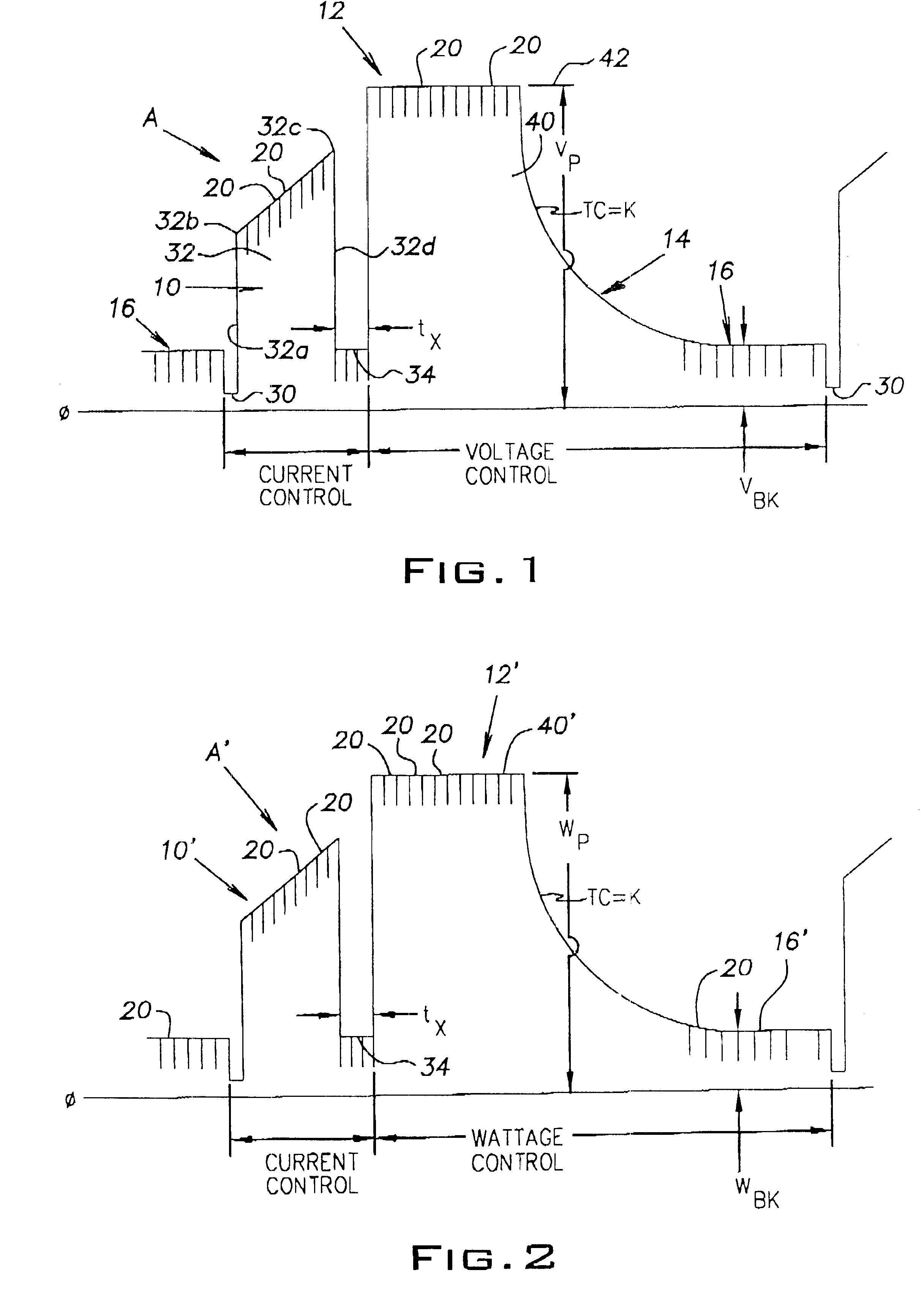

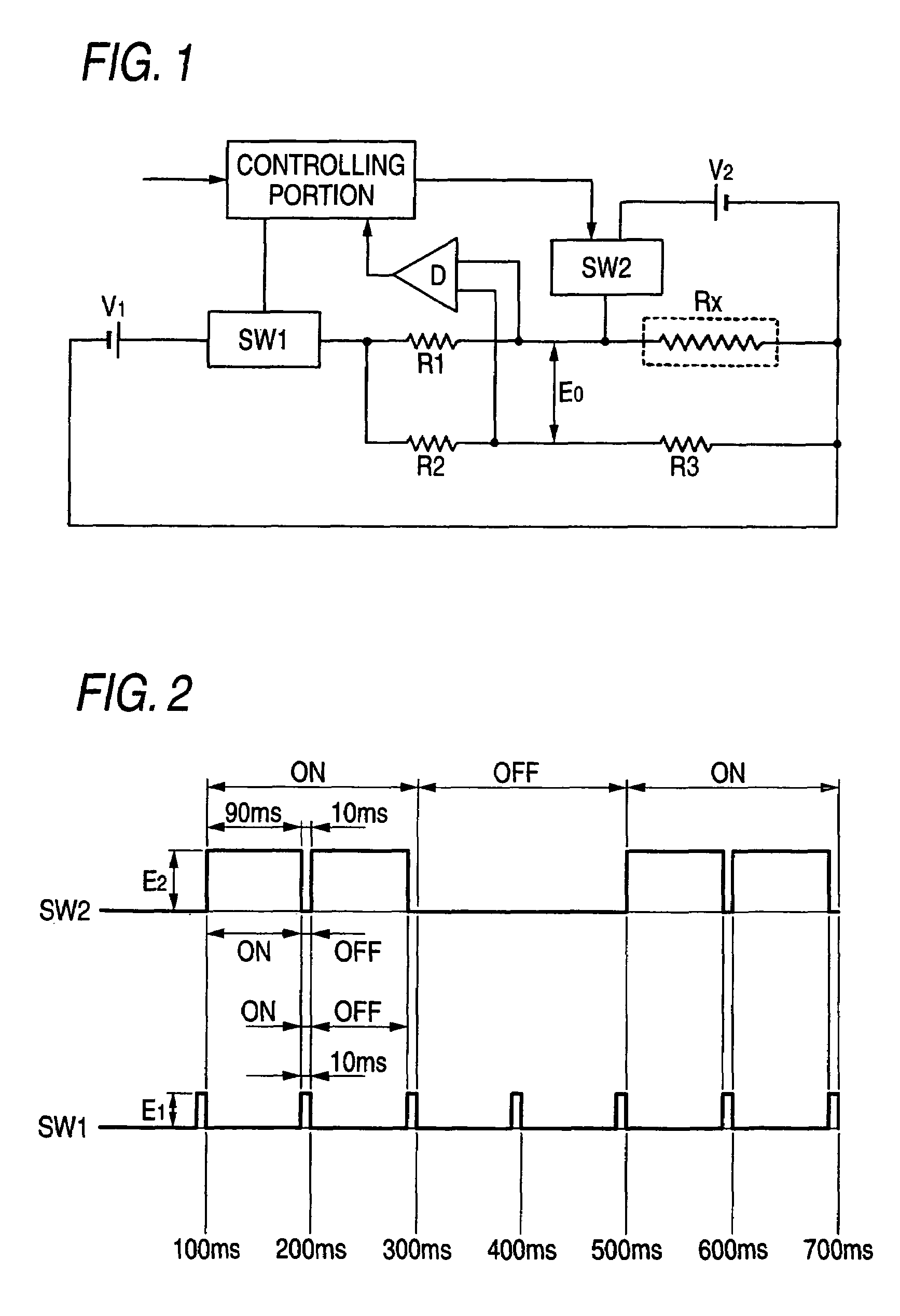

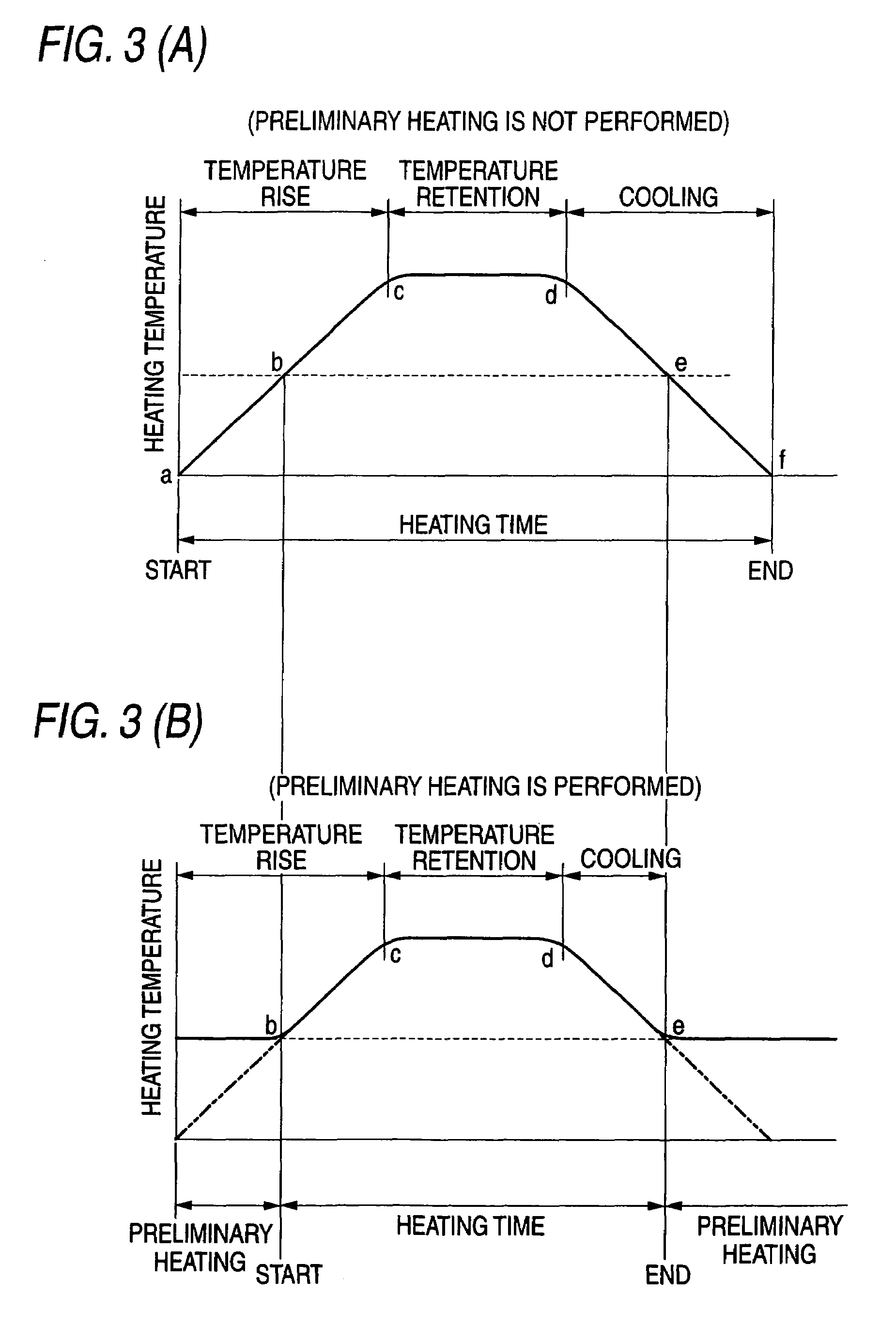

ActiveUS7699540B2Reduce component countEasy to detectCoupling light guidesElectrical resistance and conductanceEngineering

An optical fiber reinforcement processing apparatus and reinforcement processing method are provided where it is not necessary to dispose a temperature detecting device such as a thermistor, and a heating control in which the detected temperature is not varied, the power consumption is low, and which is accurate is enabled.An optical fiber reinforcement processing apparatus in which a fusion-spliced portion of an optical fiber is covered by a heat-shrinkable reinforcing sleeve to perform reinforcement has: heating controlling means for performing a heating control on a heater which heats the reinforcing sleeve; and temperature detecting means for detecting a heating temperature of the heater on the basis of a change of the resistance of the heater. The heating control and the temperature detection are performed by controlling time periods of turning on / off a power supply to the heater. The temperature detection is performed by detecting a voltage change Eo of the midpoint of a bridge circuit in which a series circuit of a first fixed resistor R1 and a heater resistor RX, and a series circuit of a second fixed resistor R2 and a third fixed resistor R3 are connected in parallel.

Owner:SUMITOMO ELECTRIC IND LTD

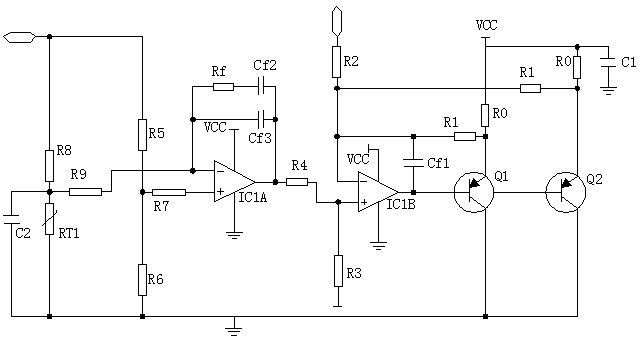

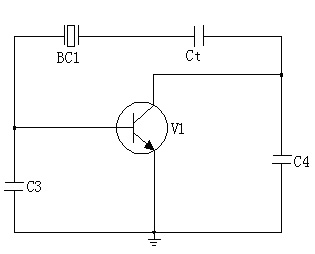

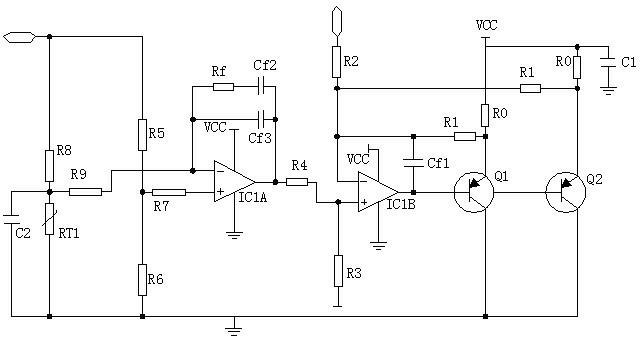

High-precision temperature-controlled crystal oscillator

InactiveCN102075142AFine control of heatingAccurate heating controlTemperatue controlOscillations generatorsHemt circuitsEngineering

The invention discloses a high-precision temperature-controlled crystal oscillator, the circuit of the oscillator comprises a temperature-controlled circuit and a main oscillation part circuit, wherein the temperature-controlled circuit comprises a medium value-B thermistance RT1 of a negative temperature coefficient, two operational amplifiers IC1A and IC1B and two plug-and-play (PNP) triodes Q1 and Q2. Considering the advantages and disadvantages of two parties in the traditional technology, a double-operation-amplifier and double-monitoring-point temperature-controlled circuit is originally created, so a precise temperature-controlled effect of three operation amplifiers can be realized; the simultaneous monitoring of thermal parameters and current parameters is utilized, so the heating control is more precise and more correct; and moreover, the production cost is reduced, and the thermistance is accessed to the circuit in a grounding way simultaneously, so the thermistance is convenient to debug, the mass production can be realized, and stronger competitive strength can be realized compared with the foreign similar products.

