Asynchronous double-frequency induction heating numerical simulation method based on specially-shaped inductors

A dual-frequency induction and numerical simulation technology, used in heat treatment furnaces, heat treatment equipment, heat treatment process control, etc., can solve the problems of large temperature non-uniformity of heating layer, reduced heating efficiency, low heating quality, etc., to improve accuracy and efficiency. , Improve the heating quality, reduce the effect of non-uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to facilitate the understanding of the present application, the present application will be described more fully below with reference to the relevant drawings. Preferred embodiments of the application are shown in the accompanying drawings. However, the present application can be embodied in many different forms and is not limited to the embodiments described herein. On the contrary, the purpose of providing these embodiments is to make the disclosure of the application more thorough and comprehensive.

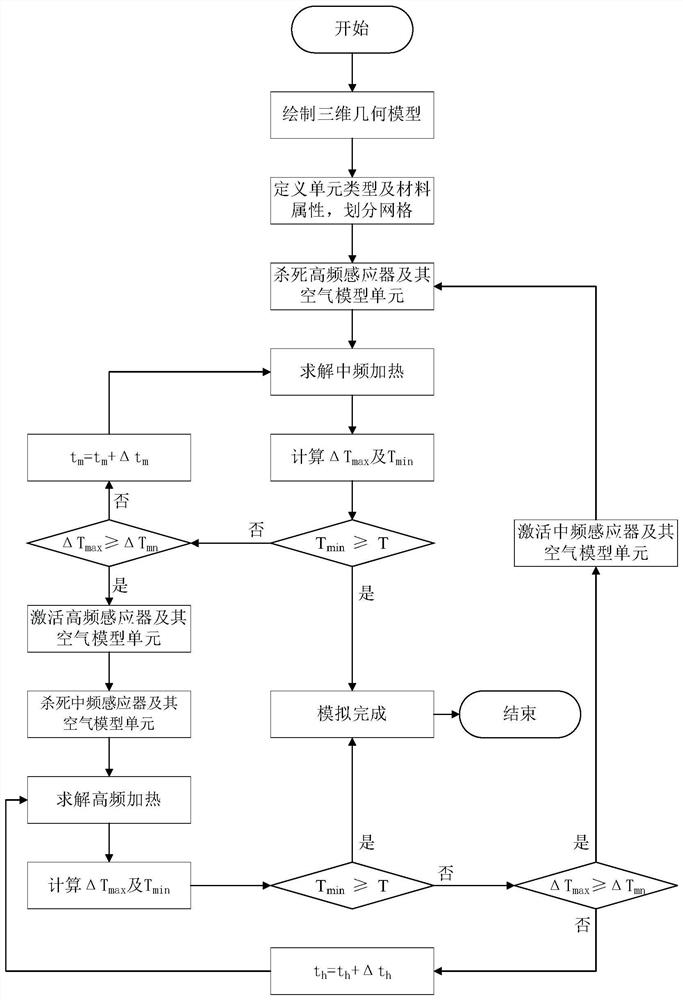

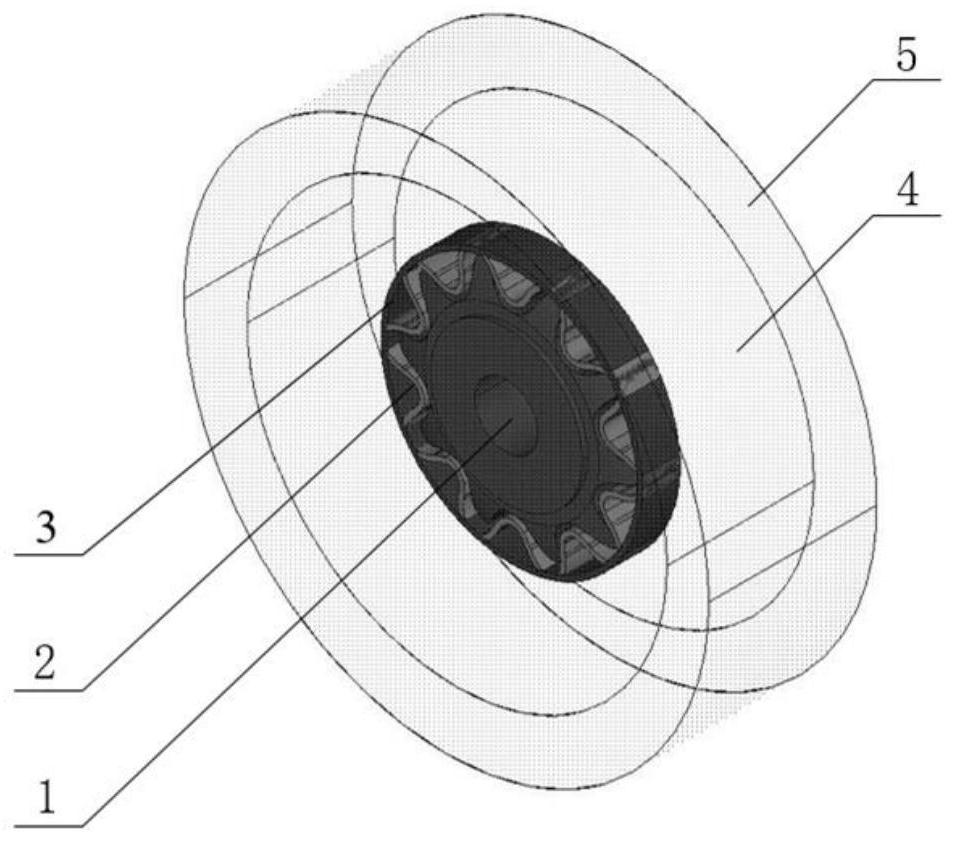

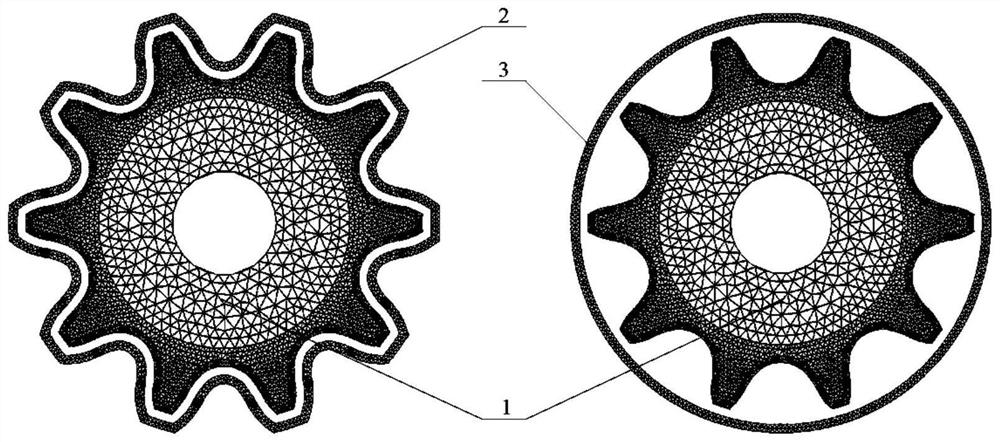

[0032] Since asynchronous dual-frequency induction heating involves complex electric-magnetic-thermal three-field coupling, using traditional experimental research methods to develop new processes will consume a lot of manpower, financial resources and time, but with the development of computer technology, finite element Numerical simulation method provides an important means for the development of induction heating process. Therefore, the asynchronous dual-f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com