Induction heating power supply and control method thereof

A technology of induction heating power supply and control method, applied in induction heating control, induction heating, induction current source and other directions, can solve the problems of difficult adjustment of control parameters, zero drift and aging, poor versatility, etc., to achieve fast response speed and heating efficiency. High and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

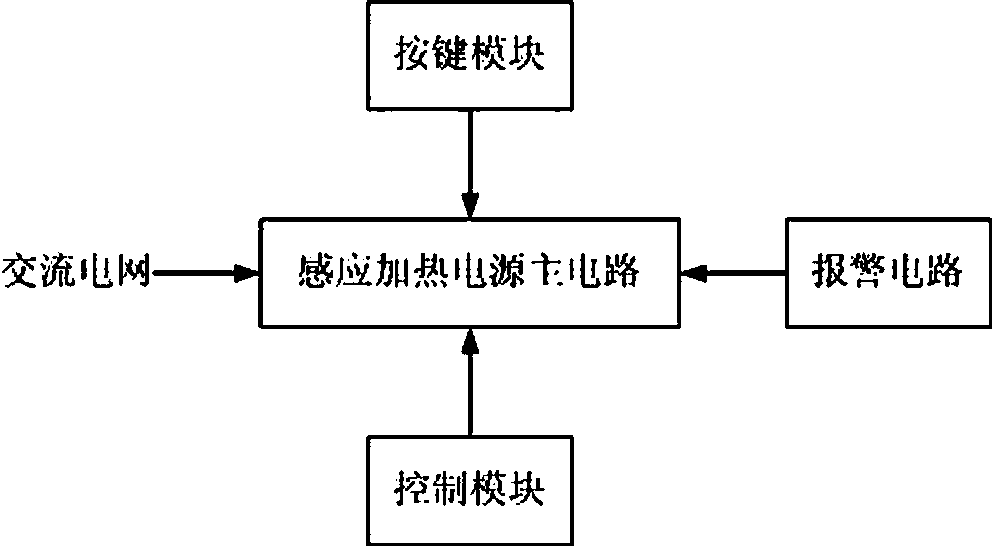

[0020] as attached figure 1 As shown, an induction heating power supply includes a main circuit of the induction heating power supply, a button module, a control module, and an alarm module. The main circuit of the induction heating power supply is connected to the button module, the control module, and the alarm module respectively.

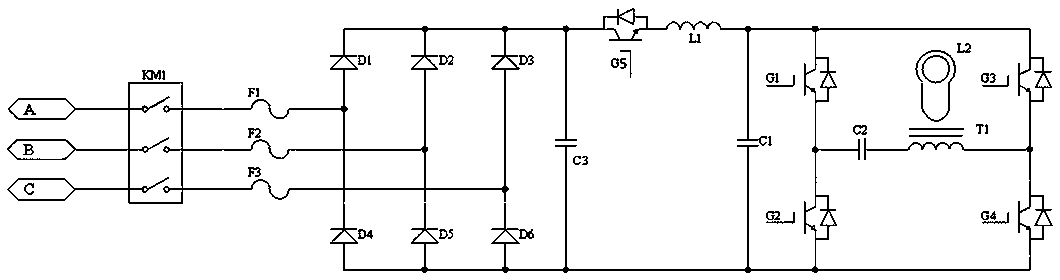

[0021] as attached figure 2 As shown, the main circuit of the induction heating power supply includes a rectification filter circuit, a chopper circuit, and a bridge inverter circuit connected in sequence, and the rectification filter circuit is connected to a three-phase alternating current, including six high-power diodes D1~D6, forming a The three-phase uncontrolled rectification system rectifies the three-phase power-frequency AC to become a DC pulsating voltage, which is filtered by the filter capacitor C3 to obtain a stable DC voltage. The chopper circuit is composed of high-power insulated gate transistor G5, reactor L1 and filter capac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com