Owner:DONGGUAN JINZHEN ELECTRONICS

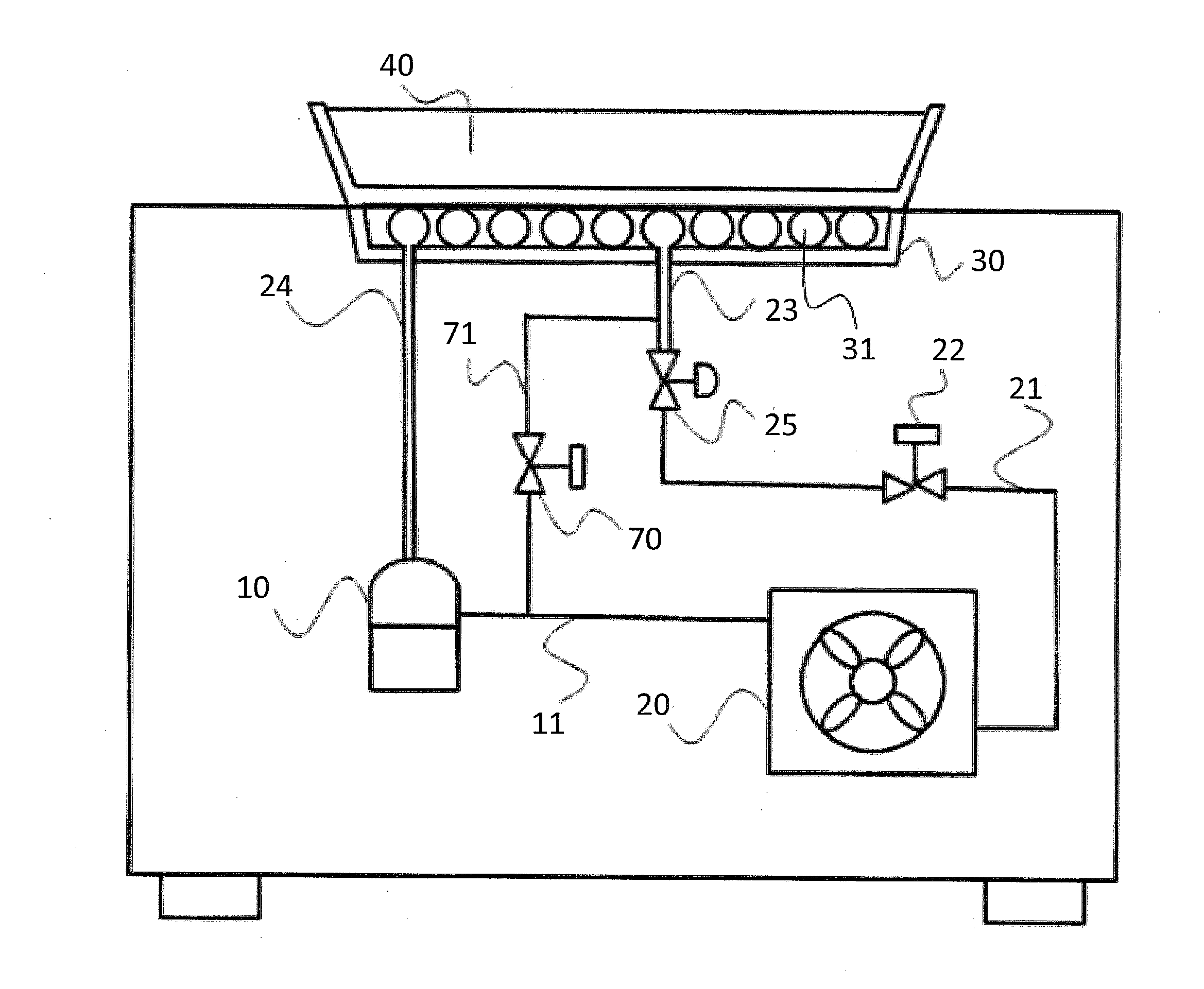

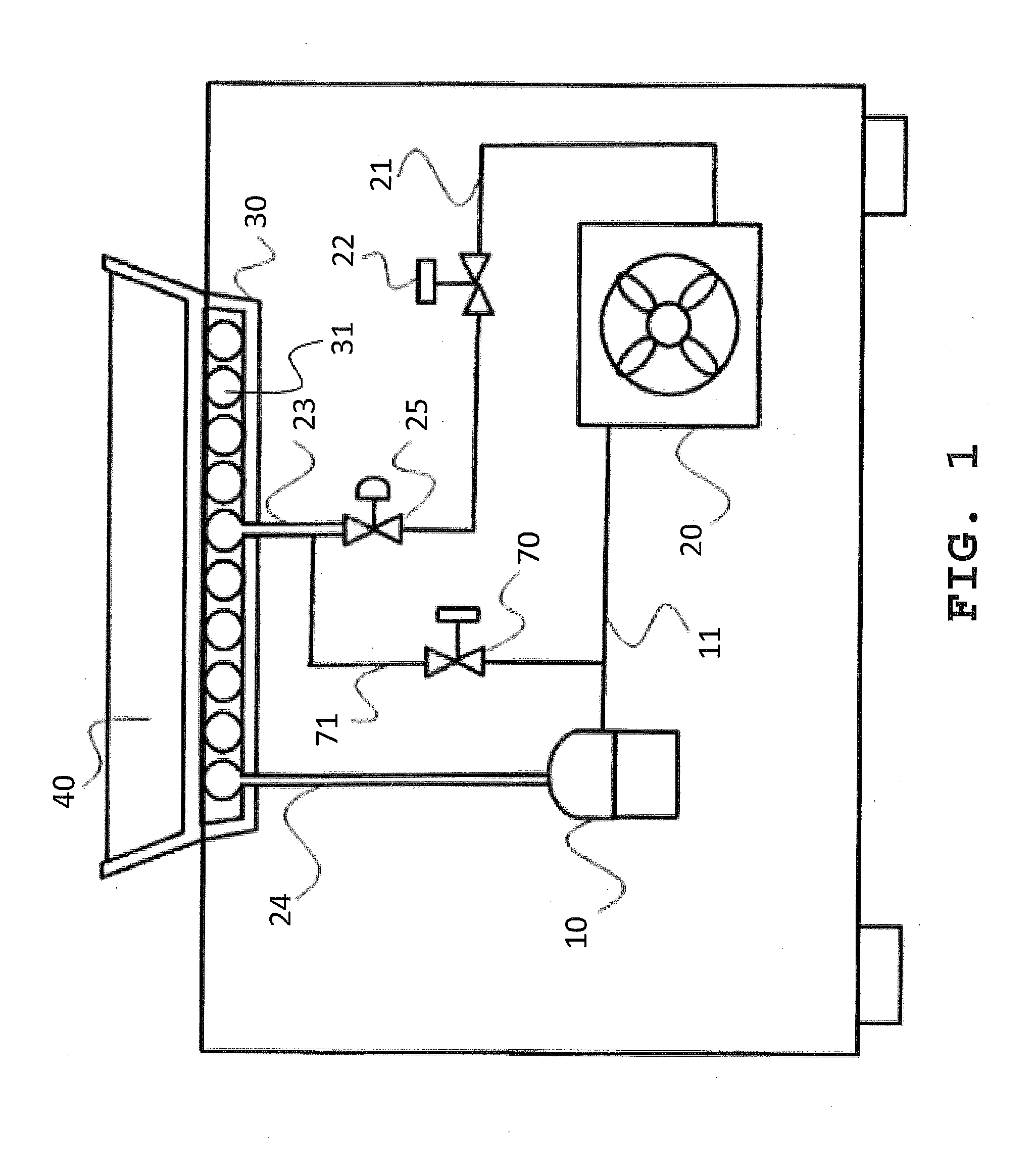

Portable Ice Making Apparatus Having a Bypass Tube

InactiveUS20140238062A1Easy to operateFaster freezing/heating operationIce productionCompression machines with non-reversible cycleEngineeringRefrigerant

This invention relates to a portable onsite ice making apparatus having a bypass tube, which includes a compressor equipped with a condenser having heat removal capacity of about 2,400˜2,600 BTU / hr; an expansion valve; an evaporator being in heat exchange relationship with an ice making tray; a bypass tube for the refrigerant to bypass the condenser and the expansion valve; and a switching means selectively changing the flow of the refrigerant from the compressor to the condenser or from the compressor to the bypass tube. The portable ice making apparatus has heat removal capacity to cool the ice making tray to −27° C.˜−26° C. within 3 minutes and heating capacity to heat the ice making tray from about −27° C.˜−26° C. to about 50° C.˜−60° C. within 30 seconds. The area of the capillary tube in the bypass tube to the area of the first discharging tube is about 1 / 25˜ 1 / 10.

Owner:SUL DONG HWAN

Optical Fiber Reinforcement Processing Apparatus and Optical Fiber Reinforcement Processing Method

ActiveUS20090052846A1Avoid wasting power consumptionReduce component countCoupling light guidesElectrical resistance and conductanceHeat sensitive

An optical fiber reinforcement processing apparatus and reinforcement processing method are provided where it is not necessary to dispose a temperature detecting device such as a thermistor, and a heating control in which the detected temperature is not varied, the power consumption is low, and which is accurate is enabled.An optical fiber reinforcement processing apparatus in which a fusion-spliced portion of an optical fiber is covered by a heat-shrinkable reinforcing sleeve to perform reinforcement has: heating controlling means for performing a heating control on a heater which heats the reinforcing sleeve; and temperature detecting means for detecting a heating temperature of the heater on the basis of a change of the resistance of the heater. The heating control and the temperature detection are performed by controlling time periods of turning on / off a power supply to the heater. The temperature detection is performed by detecting a voltage change Eo of the midpoint of a bridge circuit in which a series circuit of a first fixed resistor R1 and a heater resistor RX, and a series circuit of a second fixed resistor R2 and a third fixed resistor R3 are connected in parallel.

Owner:SUMITOMO ELECTRIC IND LTD

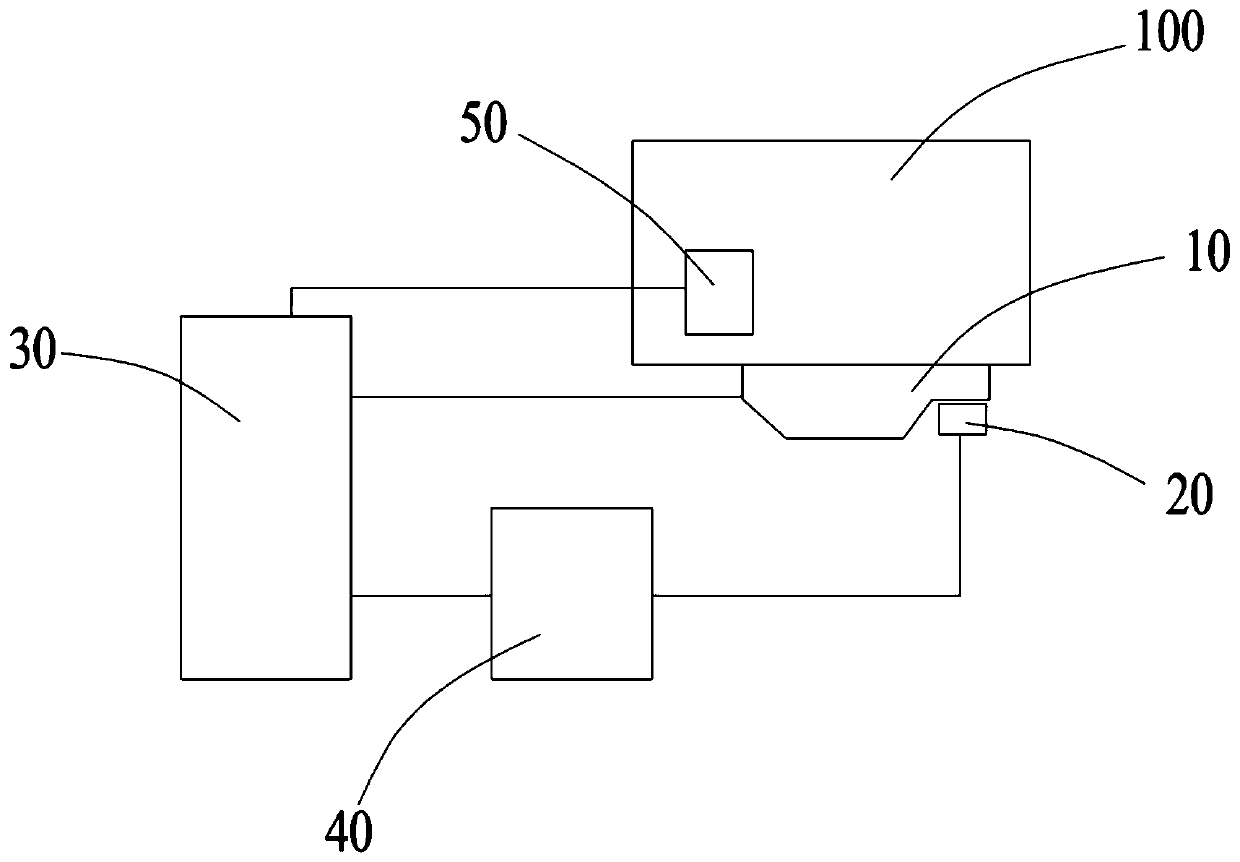

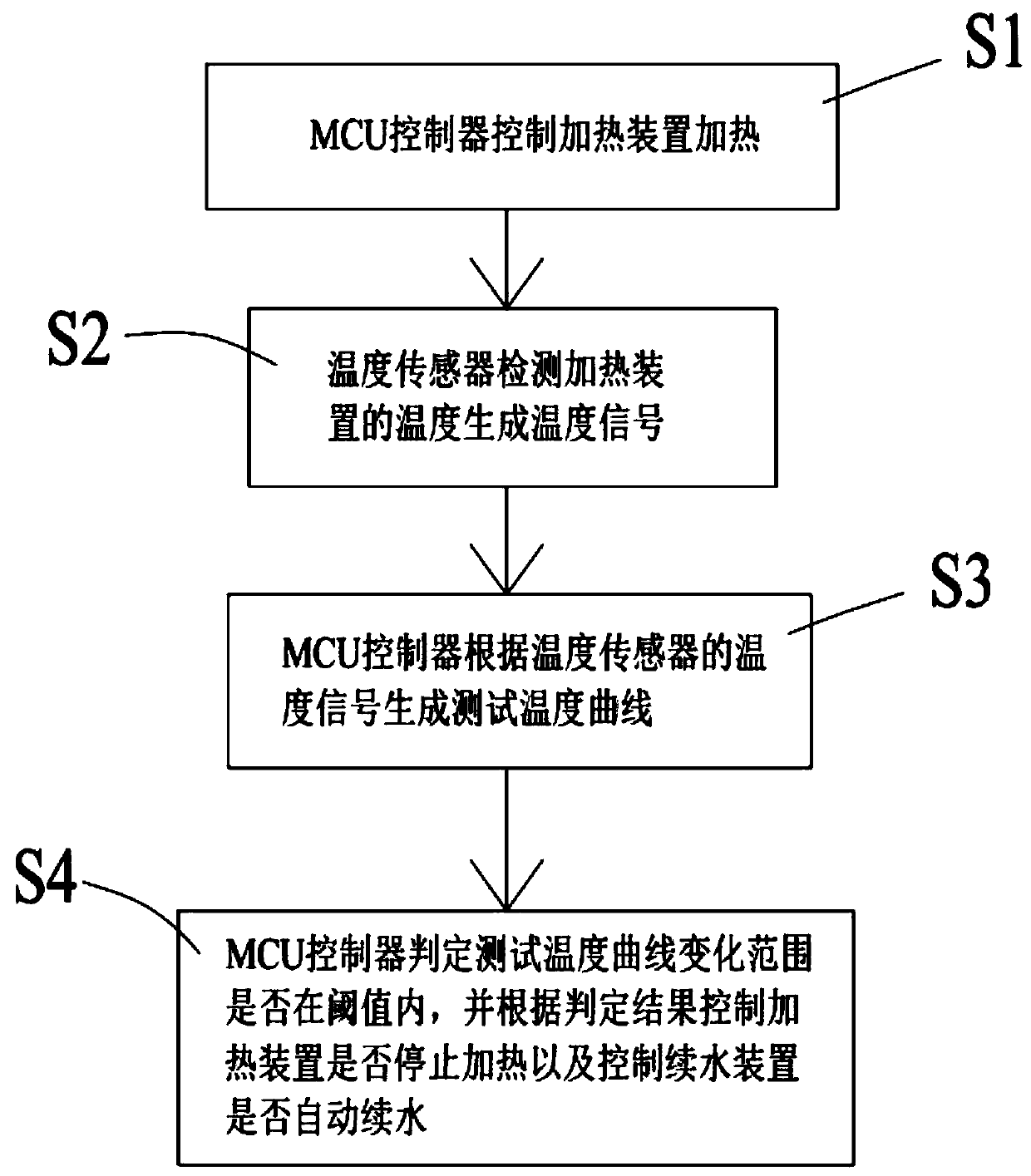

Water heater and anti-dry-heating control method thereof

The invention discloses a water heater and an anti-dry-heating control method of the water heater. The water heater comprises a water tank, a temperature-detecting device, a heating device and a controller, wherein the water tank is used for storing water; the temperature-detecting device is arranged in the water tank to detect the temperature in the water tank; the heating device is arranged on the water tank to heat water in the water tank; the controller is connected with the temperature-detecting device and the heating device to control the heating device to be switched on or off according to a temperature-detecting value which is detected by the temperature-detecting device. According to the water heater disclosed by the invention, not only is the structure simple, but also the heating of the water tank is more accurately controlled, so that the use of a user is more facilitated.

