Gravity forming continuous thermal bending furnace and using method thereof

A hot bending furnace and gravity technology, applied in glass forming, glass reshaping, glass manufacturing equipment, etc., can solve the problem that the lifting time and height of the furnace wire cannot be guaranteed, the upper furnace body cannot be fully utilized, and the production process cannot be continuous To achieve the effect of ingenious structural design, simple structure, convenient and quick maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so as to help understand the content of the present invention. The methods used in the present invention are conventional methods unless otherwise specified; the raw materials and devices used are conventional commercially available products unless otherwise specified.

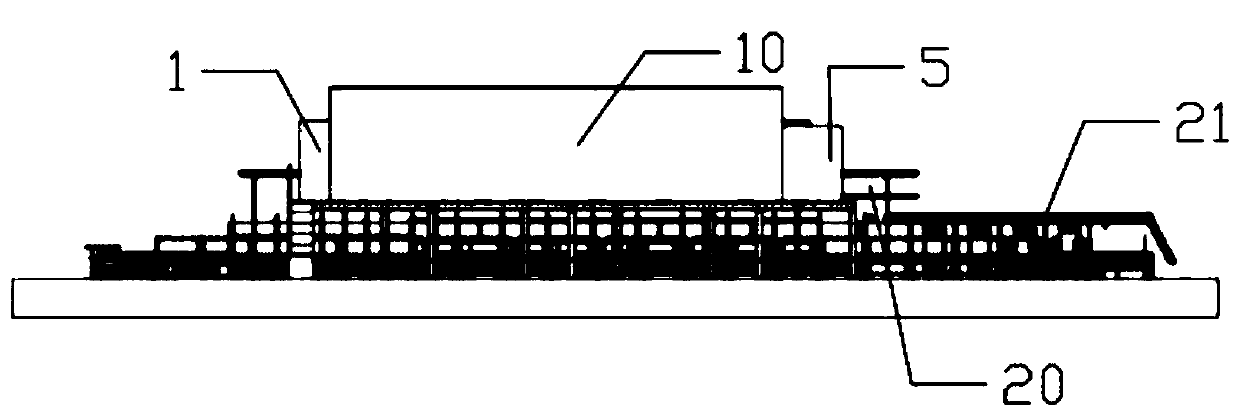

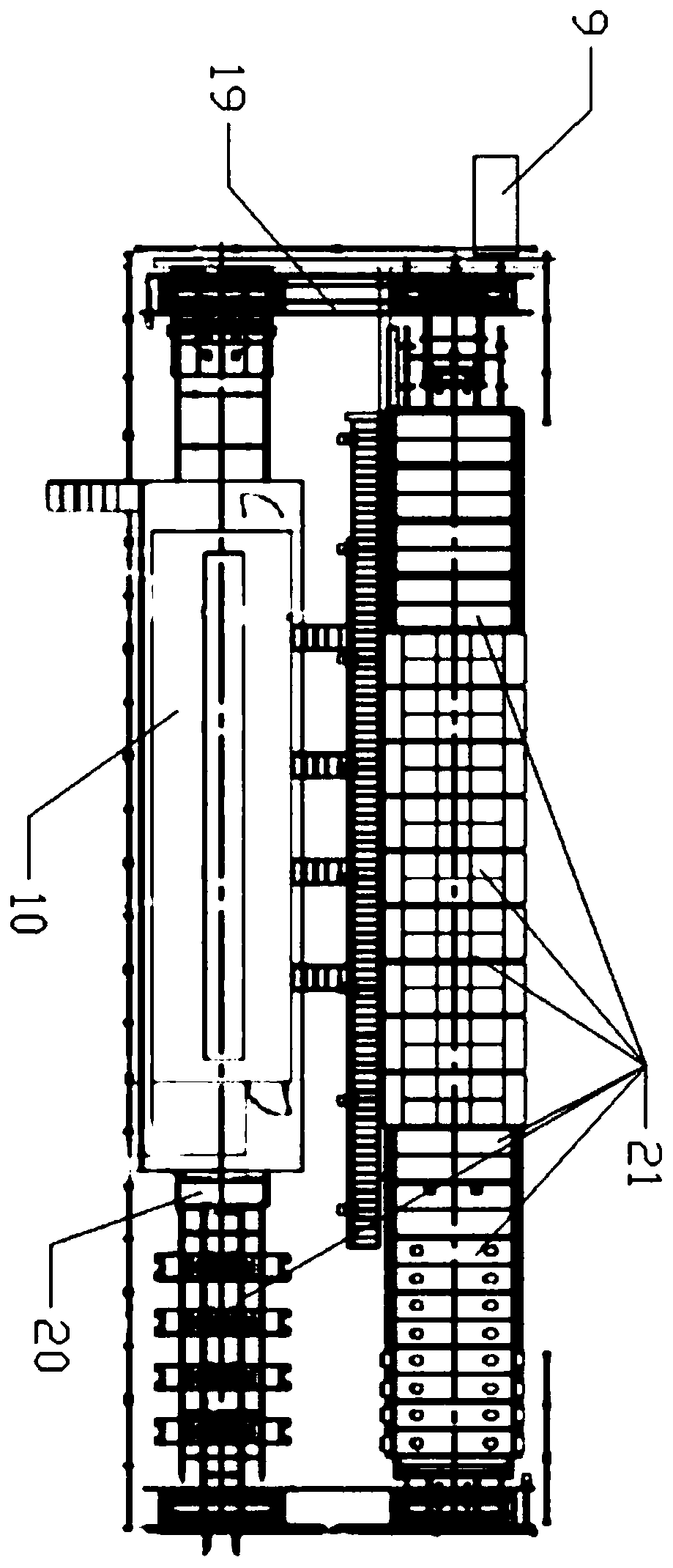

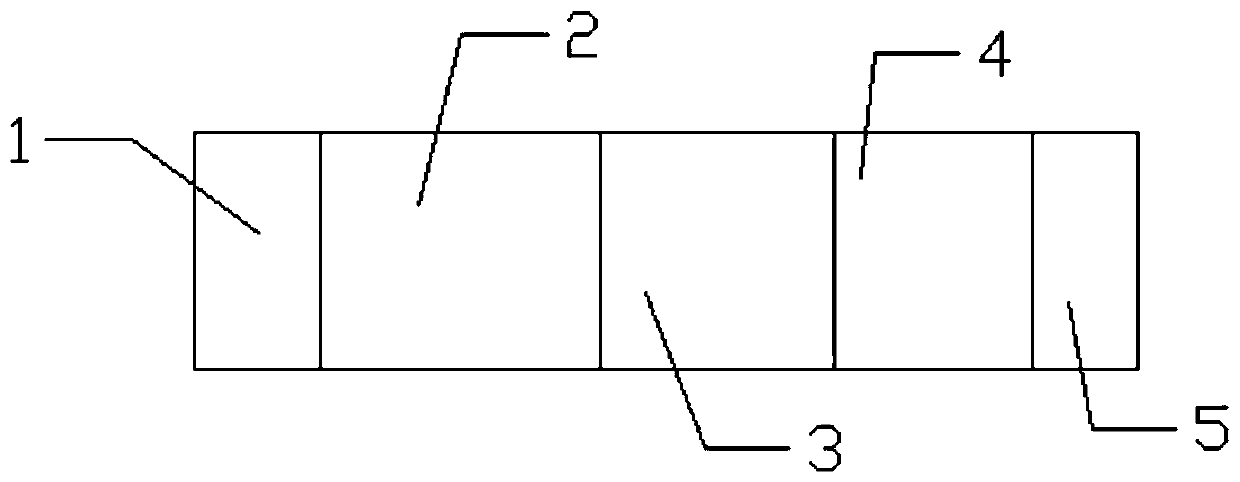

[0055] Such as Figure 1-Figure 5 As shown, the continuous hot bending furnace for gravity forming provided by the present invention includes a furnace body frame 10 that is tightly arranged inside to form a closed cavity by insulating materials. The furnace body frame 10 includes preheating stations in sequence from front to back Device 1, pre-bending station device 2, forming station device 3, quenching station device 4 and cooling station device 5; the furnace body is also equipped with a single-layer arrangement and distributed along the length of the furnace body frame Car ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com