Rosin refining kettle and method

A refining method and refining kettle technology, applied in natural resin refining, distillation in boilers/distillates, etc., can solve the problems of large invalid volume of elliptical head, heavy burden of vacuum pump group, affecting refining efficiency, etc., so as to avoid unsatisfactory refining complete, reduce rosin backflow, and improve product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

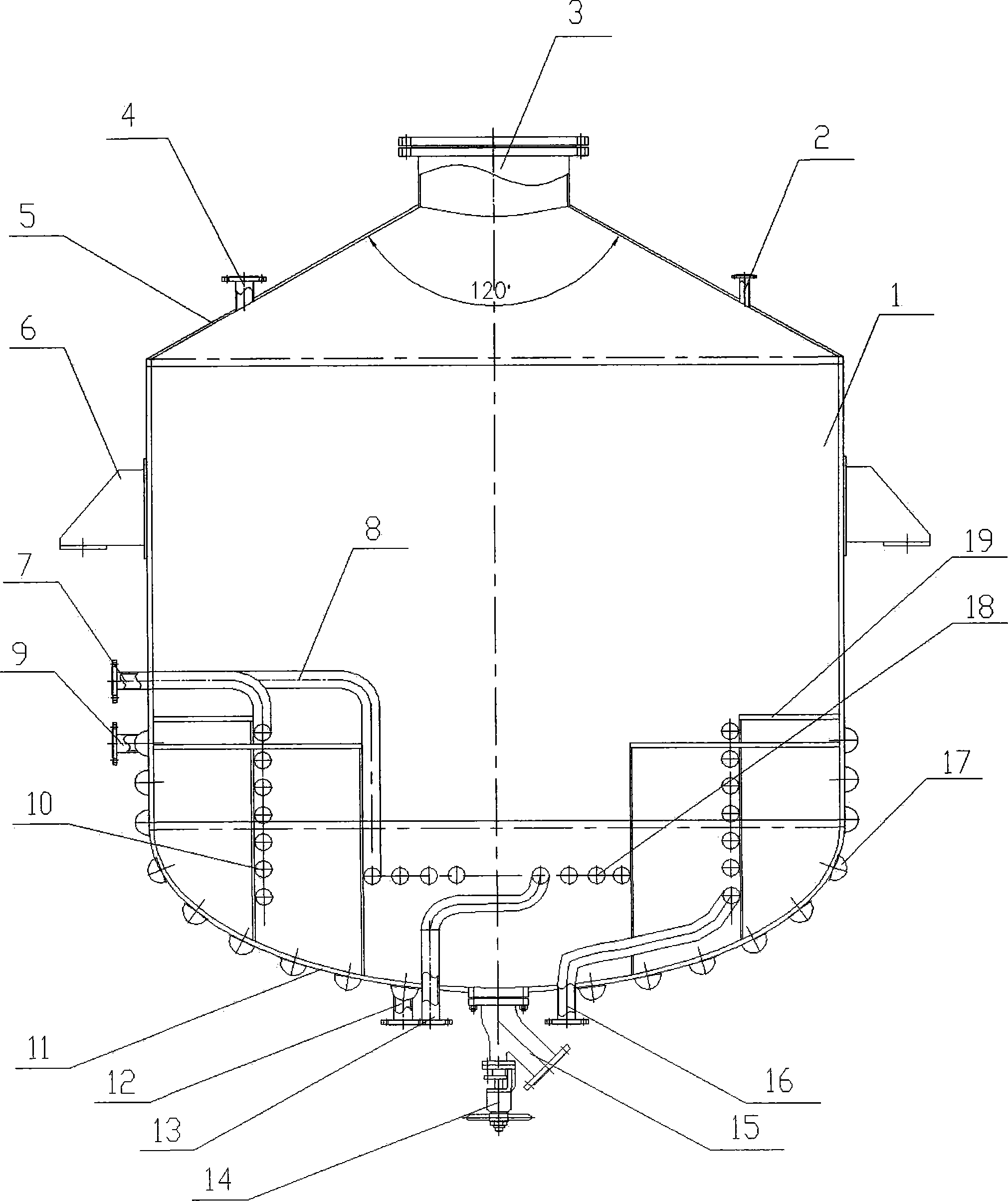

[0040] The present invention illustrates the rosin refining kettle of the present invention through the following examples. However, those skilled in the art understand that any improvement or change made to the present invention falls within the protection scope of the present invention.

[0041] The embodiment of this rosin refining kettle is described below in conjunction with the rosin refining flow process.

[0042] Put the metered liquid rosin into the refining kettle body 1 and the oval lower head 11 from the feed port 4, respectively open the oil inlet and outlet valves of the serpentine coil, the oil inlet and outlet valves of the mosquito coil coil, and the outer The oil inlet and outlet valves of the semi-circular coil allow the high-temperature heat transfer oil to enter the serpentine coil 10 and the mosquito coil respectively from the oil inlet 16 of the serpentine coil, the oil inlet 13 of the mosquito coil, and the oil inlet 12 of the outer semicircular coil. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com