Owner:GD MIDEA HEATING & VENTILATING EQUIP CO LTD +1

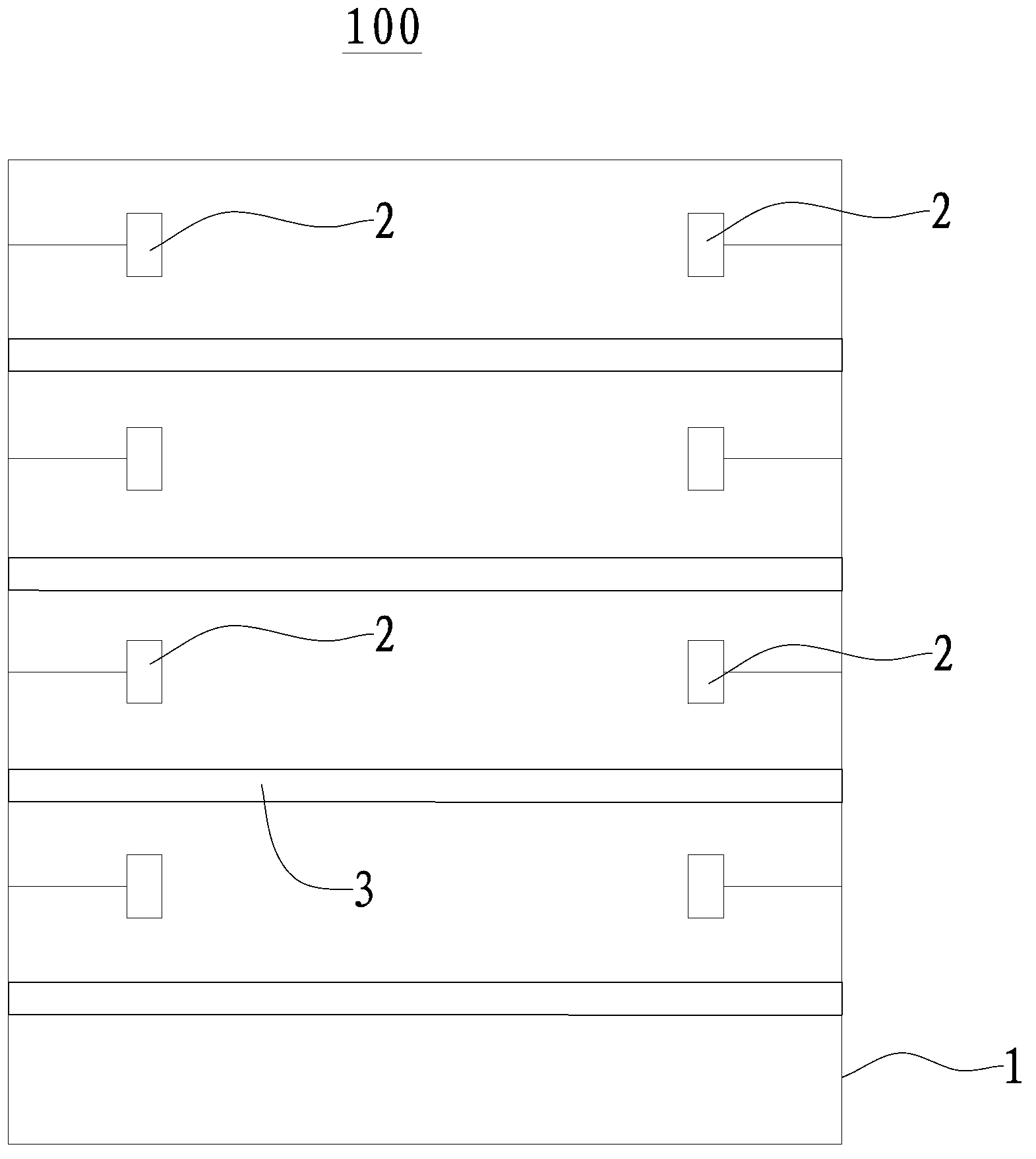

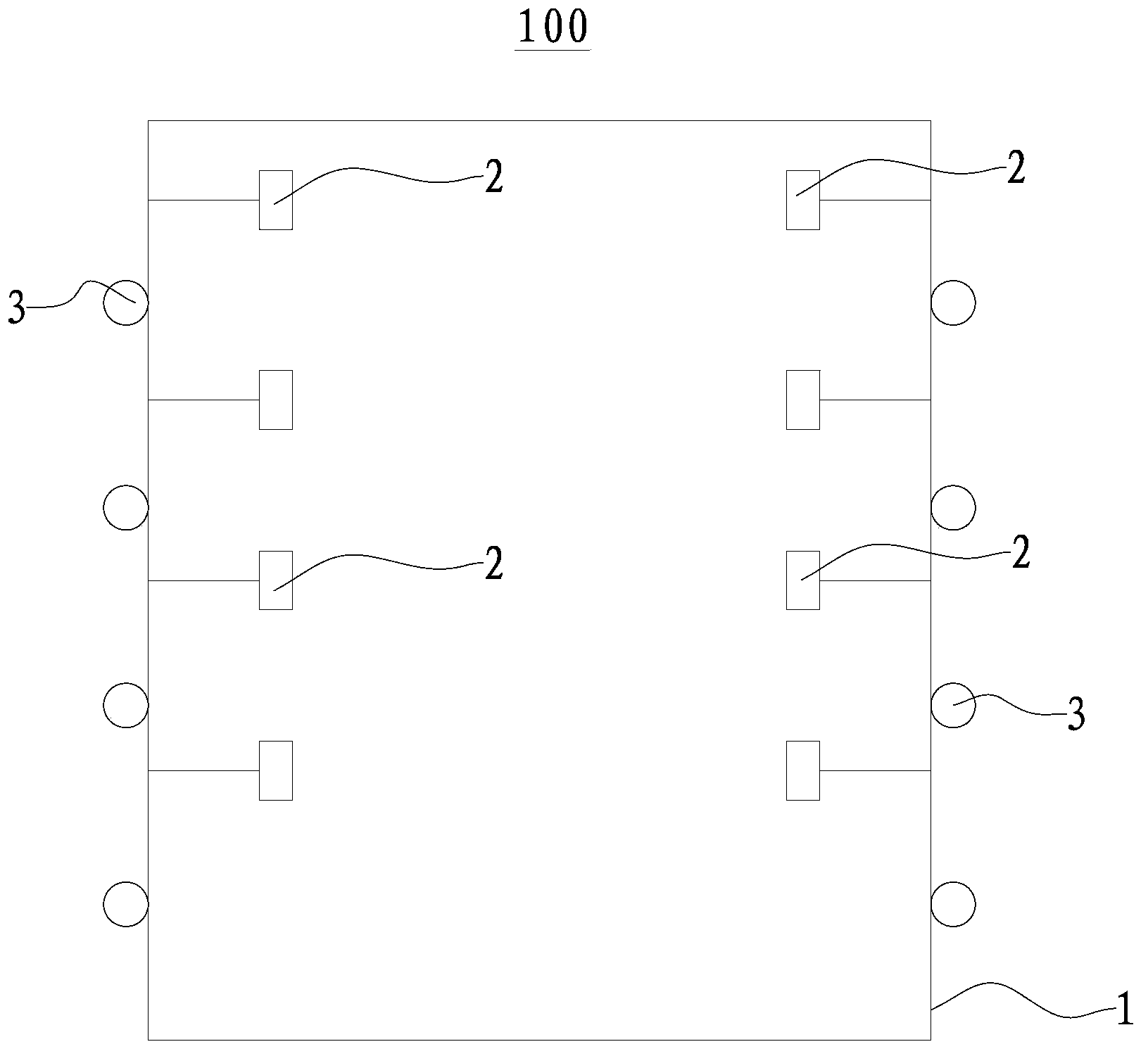

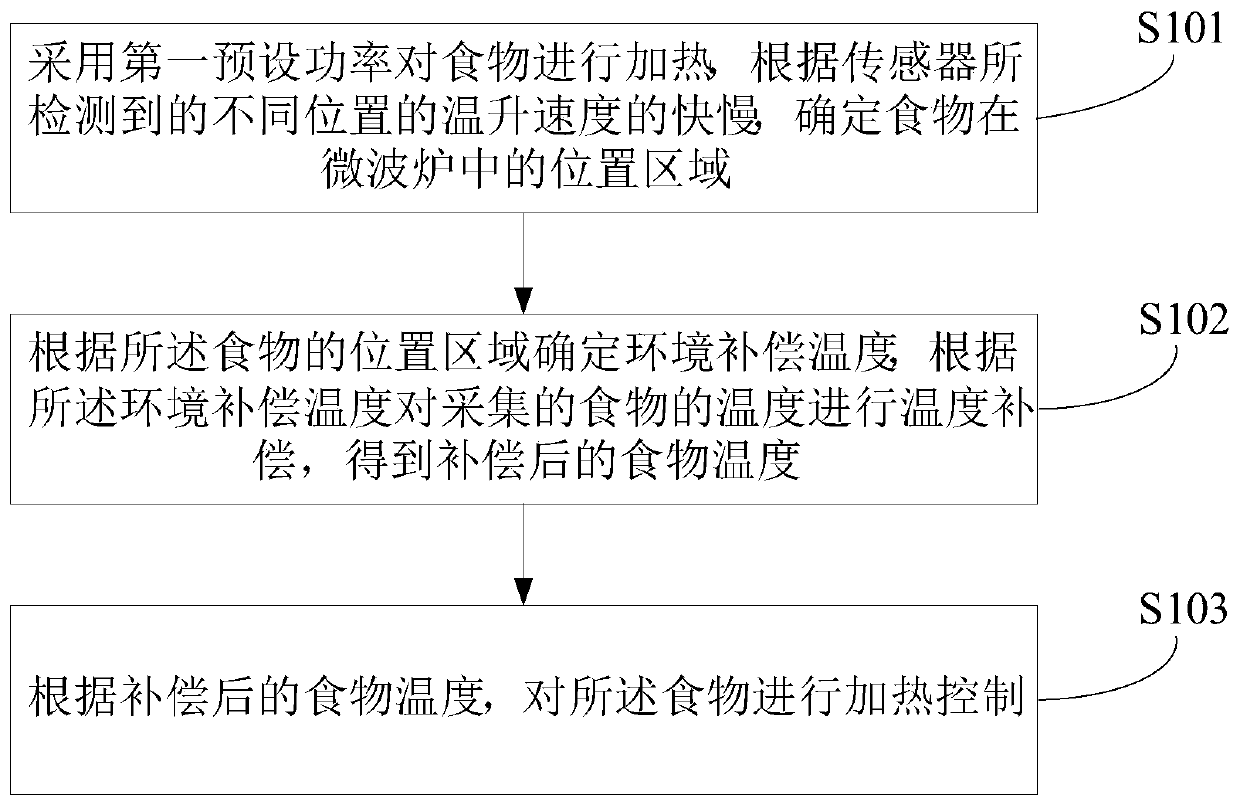

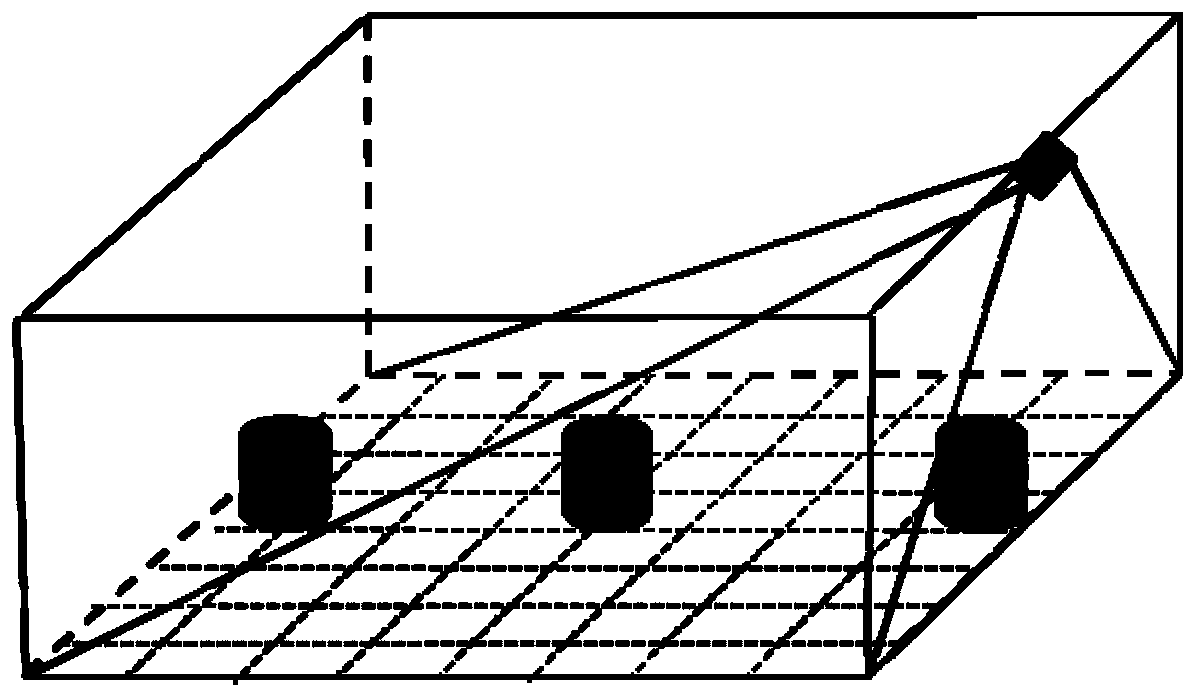

Microwave oven, heating control method thereof, and readable storage medium

ActiveCN110145769AAccurate temperatureAccurate heating controlDomestic stoves or rangesLighting and heating apparatusMicrowave ovenProcess engineering

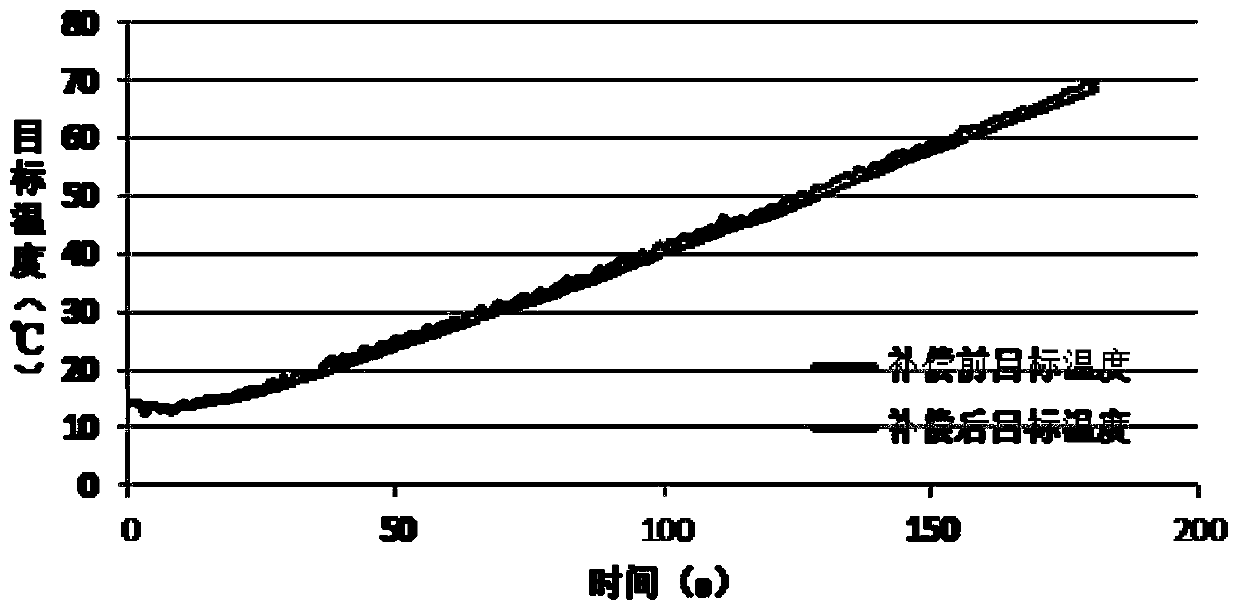

The invention provides a heating control method of a microwave oven. Infrared sensors used for detecting the temperatures at different positions are arranged in the microwave oven. The heating controlmethod of the microwave oven comprises the steps that food is heated at a first preset power, and the positional area of the food in the microwave oven is determined according to the temperature riserates, detected by the sensors, at different positions; an environmental compensation temperature is determined according to the positional area of the food, and an acquired temperature of the food is compensated for according to the environmental compensation temperature, so that a compensated food temperature is obtained; and heating control is conducted on the food according to the compensatedfood temperature. According to the heating control method of the microwave oven, the positional area of the food can be effectively determined according to the temperature rise rate in the food heating process, and temperature compensation of the food is calculated according to the positional area, so that a more accurate food temperature is obtained, and more accurate heating control of the foodis facilitated.

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

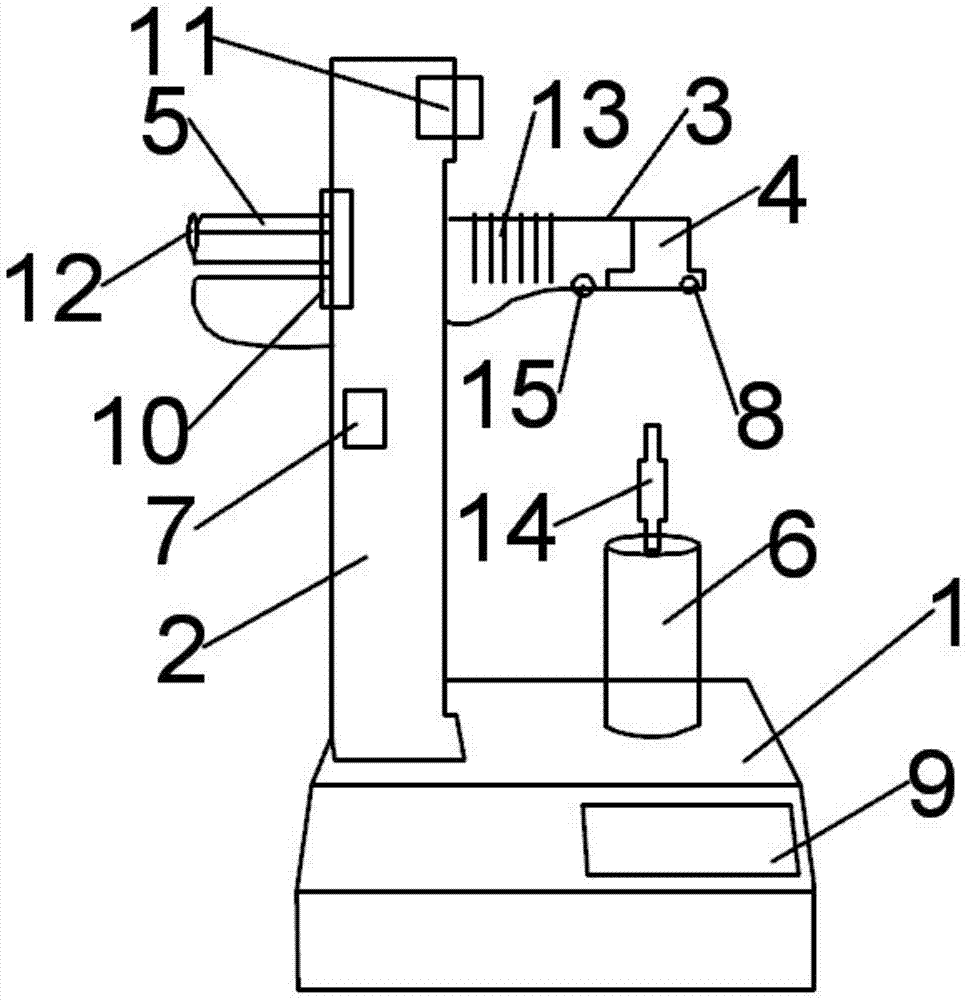

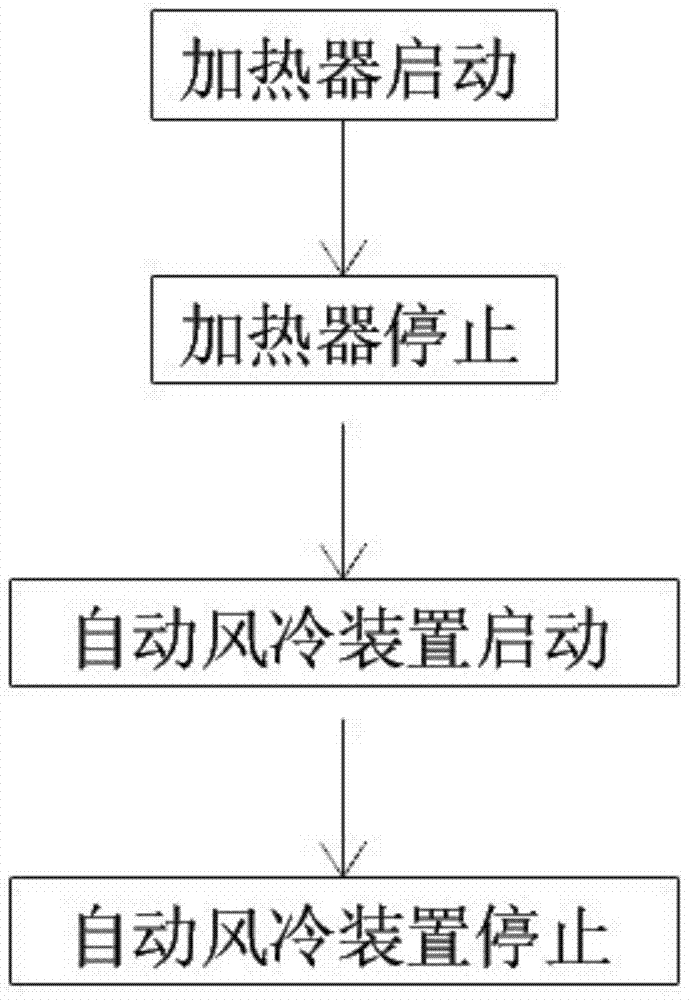

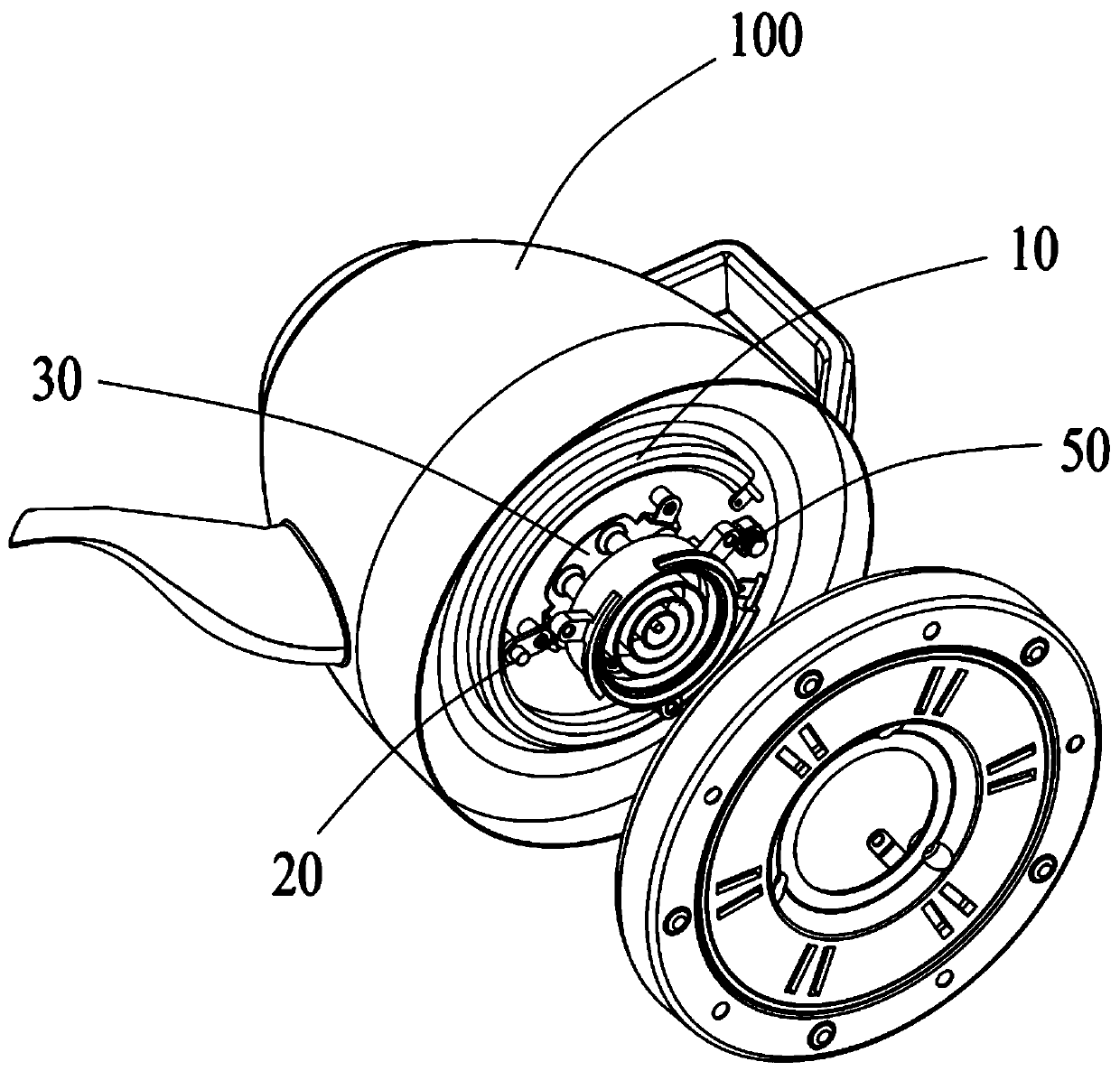

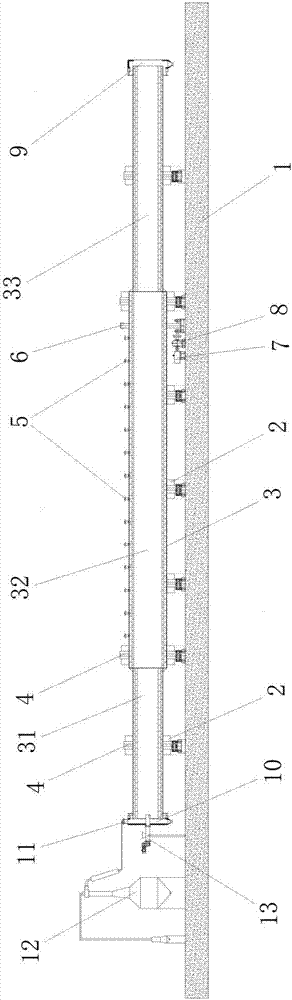

Cutter handle heater and operation method thereof

InactiveCN104493423AImprove the heating effectAccurate heating controlMetal working apparatusEngineeringHeating effect

The invention provides a cutter handle heater and an operation method thereof. The cutter handle heater comprises a working platform, wherein a lifting bracket is arranged on one side of the working platform; a heating device capable of rising and falling on the lifting bracket is arranged on the lifting bracket; the heating device comprises a heating gun and a heating gun body which are arranged on the inner side and the outer side of the lifting bracket respectively; a base used for fixing cutters is arranged on the working platform under the heating gun; an electromagnetic valve connected with an automatic air cooling device is arranged under the heating gun; a temperature sensor is arranged on the heating gun; the temperature sensor and the heating gun are electrically connected with an electric control box on the working platform; the cutter handle heater is connected with the heating gun, the automatic air cooling device, the electric control box and the temperature sensor, so that the heating control is more accurate. The cutter handle heater is simple in structure, convenient to use and excellent in effect of heating cutters.

