Rod member heating method, heating device and computer-readable storage medium

A heating method and computer program technology, applied in the field of workpiece processing, can solve problems such as affecting the efficiency of line operation, rapid wear, and unfavorable train running smoothness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

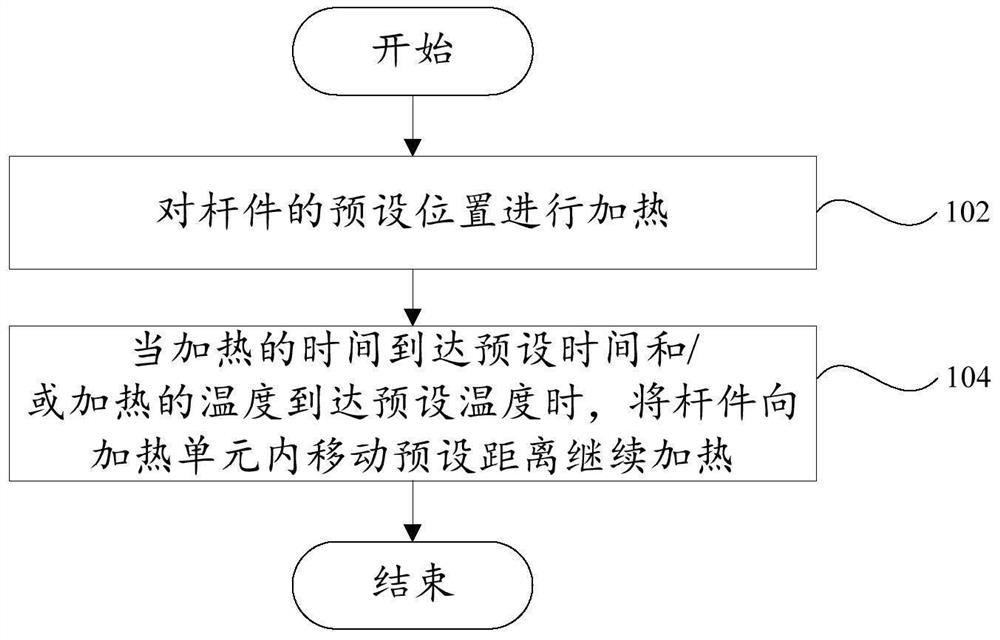

[0044] like figure 1 As shown, the flow of the rod heating method according to an embodiment of the present invention includes:

[0045] Step 102: Heat the preset position of the rod member;

[0046] Step 104, when the heated time reaches the preset time and / or the heated temperature reaches the preset temperature, the rod member is moved to the heating unit to move the preset distance to the heating unit.

[0047] During the heating method of this embodiment, the rod is heated during the heating method, and the rod member is continuously heated to the heating device, in this manner, in this manner can significantly shorten the rod to local heating. In the process, the temperature and the length of the tissue transition zone at the heating unit are significantly shortened, and the length of the heat affects the tissue of the spheroidal region is significantly shortened, and the hardness of the heat affected zone is improved.

[0048] Further, the timing and / or temperature of the...

