Portable Ice Making Apparatus Having a Bypass Tube

a technology of bypass tube and ice making apparatus, which is applied in the direction of refrigeration safety arrangement, light and heating apparatus, refrigeration components, etc., can solve the problems of little more time, damage to the compressor, and the conventional apparatus does not have a separator to collect liquefied refrigerant, etc., to achieve precise heat control, and fast freezing and heating operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

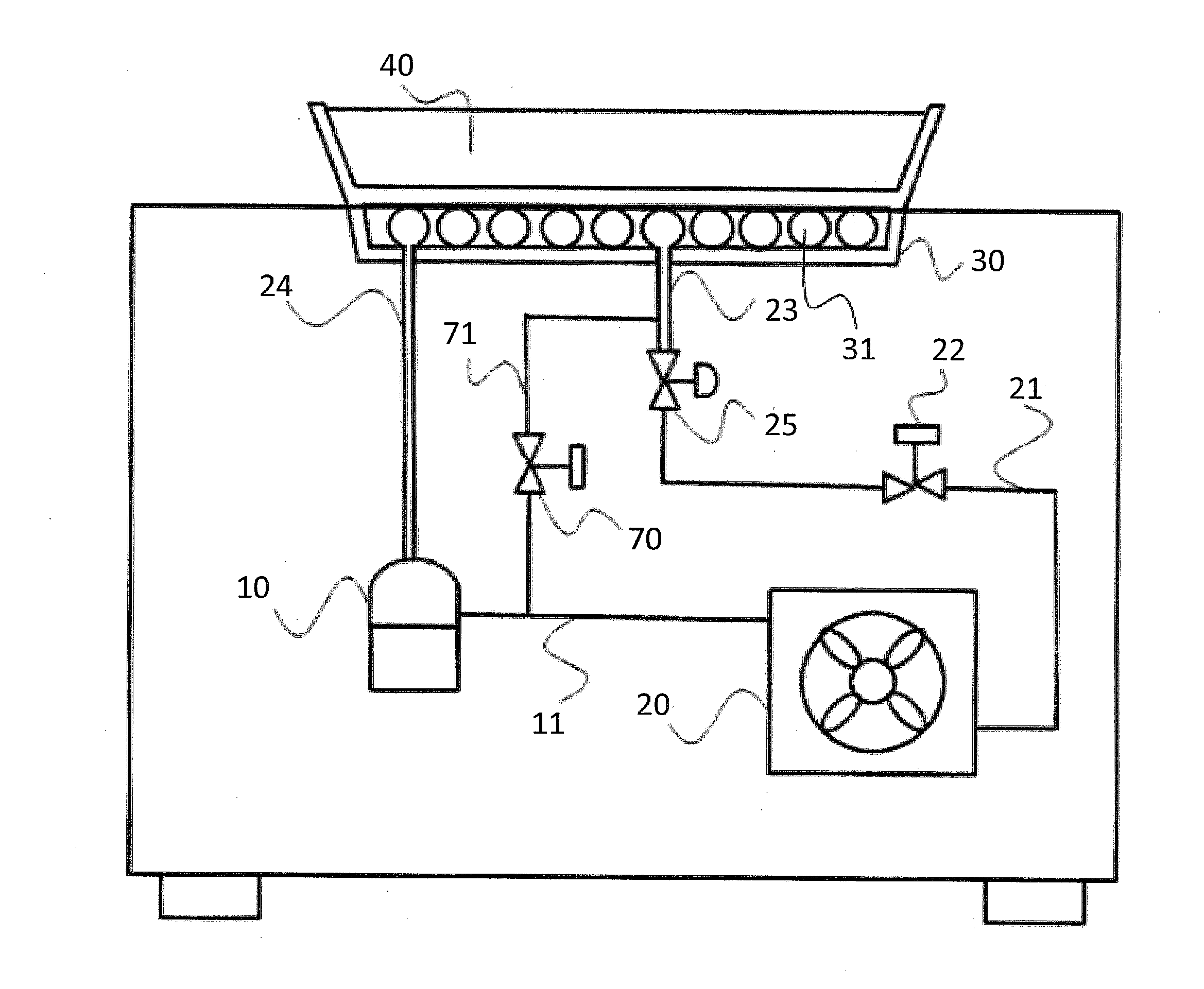

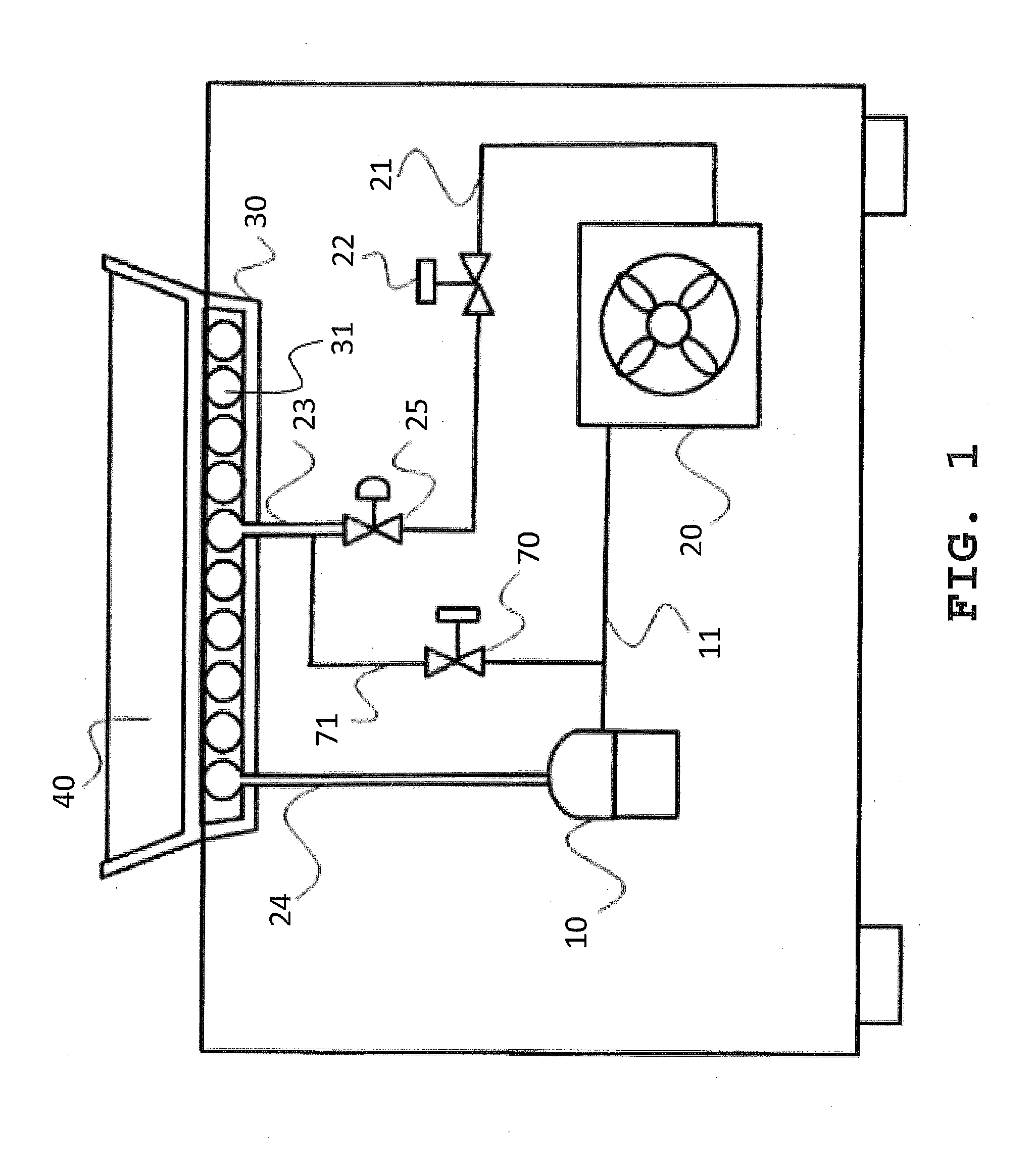

[0022]FIG. 1 shows a conventional ice making apparatus. The apparatus includes a first discharging tube 11 connecting the compressor 10 to the condenser 20, the second discharging tube 21 connecting the condenser 20 to the expansion valve 22 and an inlet tube 23 connecting the expansion valve 22 and the evaporator 30. The bypass line 71 connects the first discharging tube 11 and the inlet tube 23 and the switching means 70 is installed in the middle of the bypass line 71. An additional switching means 25 is installed in the middle of the inlet tube. There is no separator to collect liquefied refrigerant from the pipe which connects the evaporator 30 to the compressor 10, and the coolant pipe 31 is configured to have a coil from the inlet tube 23 to the outlet tube 24.

[0023]In the freezing mode, refrigerant flows from the compressor 10 to the condenser 20, to the expansion valve 22, to the evaporator 30, and then back to the compressor 10. But, in the heating mode when the switching ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com