Owner:SICHENG ELECTROMECHANICAL TECH

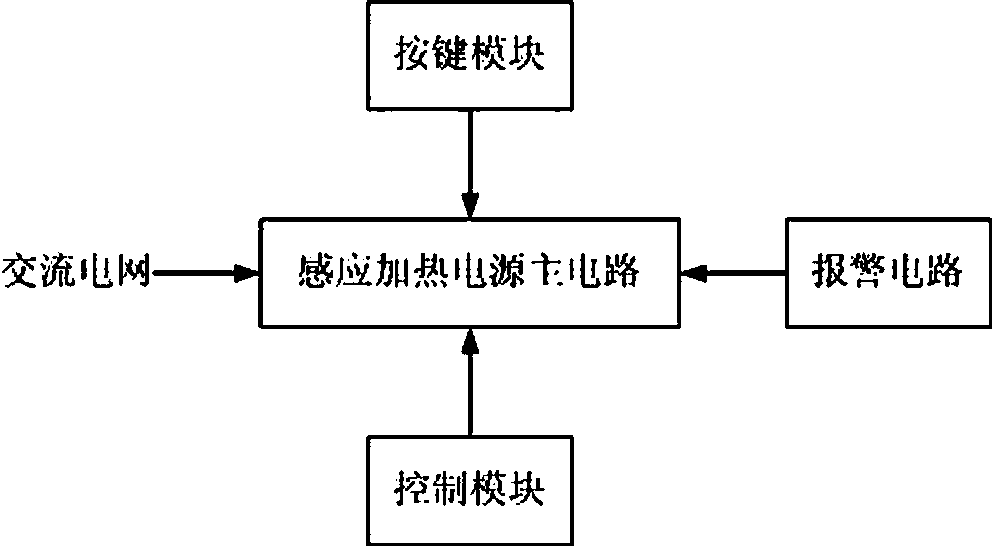

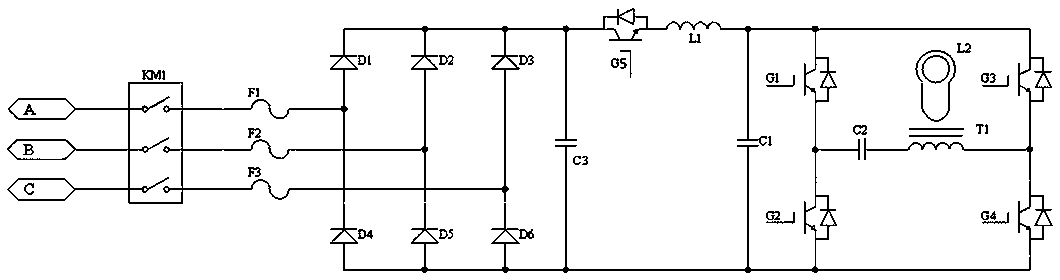

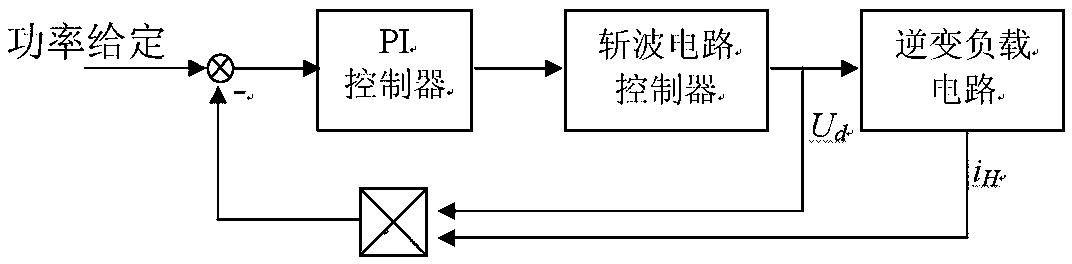

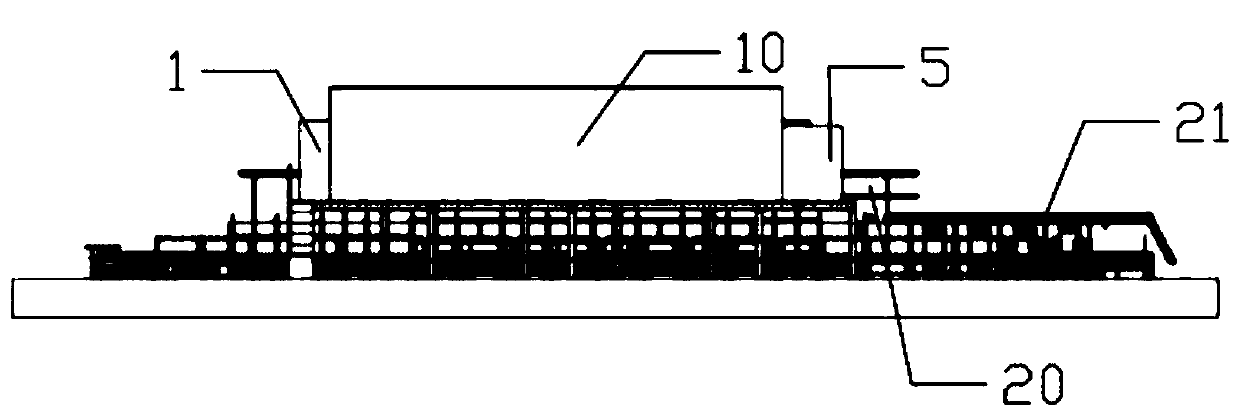

Induction heating power supply and control method thereof

InactiveCN107949086AImprove heating efficiencyImprove reliabilityInduction current sourcesInduction heating controlCapacitanceTransformer

The invention relates to an induction heating power supply. The induction heating power supply comprises an induction heating power supply main circuit, a control module and an alarming module; the induction heating power supply main circuit is connected with the control module and the alarming module separately; the induction heating power supply main circuit comprises a rectifying and filteringcircuit, a chopper circuit and a bridge type inversion circuit connected in sequence; the rectifying and filtering circuit is connected with a three-phase alternating current; the chopper circuit consists of a high-power insulated gate type triode IGBT (G5), an electric reactor (L1) and a filtering capacitor (C1); and the bridge type inversion circuit consists of four groups of IGBT (G1-G4), a resonance capacitor (C2) and a primary matched transformer (T). The induction heating power supply provided by the invention is high in heating efficiency, and the output power of the power supply can becontrolled by controlling the duty ratio of a chopping PWM signal through a digital algorithm; and the output frequency of the power supply can be controlled by controlling the frequency of an inversion PWM signal through a digital PID algorithm, so that high reliability, accurate heating control and high reaction speed are achieved.

Owner:ZHENGZHOU KECHUANG ELECTRONICS

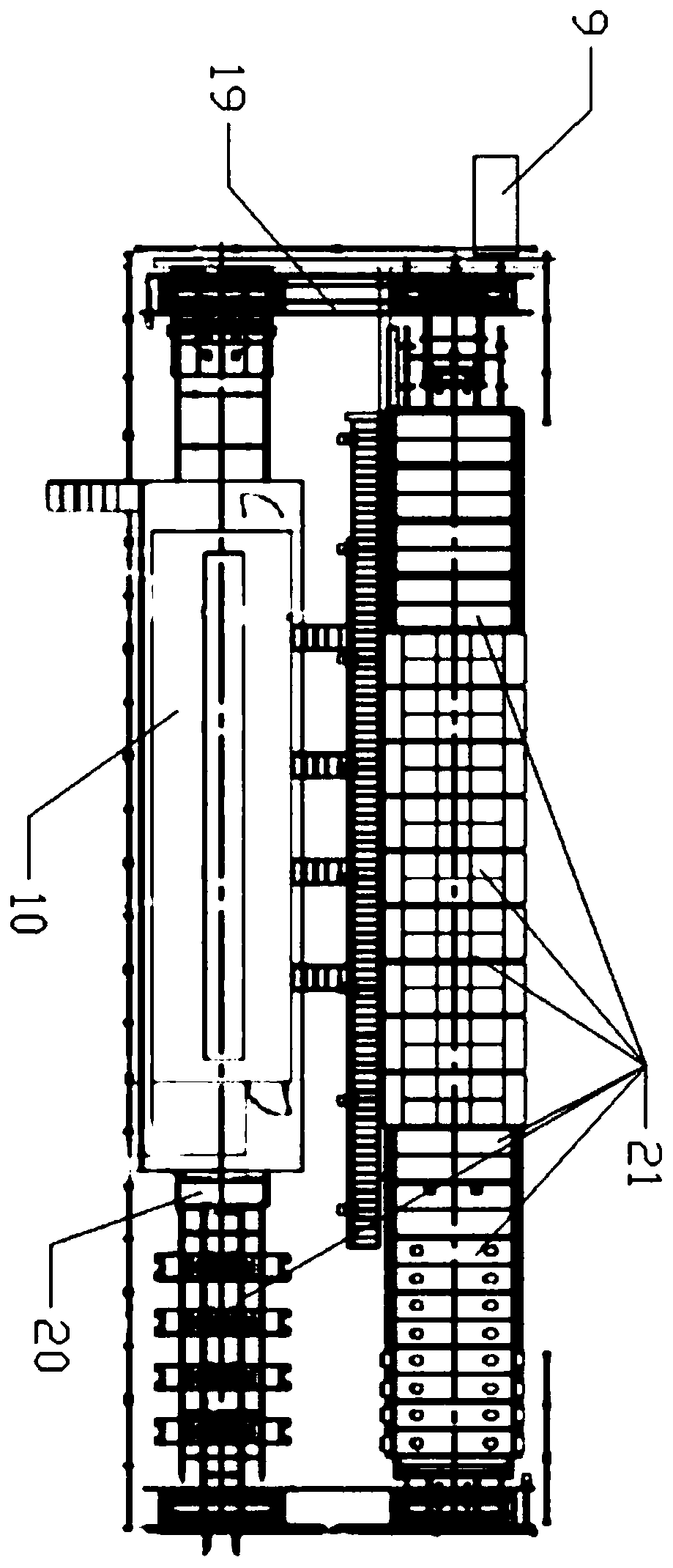

Gravity forming continuous thermal bending furnace and using method thereof

PendingCN110342794AReduce lossesIngenious structural designGlass reforming apparatusGlass productionMotor driveEngineering

The invention discloses a gravity forming continuous thermal bending furnace and a using method thereof.The technical problems that the existing thermal bending furnace is unreasonable in structural design, during thermal bending forming,glass is likely to be broken, the curvature cannot be guaranteed, the straightness of the edge cannot be guaranteed, optical quality of the glass is poor, the yield rate is low, the production process is not continuous, and the production efficiency is low are solved. The gravity forming continuous thermal bending furnacecomprisesa furnace body frame, whereinaheat insulating material is closely arranged in the interior of the furnace body frame to form a closed cavity, the furnace body frame comprises sequentially from front to back a preheating station device, a pre-bending station device, a forming station device, a quenching station device, and a cooling station device; a trolley arranged in a single layer in the longitudinal direction of the furnace body frame and a motor-driven mobile system device are arranged in a furnace body, a mold is mounted on the trolley and driven to move from front to back by the movement of the motor-driven mobilesystem device; andmeanwhile the using method of gravity forming continuous thermal bending furnace is provided and can be widely applied to the field ofautomotive glass manufacturing.

Owner:MING CHI GLASS CO LTD

Water level detection and heating control system, water level detection and heating control method and electric kettle

InactiveCN111012174AAvoid damageExtended service lifeWater-boiling vesselsEnvironmental geologyMechanical engineering

Owner:韦星

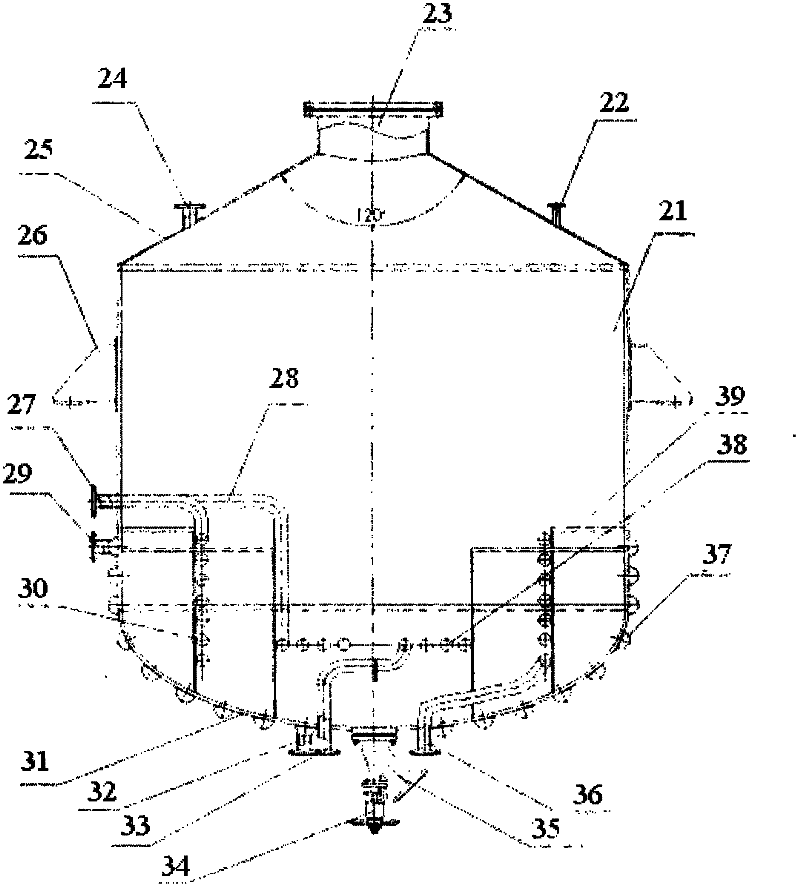

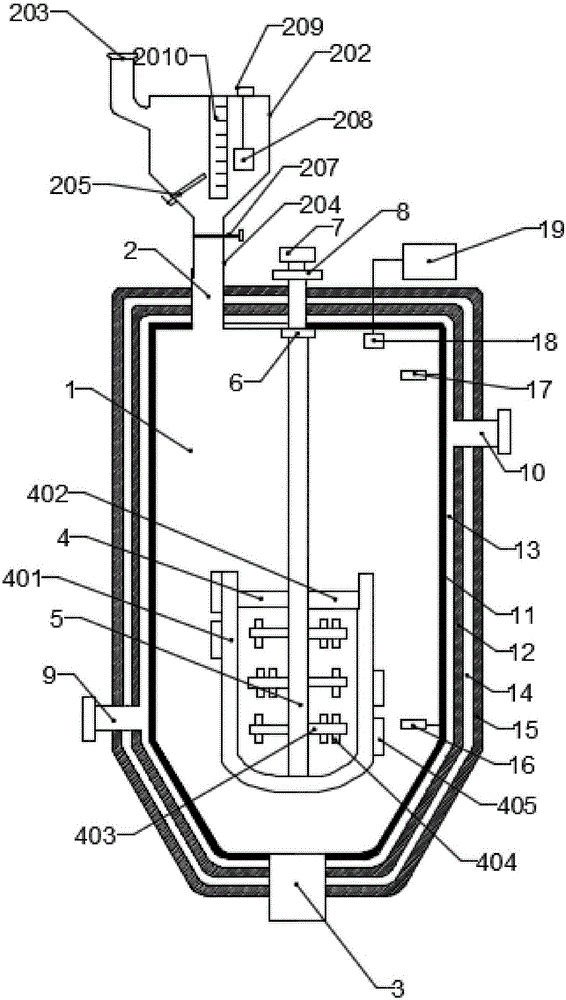

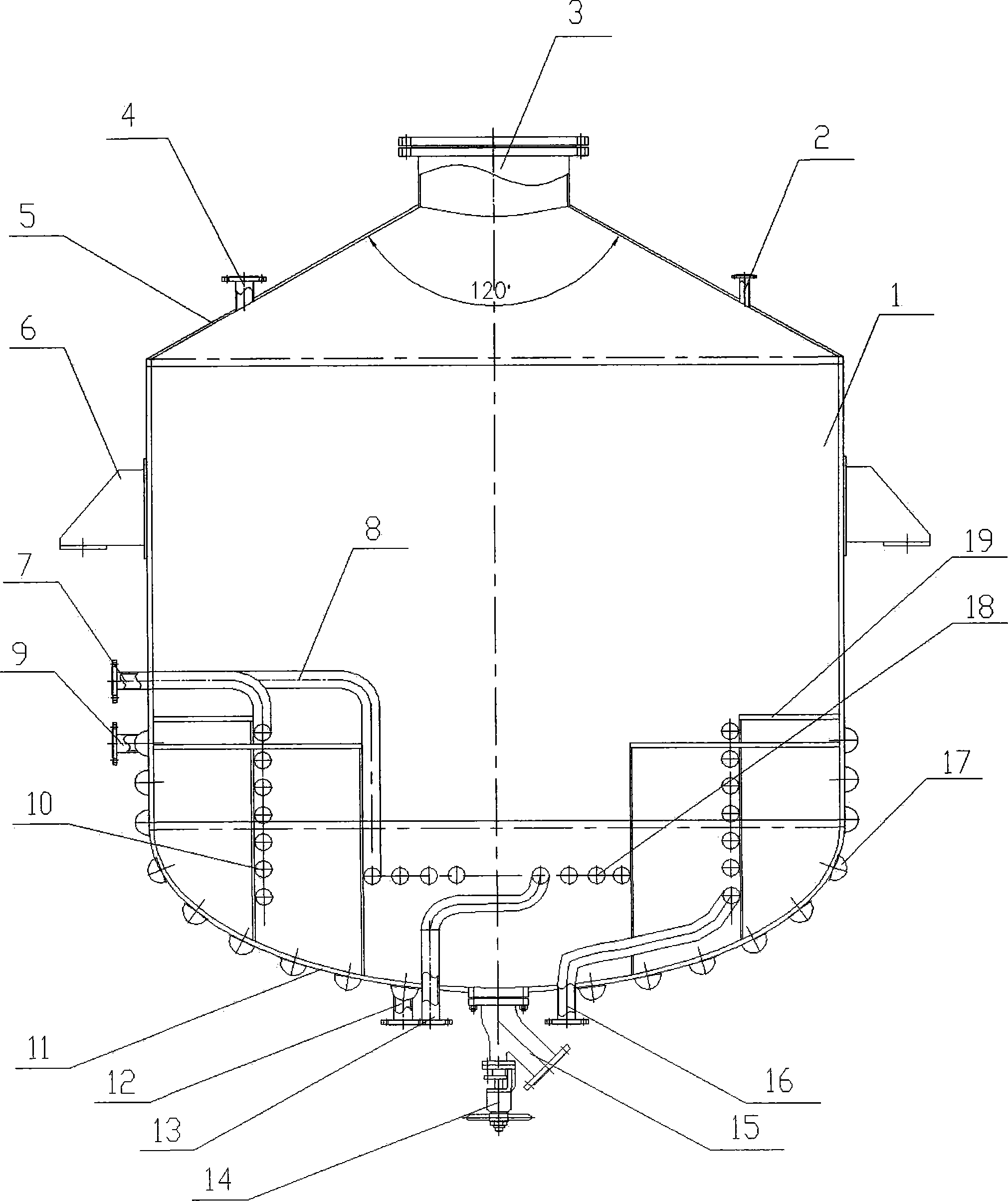

Reaction kettle

InactiveCN105148825AEasy outflowAccurate heating controlChemical/physical/physico-chemical stationary reactorsAtmospheric pressureHeating temperature