Embodiment 2

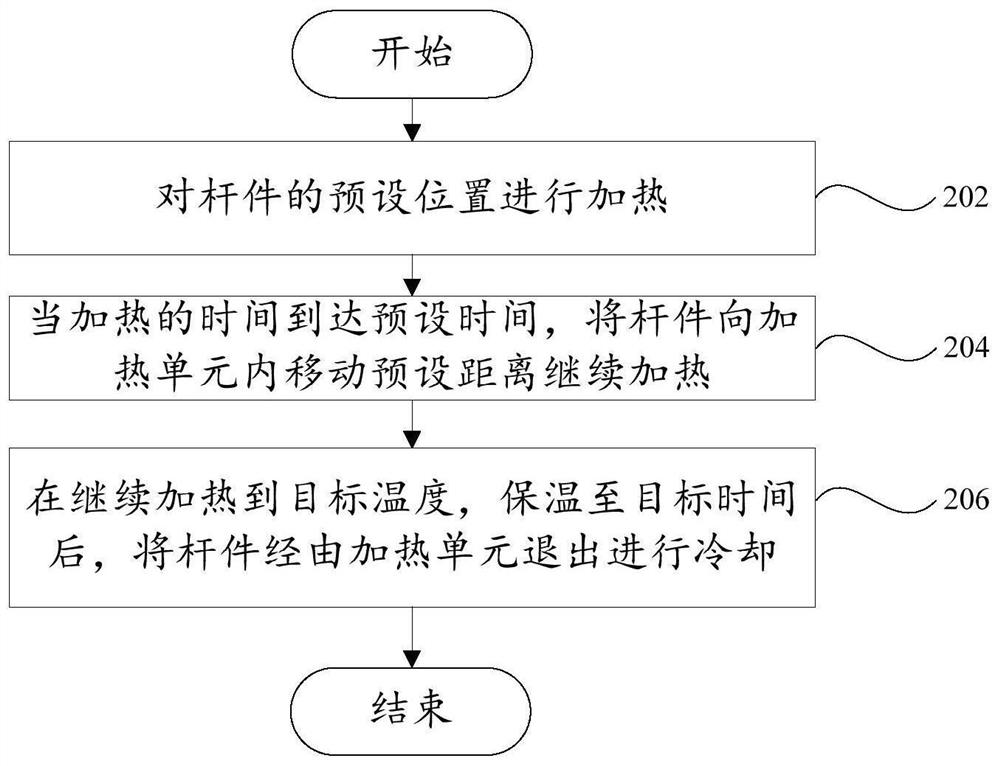

[0051] like figure 2 As shown, the flow of the rod heating method according to an embodiment of the present invention includes:

[0052] Step 202, heating the preset position of the rod member;

[0053] Step 204, when the heating time reaches the preset time, the rod member is moved to the heating unit to move the preset distance;

[0054] Step 206, after continuing to heat to the target temperature, after insulation to the target time, the rod is removed by the heating unit.

[0055] In this embodiment, the heating temperature is further heated until the heating temperature reaches the target temperature and the heat insulation target time, ensuring the predetermined heating effect, and then moves the lever out of the heating unit Cool, complete the heating of the rod.

[0056] Alternatively, the value range of the preset distance is greater than or equal to 50 mm.

[0057] In this embodiment, the selection of the preset distance is positively correlated with the rod heating targ...

Embodiment 3

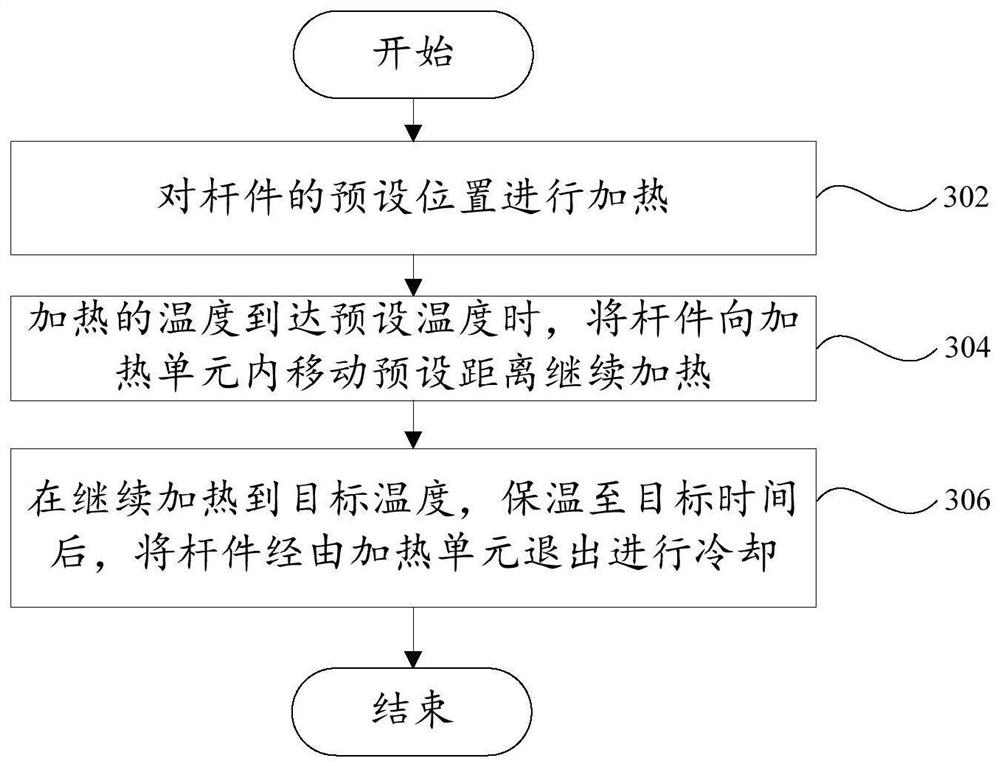

[0061] like image 3 As shown, the flow of the rod heating method according to an embodiment of the present invention includes:

[0062] Step 302, heating the preset position of the rod member;

[0063] Step 304, when the heated temperature reaches the preset temperature, the rod member continues to heat the preset distance within the heating unit;

[0064] Step 306, after continuously heating to the target temperature, after insulation to the target time, the rod is removed by the heating unit.

[0065] Alternatively, the value range of the preset distance is greater than or equal to 50 mm.

[0066] Alternatively, the heating temperature reaches the preset temperature comprises: obtaining the heating temperature at the preset position reaches the first temperature threshold; and / or acquire the heating temperature of the rod member at the holster of the heating unit to reach the second temperature threshold.

[0067] In this embodiment, the heating temperature of the rod member i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com