Incineration tower capable of gasifying and melting domestic waste directly

A technology for gasification, melting, and household waste, applied in incinerators, combustion methods, combustion types, etc., can solve the problems of cooling and dust removal that cannot be completely solved, difficulty in industrialization control and promotion, complex process flow, and complex systems. Small land area, high degree of automation, and the effect of improving heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

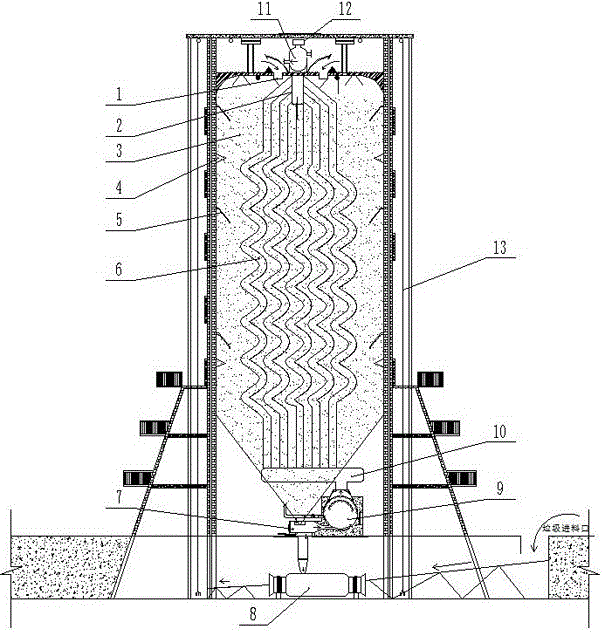

[0052] A direct gasification and melting incineration tower for domestic waste, comprising a feed inlet 1, a tower bin 3, a heat collector 10, a secondary combustion chamber 9, an incinerator 7, a dryer 8, a flue gas pipeline 2, a cooling furnace 11 and a heating system 12; the feed inlet 1 is set at the top of the tower bin 3; the flue gas pipeline 2 is set above the tower bin 3.

[0053] The bottom of the tower bin 3 is provided with a discharge port and an ash circulation outlet; the ash circulation outlet is connected to the incinerator inlet 76; the inner wall of the tower bin 3 is provided with baffle plates 5 and temperature measuring Instrument 4.

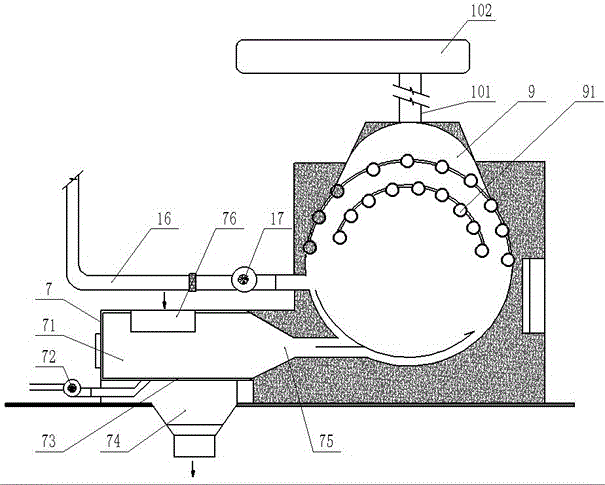

[0054] The incinerator 7 is also provided with an ash outlet 74 and a waste gas outlet 75; the ash outlet 74 is connected to the heat conduction inlet 83 of the dryer 8; the waste gas outlet 75 is connected to the secondary combustion chamber 9. The inner cavity of the incinerator 7 is a furnace 71; the furnace bridge 73 i...

Embodiment 2

[0064] The difference from Example 1 is:

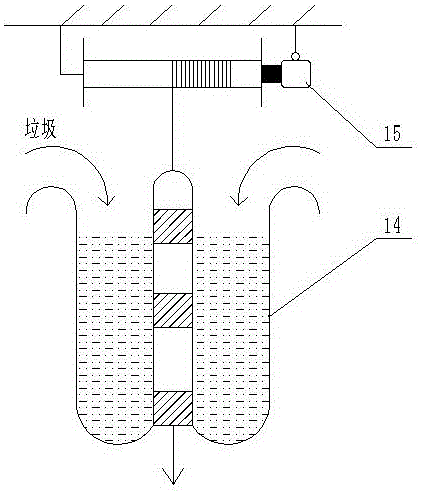

[0065] The incineration tower also includes a feed device; the feed device includes a grab bucket 13, a conveyor and a buffer bag 14; the grab bucket 13 is arranged outside the tower bin 3, and the highest point is fixed at the feed port 1 Above, the lowest point is on the same level as the base of the dryer 8; the conveyor moves between the grab bucket 13 and the feed port 1; the mouth of the buffer bag 14 is fixed at the above. The center of the bottom of the buffer bag 14 is connected with the capstan 15, and the capstan 15 is fixed above the feed port 1; gaps are provided around the buffer bag 14 at intervals.

[0066] Garbage enters from the basement and is transported to the dryer 8 by the conveyor belt for pretreatment of the garbage. The dried garbage is transferred to the grab bucket 13 and then lifted to the top of the tower bin 3, and is transported to the feed port 1 by the conveyor. , the bottom of the buffer bag 14 con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com