The invention discloses a reaction kettle which comprises a kettle body, wherein a material inlet is formed in the top of the kettle body; a material outlet is formed in the bottom of the kettle body; the kettle body comprises an inner layer and an outer layer; a heat preservation layer is arranged at the outer side of the outer layer; a temperature detection device is arranged at the lower side wall of the kettle body; a bearing in the top of the kettle body is in tight connection with a stirring shaft; a motor and a speed reducing machine are arranged above the stirring shaft; the stirring shaft positioned at the lower part of the kettle body is connected with a stirring device blew the stirring shaft. The reaction kettle can be used for improving the heat exchange efficiency, and the heating temperature is easy to control; the whole kettle body is heated, so that liquid materials can be uniformly heated; the stirring effect is good, and the flowing directions of the materials are changed in a stirring process, so that the reaction of the materials is relatively full; an air valve is adopted for controlling the output of gas generated in a reaction process; parameters such as the temperature, air pressure and stirring speed can be controlled; a temperature sensor in a feeding device can effectively sense the temperature of the materials.

Owner:成都米戈科技有限公司

Preparation method of rare earth doped LiNi0.5 Mn1.5O4 as anode material for super capacitor

InactiveCN102324322ALow costReduce energy consumptionElectrolytic capacitorsSupercapacitorAqueous solution

The invention provides a preparation method of rare earth doped LiNi0.5 Mn1.5O4 as an anode material for a super capacitor. The preparation method comprises the following steps of: respectively taking compounds of Ni, Mn and Li according to the mole ratio that Ni to Mn to Li to rare earth is 1:3.0:(2.05-2.24):(0.003-0.02), adding the compounds of Ni, Mn and Li in a reaction pot and adding pure water to obtain a mixed solution A; based on a target product, respectively taking 6-30% of citric acid, 300-600% of pure water and 0.002-0.01% of dispersing agent, adding the citric acid and the dispersing agent to the pure water, and uniformly stirring; and then adding the rare earth to the aqueous solution of citric acid to obtain a solution B; adding the solution B to the solution A to obtain a solution C; adjusting the pH value of the solution C to 5-7, heating the solution C in a water bath manner to obtain a precursor; and putting the precursor in a metal container and carrying out microwave baking on the precursor to obtain the target product. According to the invention, the conductivity of LiNi0.5 Mn1.5O4 and the energy density of the super capacitor are improved greatly, the preparation process is simplified by adopting a microwave treatment technology, and thus the preparation method is easy for industrial implementation.

Owner:HENAN COAL CHEM IND GROUP INST +1

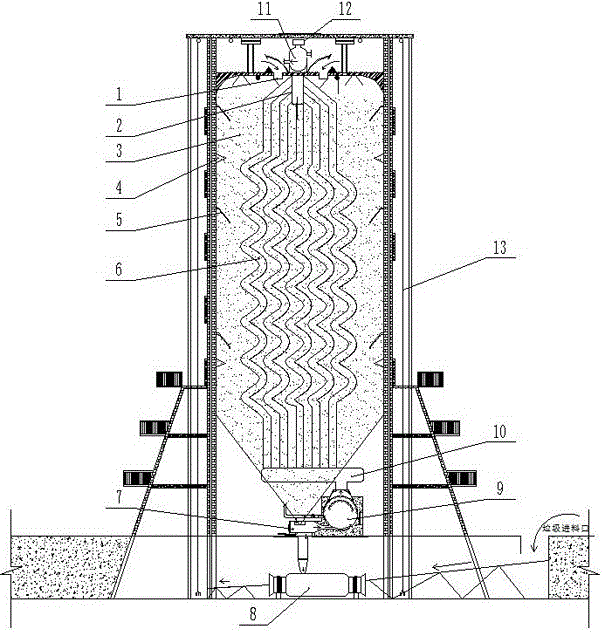

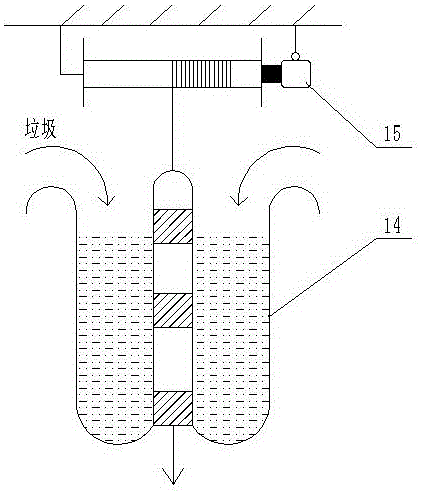

Incineration tower capable of gasifying and melting domestic waste directly

PendingCN106765139ASmall footprintLow running costIncinerator apparatusCombustion chamberExhaust fumes

The invention discloses an incineration tower capable of gasifying and melting domestic waste directly. The incineration tower capable of gasifying and melting domestic waste directly comprises a feeding port, a tower bin, a heat collector, a secondary combustion chamber, an incinerator, a drying machine, a smoke pipeline, a cooling furnace and a heating system. The feeding port is formed in the top end of the tower bin. The smoke pipeline is arranged above the tower bin. A discharging port and an ash circulating outlet are formed in the bottom of the tower bin. The ash circulation outlet is connected with an inlet of the incinerator. The incinerator is further provided with an ash outlet and a waste gas outlet. The ash outlet is connected with a heat conduction inlet of the drying machine. The waste gas outlet is connected with the secondary combustion chamber. The heat collector comprises a heat collection pipe, a heat collection disc and S-shaped guide pipes, wherein the lower portion of the heat collection disc is connected with the heat collection pipe, the bottoms of the S-shaped guide pipes are mounted on the heat collection disc, and the S-shaped guide pipes are evenly distributed in the tower bin. The secondary combustion chamber is connected with heat collection pipe. An inlet of the cooling furnace is connected with the smoke pipeline, and an outlet of the cooling furnace is connected with the heating system. The incineration tower is small in occupied area, waste sorting is not needed, no comburent needs to be added, investment cost and operating cost are low, maintenance is convenient, and incineration tower can be widely popularized easily.

Owner:广西威荣供应链有限公司

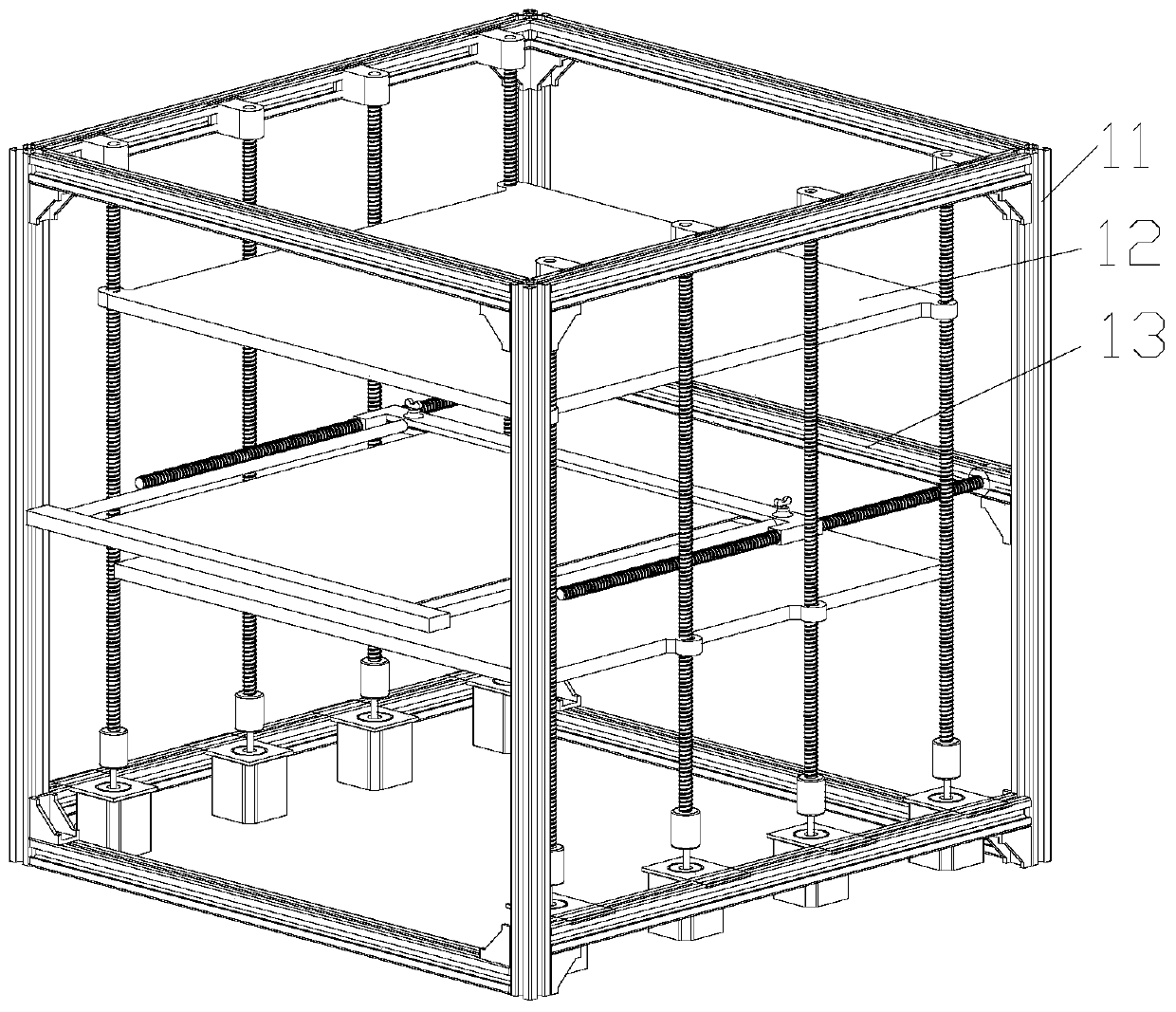

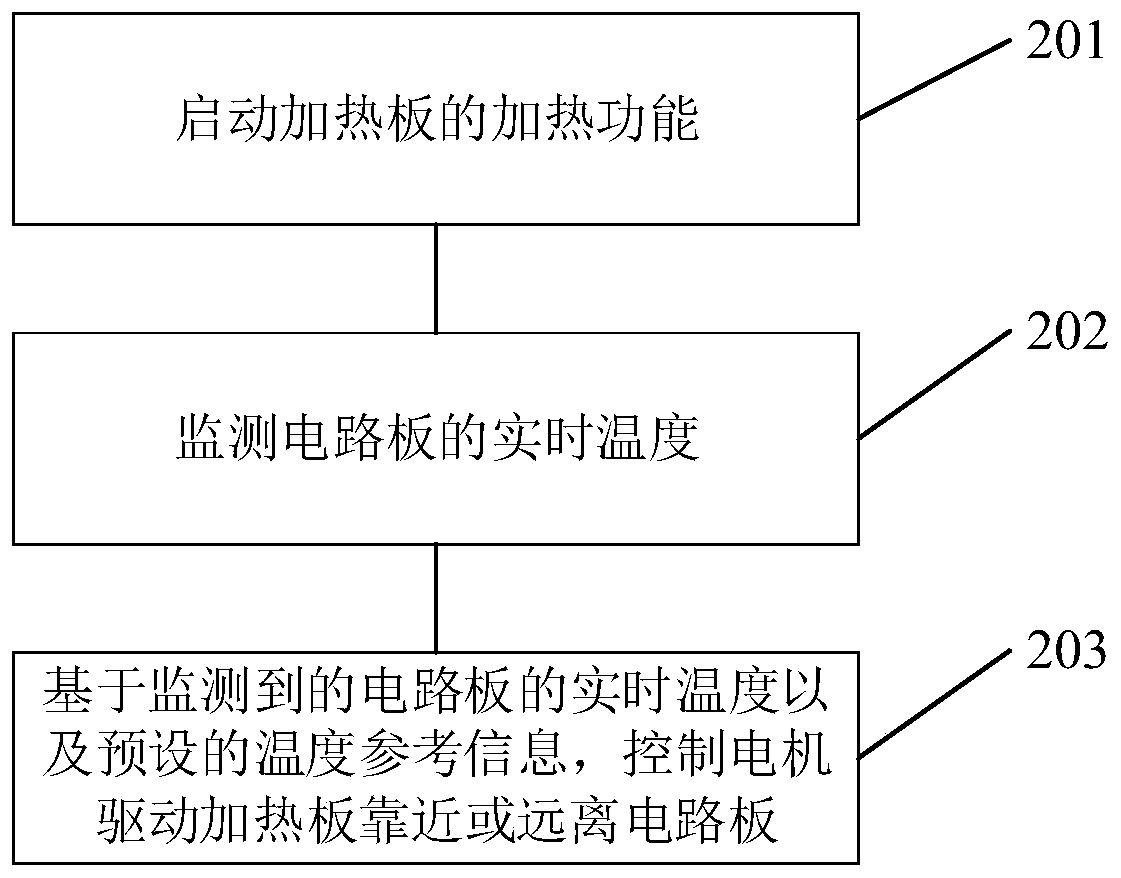

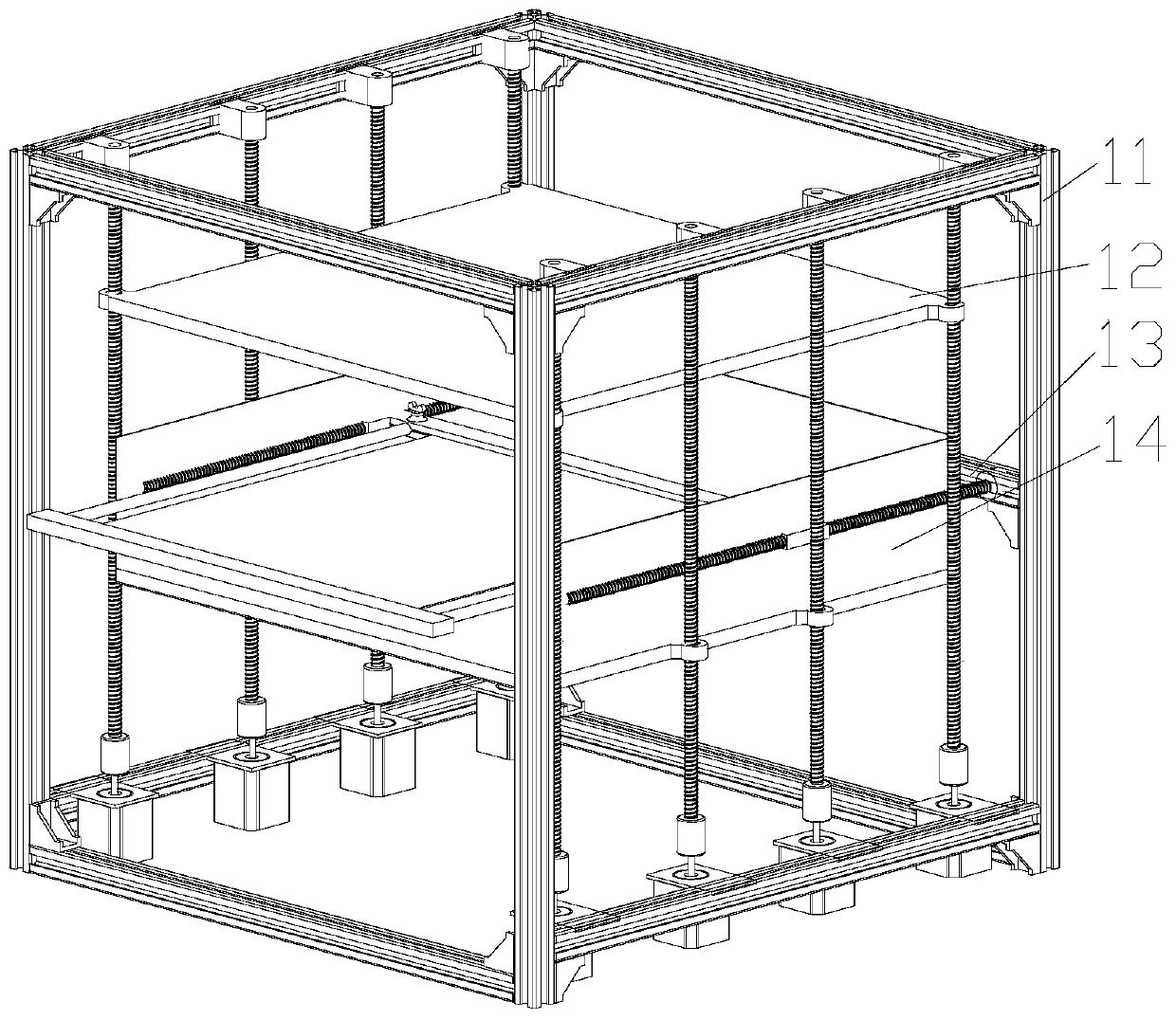

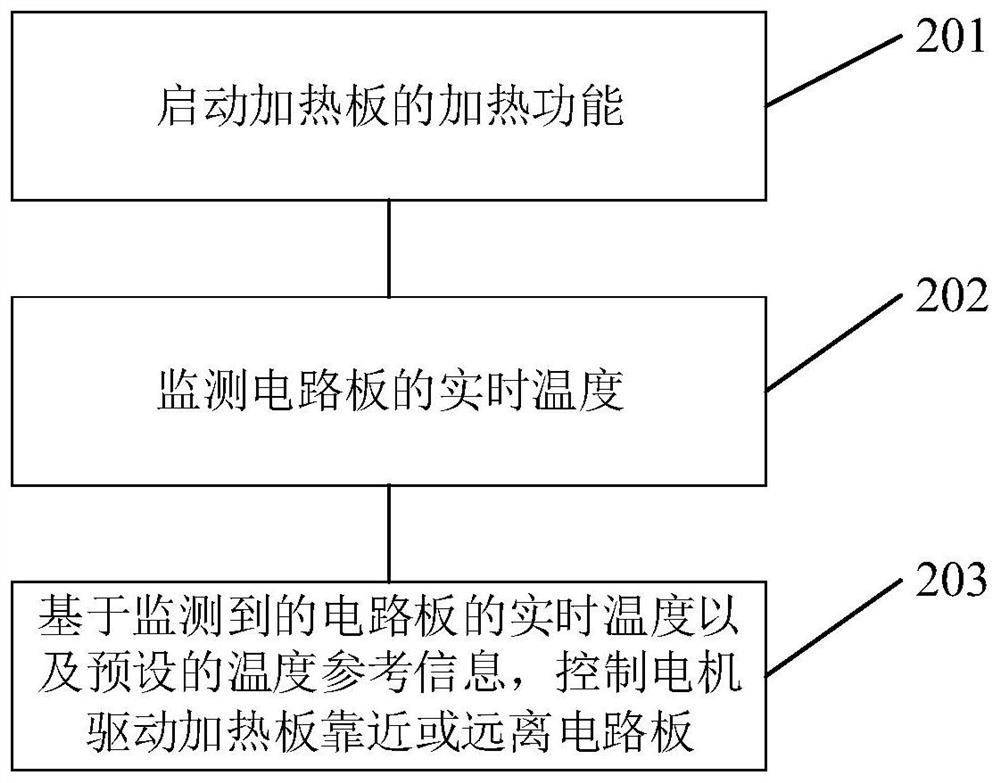

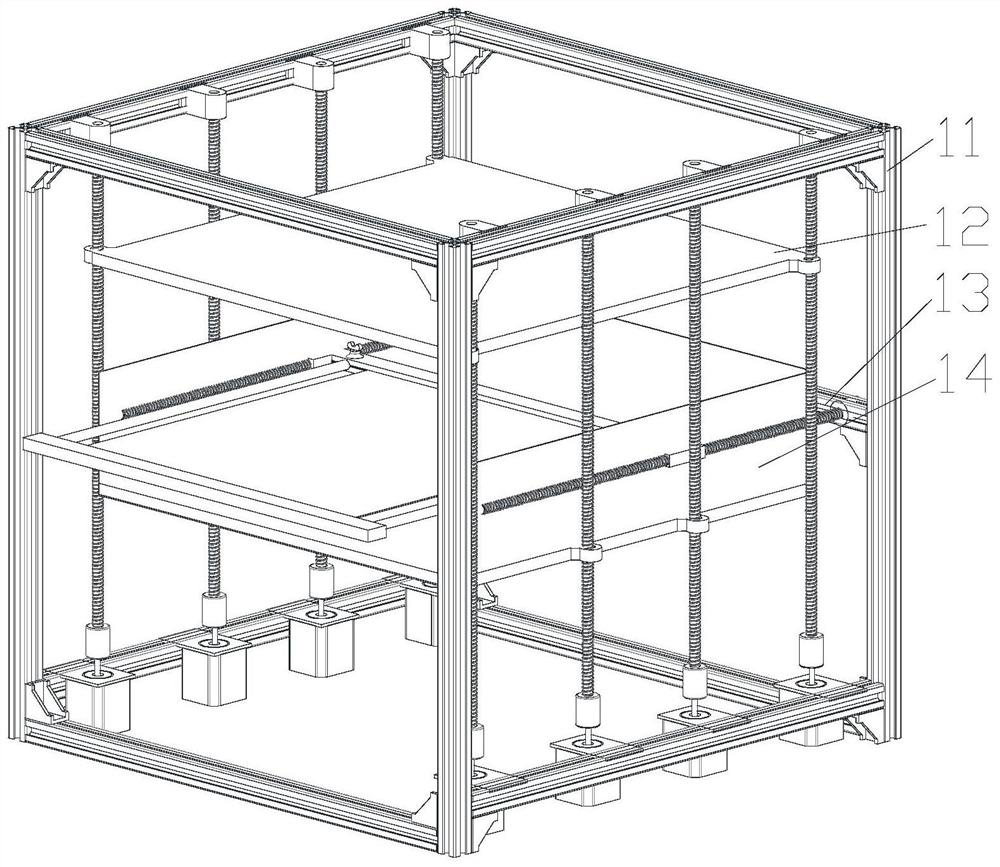

Circuit board heating method and device based on circuit board heating equipment

ActiveCN110913605AAchieve heating controlAccurate heating controlPrinted circuit assemblingTemperature control using electric meansThermodynamicsElectric machine

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

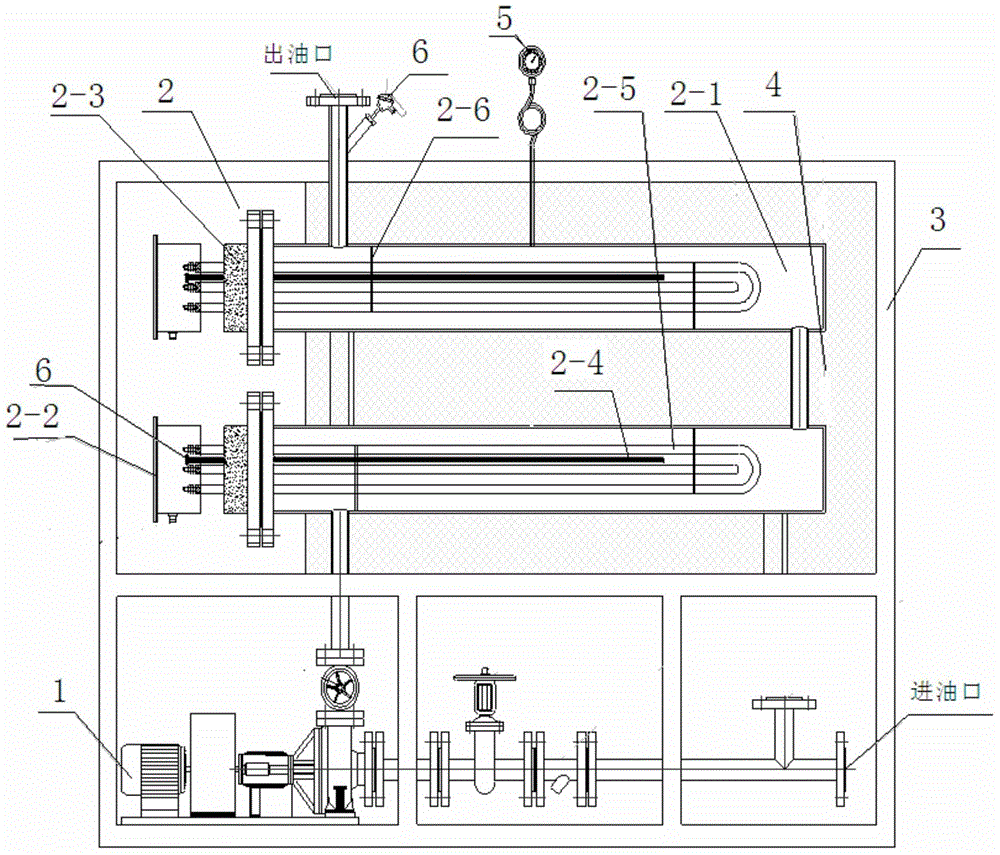

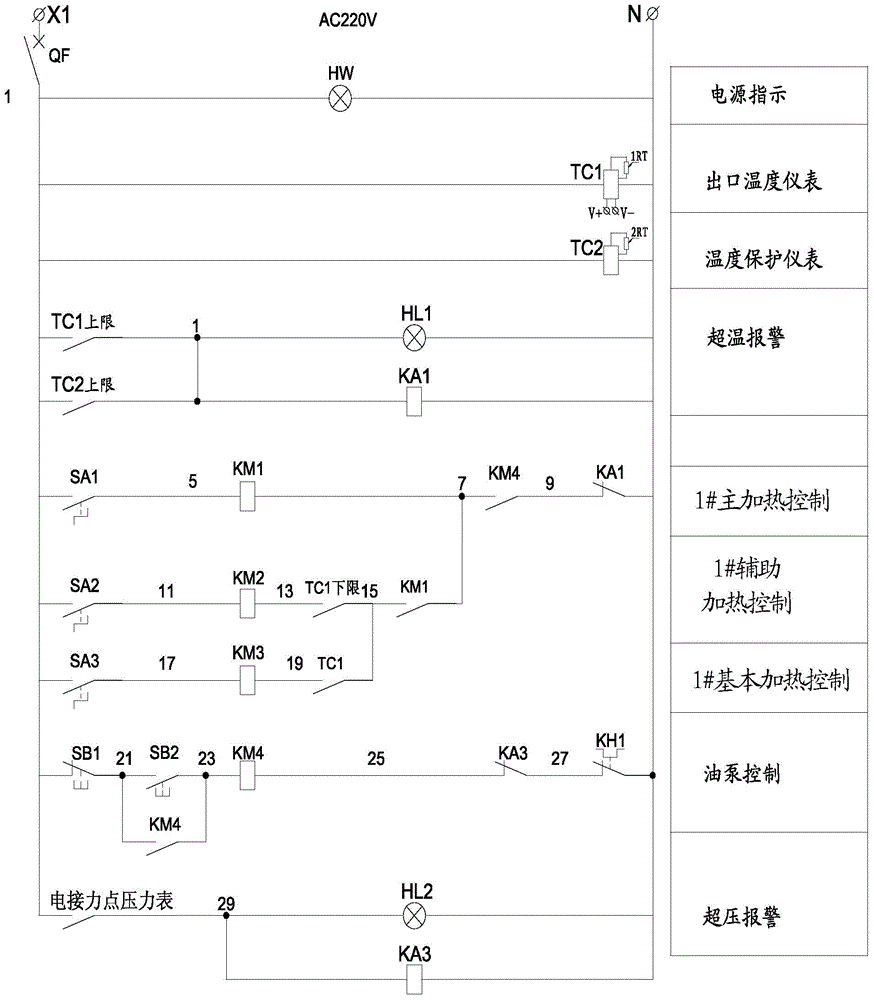

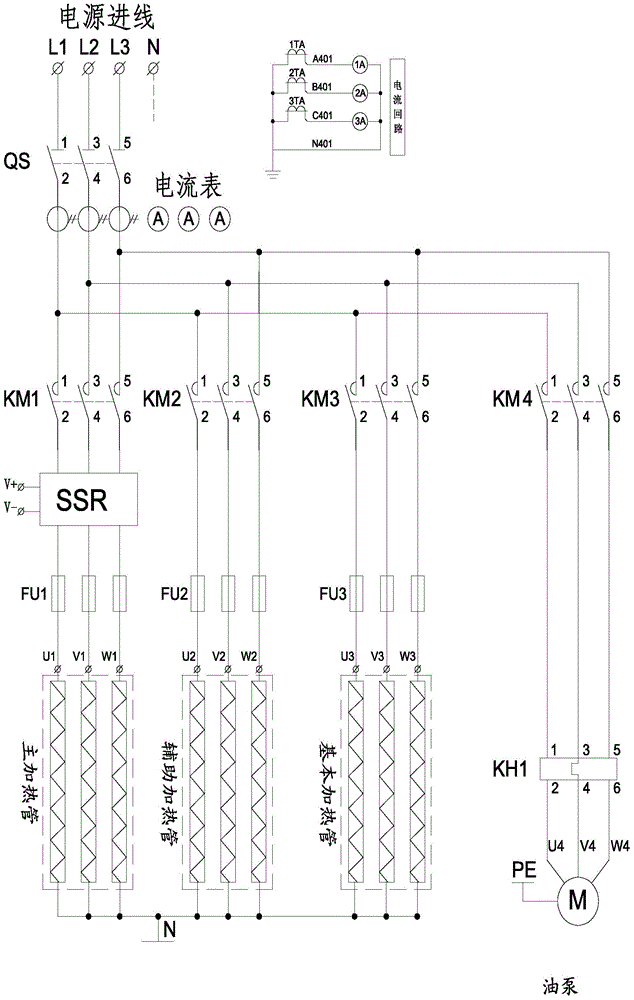

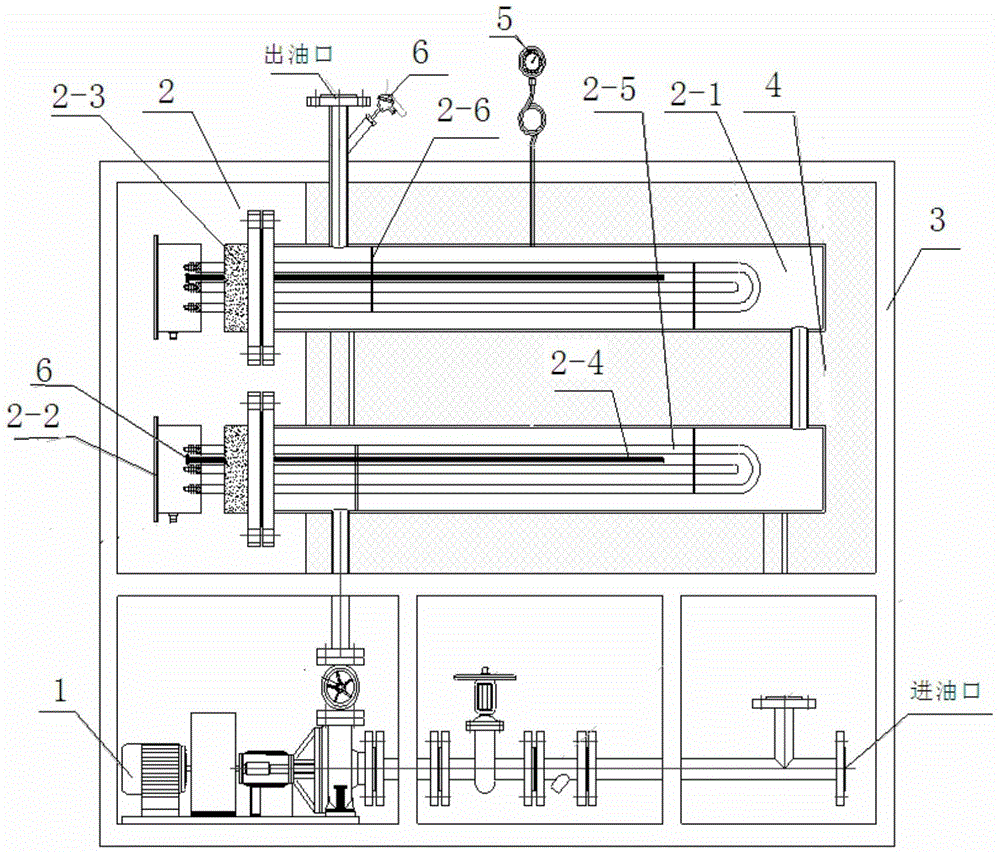

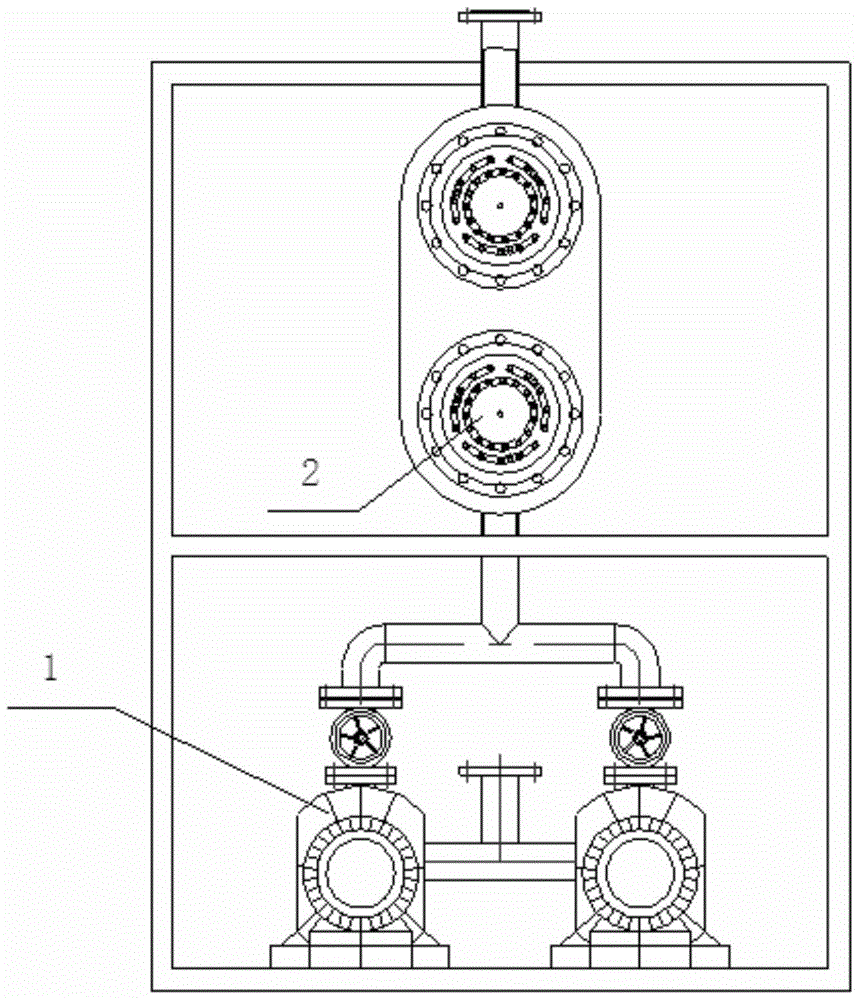

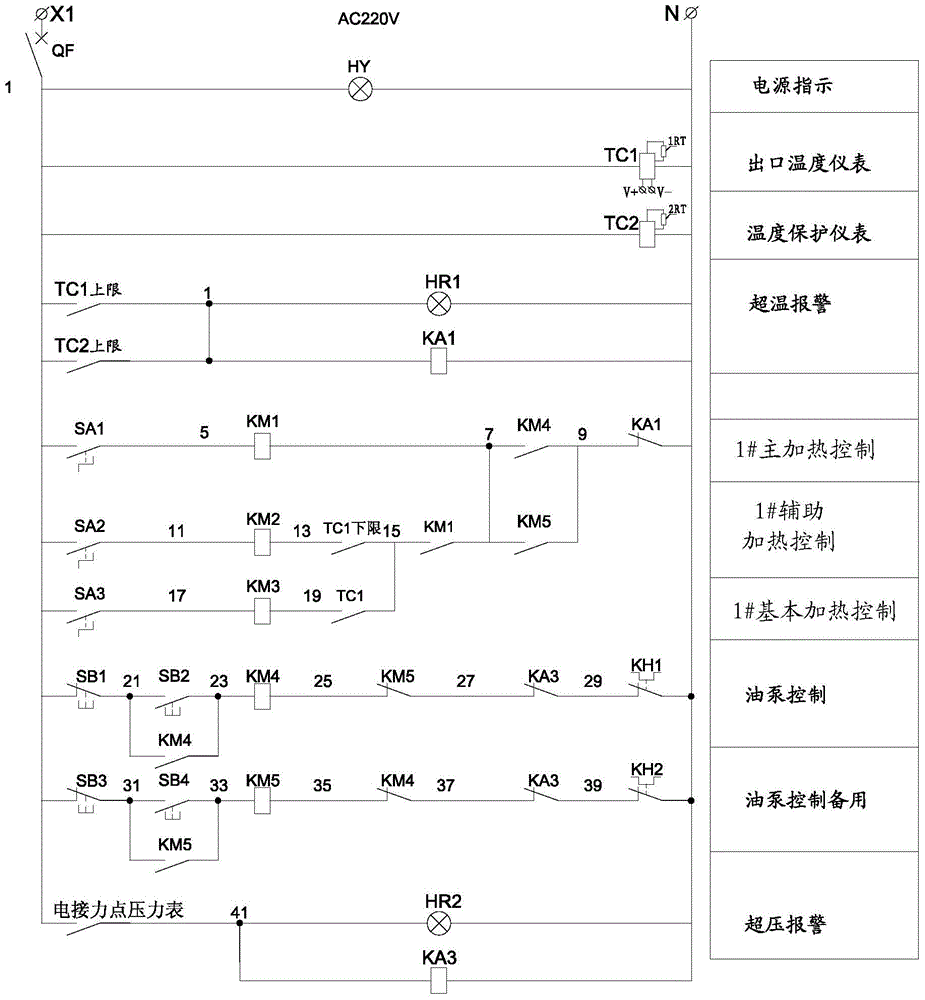

Single-pump conduction oil heating system

ActiveCN104019548ASlow down the temperature dissipationThe temperature dissipated reachesStorage heatersHeating effectEngineering

The invention discloses a single-pump conduction oil heating system. The single-pump conduction oil heating system comprises a hot oil pump, more than one heating element and a control unit, wherein the heating elements are arranged in a heat insulation box; heat insulation cotton is filled in the gaps between the heating elements and the heat insulation box; each heating element comprises an oil storage cavity, an anti-explosion box, a heat insulating layer, a temperature tube, more than one heating tube and more than one guide plate. The single-pump conduction oil heating system has a simple structure, is accurate in heating control, has high efficiency of the heating mode and good temperature uniformity of the heating effects, is energy-saving and environment-friendly and reduces the production cost.

Owner:JIANGSU ZONRE MECHANICAL EQUIP

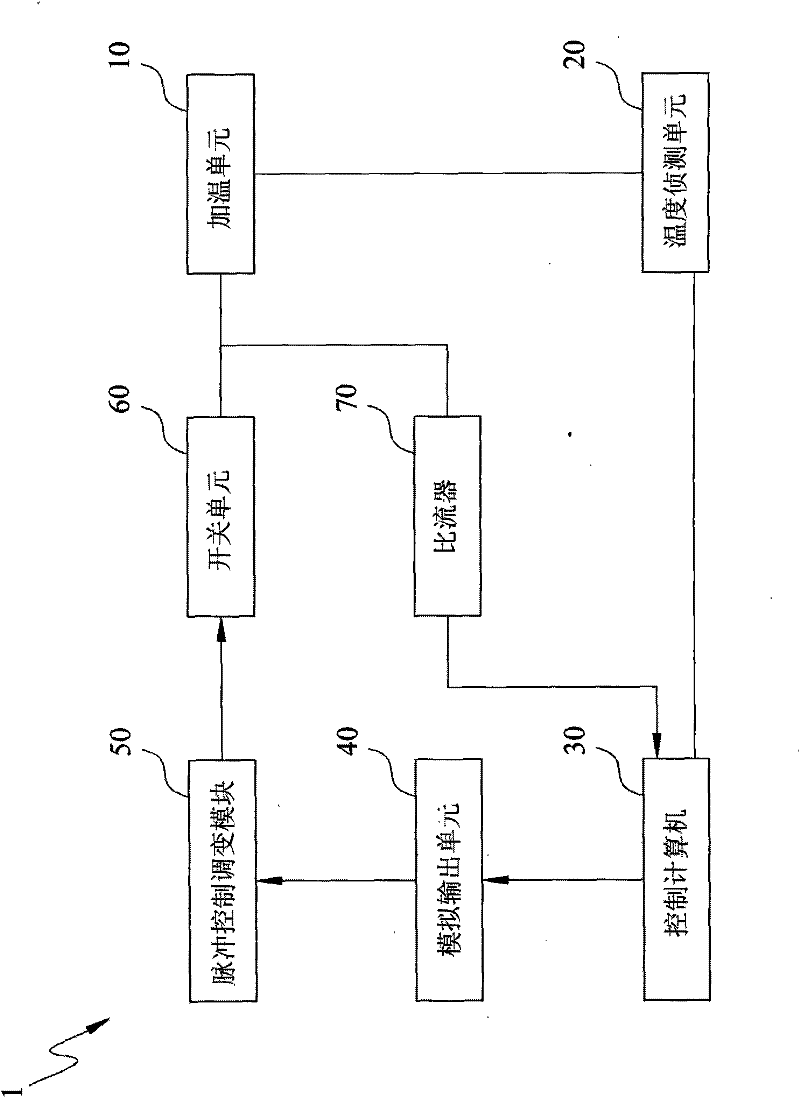

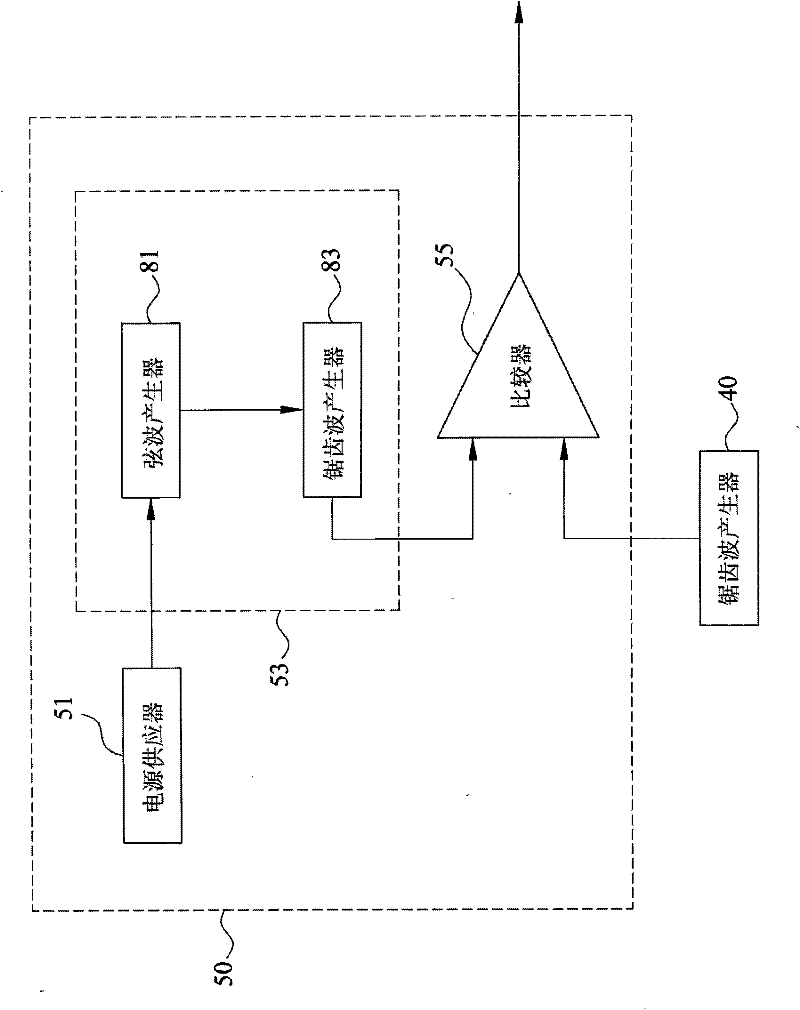

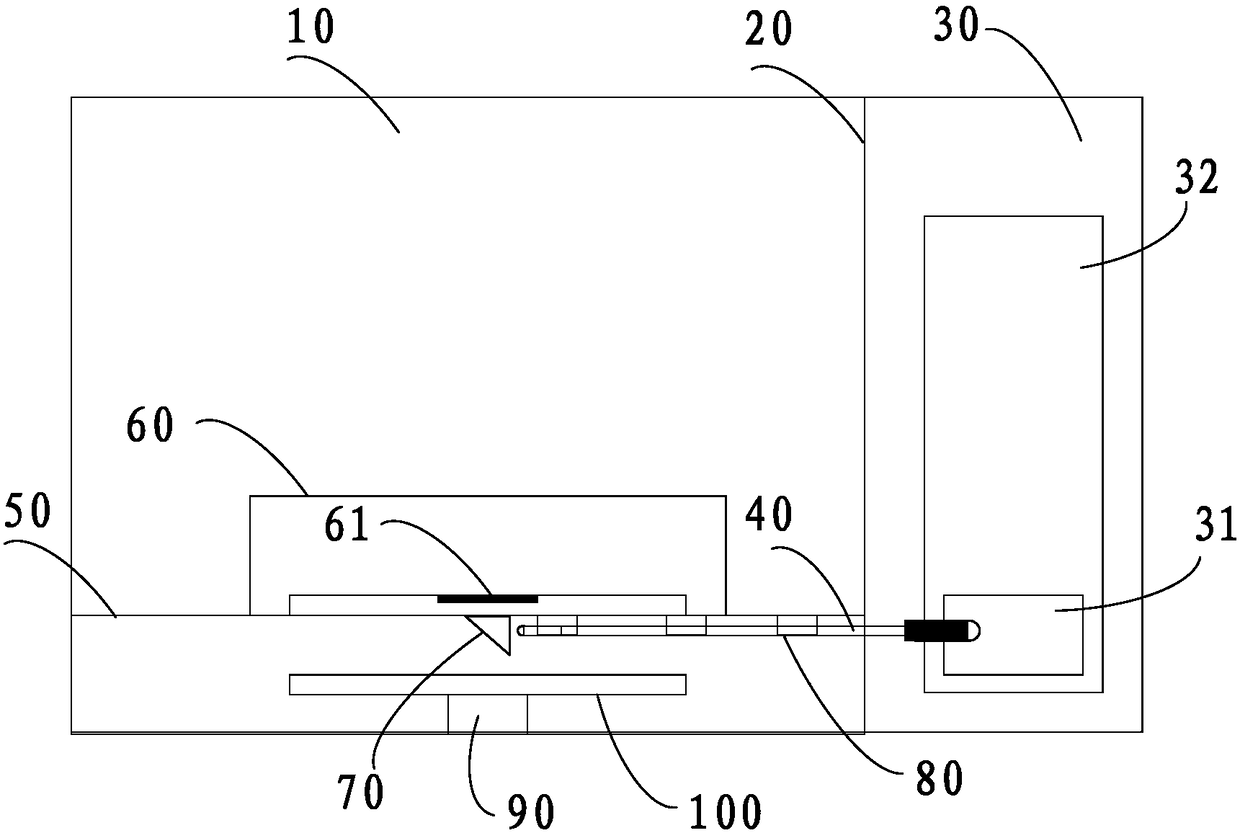

Rapid cooling device and temperature control method thereof

ActiveCN102455716AAccurate heating controlImprove process qualityTemperatue controlElectrical batteryElectric heating

The invention discloses a rapid cooling device and a temperature control method thereof. The device comprises a heating unit, a temperature detection unit, a control computer, an analog output unit, a pulse control and modulation module and a switch unit. By using a pulse width modulation method, the existing electric heating adjuster is replaced by the pulse control and modulation module which is integrated with a power supplier, a waveform conversion circuit and a comparator, the total volume of a system is reduced, group control is not required, the noise and interference are reduced, the heating of a chamber can be controlled more accurately, and the process quality of various rapidly heated targets such as wafers, solar cells, photoelectric chips and the like can be promoted.

Owner:PREMTEK INT

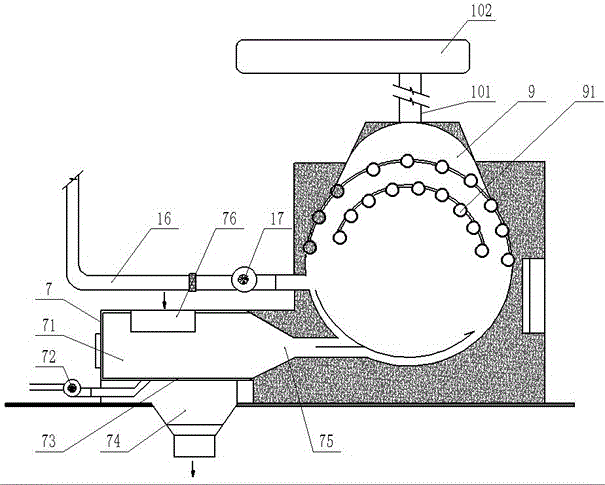

Rocking kiln

PendingCN107957189ARecycling is simple and low costAccurate heating controlRotary drum furnacesTemperature controlThermocouple

The invention provides a rocking kiln arranged in the shape of an inclined barrel and driven by a driving mechanism to rotate and rock side to side; material enters from a feed end that is high, to bespecific, the material rolls along the periphery and moves axially toward a discharge end that is low. Burners and nozzles may be arranged radially in the middle of the kiln where the material is calcined and heated, and heat that is generated may be transmitted from the middle of the kiln to a head of the kin and is finally guided into a dust remover for centralized treatment. According to the technical scheme, a calcining portion is arranged in the middle of a kiln barrel; flexible adjustments can be made according to kiln length during calcining; a thermocouple has higher temperature control precision; zonal control can be provided so that control precision for a material heating process curve is increased to + / - 2 DEG; waste gas is guided out of the head, centralized collection of thewaste gas is achieved, and raw material that is not heated can be preheated to certain degree; the calcining process is accompanied by roll-conveying of the material, the heating mode is more uniform, and energy utilization rate is increased.

Owner:山东优益环保设备有限公司

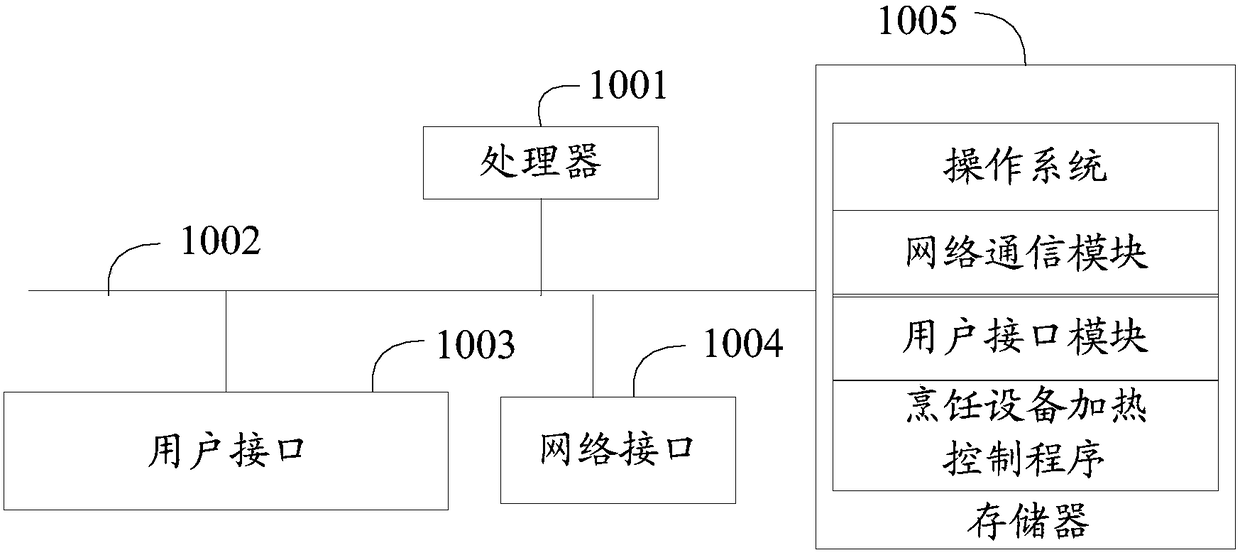

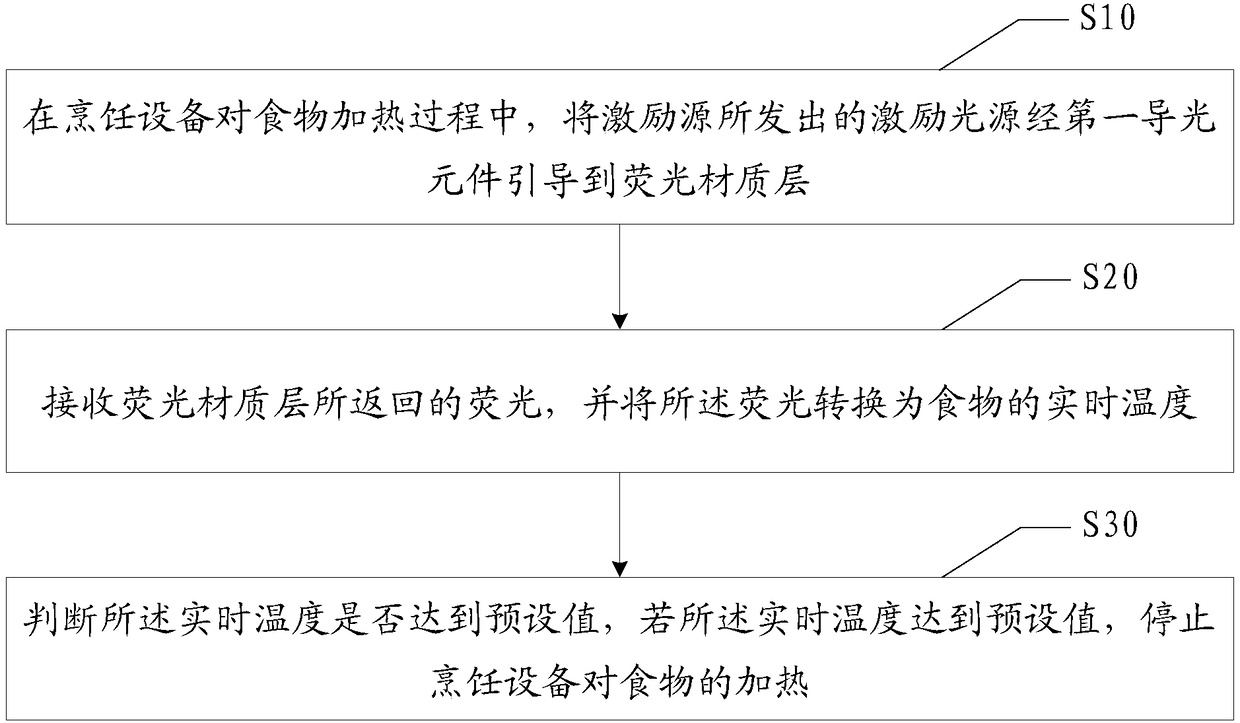

Cooking device, heating control method thereof, control terminal and computer storage medium

PendingCN108577488AAccurate heating controlAccurate temperatureThermometers using physical/chemical changesSteam cooking vesselsUltrasound attenuationComputer terminal

The invention discloses a cooking device, a heating control method of the cooking device, a control terminal and a computer storage medium. The heating control method of the cooking device comprises the following steps: during the process that the cooking device heats food, guiding an exciting light source emitted by an exciting source to a fluorescent material layer through a first light guide element; receiving fluorescence returned by the fluorescent material layer, and converting the fluorescence into the real-time temperature of food; and judging that whether the real-time temperature achieves a preset value or not, if the real-time temperature achieves the preset value, stopping the heating of the cooking device for food. According to the technical scheme, during the process of heating food, the exciting light source of the exciting source is transmitted to the fluorescent material layer through the first light guide element, then the fluorescence returned by the fluorescent material layer is received, and the temperature of food is calculated through the attenuation characteristic of fluorescence; the attenuation of fluorescence is related to the temperature, but is not related to the intrinsic nature of food, thus the detected temperature of food is more accurate, and the heating of the cooking device is accurately controlled.

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

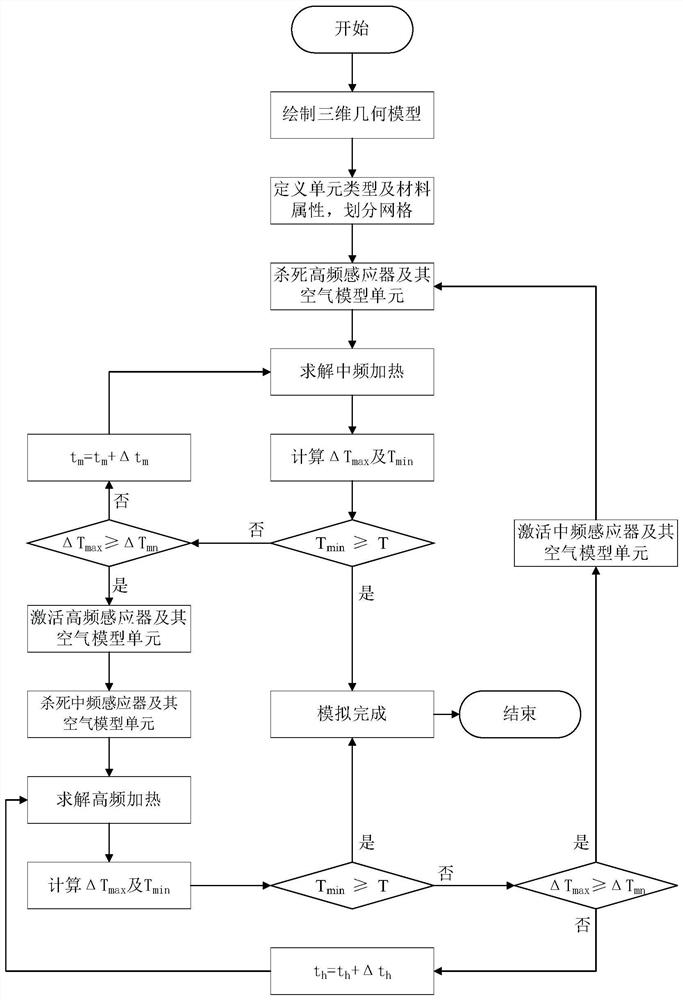

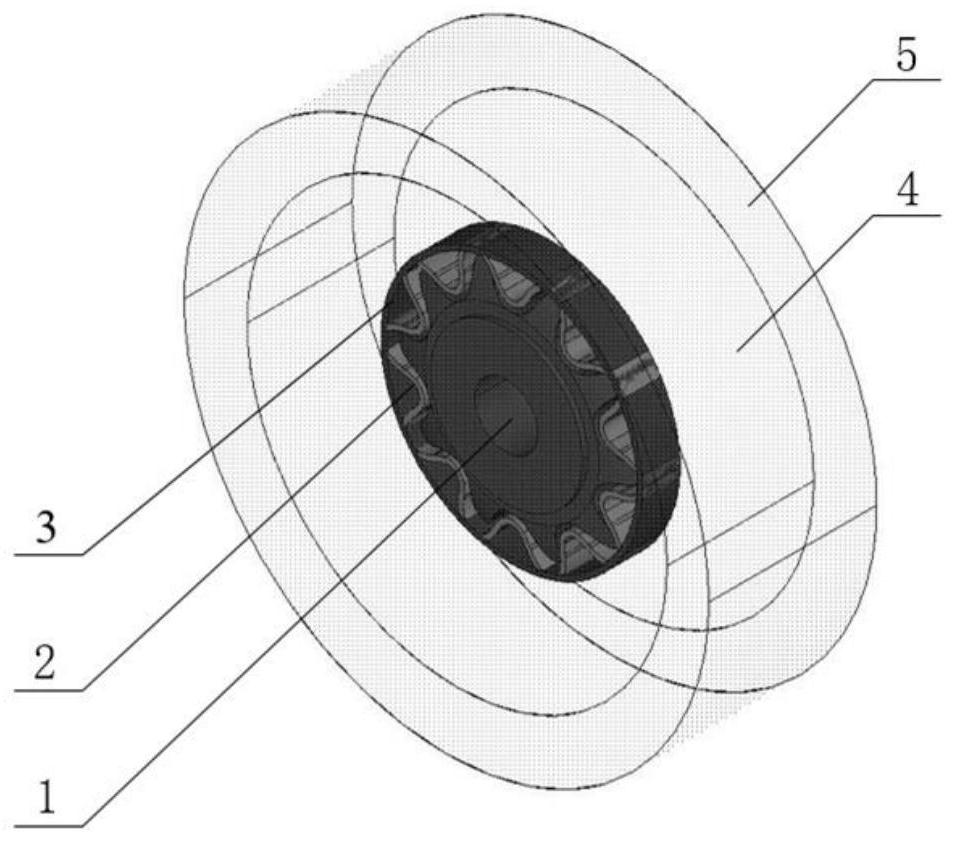

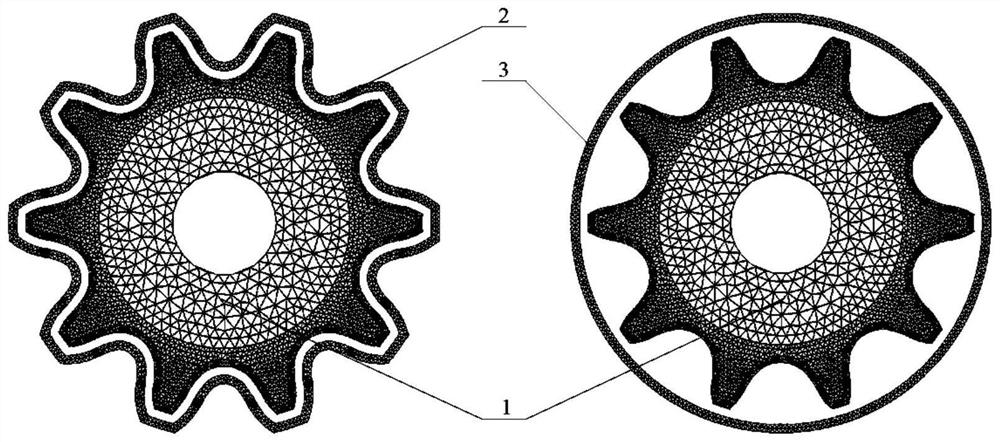

Asynchronous double-frequency induction heating numerical simulation method based on specially-shaped inductors

ActiveCN112877508AReduce unevennessImprove heating qualityIncreasing energy efficiencyFurnace typesPhysicsSprocket

The invention discloses an asynchronous double-frequency induction heating numerical simulation method based on specially-shaped inductors, and belongs to the technical field of asynchronous double-frequency induction heating. The method is based on ANSYS finite element numerical simulation software, medium-frequency and high-frequency inductors in different shapes are used for heating a chain wheel, and the nonuniformity of asynchronous double-frequency induction heating temperature distribution of the chain wheel is reduced; asynchronous double-frequency heating simulation of the chain wheel under the specially-shaped inductors is realized with a unit birth-death method, and the calculation time is shortened in a modeling mode that overlapped parts among sub-models are still kept independent from one another; switching of medium-frequency and high-frequency induction heating working conditions is achieved under the same model, the tooth profile temperature difference is used as the basis of medium-frequency and high-frequency heating switching, a traditional simulation method based on heating time is abandoned, more accurate heating control directly based on a targeted target is achieved, the precision and efficiency of medium-high frequency switching control are greatly improved, and simulation is closer to real production.

Owner:NORTHEASTERN UNIV

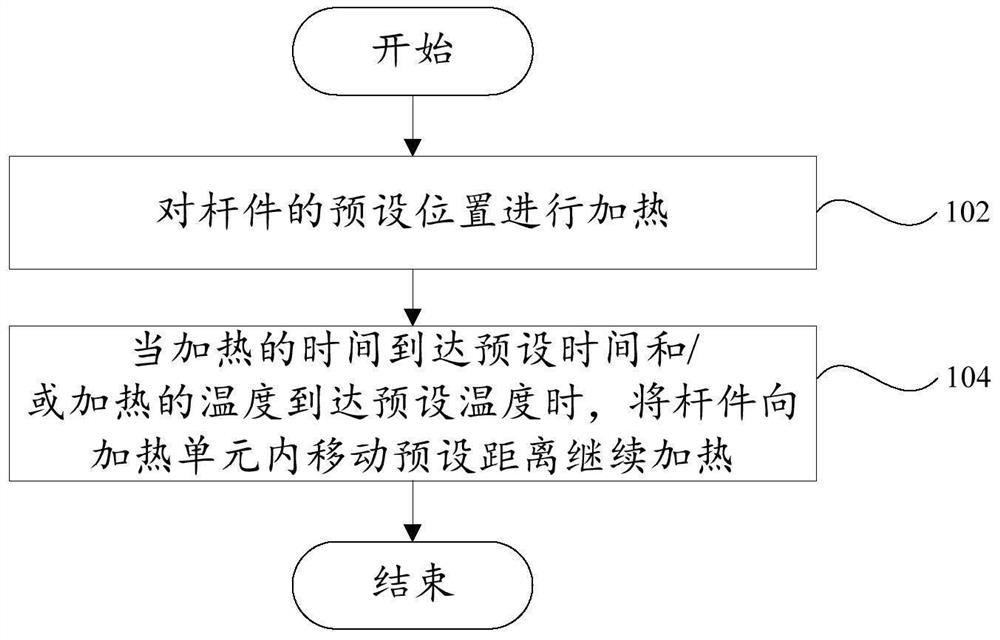

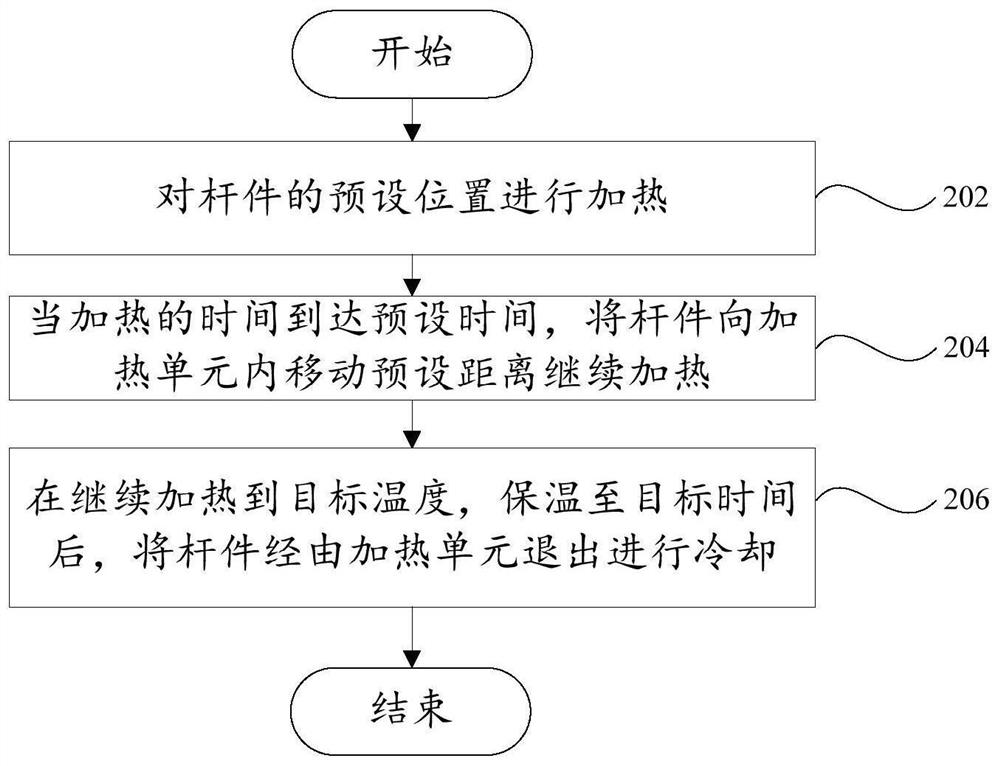

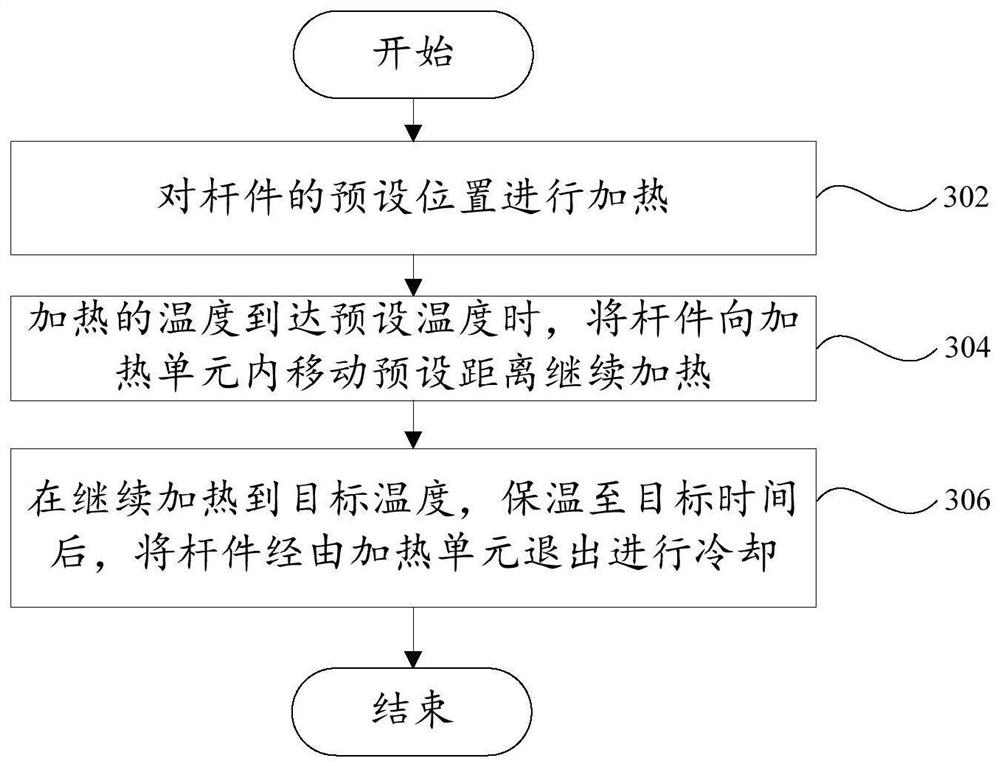

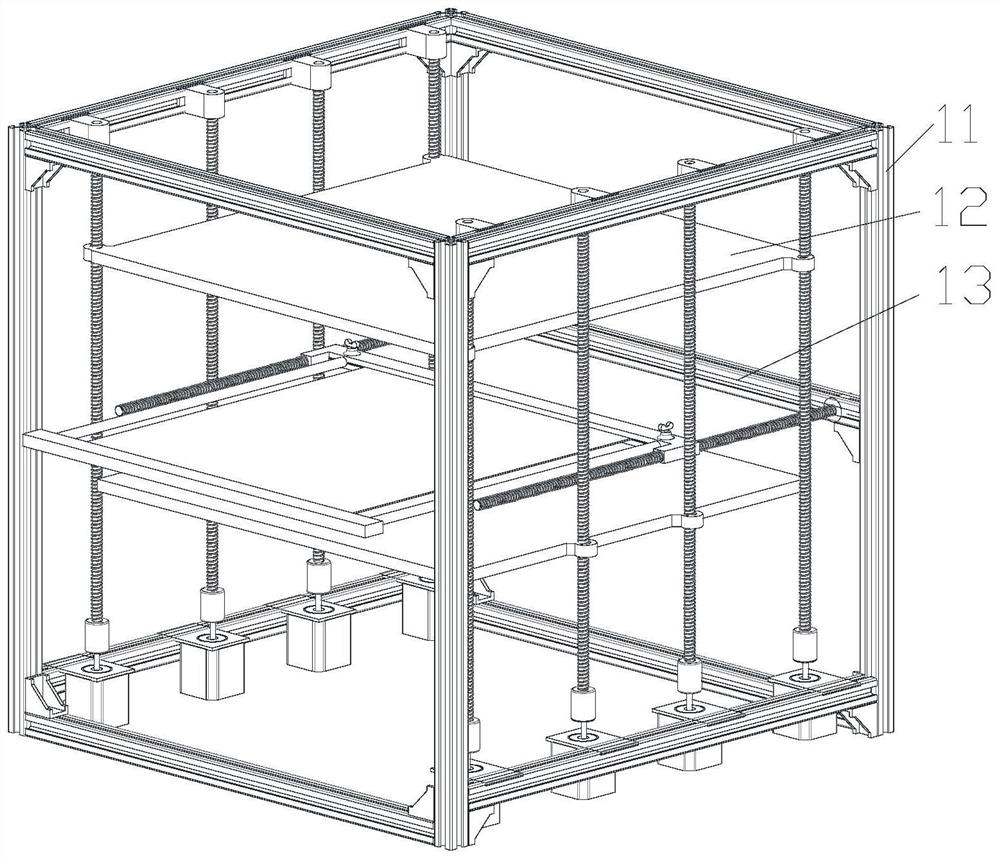

Rod member heating method, heating device and computer-readable storage medium

ActiveCN110777245BShorten the lengthHigh hardnessFurnace typesIncreasing energy efficiencyThermodynamicsHeat-affected zone

The present invention provides a rod heating method, heating equipment and computer-readable storage medium, wherein the rod heating method includes: heating a preset position of the rod; when the heating time reaches the preset time and / or the heating When the temperature reaches the preset temperature, the rod is moved into the heating unit for a preset distance to continue heating. The rod heating method of the present invention can significantly shorten the temperature of the rod at the furnace mouth of the heating unit and the length of the tissue transition zone during the local heating process, significantly shorten the length of the tissue in the nodularization zone affected by heating heat, and increase the hardness of the heat-affected zone .

Owner:CHINA RAILWAY CONSTR HEAVY IND

A circuit board heating method and device based on circuit board heating equipment

ActiveCN110913605BAchieve heating controlAccurate heating controlPrinted circuit assemblingTemperature control using electric meansThermodynamicsElectric machine

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

Rosin refining kettle and method

InactiveCN102266676BIncrease the heating areaEvenly heatedDistillation in boilers/stillsNatural resin purificationDiameter ratioRosin

The invention provides a rosin refining kettle, which comprises a cylindrical pot body, an upper sealing head and a lower sealing head and is characterized by further comprising a mosquito-repellent incense coiler, and preferably comprising a snake-shaped coiler and an outer semicircular coiler. The invention also provides a refining method by using the rosin refining kettle. By the high-efficiency rosin refining kettle, a height-diameter ratio can be controlled effectively and a heating position can be flexibly adjusted according to change of a liquid level during rosin refining, and the load on a vacuum pump set is low. By the refining method, the grade of an obtained rosin product is much higher than the standard of a special grade in China.

Owner:景东力奥林产集团林业化工有限公司

A double-pump heat transfer oil heating system

ActiveCN104019547BSlow down the temperature dissipationSolve uneven heatingStorage heatersThermal insulationEngineering

The invention discloses a double-pump heat-conducting oil heating system, which comprises a heat-oil pump, more than one heating element and a control unit. Cotton; the heating element includes an oil storage chamber, an explosion-proof box, a heat insulation layer, a temperature measuring tube, more than one heating tube and more than one deflector. The invention has the advantages of simple structure, precise heating control, high heating mode efficiency, good temperature uniformity of heating effect, energy saving and environmental protection, and reduced production cost.

Owner:JIANGSU ZONRE MECHANICAL EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com